A kind of activated carbon fiber adsorbent and its preparation method and its application in the adsorption of benzene series

A technology of activated carbon fiber and adsorbent, applied in the field of volatile organic compound treatment, can solve the problems of low introduction amount and uneven distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

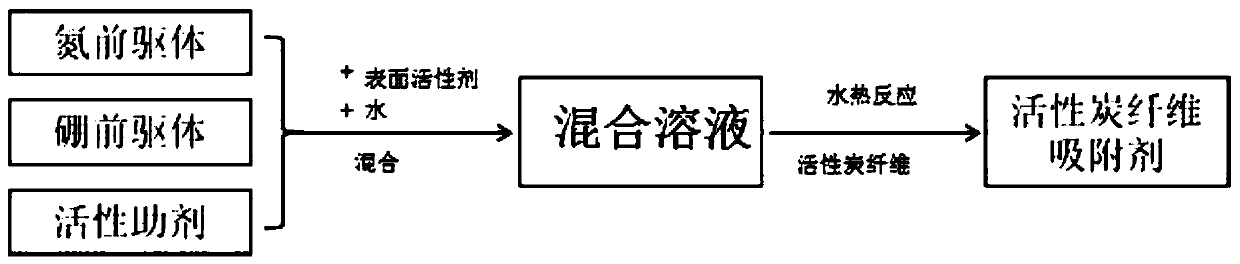

[0028] The invention provides a kind of activated carbon fiber adsorbent (B-C 3 N 4 / ACF) preparation method, comprises the following steps:

[0029] (1) Boron precursor, water-soluble nitrogen-containing organic matter, coagent, surfactant and water are mixed to obtain a mixed solution, and the coagent is glucose, citric acid or ascorbic acid; the boron precursor is meta-amino Phenylboronic acid, p-aminophenylboronic acid, m-cyanophenylboronic acid or p-cyanophenylboronic acid;

[0030] (2) After the mixed solution obtained in the step (1) is mixed with activated carbon fibers, hydrothermal reaction is carried out to obtain an activated carbon fiber adsorbent.

[0031] The present invention mixes the boron precursor, water-soluble nitrogen-containing organic matter, coagent, surfactant and water to obtain a mixed solution, the coagent is glucose, citric acid or ascorbic acid; the boron precursor is m-aminobenzene Boric acid, p-aminophenylboronic acid, m-cyanophenylboronic ...

Embodiment 1

[0060] Using m-aminophenylboronic acid as boron precursor, urea as water-soluble nitrogen-containing organic matter, and glucose as active auxiliary agent, prepare 100 g of mixed solution according to the mass ratio of 1:1:0.5:97.5, and add 1 g of boric acid monoglyceride monofatty acid ester As a surfactant, stir at room temperature until complete dissolution.

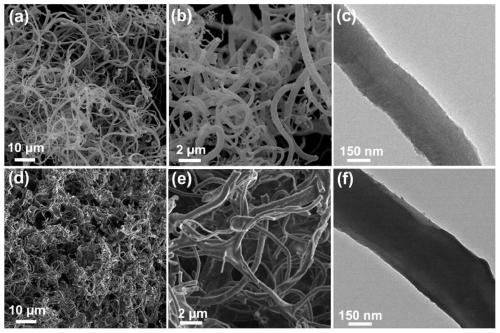

[0061] Weigh 200g of viscose-based activated carbon fiber, dip it in the mixed solution prepared above, stir evenly, then conduct hydrothermal reaction at a constant temperature of 120°C for 1h, then sonicate for 0.1h, and then dry at 80°C for 12h to obtain the coated The amount of 1% boron-doped nitrogen carbide modified activated carbon fiber adsorbent (1% B-C 3 N 4 / ACF).

