Silicon-carbon negative electrode material, preparation method and application thereof, and prepared lithium ion battery

A technology of lithium-ion battery and negative electrode material, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high full-charge expansion, low first Coulomb efficiency, low first reversible specific capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

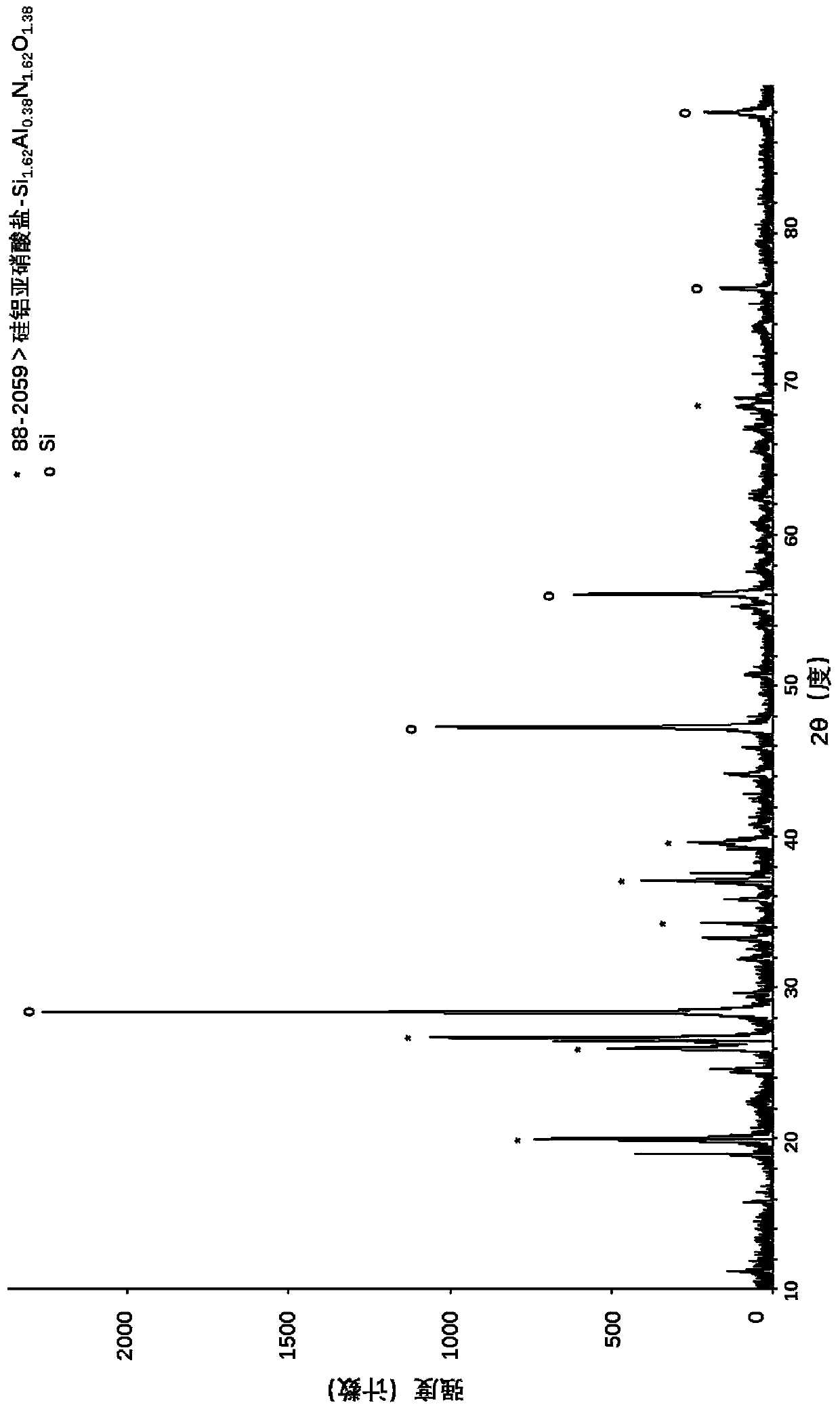

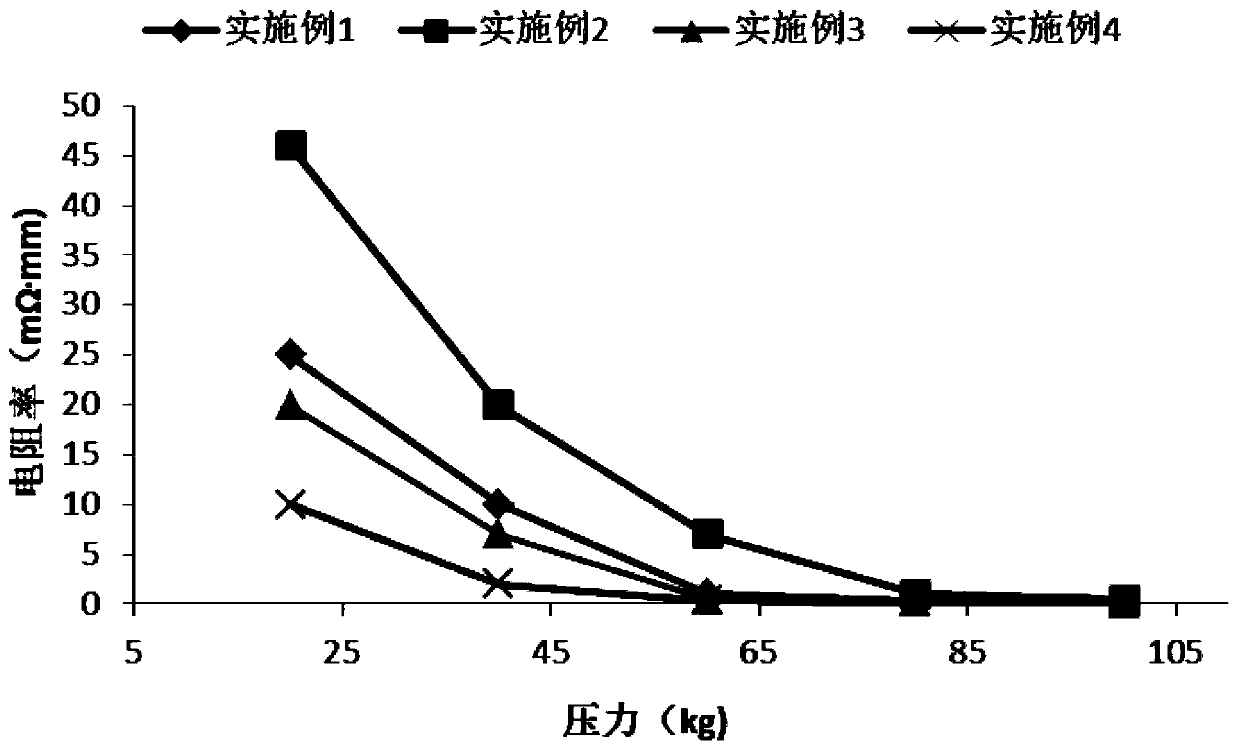

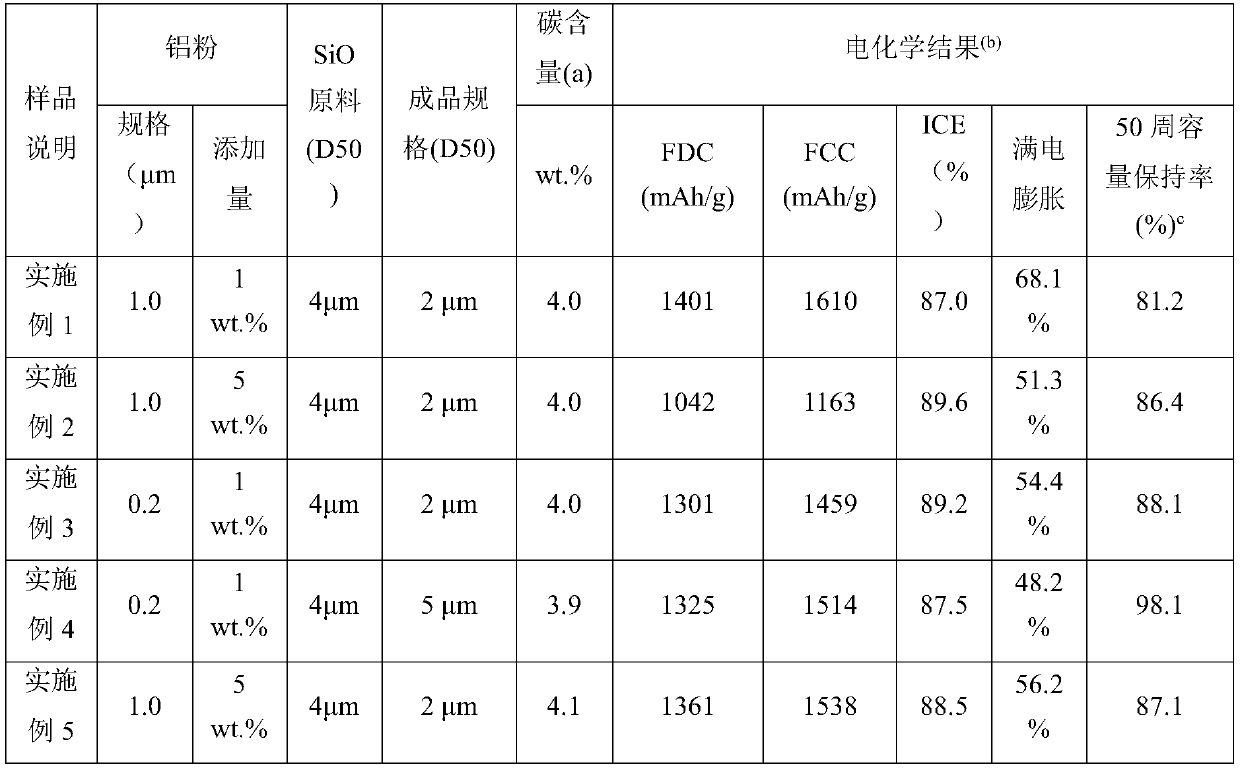

Embodiment 1

[0055] Select silicon oxide with a median particle size of 4 μm (purity>99.9%, mass percentage, Beijing Shengbo Gaotai Optical Technology Co., Ltd.), aluminum metal powder with a median particle size of 1 μm (purity>99.9% mass percentage, chapter Qiu City Metal Pigment Co., Ltd.), according to the addition of metal powder 1% (metal powder accounts for the weight percentage of the total raw material), the two are fully mixed and transferred to the atmosphere furnace, the nitrogen flow is controlled to be 30sccm, and the nitrogen flow rate is 5°C / min After heating up to 700°C, react for 20 hours and then cool down to room temperature naturally; then ball mill the