Preparation method of boron particle reinforced metal matrix composite material, composite material and application of composite material

A particle-reinforced, composite material technology, used in additive processing, reactors, additive manufacturing, etc., can solve problems such as low boron content, internal cracks, brittle fractures, etc., to achieve uniform crystal phase distribution, low production costs, and thickness. adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment discloses a method for preparing a boron particle reinforced aluminum matrix composite material, the steps are as follows:

[0039] First take 5.5 grams of amorphous element boron powder and mix with 13.5 grams of micron aluminum powder, and initially stir evenly;

[0040] Put the mixed powder, 800 grams of zirconia balls with a first diameter of 4 mm, and 200 grams of zirconia balls with a second diameter of 6 mm into the grinding chamber of the resonance ball mill, and resonate ball milling for 6 hours to obtain fully mixed boron-aluminum micron powder;

[0041] Place the boron-aluminum micron powder in the raw material chamber of the supersonic low-pressure cold spraying equipment, and spray it on the smooth aluminum plate for 1 min under the heating condition of 500 ℃ to prepare the boron particle-reinforced aluminum matrix composite material.

Embodiment 2

[0043] This embodiment discloses a method for preparing a boron particle reinforced aluminum matrix composite material, the steps are as follows:

[0044] First take by weighing 5.5 grams of amorphous element boron powder and 13.5 grams of micron aluminum powder and mix, and initially stir evenly;

[0045] Then put the mixed powder together with 200 grams of zirconia balls with a second diameter of 6 mm and 800 grams of zirconia balls with a first diameter of 4 mm into the cavity of the resonance ball mill, and conduct resonance ball milling for 6 hours to obtain fully mixed boron-aluminum micron powder ;

[0046] Place the prepared boron-aluminum micron powder in the raw material chamber of supersonic low-pressure cold spraying equipment, and spray it on the surface of a slowly rotating smooth aluminum tube under the heating condition of 500°C for 1 minute to form a boron particle-reinforced aluminum matrix composite Material.

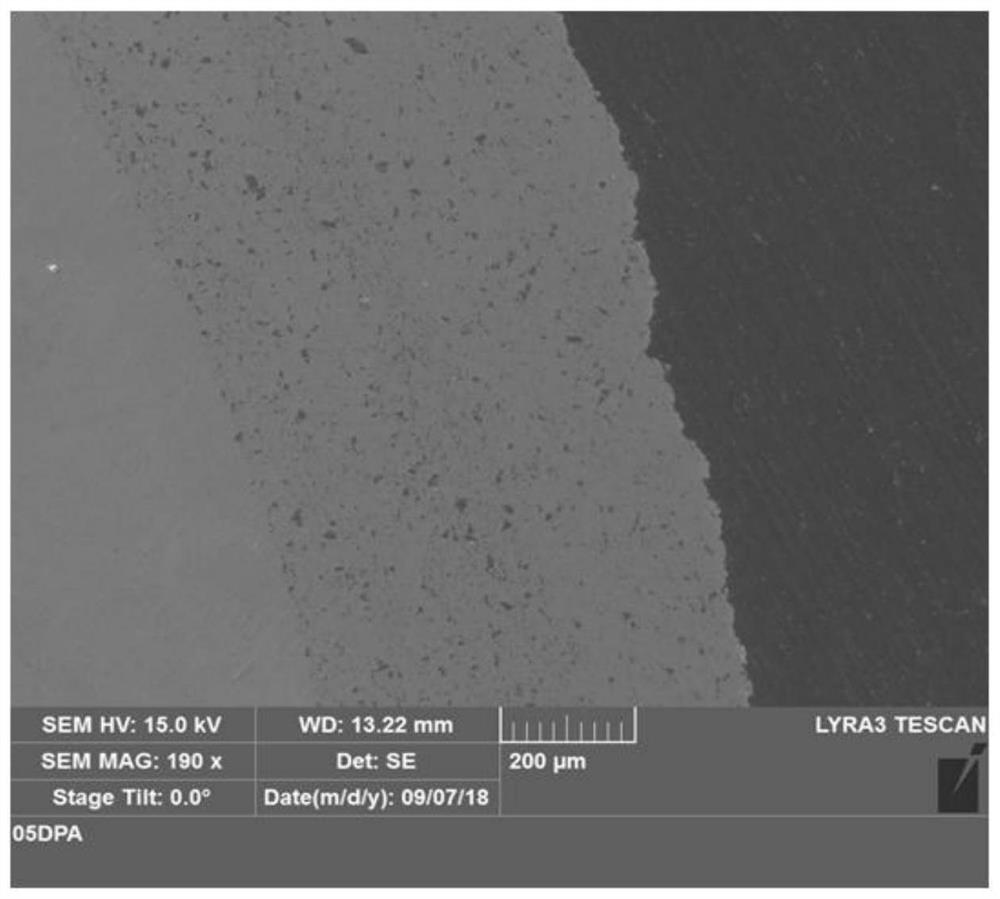

[0047] Energy spectrum analysis is carried ou...

