Method of Improving the Mechanical Properties of Microbial Cemented Sand and Soil Using Protein Cementitious Materials

A technology of microbial glue and mechanical properties, which is applied in the field of improving the mechanical properties of microbial cemented loose sand and soil by using protein gelling materials, and improving the mechanical properties of microbial cemented loose sand, which can solve the problem of biological activity and function of exogenous additives that do not have artificial directional control And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

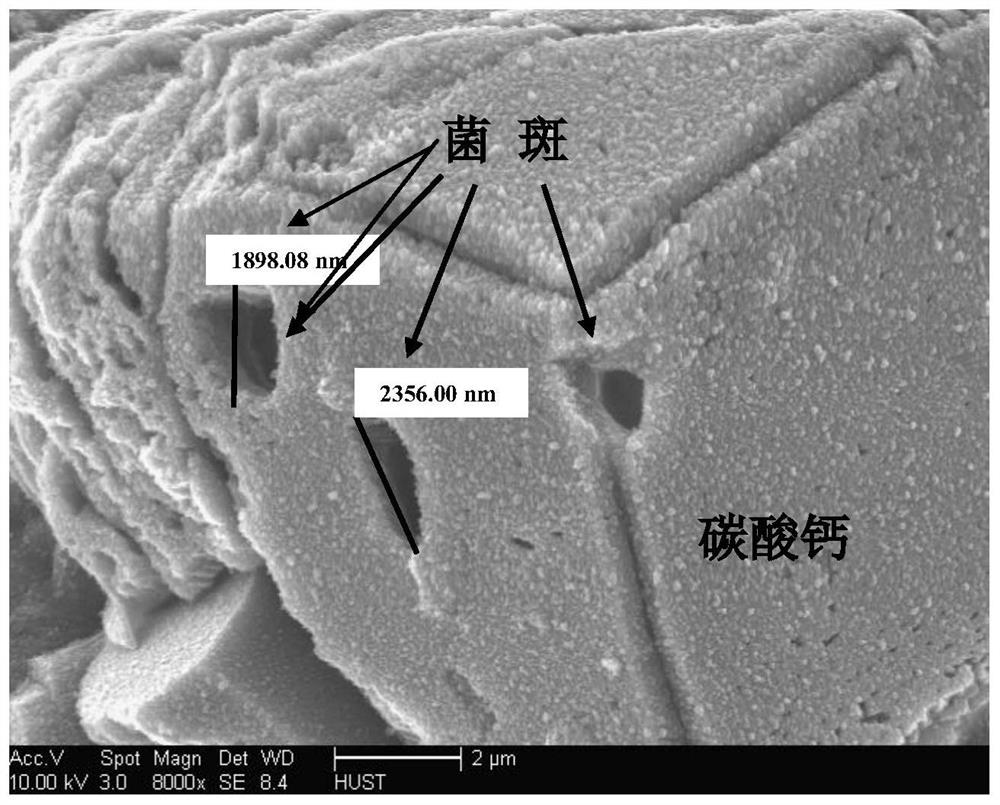

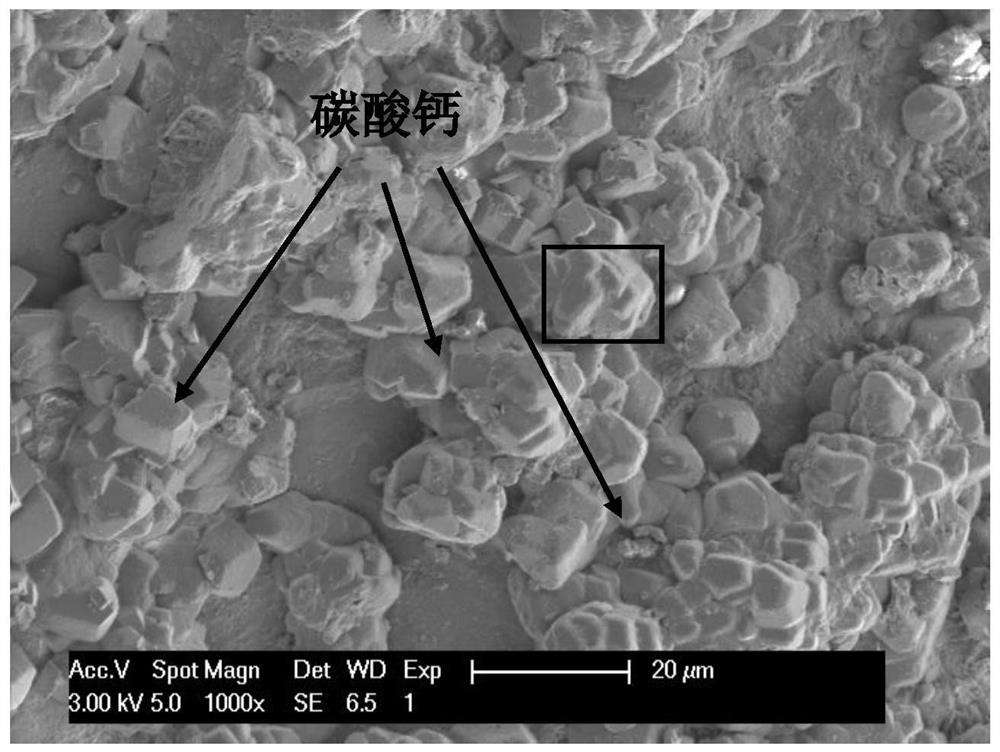

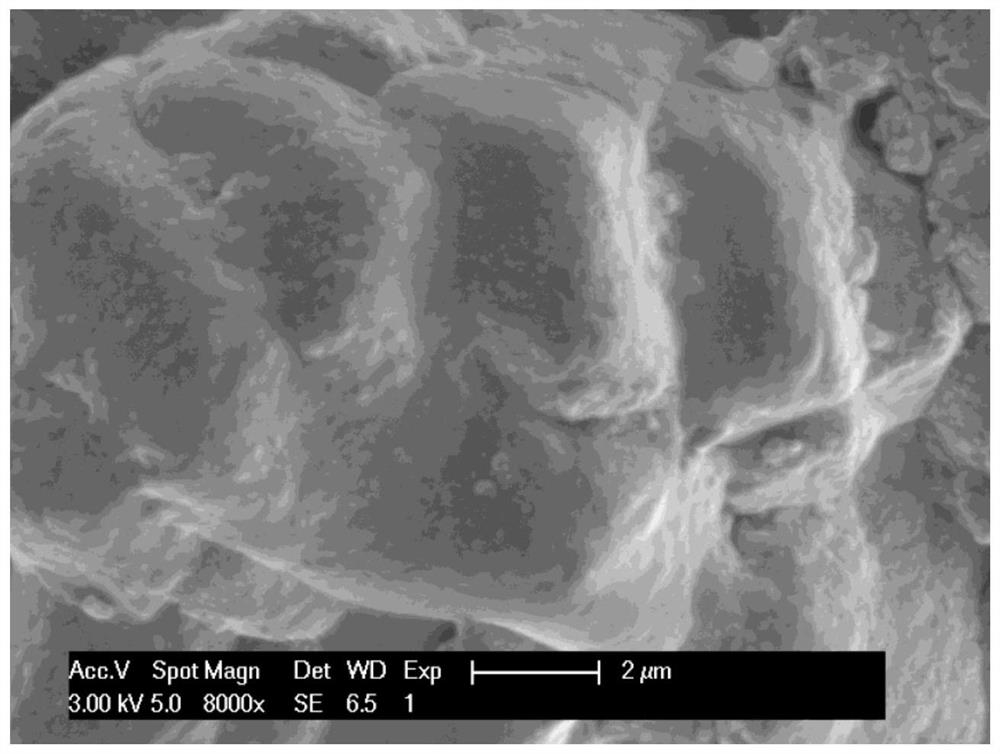

[0065] Take a certain amount of quartz sand, add 1 times the pore volume water and mix well. Add it into the rectangular mold of 40×40×160mm in three times, and fill in one third of the sand and compact it to the third division line of the mold height. Keep the sandy soil saturated after compaction and filling. Prepare a mixed bacterial solution after activating the Bacillus sarcina bacteria solution, the formula is: 0.5M CaCl 2 Mix with bacteria solution according to 1:10 (V / V). Inject 0.4 times the pore volume of bacterial solution into the filled sand, and then pour 0.6 times the pore volume of the mixed bacterial solution at 30°C for 8 hours for bacterial immobilization. Use amino acid polymers such as polyglutamic acid (PGA) as protein gelling material to prepare fresh protein cementing solution, the formula is: 0.5M urea, CaCl 2 0.5M, PGA 2.25g / L. Pour 1 times the pore volume of fresh protein cementing solution into the sand treated with bacteria immobilization. Aft...

Embodiment 2

[0068] In this embodiment, the steps are basically the same as in Embodiment 1, the difference is that:

