Inner lining paper gluing and bonding mechanism of paper box machine

A technology of lining paper and glue bonding, which is applied to paper/cardboard containers, papermaking, container manufacturing machinery, etc., can solve the problems of low production efficiency, affecting the bonding of lining paper and the bottom of the carton, and high labor costs. The effect of stable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

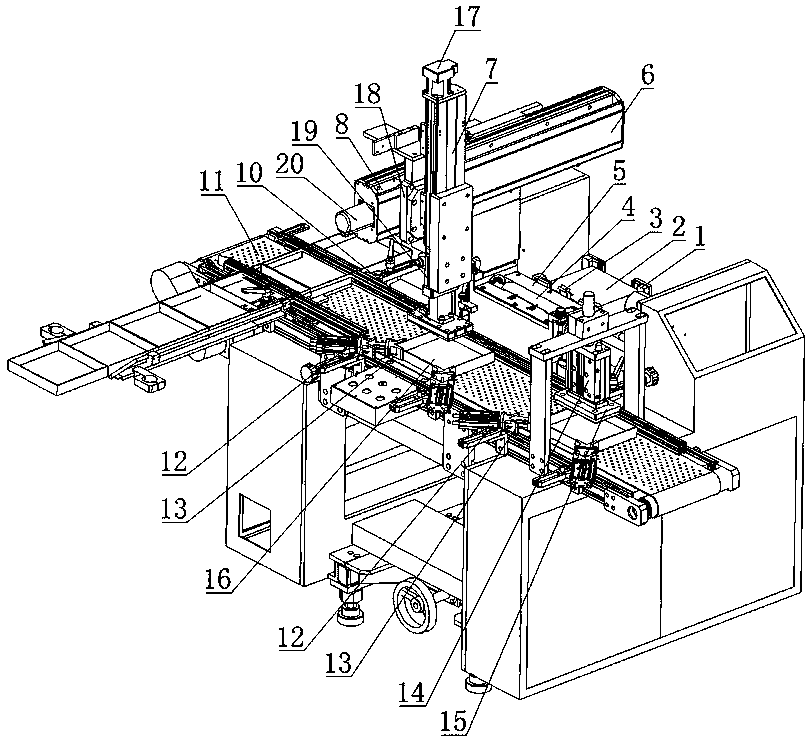

[0013] As shown in the figure, the inner lining paper gluing mechanism of the paper box machine disclosed by the present invention includes a paper storage rack 1 and a paper suction board 10. Paper suction holes are arranged at the bottom of the paper suction board 10, and the paper storage rack 1 is used for inner lining. Centralized stacking of backing paper 2, there is a sensor 3 on the paper storage rack, which is used to sense the inner lining paper 2 in the paper storage rack 1, when the sensor 3 senses that the amount of inner lining paper in the paper storage rack 1 is too small , an alarm will be sent to remind you to add paper, so as to ensure the normal operation of the equipment. One side of the paper storage rack 1 is provided with a glue storage box 5 and a conveyor belt 11 in turn. The glue storage box 5 is provided with a rubber roller 4 higher than the glue storage box 5. With the rotation of the glue roller 4, the glue storage The glue in the box 5 will adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com