Tool assembly for machining inner spherical surfaces

A combination and inner spherical technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of difficult fine processing, difficult to achieve mass production, low production efficiency, etc., and the position of the center of the ball is easy to determine and adjust Simple, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

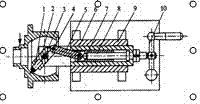

[0013] The support seat (9) is fixed on the middle supporting plate in front of the lathe square tool holder with screws, the center height is adjusted to the center line of the lathe spindle and pinned with a 1:50 taper pin, and the guide rod (6) is fixed on the In the inner hole of the support seat; the tool sleeve (2) passes through the pin shaft I (3) is fixed on the front end of the guide rod (6), the tool holder (2) is connected with the sliding screw sleeve (7) through the connecting rod (5), and the connecting rod and the cutter holder are connected through the pin shaft II (4); the cutter body (1) Fix it in the knife holder (2) with a screw; the screw rod (8) is screwed into the sliding screw sleeve (7); the handle (10) is connected with the end of the screw rod (8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com