Nonplanar micron/submicron microneedle array and method for producing same

A micro-needle array, sub-micron technology, which is applied in chemical instruments and methods, separation methods, photo-engraving processes of pattern surfaces, etc., can solve the problems of high preparation cost, limited application field and scope, etc. Simple and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

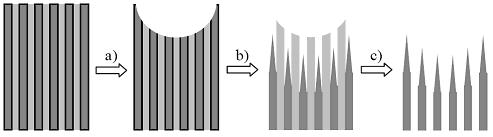

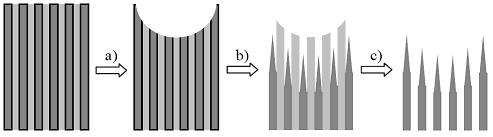

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Cut the composite structure of quartz glass fiber and polymethyl methacrylate with a diameter of 200nm into a short column, process the end face of the short column into a convex surface by cutting, and put it into a 40% HF acid corrosion solution , at a temperature of 90° C., corroded for 10 seconds to form a needle-like array structure, and the polymethyl methacrylate was removed by soaking in chloroform to obtain convex micron and submicron microneedle arrays.

Embodiment 2

[0016] Embodiment 2: Cut the composite structure of soda-lime-silica glass fiber and polystyrene with a diameter of 3um into a short column, process the end face of the short column into a concave surface by grinding, and put it into a HF acid corrosion solution with a concentration of 20%. At 50°C, corrode for 2 hours to form a needle-like array structure, and remove polystyrene by soaking in toluene to obtain concave micron and submicron microneedle arrays.

Embodiment 3

[0017] Embodiment 3: SiO with a diameter of 1000um 2 The composite structure of fiber and rosin is cut into a short column, and the end surface of the short column is treated into a groove shape by grinding, put into a HF acid corrosion solution with a concentration of 0.01%, and corroded for 72 hours at a temperature of 80°C to form a needle shape. For the array structure, rosin is removed by soaking in ethanol to obtain groove-like micron and submicron microneedle arrays.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com