Middle plate tooth joint machine

A technology of plate teeth and tooth joining, applied in the field of wood processing equipment, can solve the problems of uneven wood board, low splicing efficiency, unstable wood board quality, etc., and achieve the effect of reducing workload, convenient gluing, and improving efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

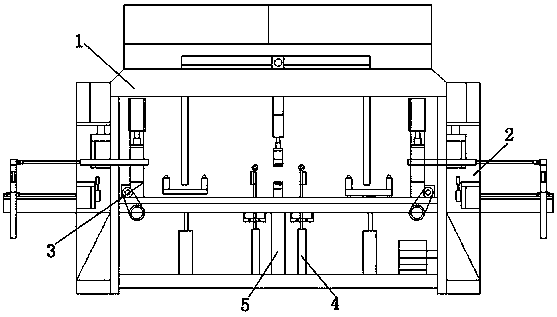

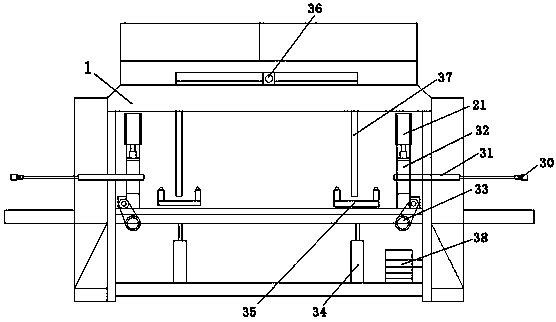

[0023] Such as Figure 1 to Figure 5 As shown, the middle plate gear jointing machine of this embodiment includes a main frame 1, a gear cutting machine 2, a transmission device 3, a gluing device 4 and a gear joint device 5, and is characterized in that: the two sides of the main frame 1 A tooth cutting machine 2 is provided, and a tooth connection device 5 is arranged in the middle. A gluing device 4 is provided between the tooth cutting machine 2 and the tooth connection device 5 , and the transmission device 3 is installed on the main frame 1 .

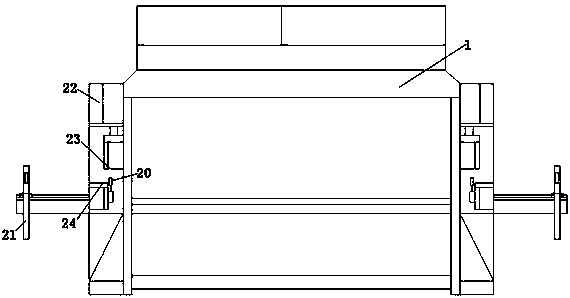

[0024] Such as figure 2 As shown, the tooth cutting machine 2 is composed of a tooth cutting clamping device and a tooth cutting device, the tooth cutting clamping device is composed of a clamping cylinder 21, and the tooth cutting device is composed of a positioning cylinder 20, an oil cylinder 22 , The upper tooth cutter 23 and the lower tooth cutter 24 constitute, the described positioning cylinder 20 is arranged on the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com