[0069]In the sand mixing and sample loading step, the rectangular mold of 40×40×160 mm in Example 1 was replaced with a cylindrical mold with a height of 60 mm and a diameter of 30 mm. Only perfuse the bacterial solution once before perfusing the protein cement solution, and no longer perfuse the bacterial solution during the perfusion of the protein cement solution. In the step of perfusing fresh protein cementing fluid, the polyglutamic acid (PGA) in Example 1 was replaced with a small molecule protein such as bovine serum albumin (BSA), and the fresh protein cementing fluid was prepared at a concentration of 2.25 g / L. A total of 14 fresh cementing fluids were perfused for a total of 7 days. The unconfined compressive test was carried out on the cemented sand, and the unconfined compressive strength of the sample was 1.61MPa, and the toughness was 2.40MJ / m 3 . The unc...

Embodiment 3

[0071] In this embodiment, the steps are basically the same as in Embodiment 1, the difference is that:

[0072] In the sand mixing and sample loading step, the rectangular mold of 40×40×160 mm in Example 1 was replaced with a cylindrical mold with a height of 60 mm and a diameter of 30 mm. Only perfuse the bacterial solution once before perfusing the protein cement solution, and no longer perfuse the bacterial solution during the perfusion of the protein cement solution. In the step of perfusing fresh protein cementing fluid, the PGA in Example 1 was replaced with natural protein hydrolyzate such as wool hydrolyzed keratin, and the fresh protein cementing fluid was prepared according to the concentration of 0.44g / L. A total of 14 fresh cementing fluids were perfused for a total of 7 days. The unconfined compressive test was carried out on the cemented sand, and the unconfined compressive strength of the sample was 1.88MPa, and the toughness was 2.50MJ / m 3 . The unconfined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com