Embodiment 3

[0050] This embodiment discloses a method for preparing a boron particle-reinforced copper-based composite material, the steps are as follows:

[0051] First take by weighing 11 grams of amorphous element boron powder and mix with 32 grams of micron copper powder, and initially stir evenly;

[0052] Then put the mixed powder together with 200 grams of zirconia balls with a second diameter of 6 mm and 800 grams of zirconia balls with a first diameter of 4 mm into the resonant ball mill cavity, and resonate ball milled for 6 hours to obtain fully mixed boron-copper micron powder ;

[0053] The prepared boron-copper micron powder is placed in the raw material chamber of the supersonic low-pressure cold spraying equipment, and sprayed on a smooth copper plate for 1 minute under the heating condition of 500 ° C to make a boron particle-reinforced copper-based composite material.

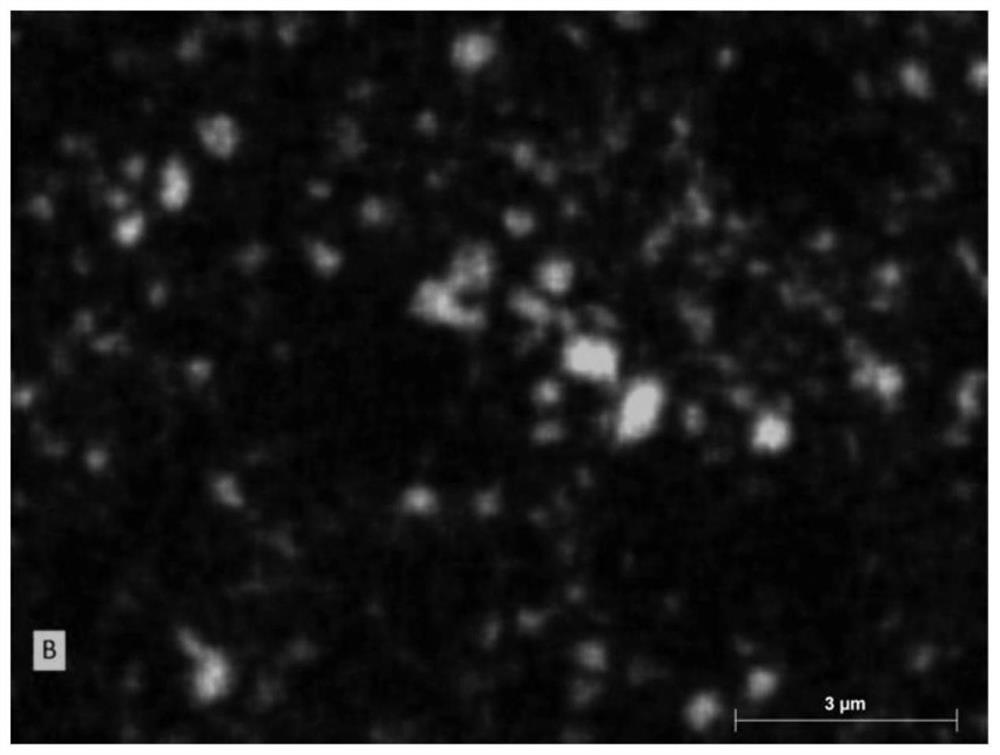

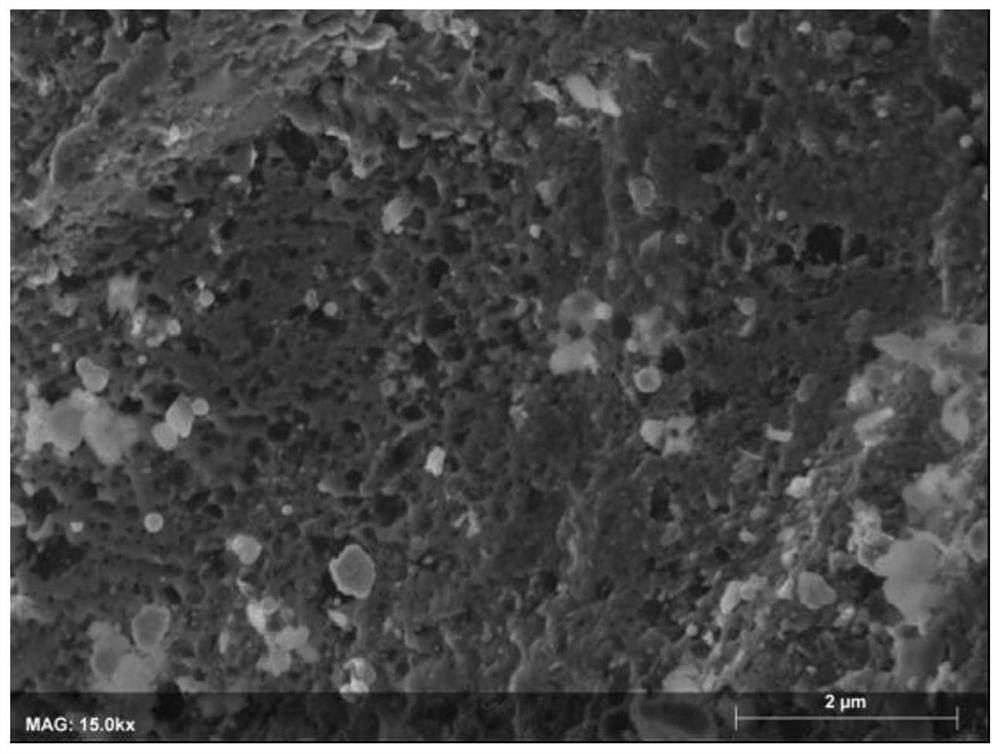

[0054] Scanning electron microscope and energy dispersive spectrometer are respectively used to carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com