Anticorrosive heat shrink sleeve for mouth-repairing for welding engineering pipeline

A heat shrinking and welding technology, used in pipeline anti-corrosion/anti-rust protection, pipeline protection, pipeline connection layout, etc., can solve the problems of low degree of mechanization, many factors of product quality, large internal stress of products, etc., and achieve high degree of mechanization , The quality is easy to control, and the internal stress of the product is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

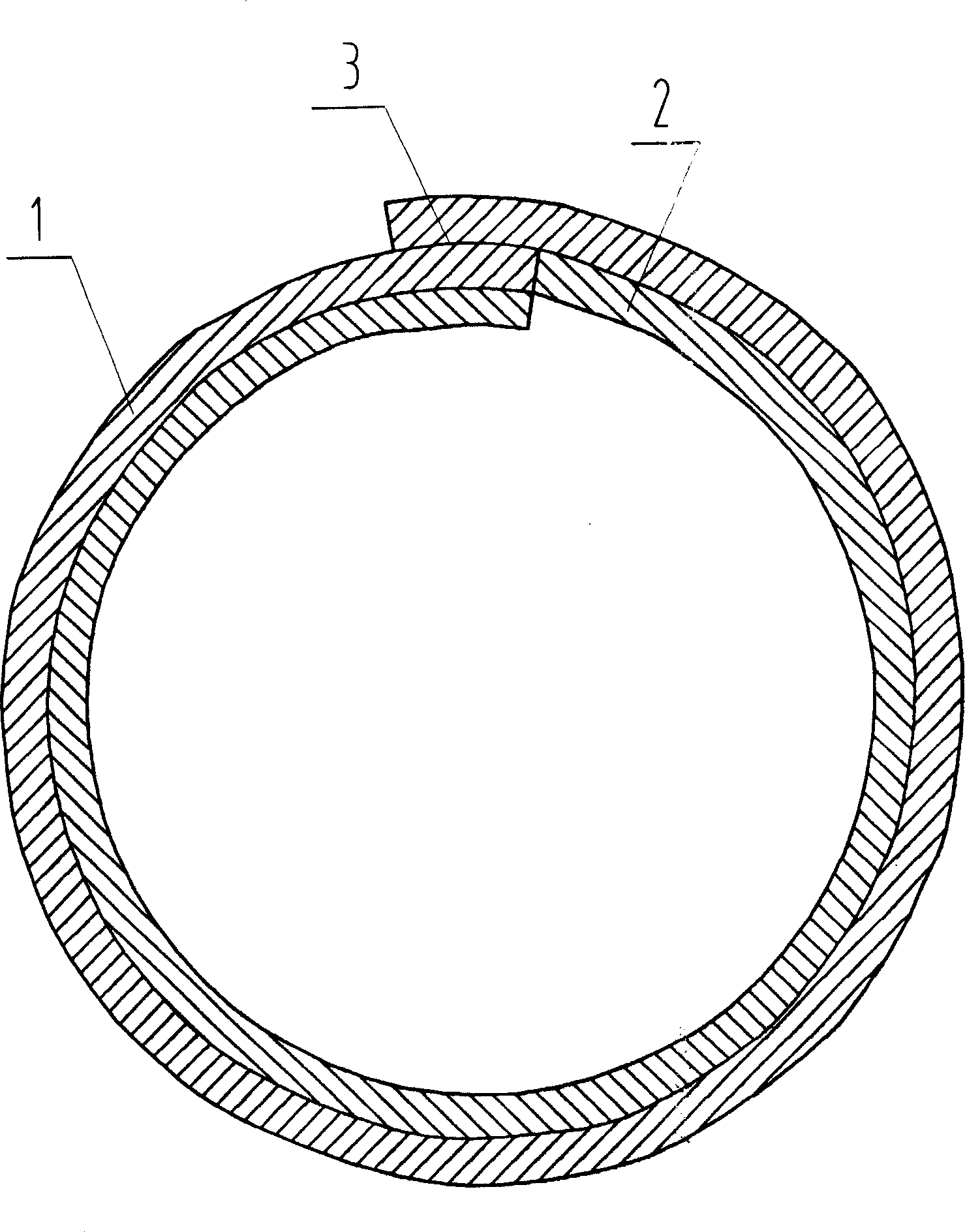

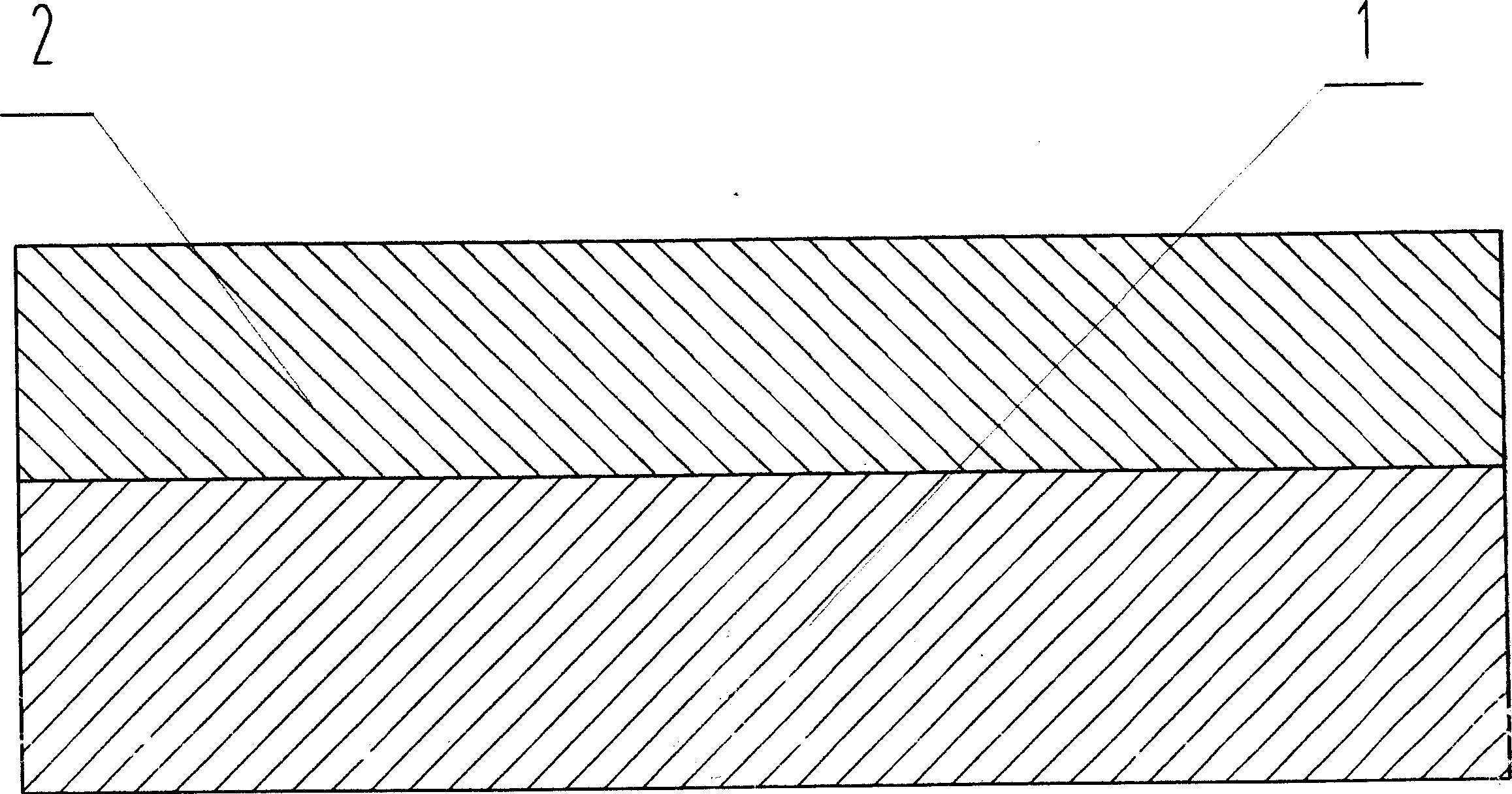

[0015] See each top view. An anti-corrosion heat-shrinkable sleeve for welding engineering pipelines, which is composed of an outer layer 1 of a base material and an inner layer 2 of hot melt adhesive coated on the outer layer 1 of the base material. The end of the heat shrinkable tape sheet is lapped into a sleeve shape, and the lap joint is welded and connected to form a heat shrinkable sleeve by an ultrasonic welding machine; The outer layers 1 of the base material overlap each other.

[0016] The production process of the heat-shrinkable sleeve in this embodiment is as follows: extruding and stretching the granulated special material for engineering pipelines (radiation cross-linked polyolefin material), then continuously irradiating, and continuously applying glue with special hot-melt adhesive , produce engineering pipeline heat shrinkable tape; then cut the heat shrinkable tape into sheets; then lap the outer layer 1 part of the sheet material into a sleeve (the lap le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com