Battery pole gluing method and battery pole gluing mechanism

A battery and pole technology, which is applied in the field of battery pole gluing method and battery pole gluing mechanism, can solve the problems of low efficiency and poor gluing effect, achieve convenient and reliable positioning, high gluing efficiency, and improve gluing efficiency. sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0039] Embodiment two, the difference with embodiment one is:

[0040] see Image 6 , one of the two gripping fingers 17 located in front of the conveying direction of the conveyor belt extends beyond the other gripping finger 25 in the direction away from the gripping block. conveyor belt in Image 6 The conveying direction in the Image 6 in the A direction. The clamping finger driving cylinder is a double-stroke cylinder. When the clamp finger drives the cylinder to extend a stroke, the clamp finger located in front of the conveying direction of the conveyor belt blocks the battery 1 on the conveyor belt from moving forward.

[0041] The process of positioning the battery in this embodiment is as follows: in the initial state, the clamping block driving cylinder is in a state of outputting one stroke, and when the battery is in contact with the clamping fingers 24 located in front of the conveyor belt in the conveying direction, the clamping block driving cylinder Exte...

Embodiment 3

[0042] The third embodiment is that the following changes have been made on the basis of the first embodiment and the second embodiment:

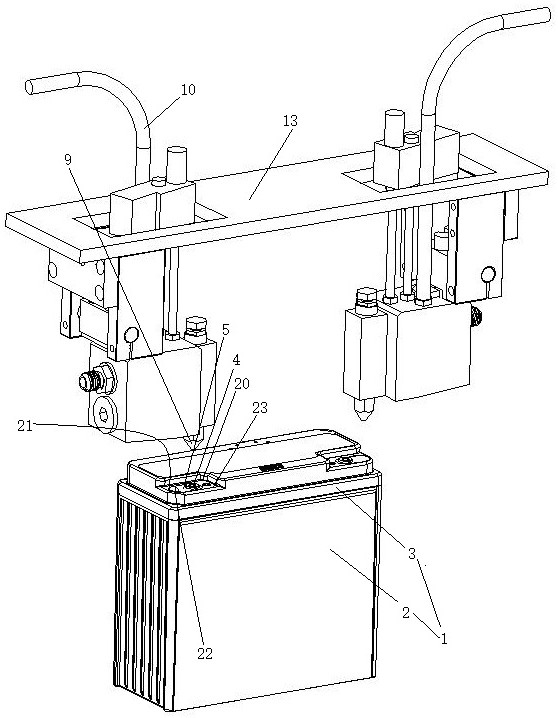

[0043] see Figure 7 , Figure 8 and Figure 9 , The frame is equipped with a flat glue mechanism for leveling the glue in the two pole glue grooves one by one. The gluing mechanism is located between the leveling gluing mechanism and the heating mechanism.

[0044] The leveling glue mechanism includes a horizontal chute 41 , a vertical pipe 26 , a cover plate translation mechanism 27 and a cover plate vertical movement mechanism 28 .

[0045] One end of the horizontal chute is provided with a cover plate outlet hole 29 . Two supporting pieces 30 which are opened downward are hinged on the lower side of the outlet hole of the cover plate. The opening area of the outlet hole of the cover plate is equal to the area of the flat cover plate 31 . The flat cover plate can just pass through the pole glue groove 5 to cover the pole glue g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com