On-line dynamic detecting device of locomotive wheel lset exterior size

A technology of external dimension and dynamic detection, which is applied in the direction of rim measurement/measurement, can solve the problems of measurement speed limit, measurement device damage, heavy workload of track reconstruction, etc., and achieve small speed limit, convenient installation and use, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

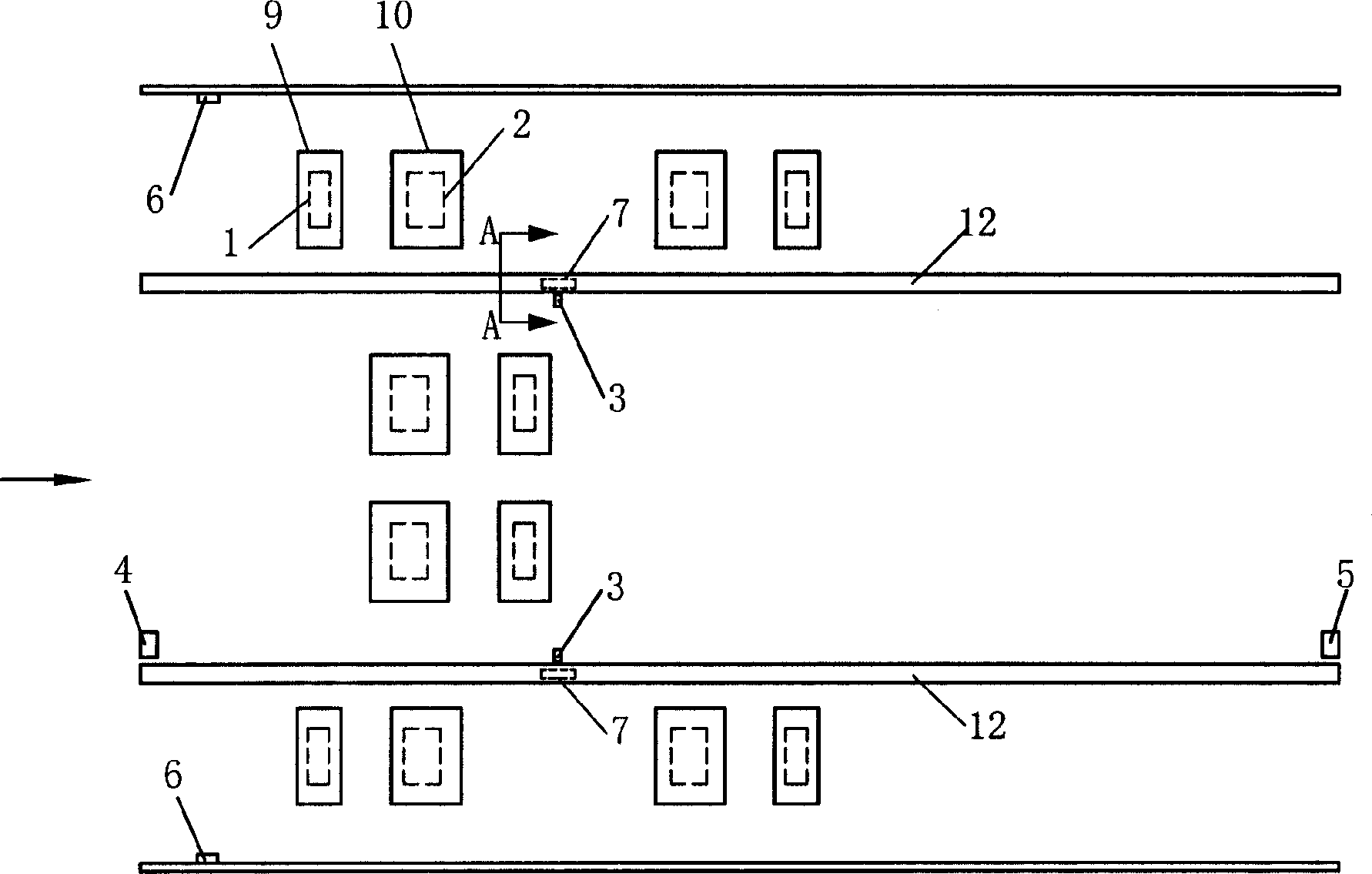

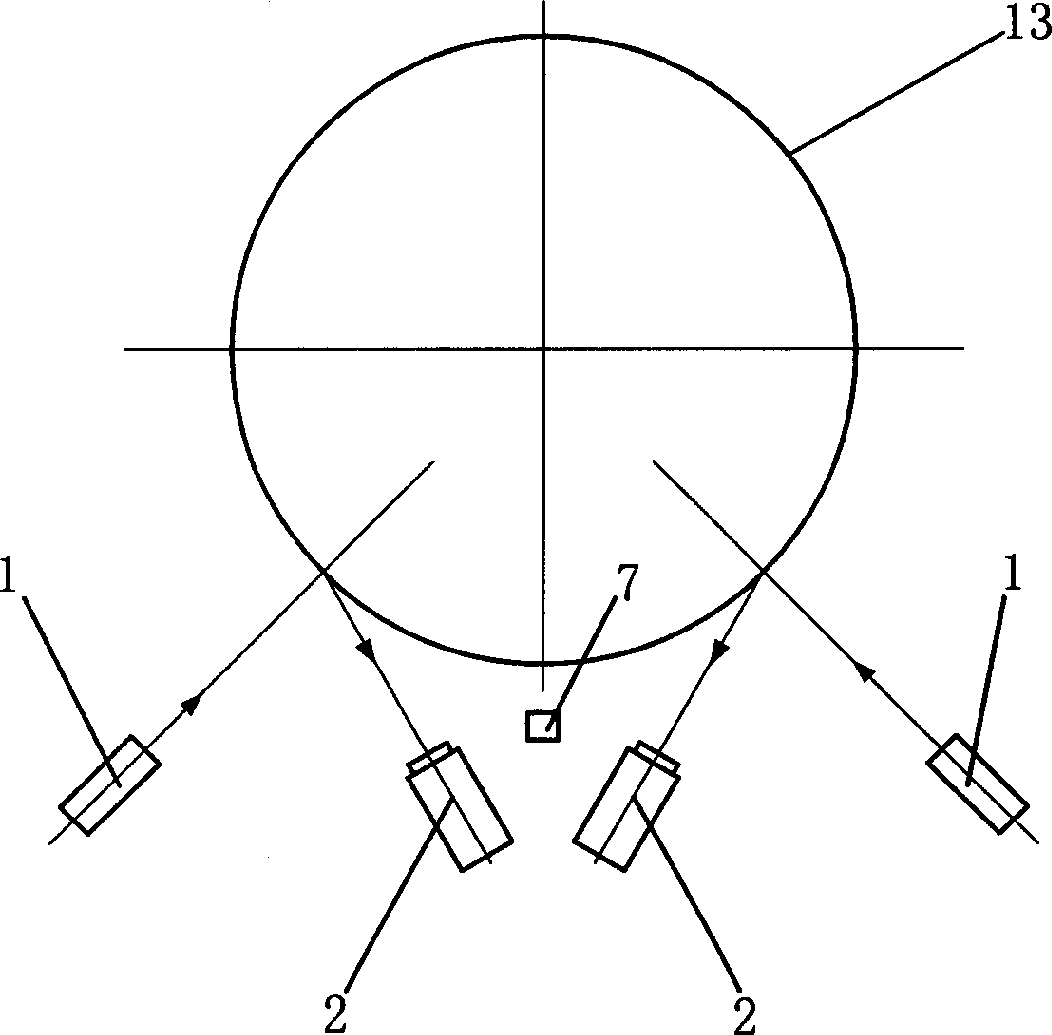

