Oral restoration and correction auxiliary device

An auxiliary device and dental prosthesis technology, applied in the field of medical devices, can solve the problems of no product, inability to remove monitoring, low efficiency, etc., and achieve the effect of accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

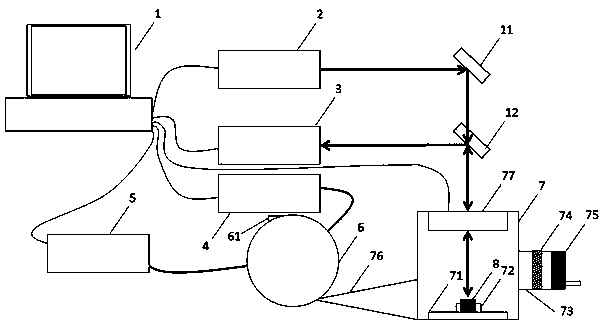

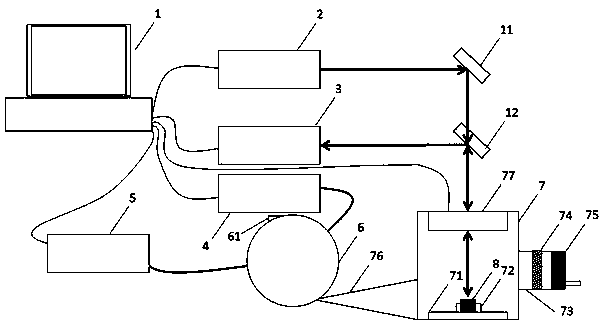

[0030] combine figure 1 , an auxiliary device for oral restoration and correction, characterized in that it includes a computer 1, a first laser 2, a first optical analyzer 3, a second laser 4, a second optical analyzer 5, a gas detection ball 6 and an ablation cylinder 7 ;

[0031] The computer 1 is connected to the first laser 2, the first optical analyzer 3, the second laser 4, and the second optical analyzer 5;

[0032] The first laser 2 emits laser light to ablate the orthodontic brackets in the ablation cylinder 7 to remove the surface adhesive, and the first optical analyzer 3 analyzes the plasma generated during the ablation process; the ablation cylinder 7 The gas produced inside enters the gas detection ball 6, the second laser 4 emits laser light to irradiate the inside of the gas detection ball 6, the second optical analyzer 5 analyzes the light absorption inside the gas detection ball 6, and sends the detection result to the computer 1.

[0033] The ablation cyl...

Embodiment 2

[0044] A method for cleaning orthodontic brackets using the above-mentioned device is characterized in that it comprises the following steps:

[0045] Step 1 Take the ablation platform 71 out of the ablation cylinder 7, fix the orthodontic bracket 8 on the clamp 72 of the ablation platform 71, and put the ablation platform 71 back into the ablation cylinder 7 to ensure ablation The seal between the platform 71 and the ablation cylinder 7;

[0046] Step 2 Start the intake pump 75 to make dry air enter the ablation cylinder 7 and discharge from the top of the optical analysis sphere;

[0047] Step 3 The computer 1 controls the first laser 2 to emit weak continuous light, and the vibrating mirror device 77 irradiates the laser light emitted by the first laser 2 to the position of the orthodontic bracket 8, and the computer 1 detects whether the first optical analyzer 3 can receive the light If the optical signal cannot be received, disassemble the machine for inspection;

[0048]...

Embodiment 3

[0052] Step 3 increases the computer to adjust the power of the first laser, so that the laser can only remove the adhesive, and will not damage the bracket itself.

[0053] Step 5 is changed to when the elements of the adhesive component analyzed by the first optical analyzer 3 fall below the threshold value, and at the same time, the absorption peak of the gas generated by the adhesive ablation in the absorption spectrum measured by the second optical analyzer 5 When the position does not drop within a certain period of time, the computer 1 controls the first laser 2 and the second laser 4 to stop working, and the cleaning process is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com