12000 T/D kiln outlet special-use castable

A castable and kiln mouth technology, which is applied in the field of high-temperature materials for building materials, can solve the problems of low-cement castables, easy peeling, non-wear resistance, etc., and achieve the goals of improving thermal shock resistance, improving non-wear resistance, and reducing internal stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

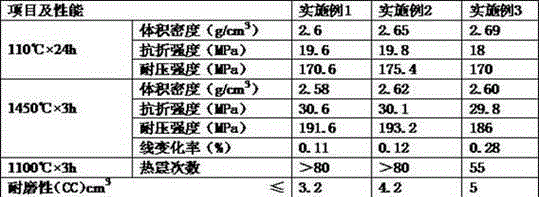

Embodiment 1

[0040] A special castable for 12000T / D kiln mouth, the weight percentage of its components is:

[0041] Mullite 25%

[0042] Sillimanite 20%

[0043] Tabular alumina 25%

[0044] Strontium titanate powder 8%

[0045] Zirconia powder 5%

[0046] Zinc aluminum spinel powder 1%

[0048] Aluminum oxide powder 5%

[0049] Pure calcium aluminate cement 6%

[0050] Polylactic acid fiber 0.2%

[0051] Sodium hexametaphosphate is 0.1%.

Embodiment 2

[0053] A special castable for 12000T / D kiln mouth, the weight percentage of its components is:

[0054] Mullite 22%

[0055] Sillimanite 20%

[0056] Tabular alumina 25%

[0057] Strontium titanate powder 8%

[0058] Zirconia powder 8%

[0059] Zinc aluminum spinel powder 2%

[0061] Aluminum oxide powder 5%

[0062] Pure calcium aluminate cement 5%

[0063] Polylactic acid fiber 0.2%

[0064] Sodium hexametaphosphate 0.1%

[0065] Leucite 0.1%

[0066] C 12 h 14 N 4 o 5 S 2 0.1%.

Embodiment 3

[0068] A special castable for 12000T / D kiln mouth, the weight percentage of its components is:

[0069] Mullite 22%

[0070] Sillimanite 20%

[0071] Tabular alumina 25%

[0072] Strontium titanate powder 10%

[0073] Zirconia powder 8%

[0074] Zinc aluminum spinel powder 3%

[0075] Boron nitride 3%

[0076] Aluminum oxide powder 5%

[0077] Pure calcium aluminate cement 4%

[0078] Polylactic acid fiber 0.2%

[0079] Sodium hexametaphosphate 0.1%

[0080] Leucite 0.1%

[0081] C 12 h 14 N 4 o 5 S 2 0.1%.

[0082] The various components used in the above examples are products well known to those skilled in the art and can be purchased in the market. The present invention extends the service life of the castable at the kiln mouth to 2 years or more.

[0083] The 12000T / D special casting material for kiln mouth of the above-mentioned examples 1-3 is prepared according to the following method: mix and stir each component and admixture evenly, then add an appropr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com