On-line high-speed detection system of train wheel set tread and wheel rim and detection method thereof

A detection system and technology for train wheels, which are applied in the direction of rim measurement/measurement, optical test flaws/defects, etc., can solve problems such as the service life of rail facilities affecting the safety of train driving, large detection errors, peeling, etc., to improve computing speed and work. Efficiency, convenient test results, convenient observation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

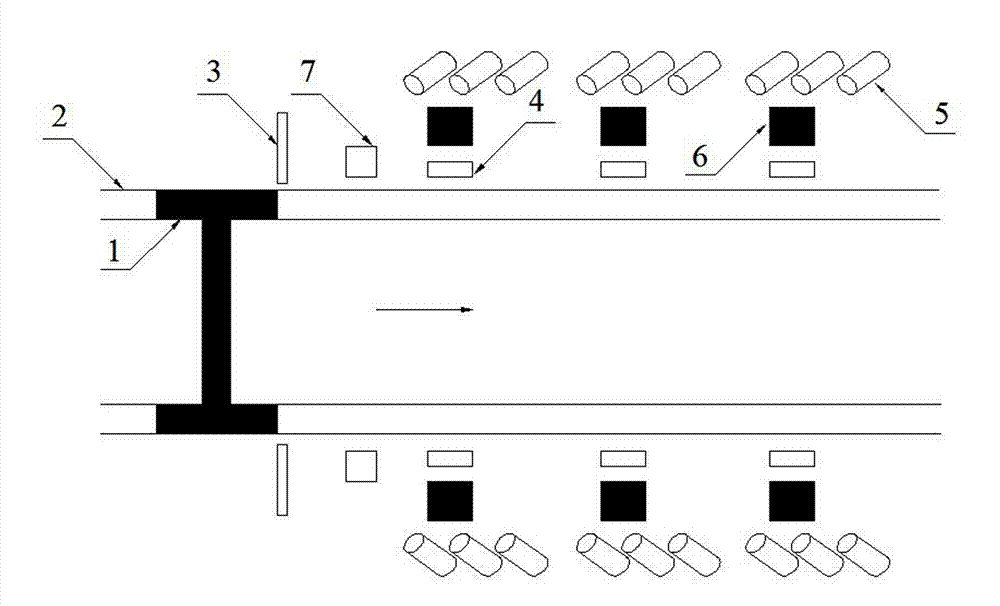

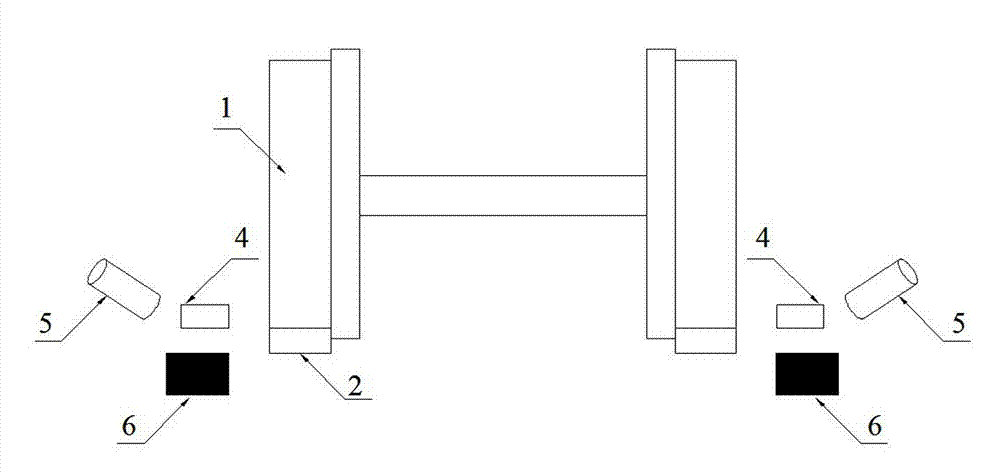

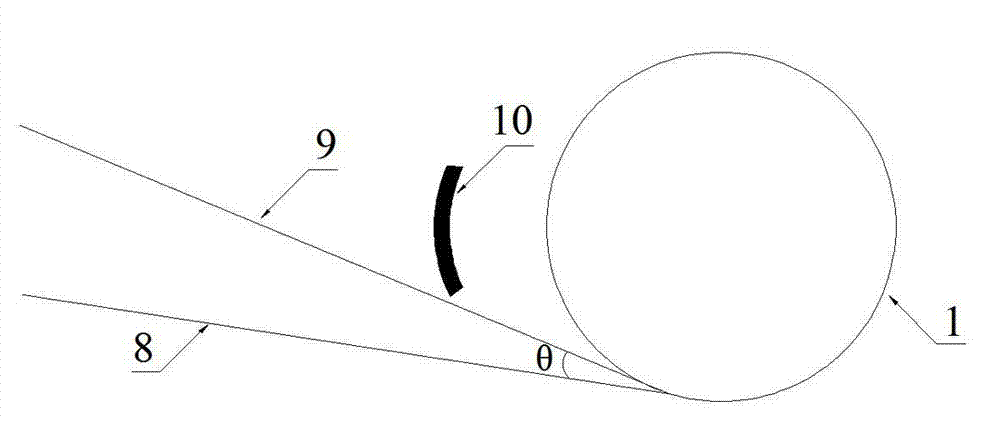

[0038] refer to figure 1 , the online high-speed detection system for train wheelset defects of the present invention includes: a target detection device 3 for detecting whether the train enters the detection area, a speed measuring device 7 for detecting the running speed of the train, and a position for judging whether the train arrives at a designated position Judging device 4, an image acquisition device for obtaining image information of the tread and wheel rim of the train wheel set 1, an image processing device (not shown) for processing the image information obtained by the image acquisition device, and a receiving target detection device 3, a speed measuring device Device 7, a system control device (not shown) that sends information from the position judging device 4 and issues control commands to the image acquisition device. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com