Non-contact type dynamic measuring device and method for wheel diameter based on laser and method thereof

A dynamic measurement and non-contact technology, applied in the field of optical measurement, can solve problems such as low measurement accuracy, wear of measuring instruments and wheels, and small operating space, and achieve the effects of simple data processing, dynamic measurement, and improved response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The invention firstly provides a simple and practical non-contact dynamic measuring device and method for the diameter of train wheels. The measuring device and method thereof are realized based on one or two laser displacement sensors, are very simple to install and use, and are especially suitable for on-line dynamic measurement of wheel diameters when trains are moving.

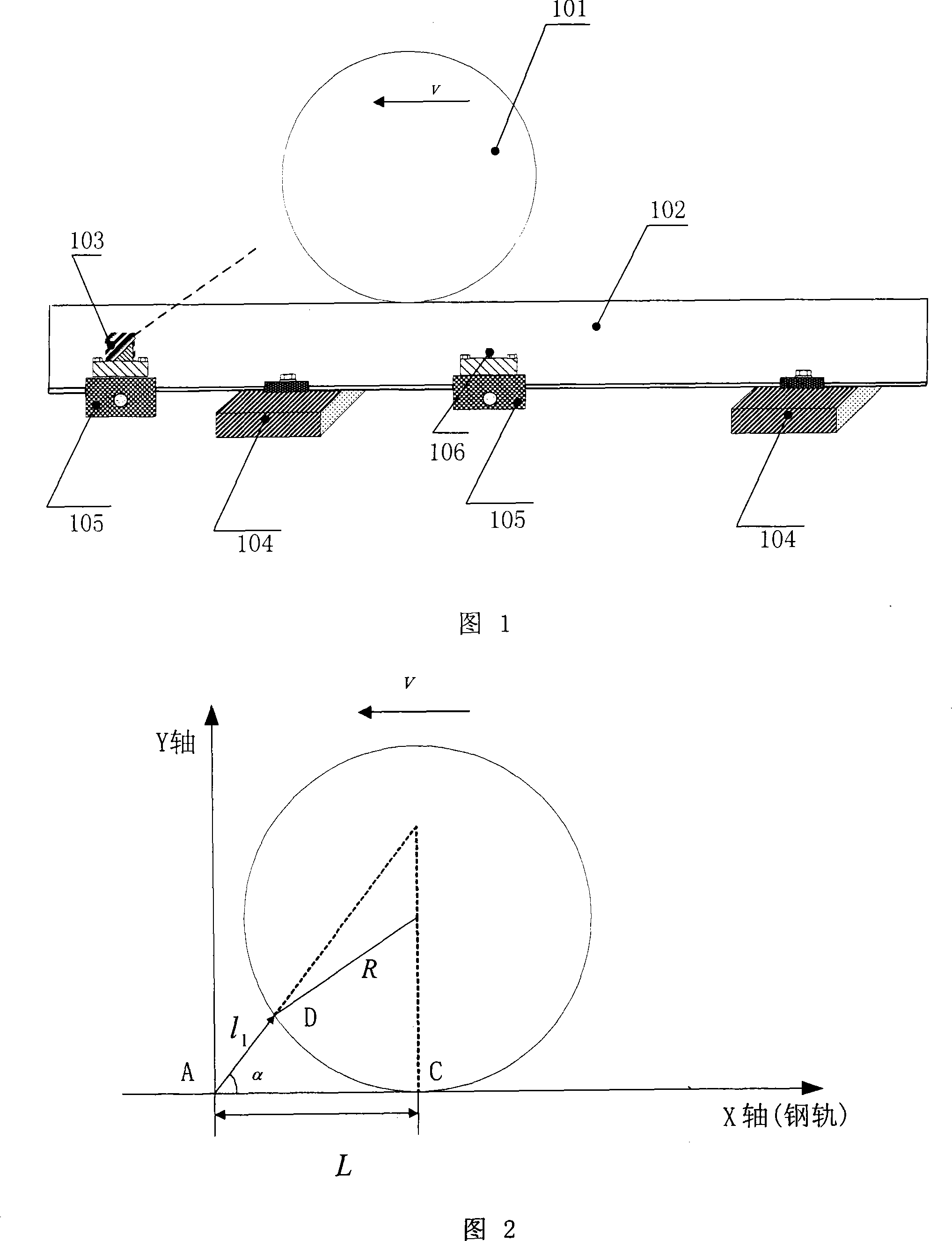

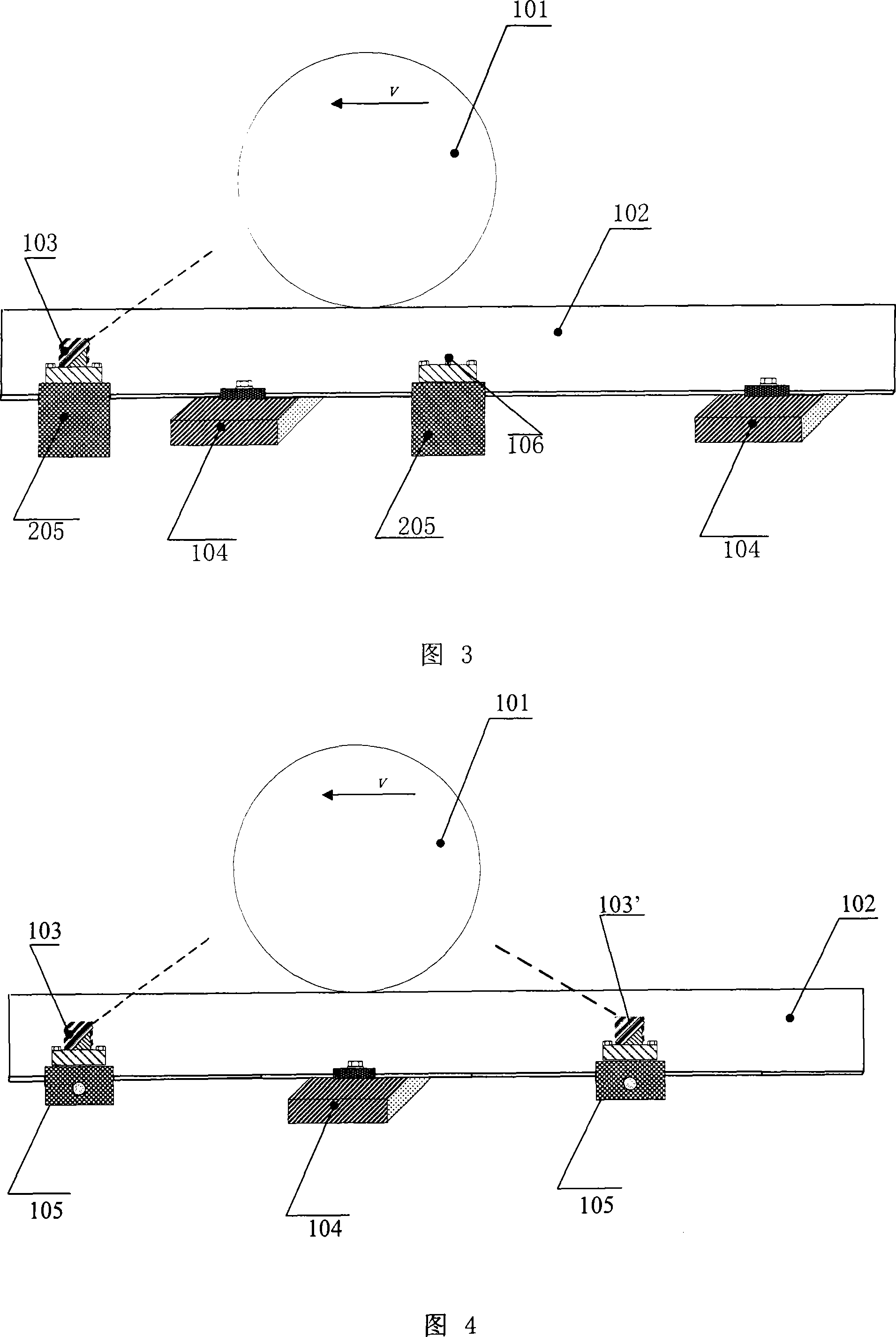

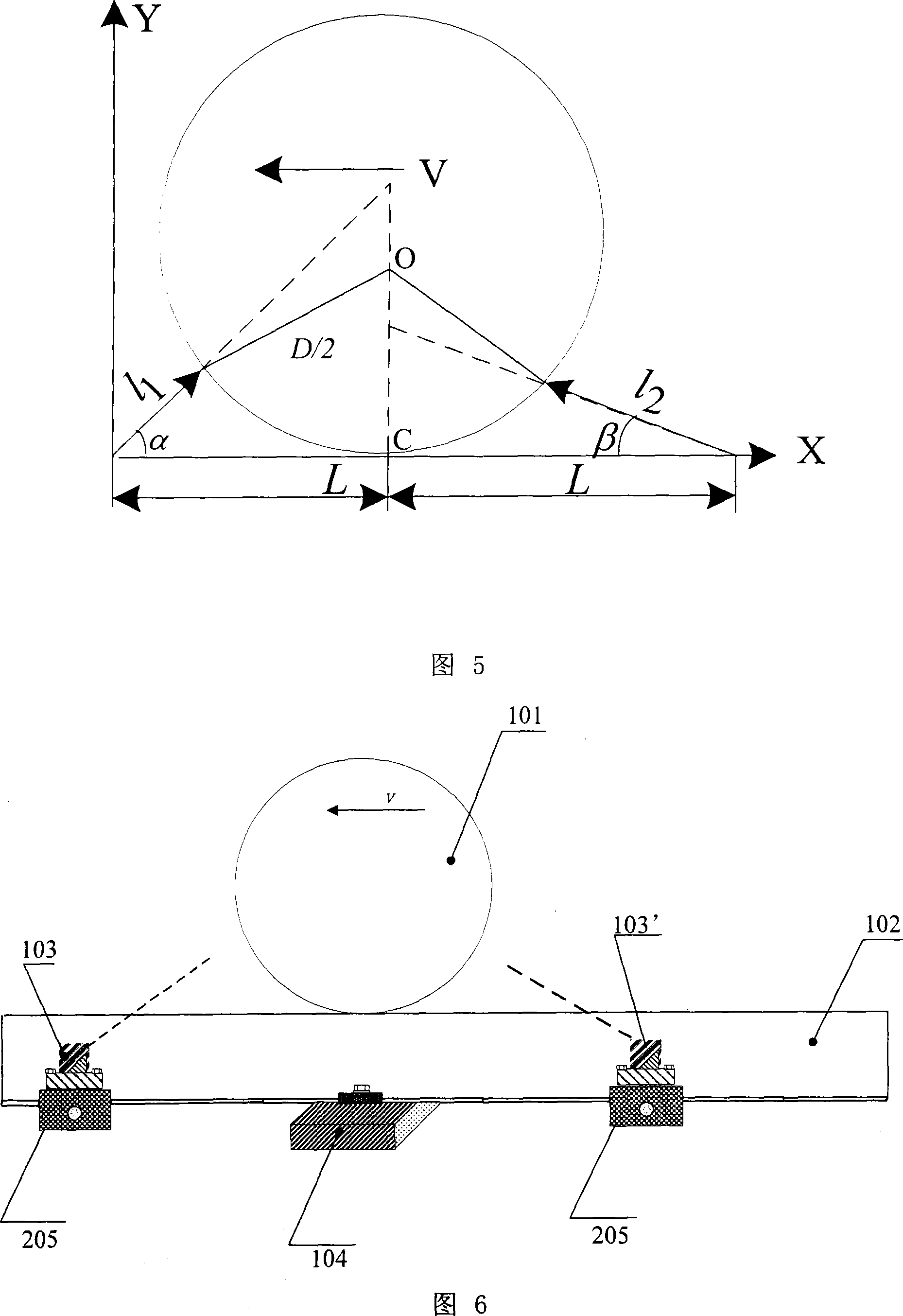

[0050] Fig. 1 shows the first embodiment of the non-contact dynamic measuring device for the wheel diameter. Referring to Fig. 1, this embodiment is a non-contact wheel diameter dynamic measurement device using a single laser displacement sensor, specifically including: a laser displacement sensor 103, a wheel alignment sensor 106 and a central processing unit (not shown). Both the laser displacement sensor 103 and the wheel alignment sensor 106 are fixed on the rail 102 through the block 105 or directly by bonding, and are located on the outside (or inside) of the rail at the same time. A pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com