Dentistry zirconia and leucite compound porcelain powder and preparing method thereof

A zirconia and leucite technology, used in dental preparations, dentistry, dental prostheses, etc., can solve the problem that the mechanical properties of ceramic materials cannot meet the requirements of use well, and reduce the synthesis process and crystal phase distribution. The effect of uniform and improved gold-porcelain matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

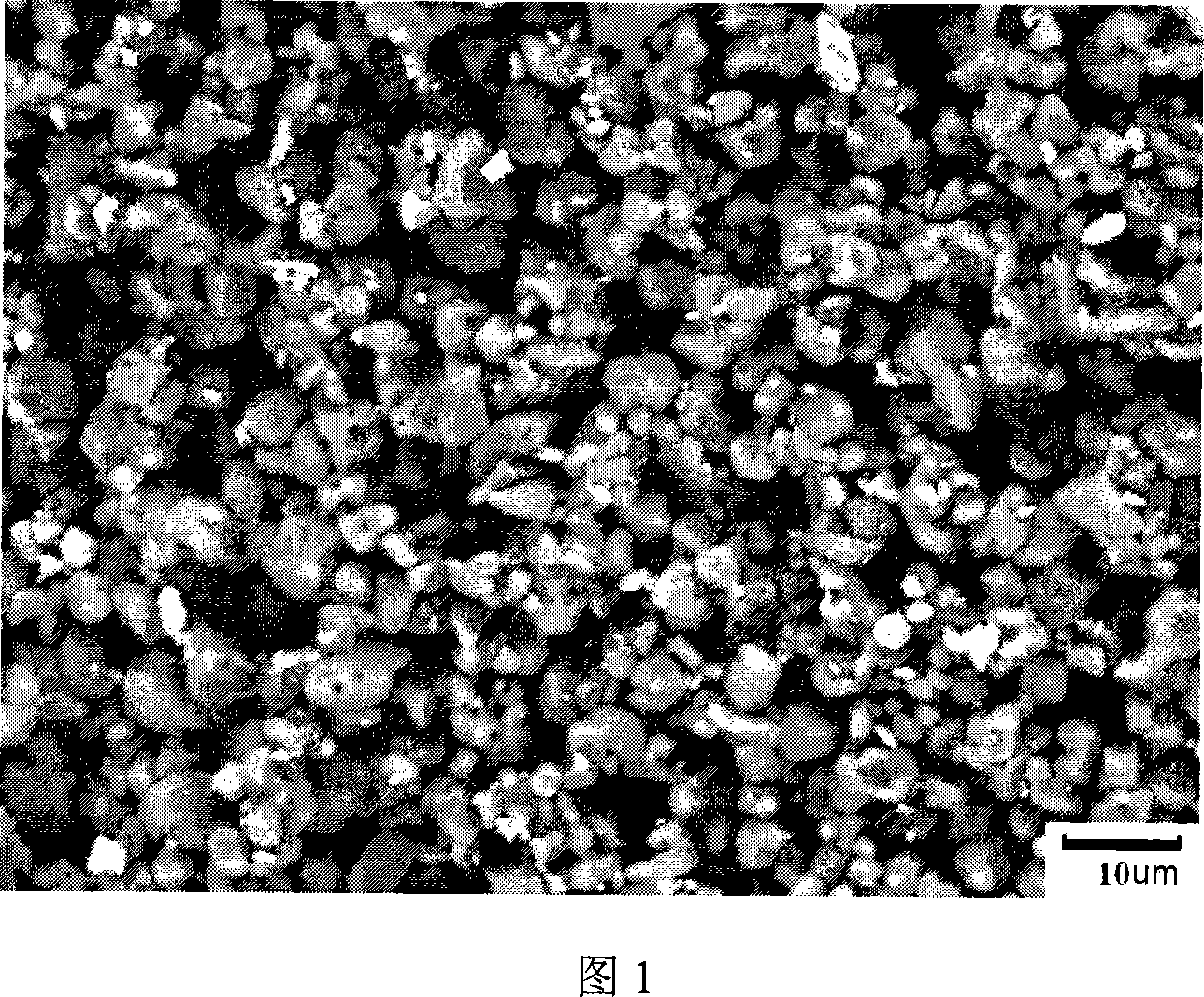

Image

Examples

Embodiment 1

[0015] (1) 73g of high-quality potassium feldspar, 20g of potassium carbonate and 7g of nano-tetragonal zirconia are put into a ball mill jar, add ethanol and a ball mill, and put into a planetary ball mill for ball milling for 5 hours;

[0016] (2) Put the powder through step (1) into an oven to dry for 6 hours, and sieve after ball milling;

[0017] (3) Put the powder in step (2) into a corundum crucible, put the crucible into a high-temperature resistance furnace and raise it to 900°C at 6°C / min, then rise to 1100°C at 4°C / min, keep it warm for 60min, and naturally Chilled porcelain blocks;

[0018] (4) put into the agate ball mill pot after the porcelain block in the step (3) is crushed, add ethanol and ball mill, put into planetary ball mill and ball mill for 24h to get porcelain powder;

[0019] (5) Taking out the porcelain powder in step (4), grinding in a mortar, and sieving to obtain porcelain powder.

[0020] (6) By testing the relevant properties of the magnetic p...

Embodiment 2

[0022] (1) 73g of high-quality potassium feldspar, 20g of potassium carbonate and 7g of nano-tetragonal zirconia are put into a ball mill jar, add ethanol and a ball mill, and put into a planetary ball mill for ball milling for 5 hours;

[0023] (2) Put the powder through step (1) into an oven to dry for 6 hours, and sieve after ball milling;

[0024] (3) Put the powder in step (2) into a corundum crucible, put the crucible into a high-temperature resistance furnace and raise it to 900°C at 6°C / min, then rise to 1200°C at 4°C / min, keep it warm for 60min, and naturally Chilled porcelain blocks;

[0025] (4) put into the agate ball mill pot after the porcelain block in the step (3) is crushed, add ethanol and ball mill, put into planetary ball mill and ball mill for 24h to get porcelain powder;

[0026] (5) Taking out the porcelain powder in step (4), grinding in a mortar, and sieving to obtain porcelain powder.

[0027] (6) By testing the relevant properties of the magnetic p...

Embodiment 3

[0029] (1) 73g of high-quality potassium feldspar, 20g of potassium carbonate and 7g of nano-tetragonal zirconia are put into a ball mill jar, add ethanol and a ball mill, and put into a planetary ball mill for ball milling for 5 hours;

[0030] (2) Put the powder through step (1) into an oven to dry for 6 hours, and sieve after ball milling;

[0031] (3) Put the powder in step (2) into a corundum crucible, put the crucible into a high-temperature resistance furnace and raise it to 900°C at 6°C / min, then rise to 1300°C at 4°C / min, keep it warm for 60min, and naturally Chilled porcelain blocks;

[0032] (4) put into the agate ball mill pot after the porcelain block in the step (3) is crushed, add ethanol and ball mill, put into planetary ball mill and ball mill for 24h to get porcelain powder;

[0033] (5) Take out the ceramic powder in step (4), grind it in a mortar, and sieve to obtain a ceramic powder with an average particle size of 30 μm.

[0034] (6) By testing the rele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com