Mouth compensating method for pipeline corrosion protection layer and integrated mouth compensating machine

A technology of anti-corrosion layer and joint filling, which is applied in the direction of pipeline anti-corrosion/rust protection, pipeline protection, pipe components, etc., which can solve the problems of low operation efficiency and achieve the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

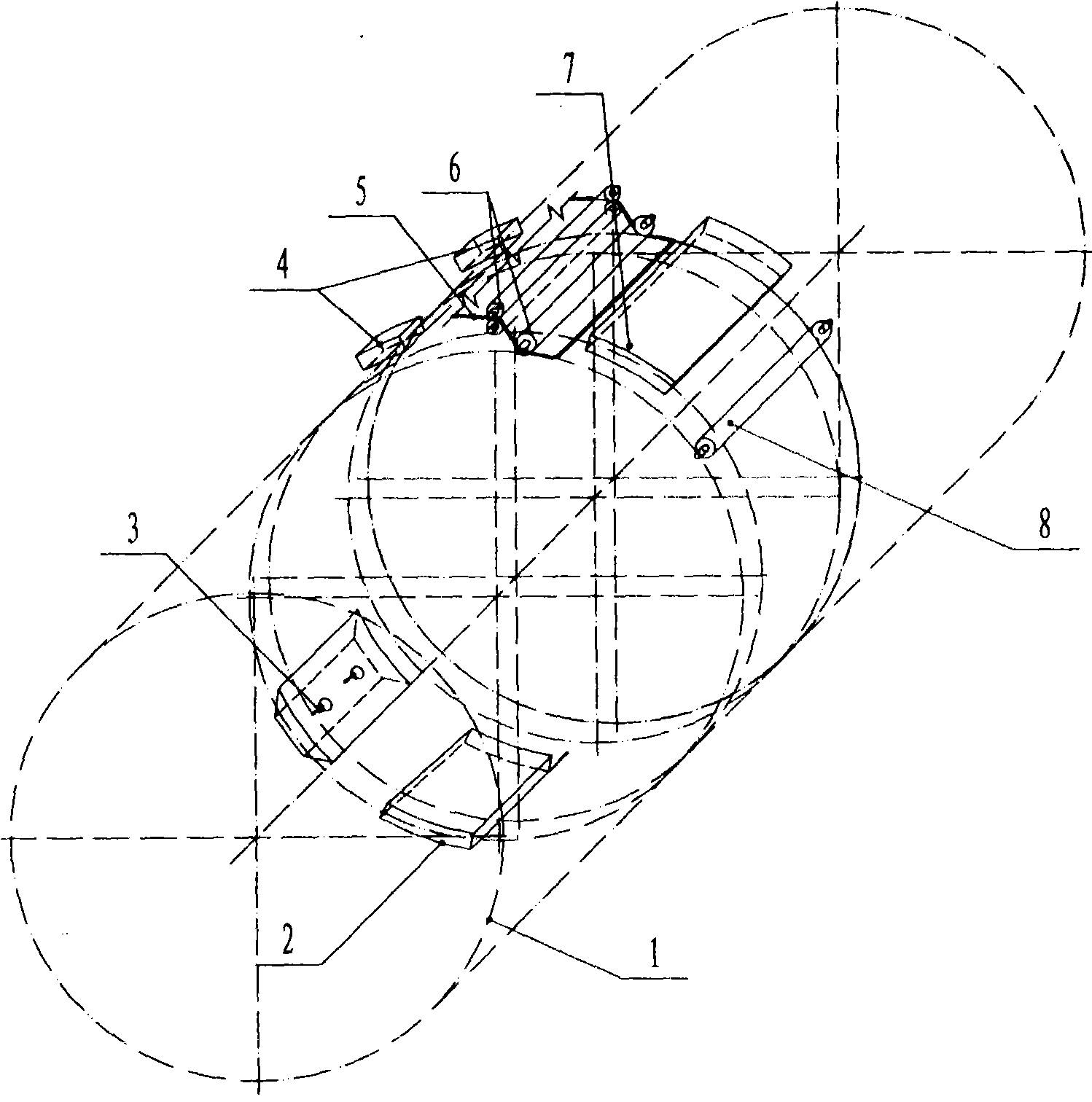

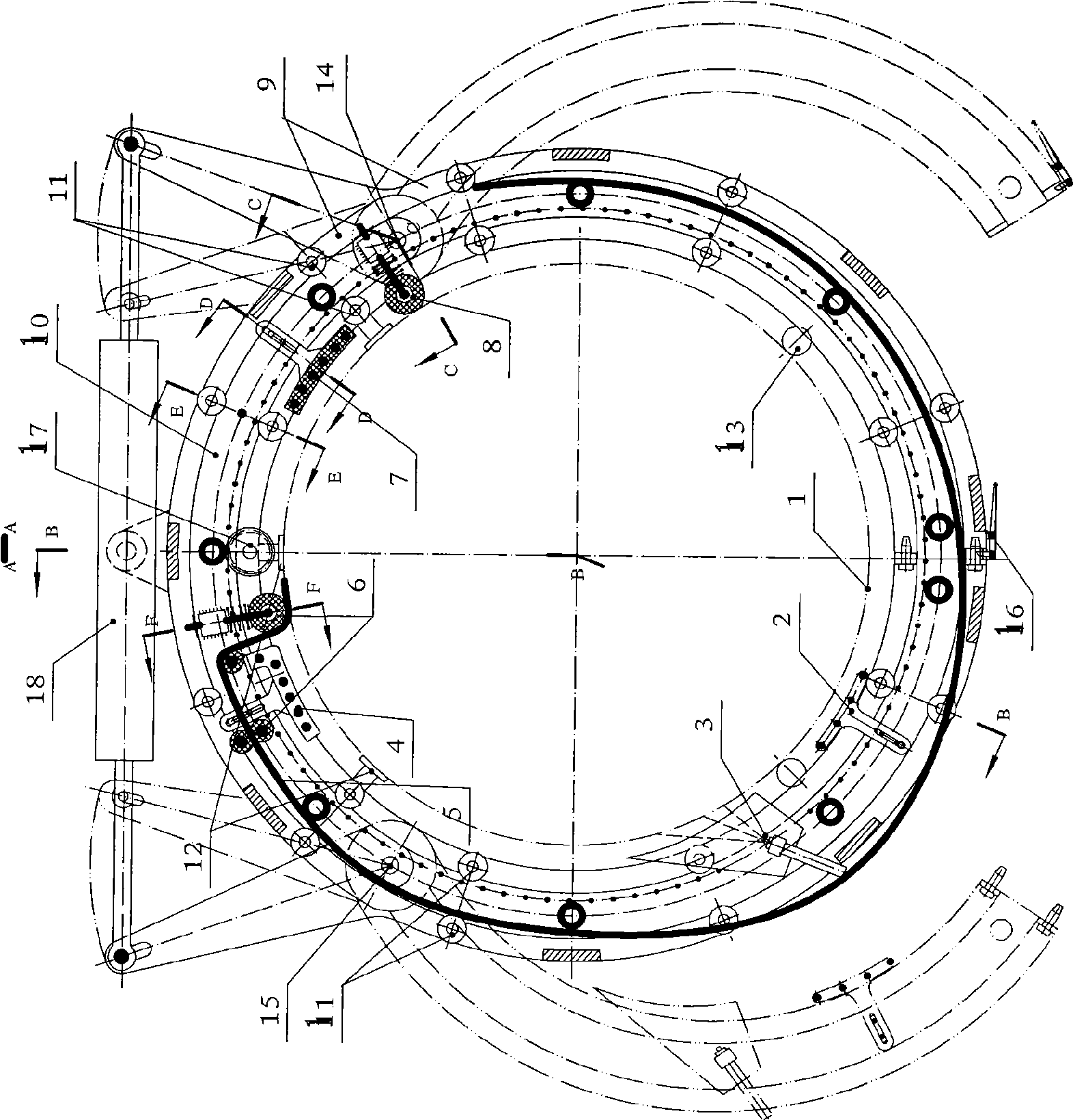

