Photocuring joint coating provided with graphene filler and preparing method thereof

A graphene, light-curing technology, applied in anti-corrosion coatings, polyester coatings, polyether coatings, etc., can solve problems such as poor surface curing and inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

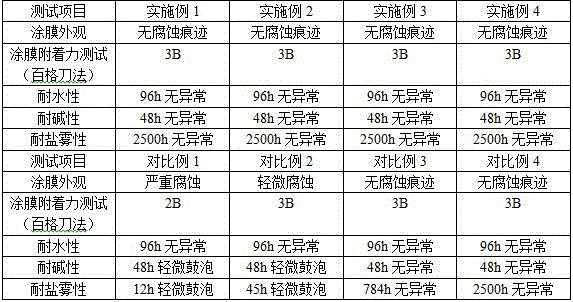

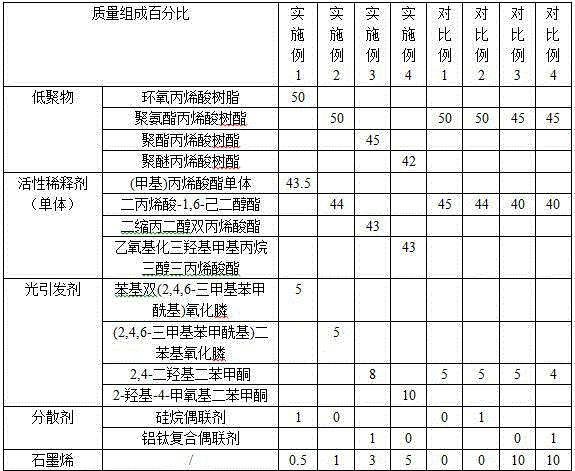

Examples

Embodiment Construction

[0024] A kind of is the preparation method of the light-cured sealing coating of graphene filler, comprises the following steps:

[0025] (1) Graphene is dissolved in a solvent, prepared into a suspension in which graphene accounts for 0.5%-5% of the total mass of the solution, and ultrasonically dispersed by an ultrasonic cell disruptor with a frequency of 15-20KHz to obtain a graphene suspension.

[0026] (2) Add oligomers, reactive diluents and dispersants to the solution obtained in step (1) while stirring, and then use an ultrasonic cell cleaner with a frequency of 30-40KHz for 30-60 minutes.

[0027] (3) Add a photoinitiator to the solution prepared in step (2) while stirring magnetically, and stir thoroughly until all the solvent evaporates to obtain a photocurable sealing coating with graphene filler.

[0028] To further improve the above technical solution: the solvent is one or a mixture of ethanol, acetone and tetrahydrofuran.

[0029] In pipeline jointing, the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com