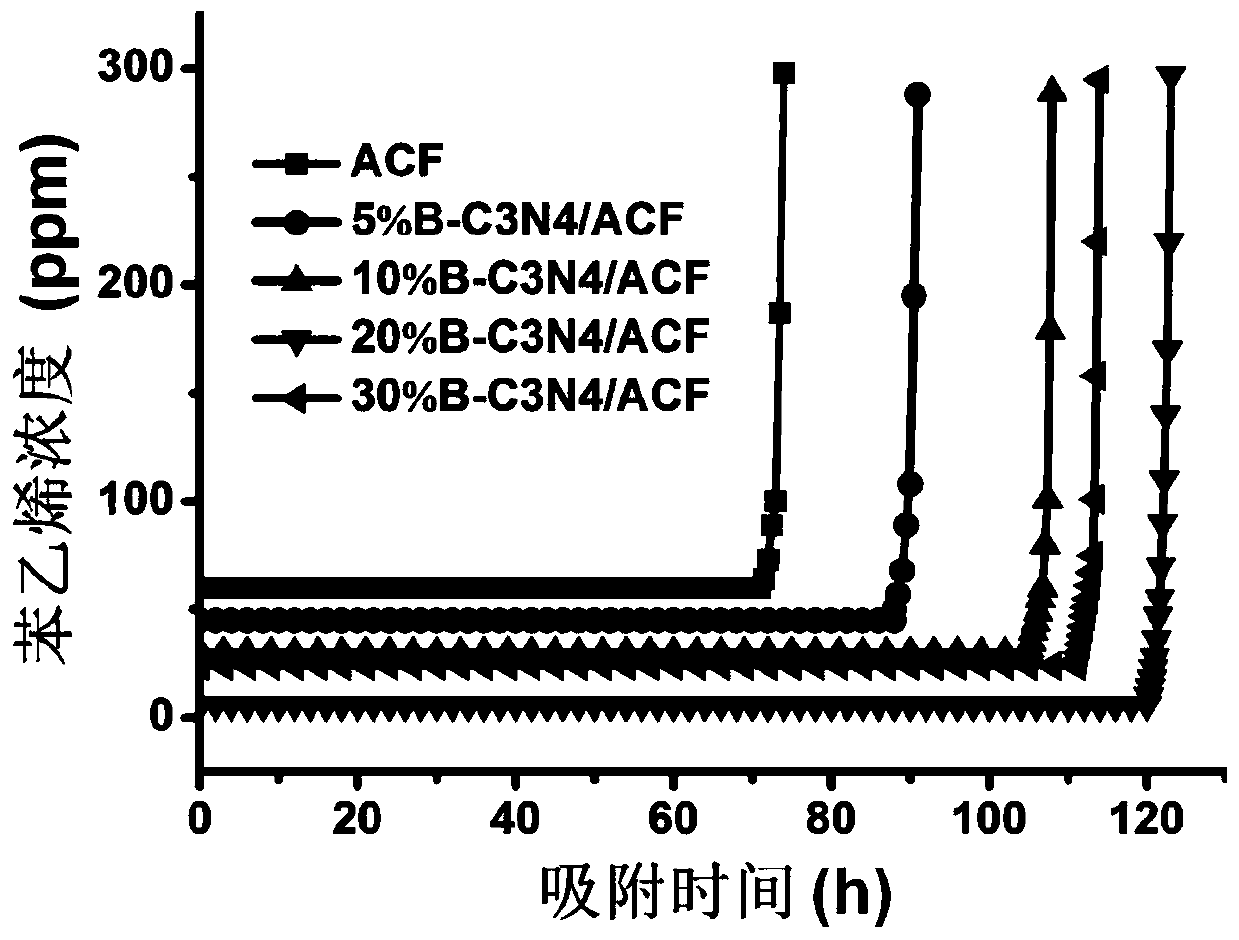

[0062] The original viscose-based activated carbon fiber and the activated carbon fiber adsorbent prepared in Example 1 were respectively packed in a fixed-bed reactor, the reaction temperature was controlled at 20°C, and benzene-containing ga...

Embodiment 2

[0064] With p-aminophenylboronic acid as the boron precursor, cyanamide as the water-soluble nitrogen-containing organic matter, and citric acid as the active auxiliary agent, 100 g of the mixed solution was prepared in a mass ratio of 15:15:5:65, and 5 g of boric acid monoglyceride poly Oxyethylene mono-fatty acid ester is used as a surfactant, and stirred at room temperature until complete dissolution.

[0065] Weigh 30g of viscose-based activated carbon fiber and 40g of polyacrylonitrile-based activated carbon fiber, 70g in total, dip into the mixed solution prepared above, stir evenly, then carry out hydrothermal reaction at 220°C for 48h, then ultrasonic for 6h, and then in Drying at 110°C for 48h, the activated carbon fiber adsorbent (30%B-C 3 N 4 / ACF).

[0066] The original activated carbon fiber and the modified activated carbon fiber adsorbent obtained in Example 2 are packed in a fixed bed reactor respectively, the reaction temperature is controlled at 80° C., and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com