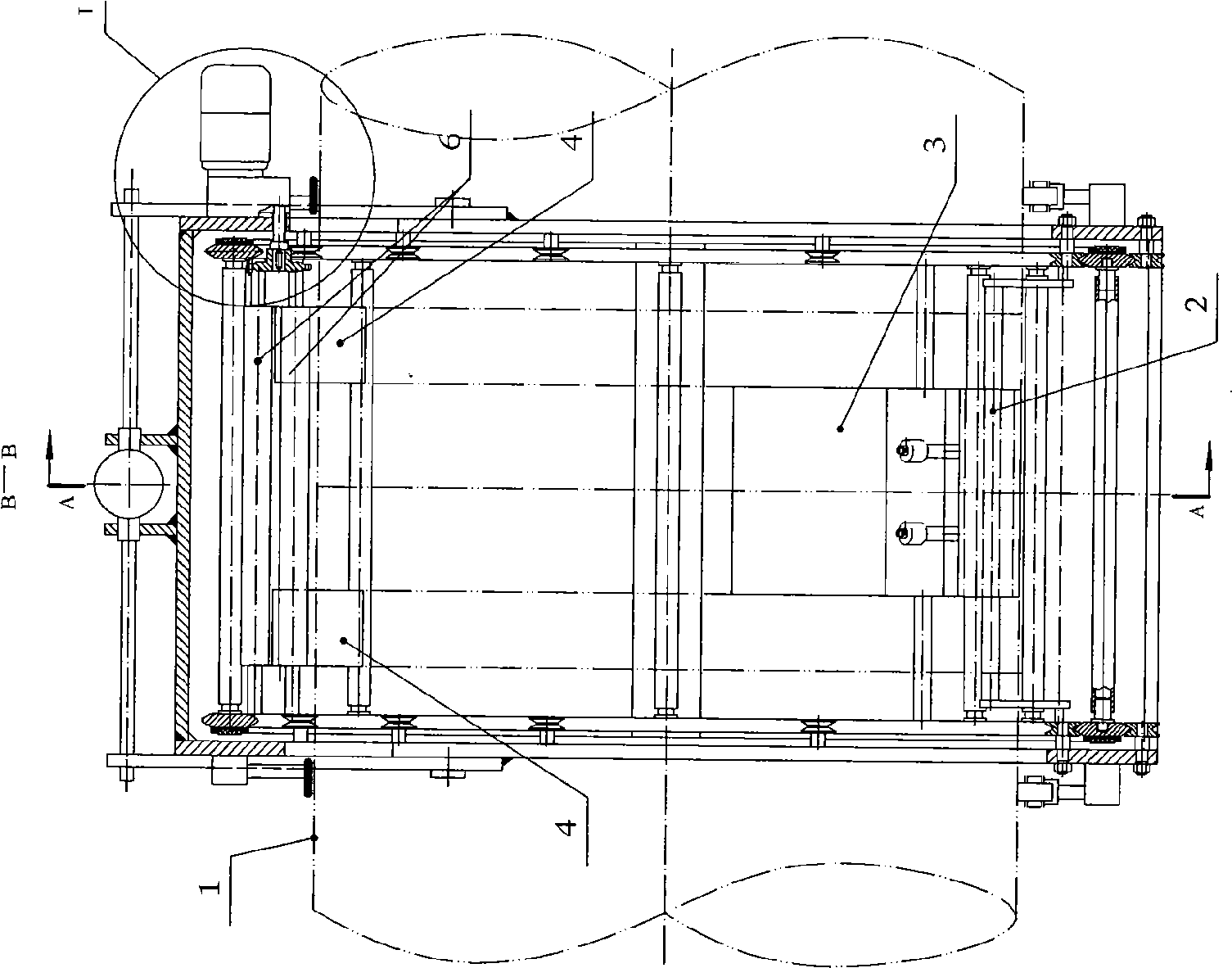

[0037] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 In the shown first embodiment of the integrated jointing machine of the present invention, the steel pipe (1) is fixed relative to the ground after butt welding, and the integrated jointing machine is set on the outer circumference of the jointing pipe section when the integrated jointing machine works; the fixed ring frame (9) is formed by A plurality of fixed legs (12) and supporting rollers (13) installed in its circumferential distribution support and fix it on the outer circumference of the joint of the pipeline; The frame (9) is guided and connected along the circumferential direction of the pipeline; the steel pipe heater (2), coater (3), lapping heater (4), feeding guide pressing mechanism (6), and jointing layer of each process component The heater (7) and the secondary pressing roller (8) are respectively installed on the rotating hoop (10) and arranged seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com