A wear-resistant high-hardness diamond glaze, preparation method and application

A high-hardness, diamond technology, applied in the field of ceramic glaze, can solve the problems of low hardness and poor wear resistance, and achieve the effect of improving wear resistance and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

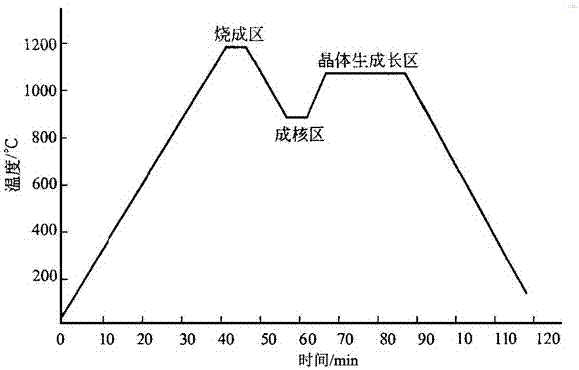

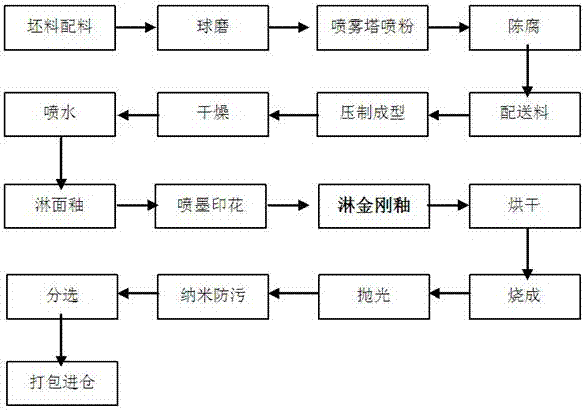

Embodiment 1

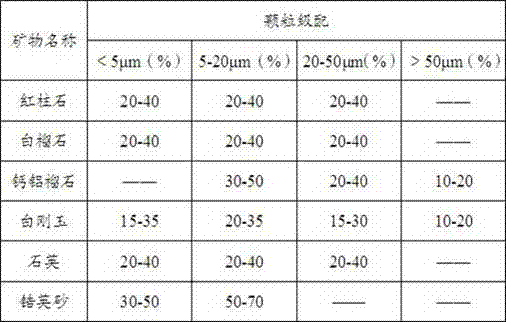

[0061] In terms of mass percentage, 10% kaolin, 8.4% andalusite, 7.5% potassium feldspar, 6.7% leucite, 2.2% grossular garnet, 13.5% nepheline from Norway, 12.2% spodumene, wollastonite 4.5%, 7.5% quartz, 7% zircon sand, 12.5% white corundum, 3% dolomite, 2.2% calcined white talc, 0.4% zinc oxide, and 2.2% additives. Material formula. Among them, in terms of mass percentage, the particle gradation of andalusite is 50μm accounting for 20%; The particle gradation of white corundum is 50 μm accounting for 15%; the particle grading of quartz is <5 μm accounting for 25%, 5-20 μm accounted for 35%, 20-50 μm accounted for 40%; the particle size distribution of zircon sand was <5 μm, accounting for 45%, and 5-20 μm accounted for 55%. Among them, the additives are 10% sodium tripolyphosphate, 40% aluminum tripolyphosphate, and 50% polyanionic cellulose in terms of mass percentage. According to the glaze formula, the ingredients are fed into the ball mill, and the glaze slurry that...

Embodiment 2

[0067] In terms of mass percentage, 8% kaolin, 8% andalusite, 9.7% potassium feldspar, 8.8% leucite, 2% grossular garnet, 10% nepheline from Norway, 10% spodumene, wollastonite 5.8%, 9.7% quartz, 9.1% zircon sand, 10.5% white corundum, 2.8% dolomite, 2% calcined white talc, 0.4% zinc oxide, and 2.2% additives. Material formula. Among them, in terms of mass percentage, the particle gradation of andalusite is 50μm accounting for 20%; The particle gradation of white corundum is 50 μm accounting for 15%; the particle grading of quartz is <5 μm accounting for 25%, 5-20 μm accounted for 35%, 20-50 μm accounted for 40%; the particle size distribution of zircon sand was <5 μm, accounting for 45%, and 5-20 μm accounted for 55%. Among them, the additives are 10% sodium tripolyphosphate, 40% aluminum tripolyphosphate, and 50% polyanionic cellulose in terms of mass percentage. According to the glaze formula, the ingredients are fed into the ball mill, and the glaze slurry that has reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com