Glass used as dental veneering porcelain, preparation method and application thereof

A technology for veneering porcelain and glass, which is applied in glass production and other fields, and can solve problems such as the performance difference of leucite glass-ceramic veneering porcelain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

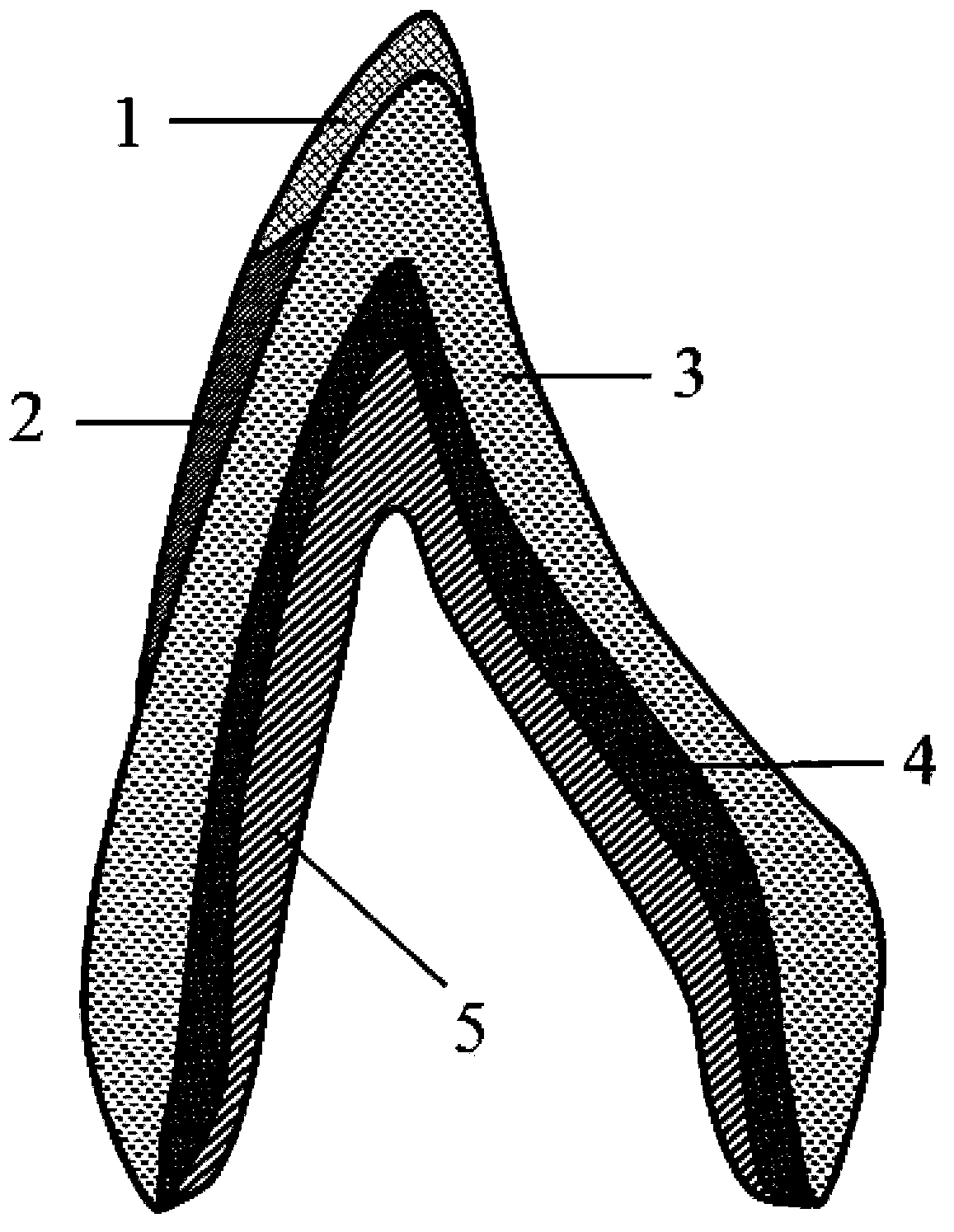

Image

Examples

Embodiment 1~11

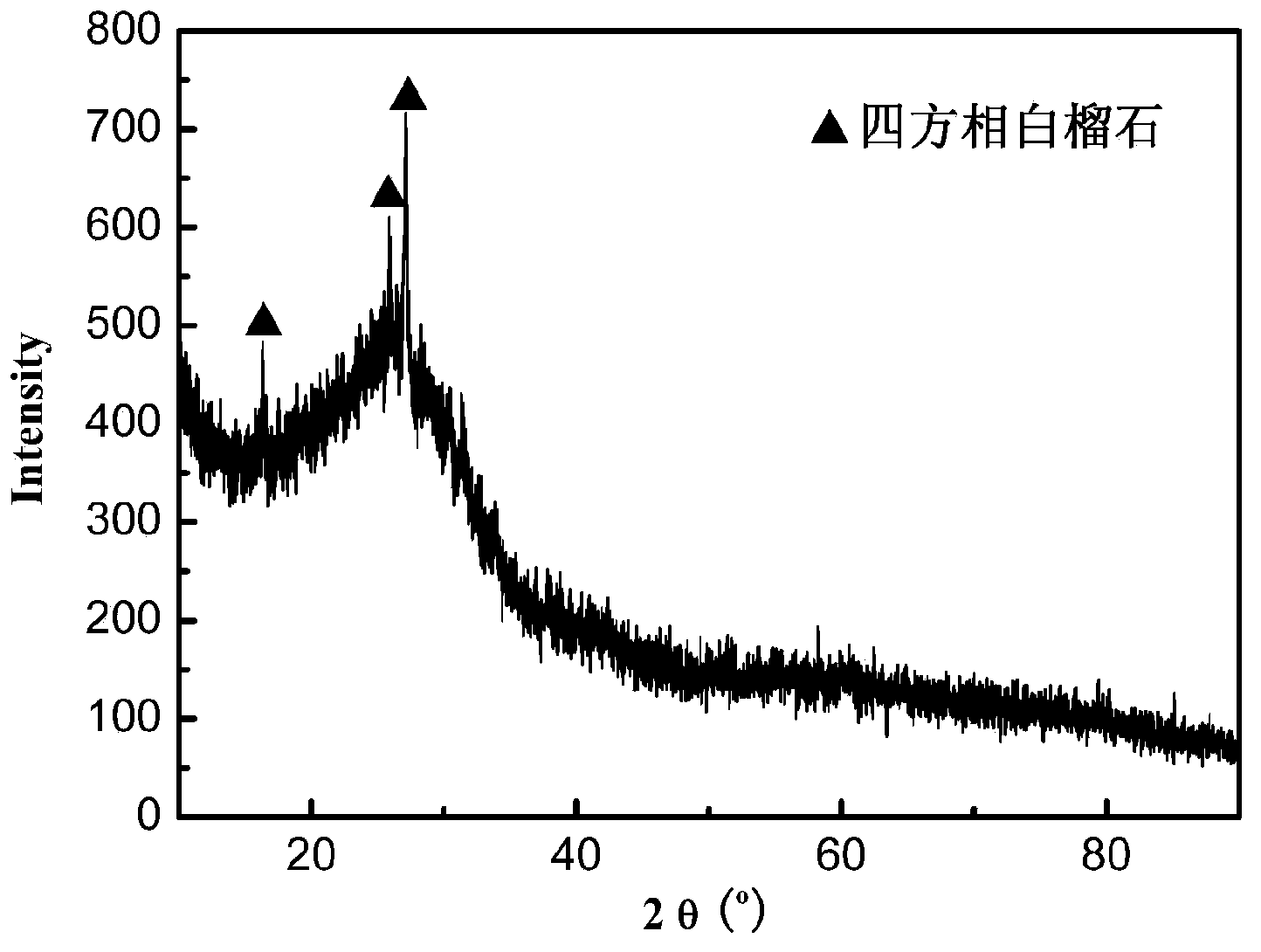

[0059] The preparation of embodiment 1~11 leucite glass-ceramics

[0060] According to each component mass percent of each embodiment listed in table 2, take respectively a certain amount of analytically pure SiO 2 , B 2 o 3 、Al 2 o 3 、Na 2 CO 3 and K 2 CO 3 , respectively with a planetary ball mill to fully mix and grind, take out and dry; respectively put the powder in a platinum alloy crucible, place it in a box-type resistance furnace, raise the temperature to 1200 ° C ~ 1400 ° C in an air atmosphere, and keep the temperature for 2 hours ~ After 5 hours, take it out at 1100°C and pour it into cold water for rapid cooling to form small pieces of glass clinker; after the glass is pulverized by a ball mill, pass through a 200-300-mesh standard sieve to obtain glass powder for dental veneering porcelain . The powder is heat-treated at 700°C to 1100°C to obtain leucite glass-ceramics. figure 2 It is the XRD spectrum of the glass-ceramic corresponding to Example 1. ...

