Air-jet loom profiled steel reed defect mouth repairing process

A technology of air-jet looms and special-shaped steel, which is applied in the direction of manufacturing tools, metal processing equipment, grinding machines, etc., can solve the problems of air-jet loom shutdown, negative effect amplification, and increased costs, so as to reduce warp breakage rate, save costs, and improve The effect of weaving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below through specific embodiments.

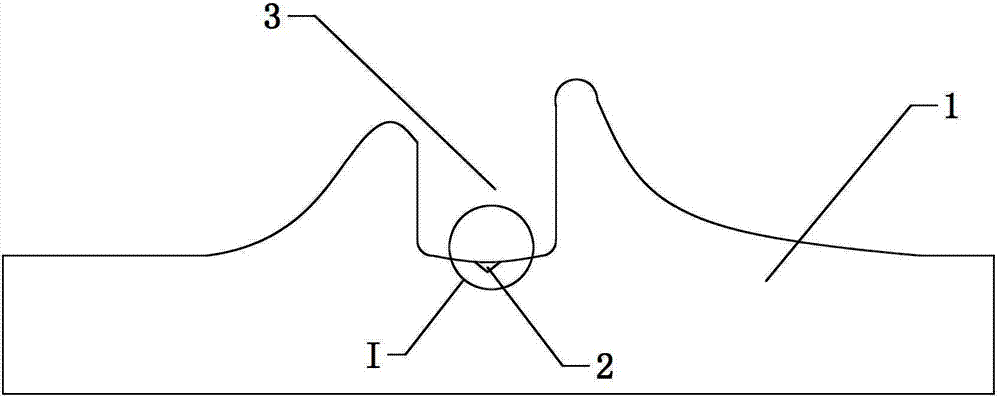

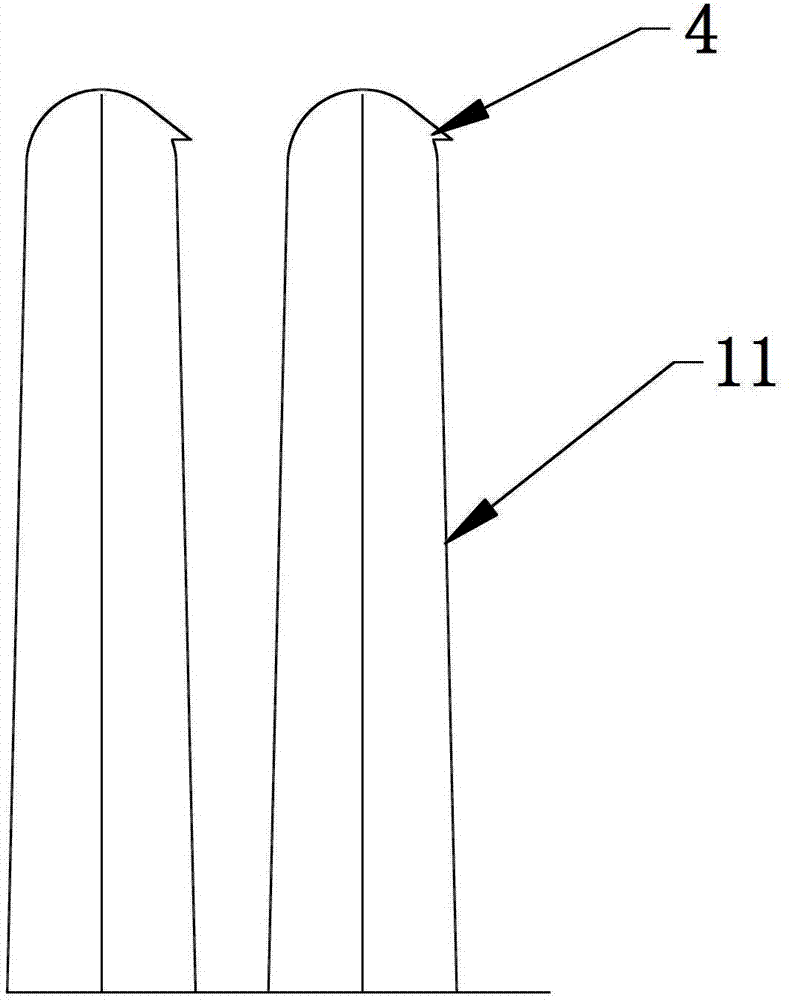

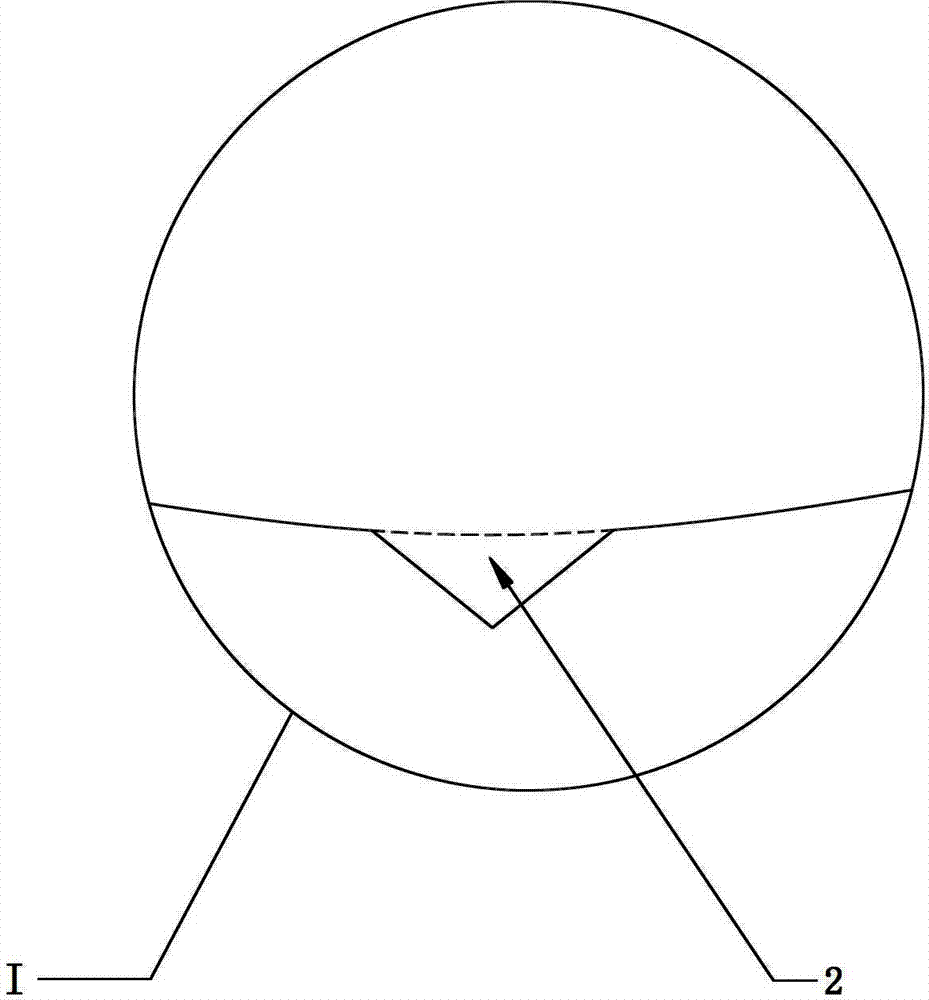

[0016] Such as figure 1 with figure 2 As shown, the profiled steel reed 1 on the air jet loom is subject to long-term high-frequency reciprocating vibrations, and the bottoms of the airflow grooves 3 at both ends of the profiled steel reed 1 are prone to image 3 In the defect 2, the defect 2 may hang up the warp, causing warp breakage, which requires frequent splicing, and the weaving efficiency of the air jet loom is low. Generally, the current way to solve this problem is to directly replace the special-shaped steel reed 1, which is likely to cause waste of materials and increase costs.

[0017] An air-jet loom special-shaped steel reed 1 defect 2 repair process, including the following steps: (1) Check the two ends of the special-shaped steel reed 1 air flow groove 3, and determine the defect of the groove bottom of the special-shaped steel reed 1 air flow groove 3 2 positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com