Rapid plugging method for fiberglass pipeline with water and pressure

A plugging method and technology of glass steel pipes, which are applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of difficult discharge of fluid in the pipeline, no place to discharge, inconvenience, etc., and achieve reduction of labor costs and internal The effect of fluid material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

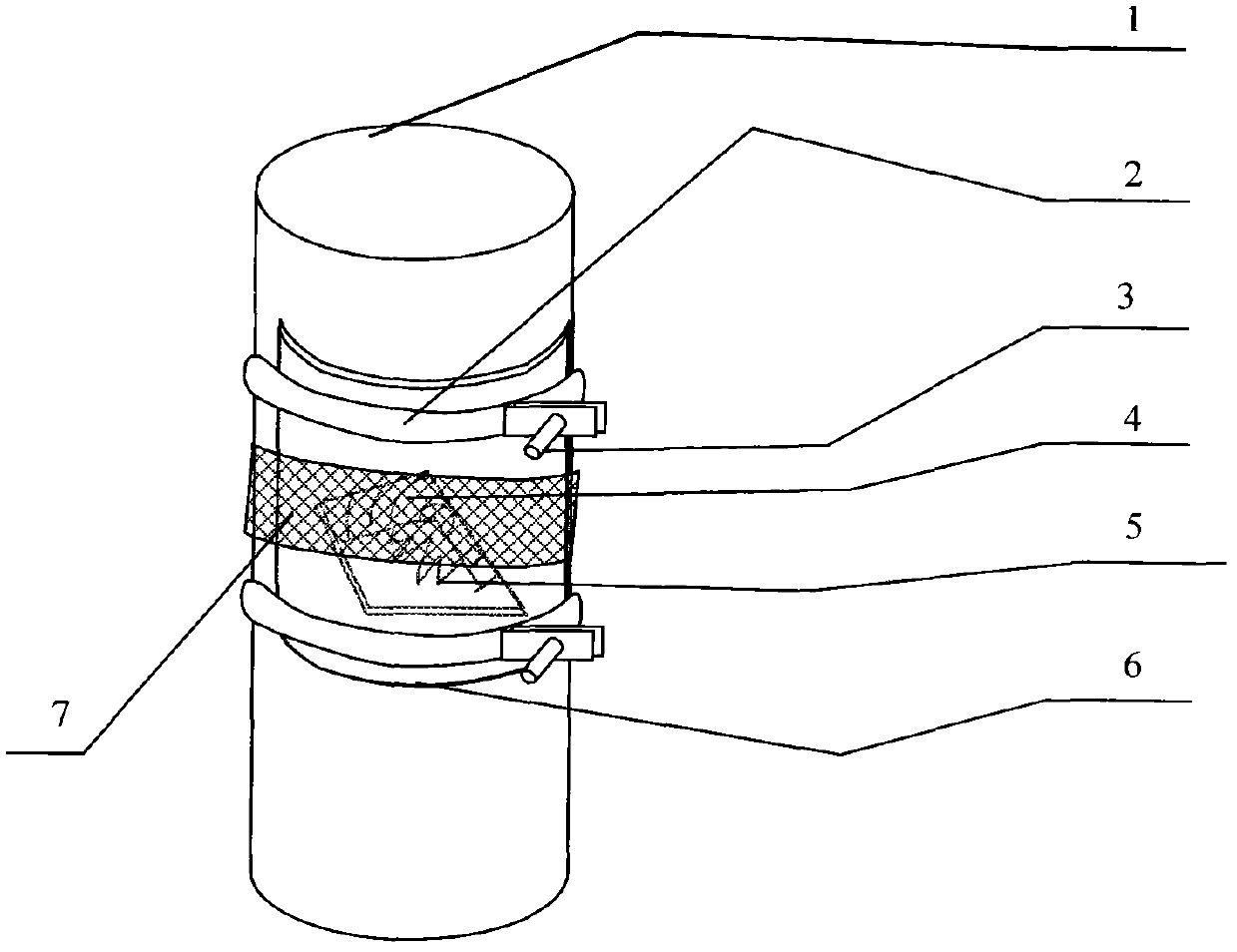

[0013] For the damaged opening 5 on the FRP pipe 1, make an apron 4, and use a semicircular FRP water sealing tape to cling to the apron 4 to form a joint reinforcing plate 6, and tighten each hoop near the two sides outside the FRP water sealing tape. The rope device 2 seals the damaged opening 5, and in the middle of the fiberglass steel pipe 1's joint reinforcing plate 6, artificially wraps glass fiber alkali-free checkered cloth and unsaturated polyester resin in a full circle until the jointing belt 7 is solidified and reaches the pressure resistance. ability; loosen the tension rope tightening device 2 at the left and right ends of the damaged opening 5 respectively; wind the glass fiber alkali-free checkered cloth and unsaturated polyester resin at the left and right ends of the mending belt 7 that has been done in the middle until the new The jointing belt 7 is formed and solidified as one.

[0014] Specifically, for the damaged opening 5 on the glass steel pipe 1, use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com