brown-gray block obtained from the above heat treatment to obtain particles with a particle size of 2 μm; transfer the above particles to a CVD furnace (Chemical Vapor Deposition, chemical vapor deposition furnace) , according to the design of the carbon content in the final obtained material as 4%, under the protection ...

Embodiment 2

[0057] Select silicon oxide with a median particle size of 4 μm (purity>99.9%, mass percentage, Beijing Shengbo Gaotai Optical Technology Co., Ltd.), and aluminum metal powder with a median particle size of 1 μm (purity>99.9%, mass percentage, Zhangqiu Metal Pigment Co., Ltd.), by metal powder add-on 5% (metal powder accounts for the weight percent of total raw material), the two are fully mixed and then transferred to the atmosphere furnace, the nitrogen flow is controlled to be 30sccm, with 5 ℃ / After raising the temperature to 700°C, react for 20 hours and then cool down to room temperature naturally; then ball mill the brown-gray block obtained from the above heat treatment to obtain particles with a particle size of 2 μm; transfer the above particles to a CVD furnace, and press The carbon content is 4% design, the temperature is raised to 900°C at 5°C / min under the protection of argon, and the ethylene / argon gas mixture with the ethylene content of 30% (volume ratio, Hang...

Embodiment 3

[0059] Select silicon oxide with a median particle size of 4 μm (purity>99.9%, mass percentage, Beijing Shengbo Gaotai Optical Technology Co., Ltd.), aluminum metal powder with a median particle size of 0.2 μm (purity>99.9%, mass percentage , Zhangqiu Metal Pigment Co., Ltd.), according to the amount of metal powder added 1% (metal powder accounts for the weight percentage of the total raw material), the two are fully mixed and then transferred to the atmosphere furnace. / min After heating up to 700°C, react for 20 hours and then cool down to room temperature naturally; then ball mill the brown-gray block obtained from the above heat treatment to obtain particles with a particle size of 2 μm; transfer the above particles to a CVD furnace, press the final material The carbon content is designed to be 4%, and the temperature is raised to 900°C at 5°C / min under the protection of argon, and then switched to an ethylene / argon gas mixture with an ethylene (Hangzhou Jingong Gas Co., L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com