Equipment and method for coating surfaces of clothing or ornaments with three-dimensional patterns

A technology for decorative objects and equipment, which is applied to the device for coating liquid on the surface, special surface, pre-treated surface, etc. It can solve the problems of difficult realization, complicated process, and inability to coat three-dimensional patterns, etc., and achieves convenient operation and high bonding strength. High, three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

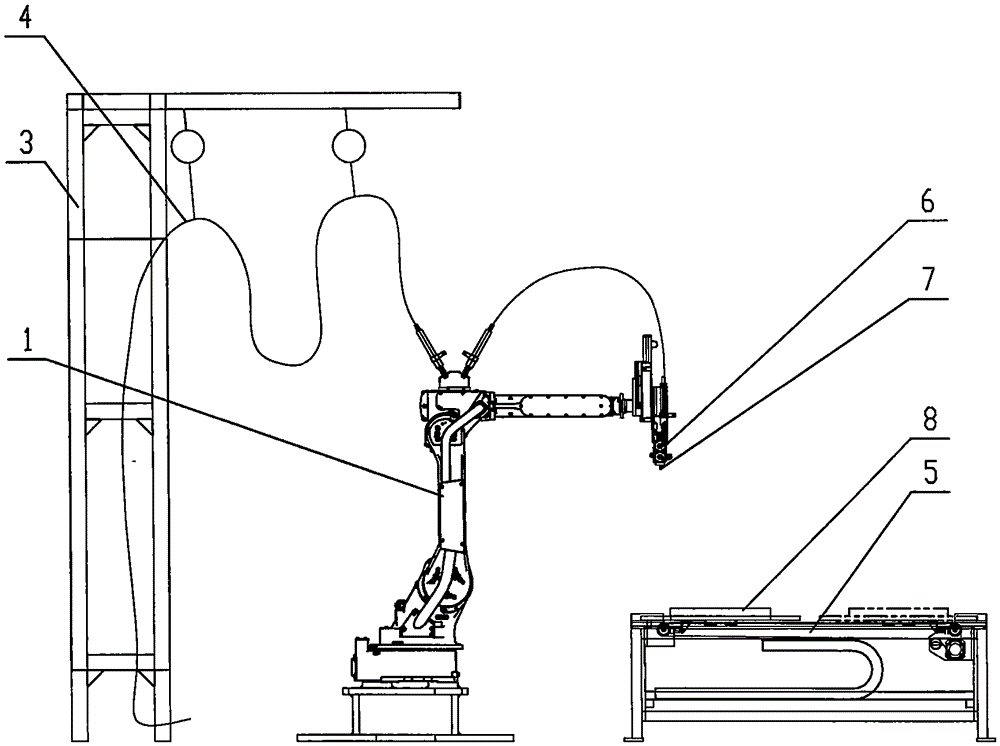

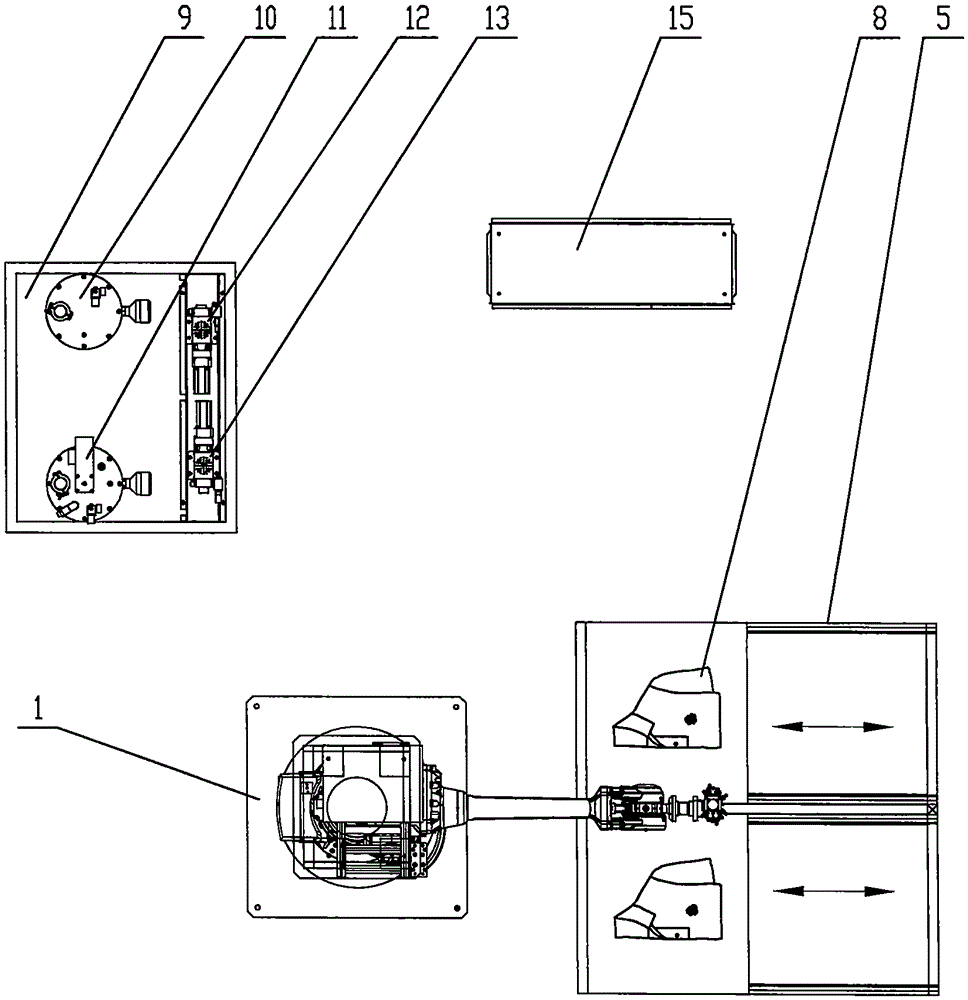

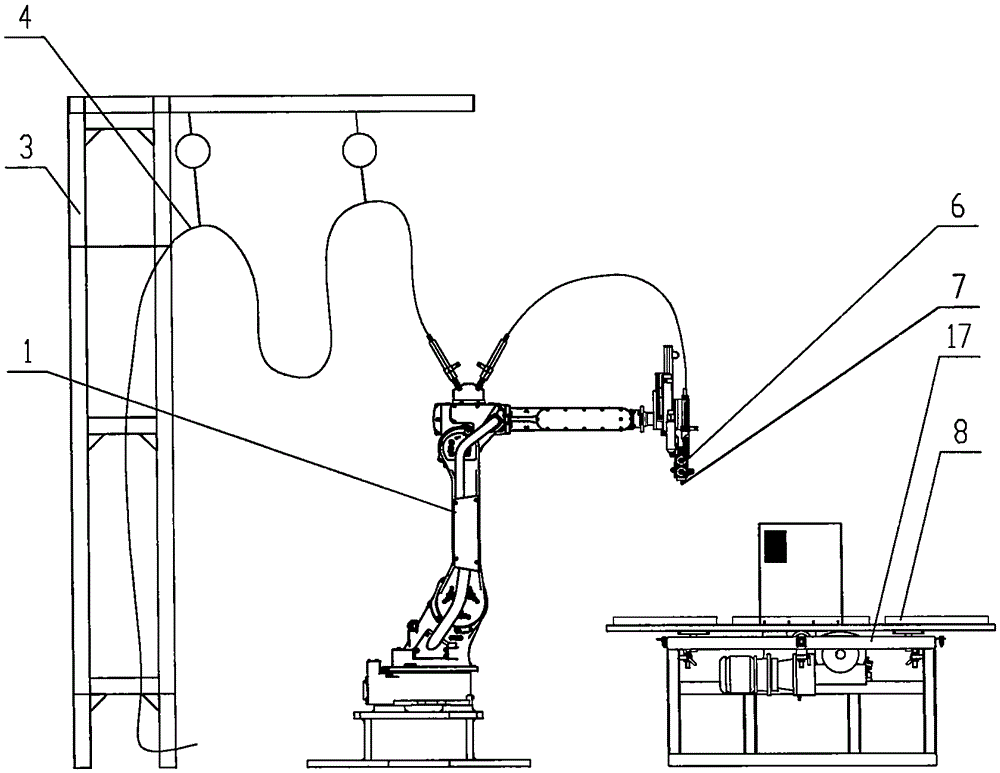

[0031] Specific implementation mode one: as Figure 1-9 As shown, the equipment for coating three-dimensional patterns on the surface of clothing or decorations includes three-axis gluing equipment 16 or robot gluing equipment 1, double-station workbench 5 or multi-station rotary workbench 17, gluing head 6 and supply The gluing device 9, the gluing head 6 is fixed on the three-axis gluing equipment 16 or the robot gluing equipment 1, the gluing head 6 communicates with the glue supplying device 9 through the glue pipeline 4, the A glue and the B glue in the glue supplying device 9 After the glue is metered and supplied, glue A and glue B are mixed in the glue head 6, the nozzle 7 of the glue head 6 moves along the track of the pattern or cartoon or the trademark 2, and the mixed two-component polyurethane flows from the nozzle 7 It flows out from inside, and evenly, quickly and efficiently coats the surface of the workpiece 8, and then puts it into a heating oven or a heating...

specific Embodiment approach 2

