A gravity retaining wall and its construction method

A construction method and retaining wall technology, applied in the field of building foundation engineering, can solve the problems of large support engineering, high cost, difficult support, etc., and achieve high safety, strong economic applicability, and strong applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

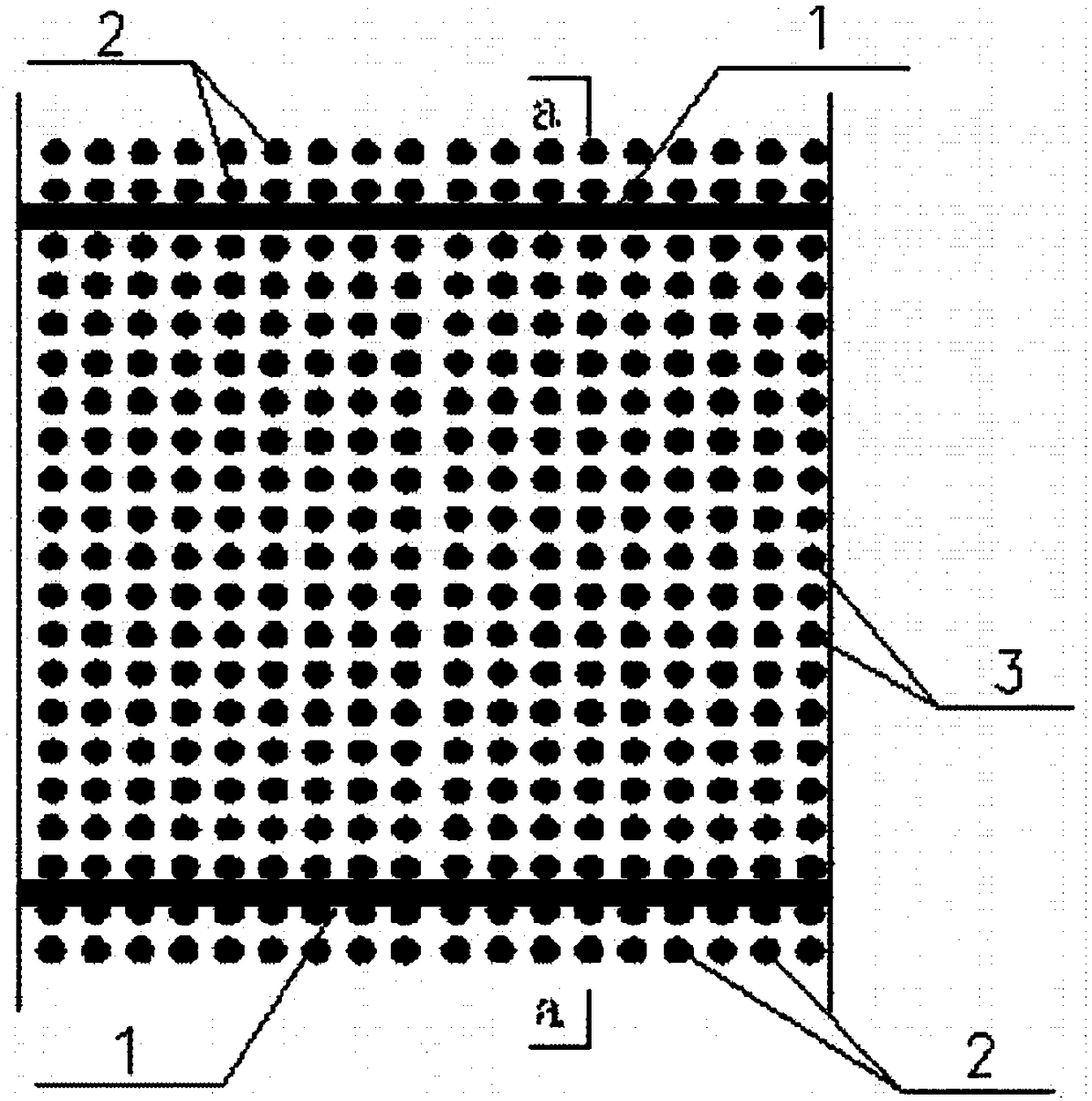

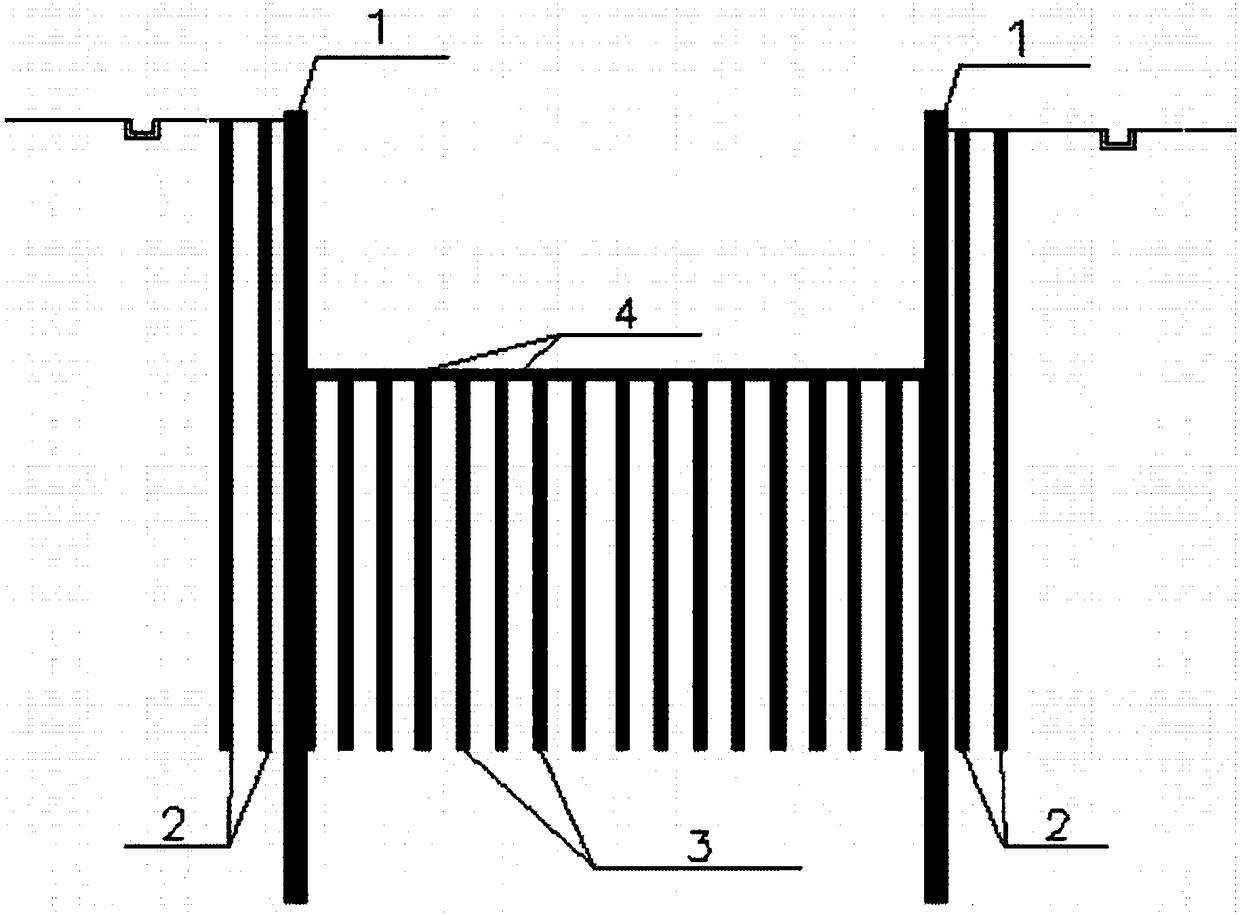

[0085] The gravity retaining wall of the present invention is especially suitable for the foundation pit of silt-like soil, which improves the engineering properties of the silt-like soil around the foundation pit, and uses the improved soil body to convert it into the main gravity unit of the gravity retaining wall .

