cars with turbochargers

A turbocharger and automobile technology, applied in the direction of machine/engine, engine control, electrical control, etc., can solve problems such as turbo exceeding, exceeding the limit value, turbocharger damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

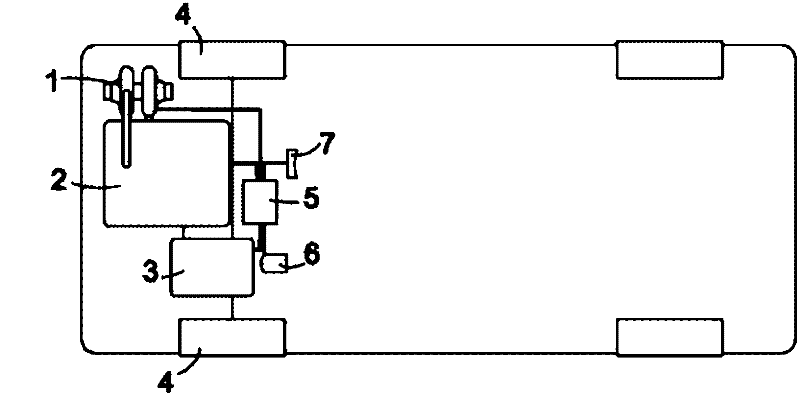

[0020] figure 1 is a schematic diagram of an automobile according to the present invention. A known turbocharger 1 with variable geometry supplies an internal combustion engine 2 with precompressed combustion air. The internal combustion engine 2 drives the wheels 4 of the motor vehicle via a transmission 3 .

[0021] A microprocessor based electronic control unit 5 is connected to an accelerator pedal 6 in order to control the fuel metering of the internal combustion engine 2 and the position of the vanes in the turbine of the turbocharger 1 depending on the position of the accelerator pedal 6 . The control unit 5 is also shown in the drawing as being connected to the transmission 3 and is designed to control the respective gear engaged in the transmission 3 . Furthermore, the control unit 5 is connected here to an ambient pressure sensor 7 which enables the control unit to evaluate the density of the combustion air sucked in by the turbocharger 1 .

[0022] As an alternat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com