Highly-heat-resistant liquid silicate water-based heat-insulating coating material and preparation method thereof

A liquid sodium silicate and silicate technology, applied in alkali metal silicate coatings, coatings, etc., can solve problems such as poor water resistance, and achieve the effects of low cost, improved water resistance, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

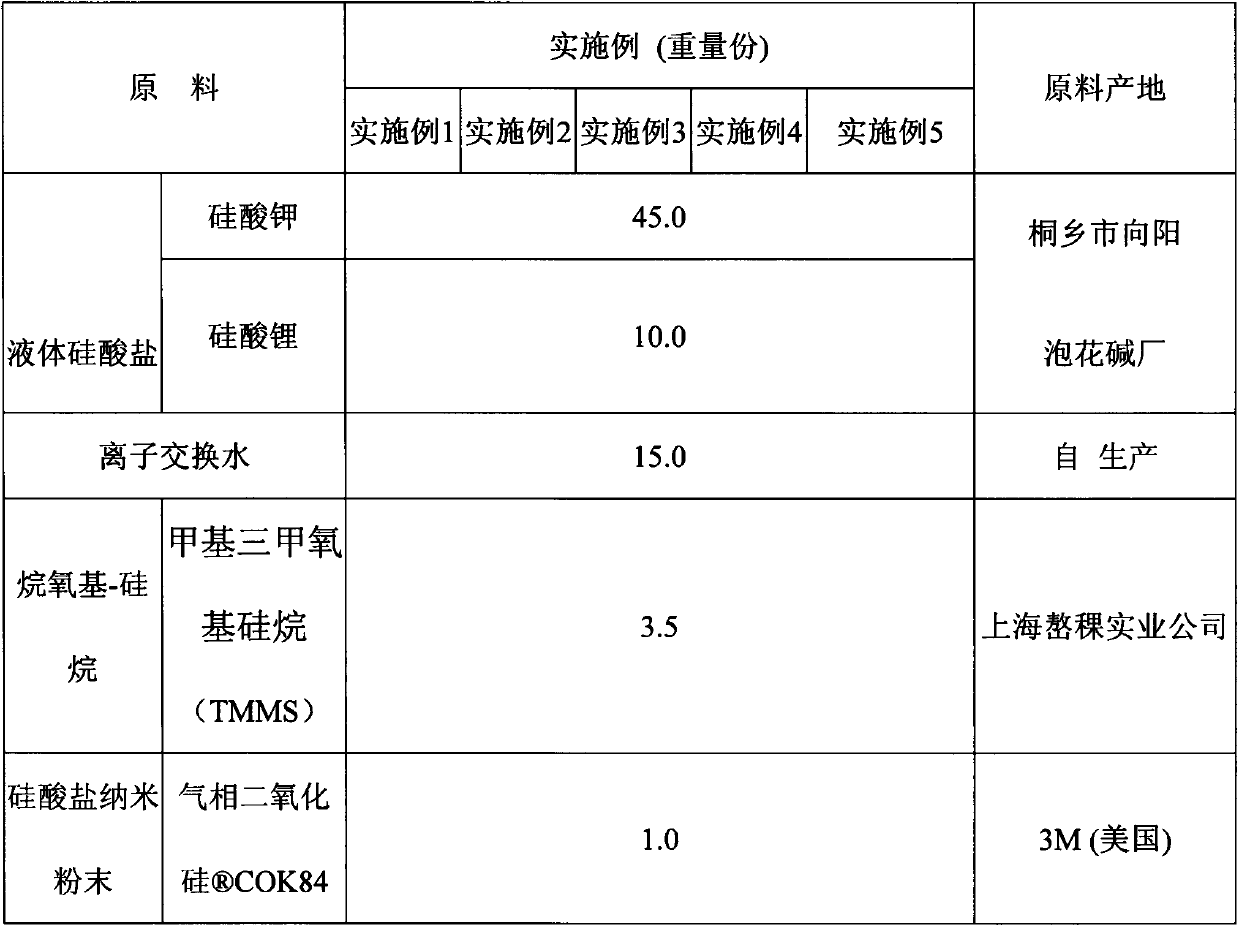

[0028] specific implementation

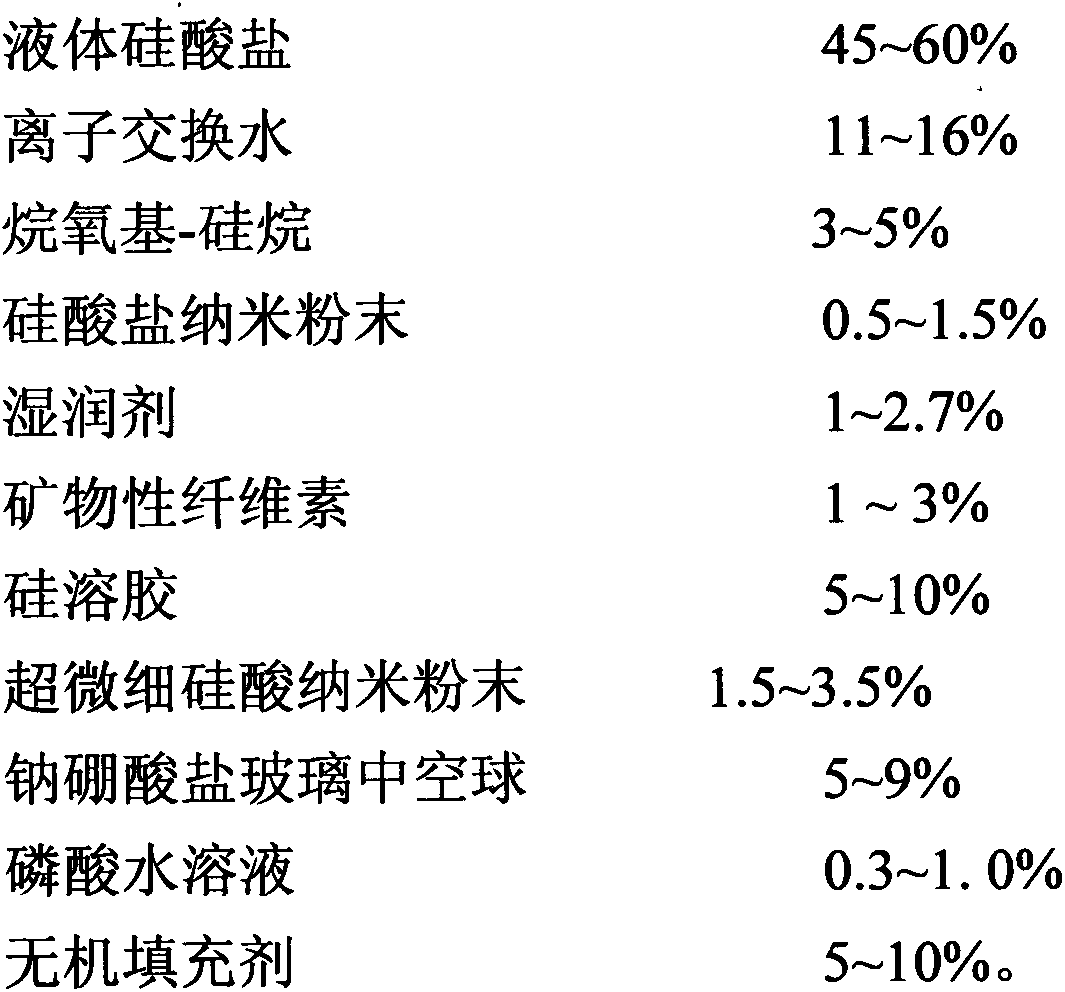

