Nonlinear correction method for piezoelectric ceramic tube scanner

A piezoelectric ceramic tube, nonlinear correction technology, applied in scanning probe technology, instruments, scientific instruments, etc., can solve the problems of scanning pattern distortion, uneven outer wall electrode segmentation, uneven tube wall thickness, etc., to eliminate scanning The effect of image distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

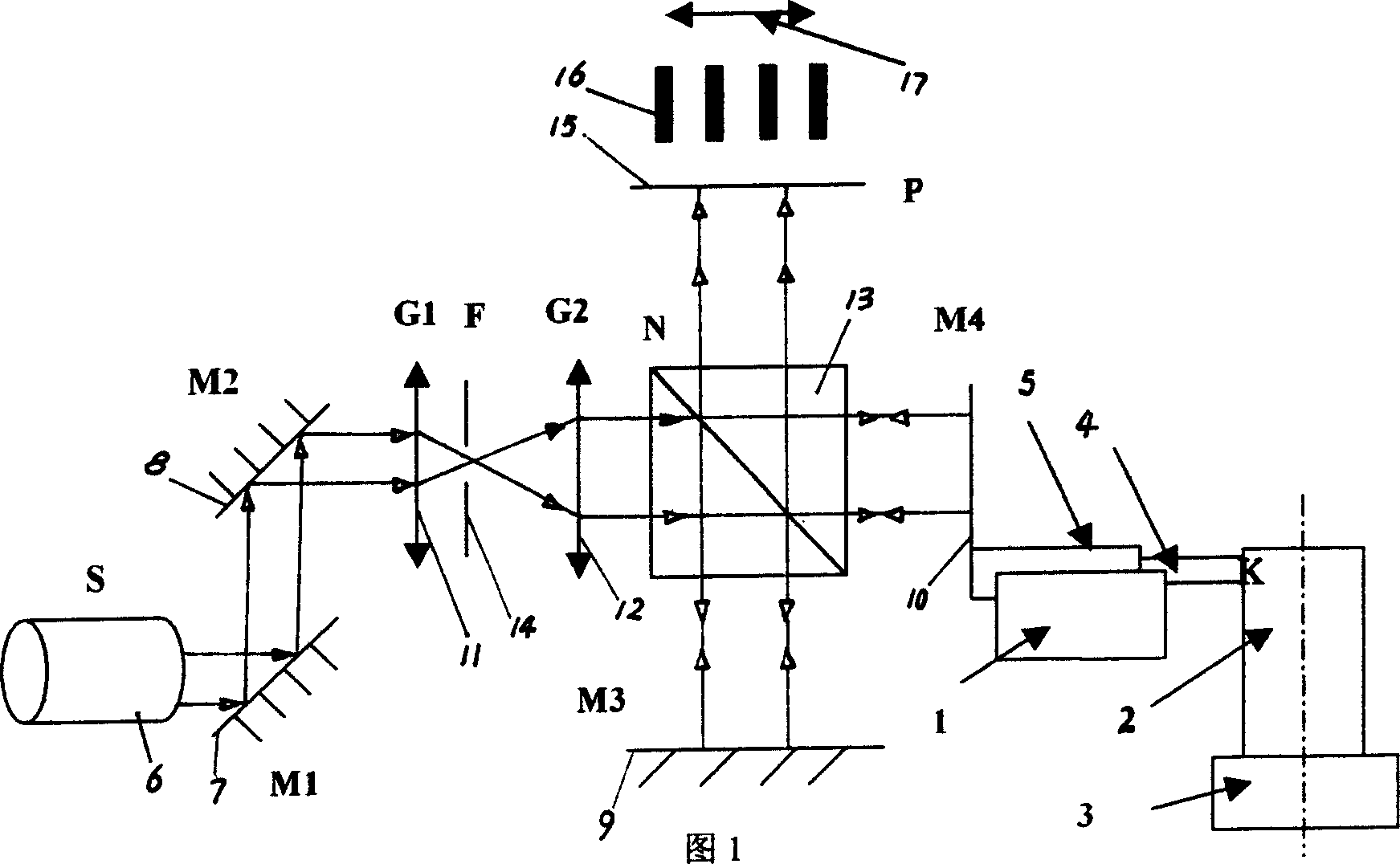

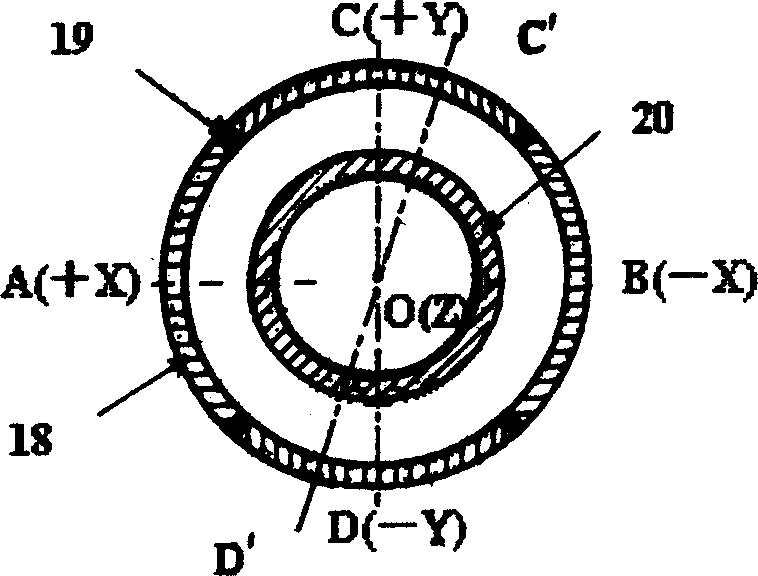

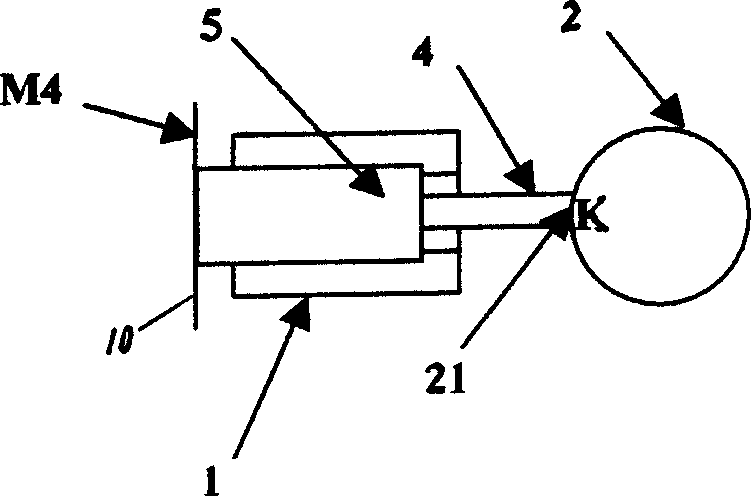

[0032] Figure 1, figure 2 with image 3 As shown, the stretching amount of the piezoelectric ceramic tube scanner of the present invention is measured using a Michelson interference device, wherein the mark 6 is a laser tube S, and the marks 7, 8, 9, and 10 are respectively plane mirrors M1, M2, M3, M4, Marks 11 and 12 are convex lenses G1 and G2 respectively, mark 14 is filter mirror F, mark 13 is beam splitter N, mark 15 is receiving screen P, mark 16 is interference fringes, mark 17 is moving direction of interference fringes, mark 18 is compression The metal coating on the outer wall of the electric ceramic tube, the mark 19 is the insulating layer, the mark 20 is the metal coating on the inner wall of the piezoelectric ceramic tube, the mark 21 is the contact point K, and the sliding table 1, the piezoelectric ceramic tube 2, the rotating table 3 and the connecting rod 4. Among them, the requirements are: the piezoelectric ceramic tube 2 is fixed on the rotary table 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com