A method for preparing nano compound resin prosthetics material

A nano-composite, oral restorative technology, applied in the field of oral restorative material preparation, can solve problems such as complicated process, damaged restoration edge closure, poor physical and mechanical properties, etc., and achieve simple preparation process, high biocompatibility, and relatively The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

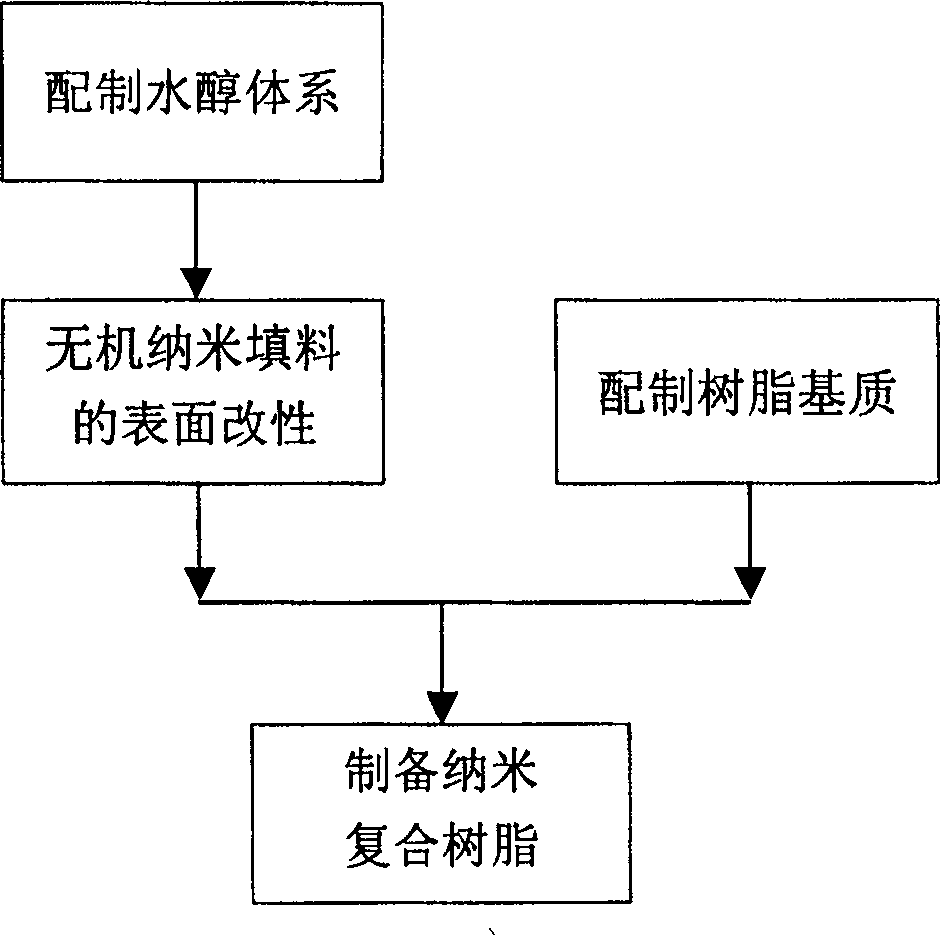

[0025] like figure 1 Shown, the present invention provides a kind of preparation method of nanocomposite resin oral restorative material, and it comprises the steps:

[0026] Prepare the hydroalcoholic system: hydrolyze the silane coupling agent under the catalysis of acetic acid to form a hydroalcoholic system containing the coupling agent;

[0027] Surface modification of inorganic nano-fillers: adding nano-inorganic powders to a water-alcohol system containing a coupling agent for ultrasonic dispersion, after the reaction is complete, washing and drying to obtain modified inorganic nano-fillers;

[0028] Preparation of resin matrix: Dilute the resin monomer with an appropriate amount of diluent to form a resin matrix with good mixing properties;

[0029] Preparation of nanocomposite resin: under the condition of avoiding light, add the prepared resin matrix to the photoinitiator and co-initiator, after stirring evenly, then add the modified inorganic nano filler, after mix...

experiment example 1

[0043] 2g KH-570 is hydrolyzed under the effect of acetic acid, the hydroalcoholic solution of adding 100ml (V 水 :V 醇 5:95), then add 20g of nano-hydroxyapatite powder, ultrasonically disperse for 60min, then move to an oven and dry at 80°C for 6h. Washing with the above-mentioned water-alcohol system, repeating the drying step, and pulverizing after drying.

[0044]Prepare 10g of composite resin: add 0.8865g of triethylene glycol dimethacrylate (TEGDMA) to 2.0685g of bisphenol A glycidyl methacrylate (Bis-GMA) to dilute, and stir evenly with a spatula to make it have a good Miscibility; under dark conditions, add 0.015g photoinitiator camphorquinone and 0.03g dimethylaminoethyl methacrylate (DMAEM) to the prepared resin matrix, stir evenly, add 7g of the above-mentioned modified inorganic Nano filler, after mixing evenly. Place it in a vacuum desiccator for 12 hours to remove air bubbles between the resins, and prepare a nanocomposite resin material. The composite resin i...

experiment example 2

[0046] 3g KH-570 is hydrolyzed under the effect of acetic acid, adds the hydroalcoholic solution of 100ml (V 水 :V 醇 3:7), then add 15g of barium-aluminum glass powder, ultrasonically disperse for 60min, then move to an oven and dry at 70°C for 8h. Washing with the above-mentioned water-alcohol system, repeating the drying step, and pulverizing after drying.

[0047] Prepare 10g of composite resin: Add 0.9850g of triethylene glycol dimethacrylate (TEGDMA) to 1.4775g of urethane dimethacrylate (UDMA) to dilute, and stir evenly with a spatula to make it have good mixing properties ; Under light-shielding conditions, add 0.0125g photoinitiator camphorquinone and 0.025g dimethylaminoethyl methacrylate (DMAEM) to the prepared resin matrix, after stirring, add the above-mentioned modified inorganic nano-filler of 7.5g , after mixing evenly. Place it in a vacuum desiccator for 14 hours to remove air bubbles between the resins, and prepare a nanocomposite resin material. The compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com