[0032] Specific implementation mode two: as Figure 1-9 As shown, the equipment for coating three-dimensional patterns on the surface of clothing or decorations, the structure of the three-axis gluing equipment 16 is a gantry or cantilever linear robot. The figure shows an example of a cantilever linear robot. The main motion transmission of the equipment is The components adopt linear guide rail, linear bearing, ball screw, rack and pinion or gear or toothed belt, reducer, servo motor or stepping motor, and the reducer, servo motor or stepping motor drives the three-axis movement of X, Y and Z ; The workpiece 8 is placed on the double-station workbench 5 or the multi-station rotary workbench 17 and is fixed for gluing. The gluing head 6 is fixed on the Z axis, and the three-axis gluing equipment 16 has an automatic control function to realize automatic gluing. The equipment has simple structure, low cost and wide applicability. Other components and connections are the same a...

specific Embodiment approach 3

[0033] Specific implementation mode three: as Figure 1-9 As shown, in the equipment for coating three-dimensional patterns on the surface of clothing or decorations, the robot gluing equipment 1 is a six-joint robot, and the glue pipeline 4 is hoisted on the bracket 3 by springs, which can reduce the load of the robot gluing equipment 1; , the workpiece 8 is placed on the double-station workbench 5 or the multi-station rotary workbench 17 and is fixed. The robot gluing equipment 1 has an automatic control function to realize automatic gluing. The equipment structure is complicated, the cost is high, and the applicability is wider. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com