Iron ore anti-radiation concrete and preparation method thereof

An iron ore and concrete technology, applied in the field of iron ore radiation-proof concrete and its preparation, can solve the problems of reduced radiation shielding effect, poor concrete construction performance, poor neutron radiation resistance, etc. The effect of sinking to the bottom and preventing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the iron ore radiation-proof concrete of the present embodiment is as follows:

[0040] Add 5.0-8.0 parts of water reducing agent to 160-200 parts of water, stir and mix evenly to obtain a mixed solution; add 1400-1800 parts of iron ore, 1000-1400 parts of iron ore, 240-400 parts of high boron glass powder, 260- Add 350 parts of cement, 60-100 parts of fly ash, and 40-70 parts of steel slag powder to the mixer for dry stirring for 1 min; add the mixed solution and stir for 2 minutes; add 6.0-9.0 parts of polypropylene fiber and stir until the mixture is uniform.

Embodiment 1

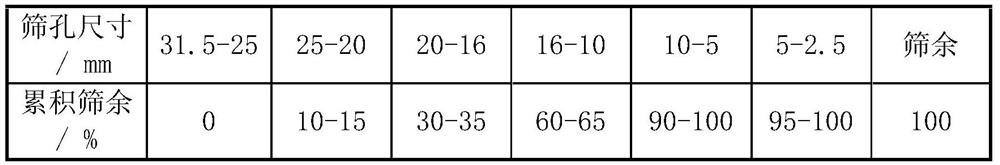

[0042]

[0043] The properties of the iron ore radiation-proof concrete are shown in Table 1.

[0044] Table 1

[0045]

Embodiment 2

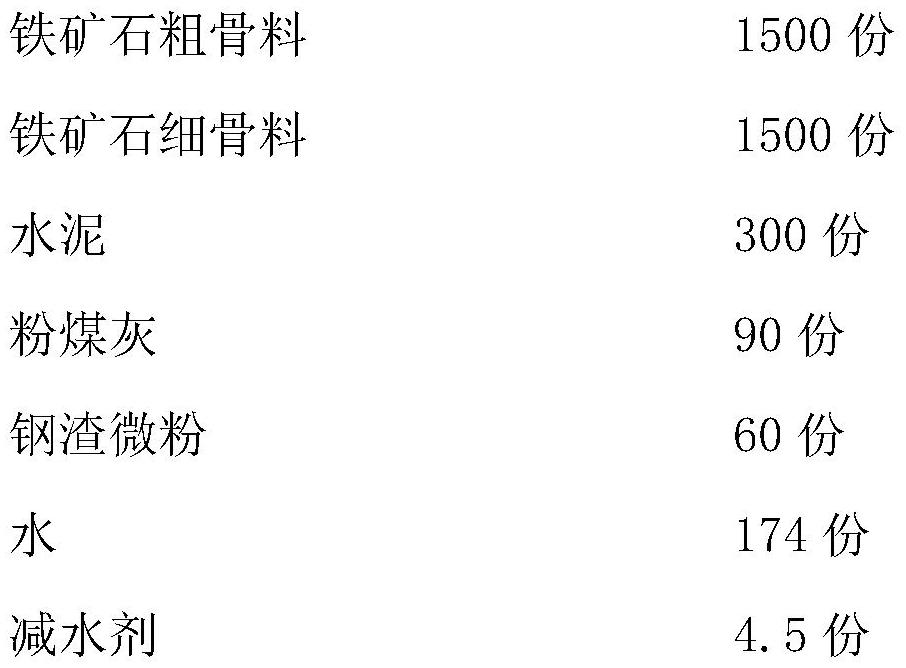

[0047]

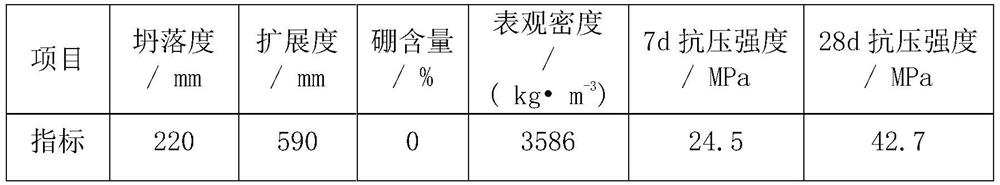

[0048] The performance of the iron ore radiation-proof concrete is shown in Table 2.

[0049] Table 2

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com