Electric curved rail lubricant coating vehicle

A lubricant, electric technology, used in rail lubrication, rail wetting/lubrication, transportation of passenger cars, etc., can solve the problems of lubrication of parts that cannot be rubbed and stressed, increase the waste of lubricating materials, reduce the service life of rails, etc. The effect of service life, improving utilization rate and extending the service life of rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

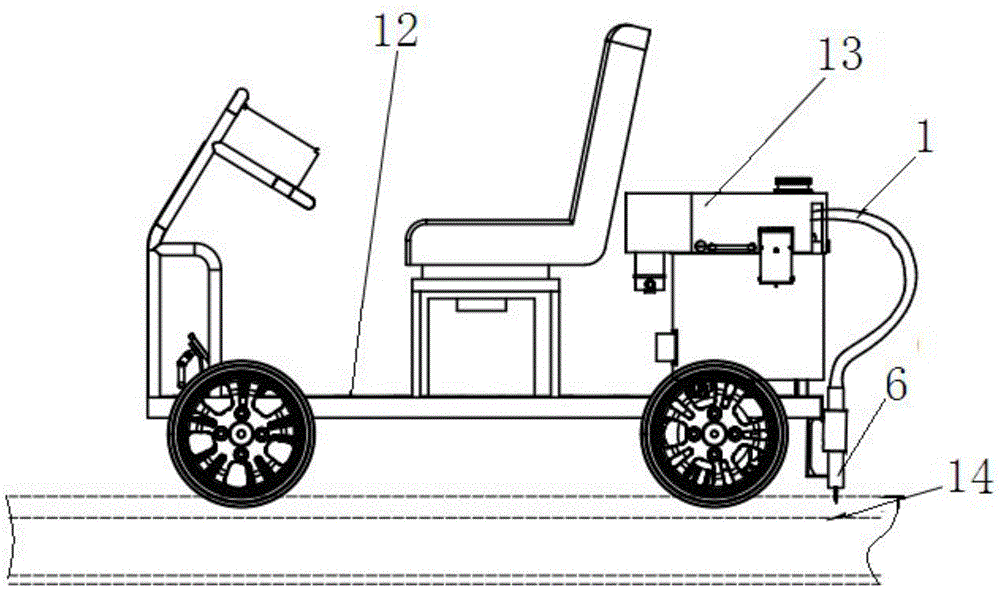

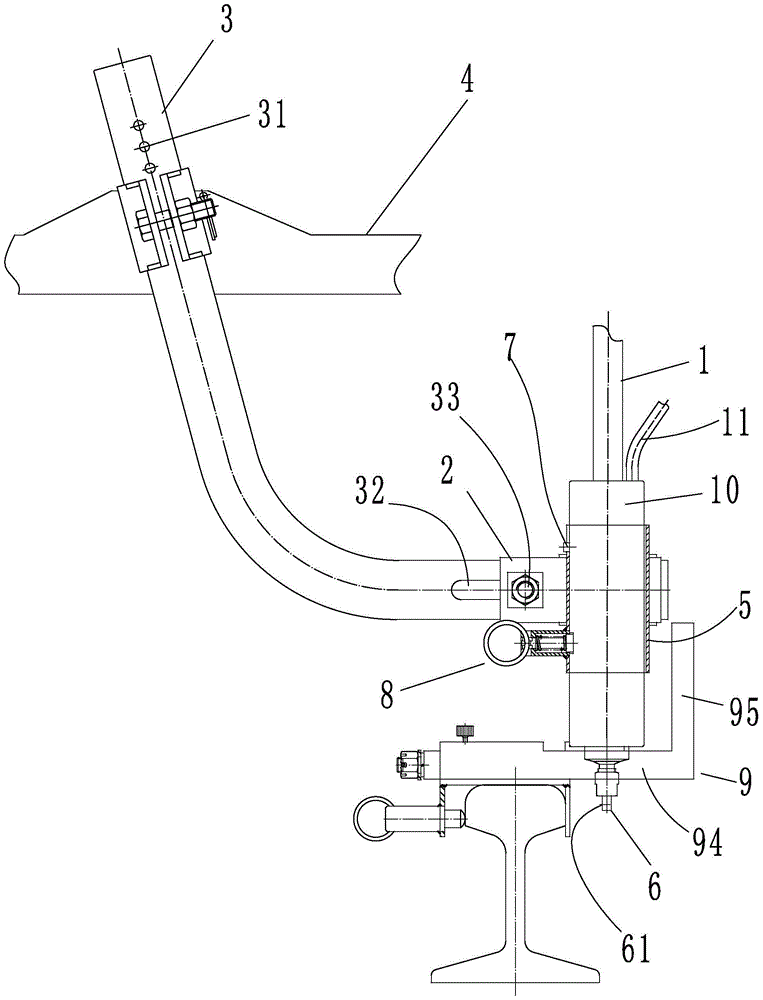

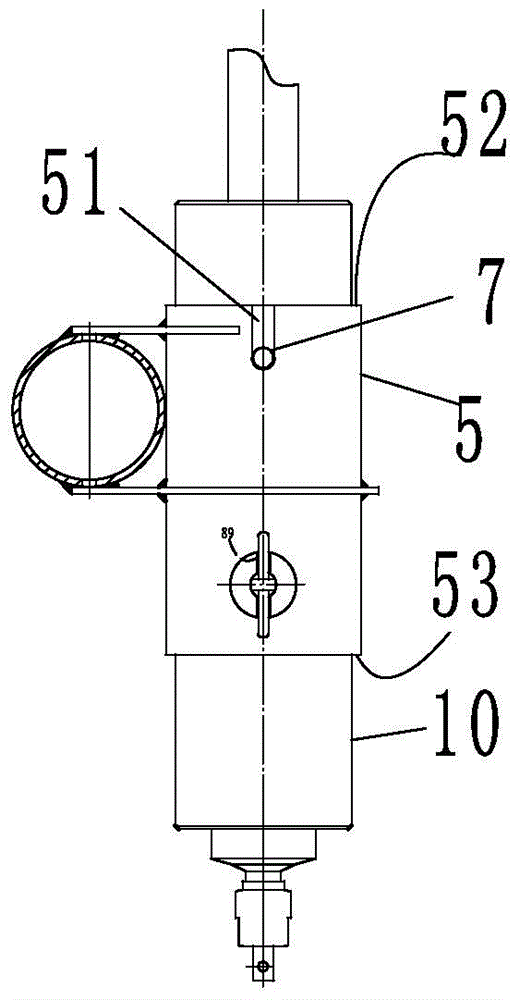

[0031] like Figure 1 to Figure 6As shown, an electric curved rail lubricant coating vehicle is used to coat the corners of the outer strands of the curved rail. The device of the present invention is different from the traditional vehicle-mounted coating device, which is placed at the tail of the train to move with the train. The way of coating the steel rail can run on the steel rail alone to coat the steel rail, which improves the coating effect and effectively prolongs the service life of the steel rail. Described electric curve rail lubricant coating car comprises rail car 12, is provided with coating device 13 above the rear portion of rail car 12, and described coating device comprises control structure, lubricant container, lubricating oil pump, and control structure controls T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com