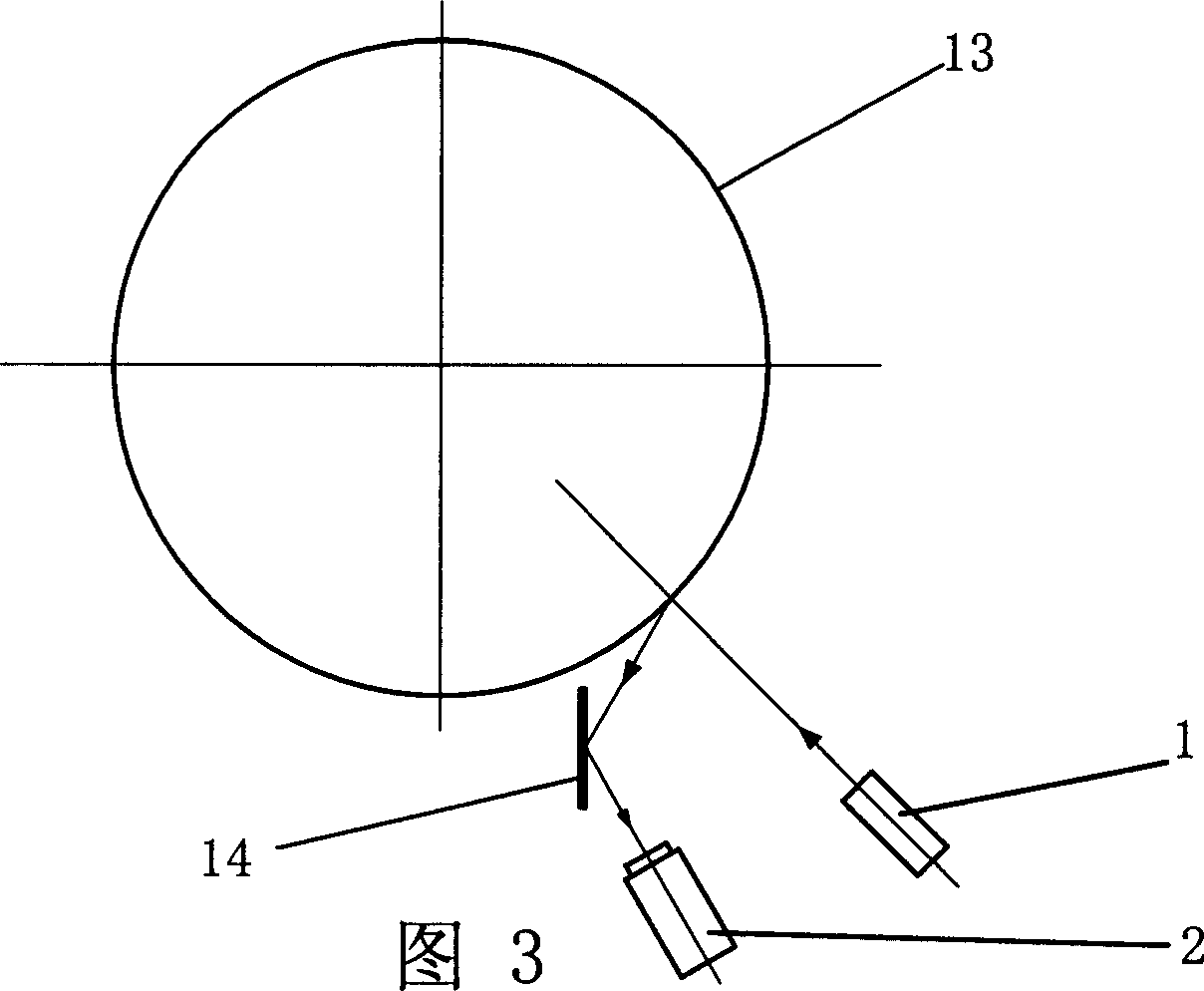

[0025] figure 1 , 2 , 4, and 5 show that a specific embodiment of the present invention is: a kind of on-line dynamic detection device for locomotive vehicle wheelset external dimensions, comprising a camera unit composed of a laser generator 1 and a camera 2 installed near the track 12, The data processing and control equipment connected with the laser generator 1 and the camera 2, the camera unit is installed on the ballast bed area inside and outside the track 12, and the wheel detector 3 is installed on the inner side of the track near the camera 2; the front of the camera unit Proximity sensor 4 is installed on track 12 side, and departure sensor 5 is installed on track 12 side behind camera unit; Wheel detector 3, proximity sensor 4, departure sensor 5 are all connected with data processing and control equipment.

[0026] Out of the track 12 both sides of the camera unit ahead, in the height range of the carriage casing, a direction determination and an axle counting ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com