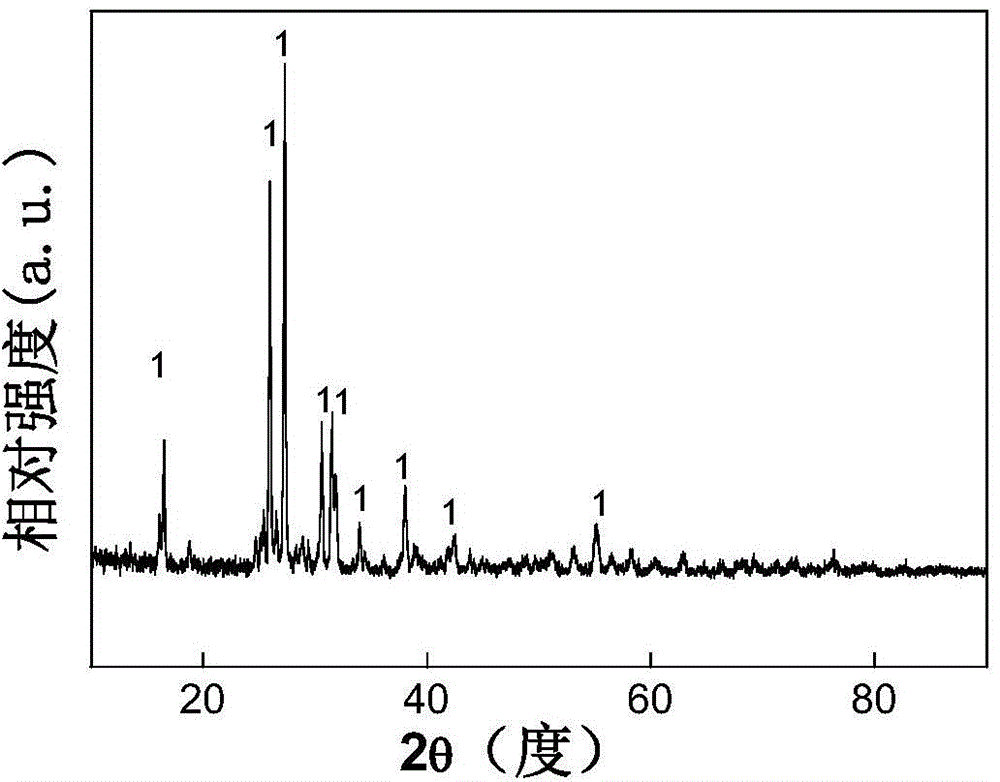

Graphene/leucite nano-composite ceramic material generated in high-temperature in-situ mode and preparation method thereof

A technology of in-situ generation and multiphase ceramics, which is applied in the field of ceramic materials and its preparation, can solve the problems of poor dispersion and poor performance, and achieve the effects of good dispersion, uniform distribution and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Embodiment 1: In this embodiment, a graphene / garnet nanocomposite ceramic material generated in situ at high temperature is prepared from graphene oxide suspension, alkali excitation solution and metakaolin powder;

[0024] The graphene oxide suspension is formed by mixing graphene oxide powder and deionized water; the volume ratio of the quality of the graphene oxide powder to deionized water is (1~20)mg:1mL;

[0025] The alkali excitation solution is formed by mixing alkali hydroxide and silica sol with a mass concentration of 25% to 45%; the metal elements in the alkali hydroxide and the mass concentration are 25% to 45% The molar ratio of silicon in the silica sol is 1:(0.5~1.5);

[0026] The volume ratio of the graphene oxide suspension to the alkali excitation solution is 1:(1.5~2.5);

[0027] The molar ratio of silicon element to aluminum element in the graphene / garnet nano-composite ceramic material generated in situ at high temperature is (1.5-2.5):1.

[0028...

specific Embodiment approach 2

[0031]Embodiment 2: This embodiment is different from Embodiment 1 in that: the alkaline hydroxide is potassium hydroxide. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: specific embodiment A kind of preparation method of the graphene / garnet nano-composite phase ceramic material of high temperature in-situ generation is carried out according to the following steps:

[0033] 1. Preparation of graphene oxide suspension: uniformly disperse graphene oxide powder in deionized water, and ultrasonically treat it for 2h-6h to obtain brown-yellow graphene oxide suspension;

[0034] The mass of described graphene oxide powder and the volume ratio of deionized water are (1~20) mg:1mL;

[0035] 2. Preparation of alkali excitation solution: adding alkali hydroxide to silica sol with a mass concentration of 25% to 45%, magnetic stirring and mixing for 24h to 72h to obtain an alkali excitation solution;

[0036] The molar ratio of the metal element in the alkaline hydroxide to the silicon element in the silica sol with a mass concentration of 25% to 45% is 1: (0.5 to 1.5);

[0037] 3. Preparation of the graphene oxide / alkal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com