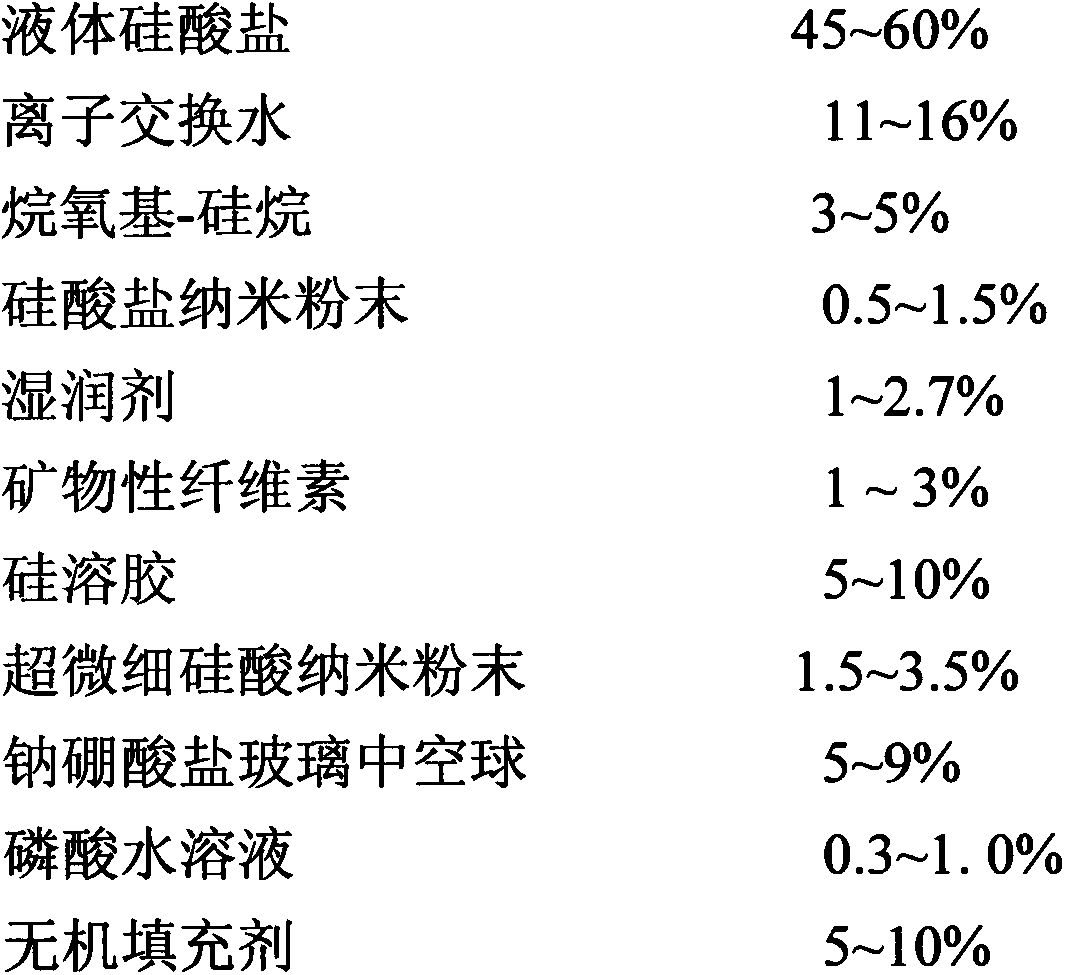

[0029] As mentioned above, in view of the deficiencies in the prior art, one aspect of the present invention aims to provide a high heat-resistant liquid silicate-based water-based thermal insulation coating, whose component ratio can be:

[0030] Liquid silicate 45-60%, ion-exchanged water 11-16%, alkoxy-silane 3-5%, silicate nano powder 0.5-1.5%, wetting agent 1-2.7%, mineral cellulose 1- 3%, silica sol 5-10%, ultrafine silicic acid nano-particle powder 1.5-3.5%, sodium borate glass hollow ball 5-9%, phosphoric acid aqueous solution 0.3-1.0%, inorganic filler 5-10%.

[0031] Another aspect of the present invention aims to provide the preparation process of the high heat-resistant liquid silicate-based water-based thermal insulation coating, which may include:

[0032]Feed and stir liquid silicate and ion-exchanged water until evenly dispersed, add alkoxy-silane and stir at low speed to fully carry out the hydration reaction, then add silicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com