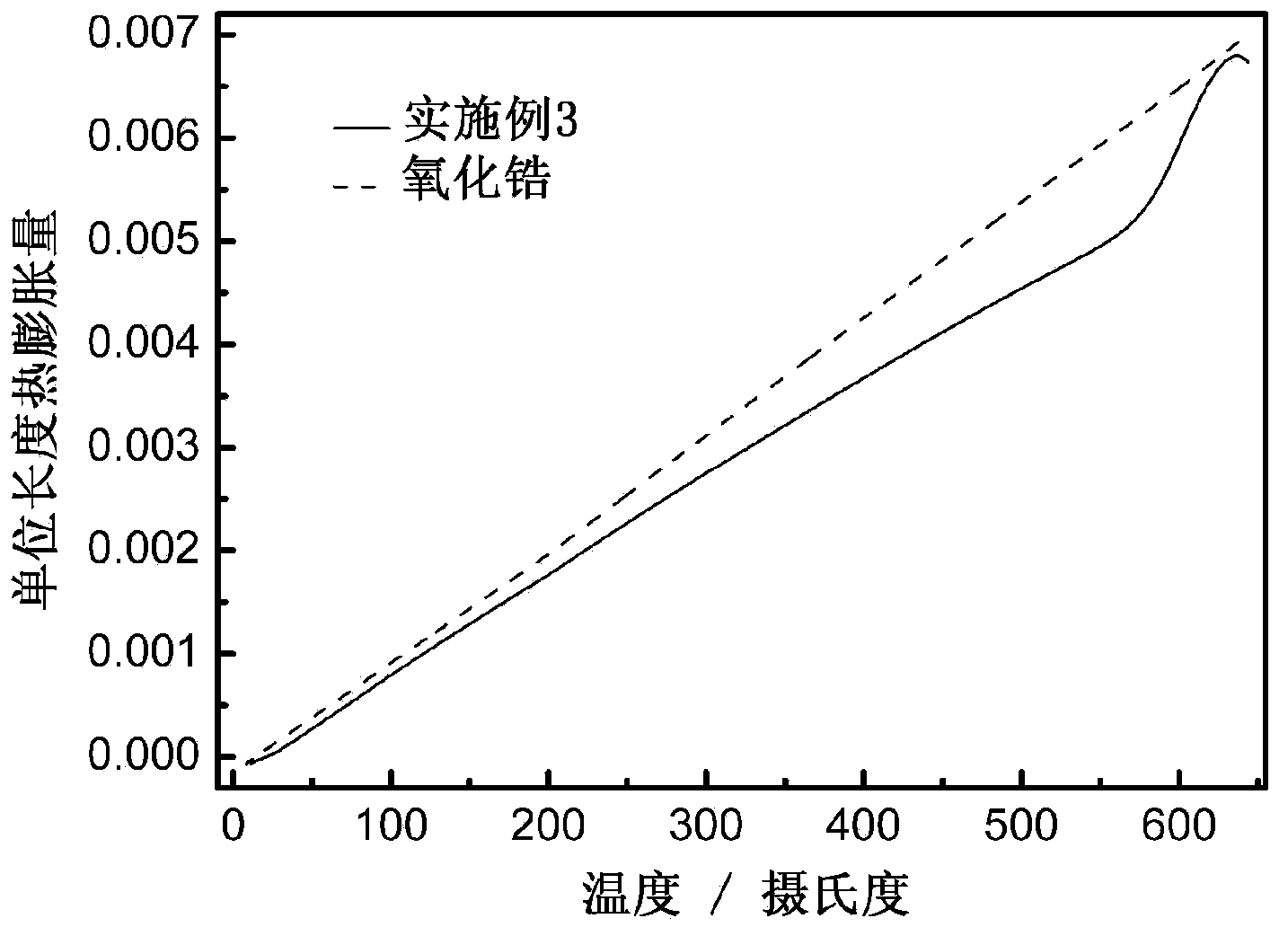

Embodiment 12

[0064] Example 12 Thermal expansion matching test of leucite glass-ceramics

[0065] Two kinds of glasses used as dental veneer porcelain were prepared according to the composition of Example 3 and Example 11 respectively, and then the two kinds of glasses used as dental veneer porcelain were respectively ball-milled into powder and passed through a 200-mesh standard sieve. The two kinds of glass powders are processed at 700°C to 1100°C respectively to form corresponding glass-ceramics, and then the two kinds of glass-ceramic balls are ground into powder and passed through a 200-mesh standard sieve for later use. Take 1 gram of the two types of glass-ceramic powders respectively, dry-press them under a pressure of 400 MPa, and then hold them under a vacuum condition of 850°C for 1 min to sinter and compact them. Cut the two glass-ceramics into cuboids with a length of 15 mm and a width of 4 mm, and use a high-temperature dilatometer (L75 / 1550, LINSEIS, Germany) to test the the...

Embodiment 13

[0066] Example 13 Leucite glass-ceramics thermal stability test:

[0067] Two kinds of glasses used as dental veneer porcelain were prepared according to the composition of Example 3 and Example 11 respectively, and then the two kinds of glasses used as dental veneer porcelain were respectively ball-milled into powder and passed through a 200-mesh standard sieve. The two kinds of glass powders are processed at 700°C to 1100°C respectively to form corresponding glass-ceramics, and then the two kinds of glass-ceramic balls are ground into powder and passed through a 200-mesh standard sieve for later use. Take 1 gram of the two types of glass-ceramic powders respectively, dry-press them under a pressure of 400 MPa, and then hold them under a vacuum condition of 850°C for 1 min to sinter and compact them. Test the thermal expansion coefficient of the glass-ceramics as a function of the number of times of porcelain firing: Cut the glass-ceramics corresponding to Example 3 into a re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com