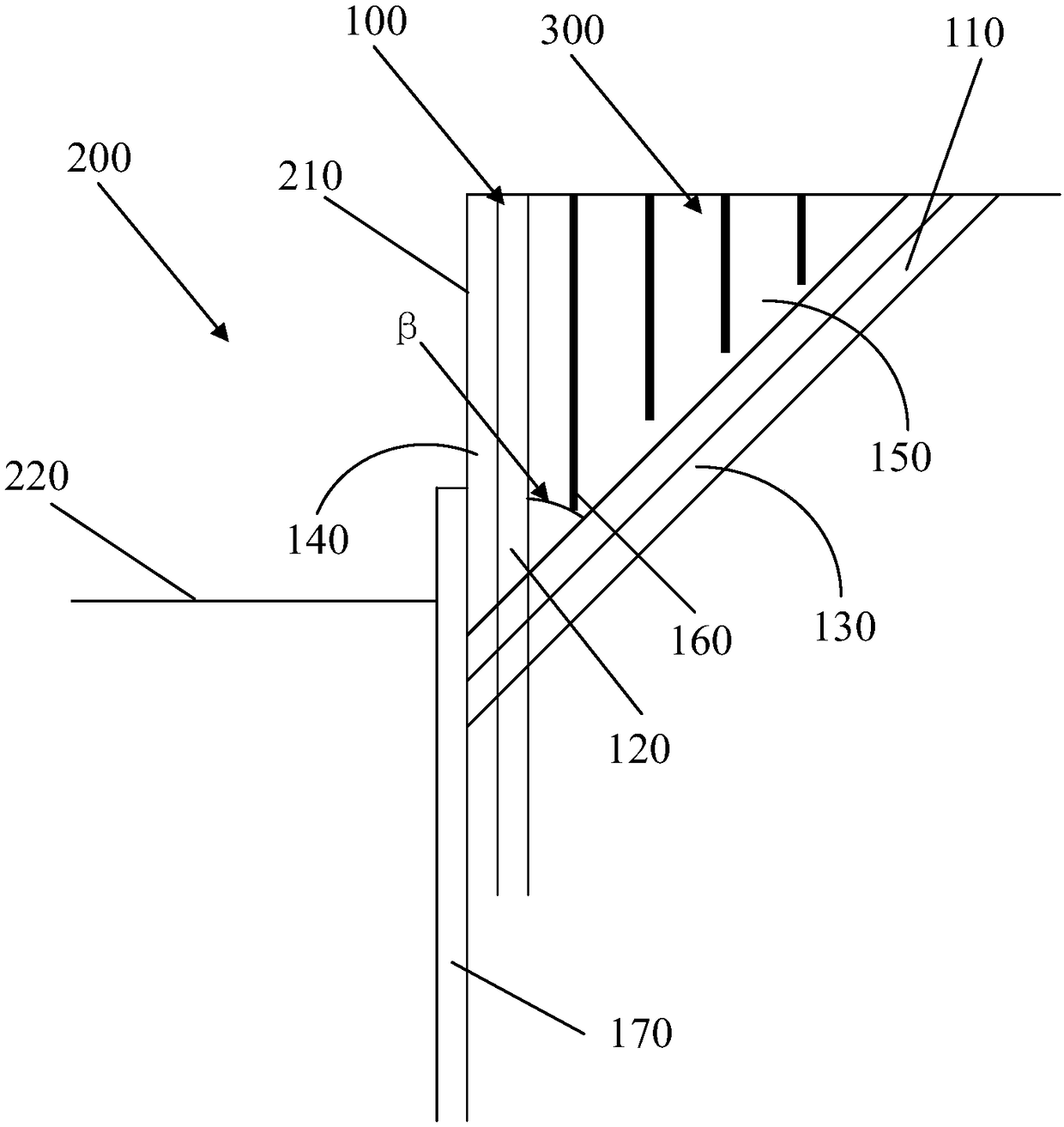

[0086] refer to figure 2 , the gravity retaining wall 100 of the present invention is set in a foundation pit 200 , and the foundation pit 200 includes a side surface 210 and a bottom surface 220 . Gravity retaining wall 100 includes inclined piles 110 and vertical piles 120 . There are a plurality of inclined piles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com