Patents

Literature

30results about How to "Quick dash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

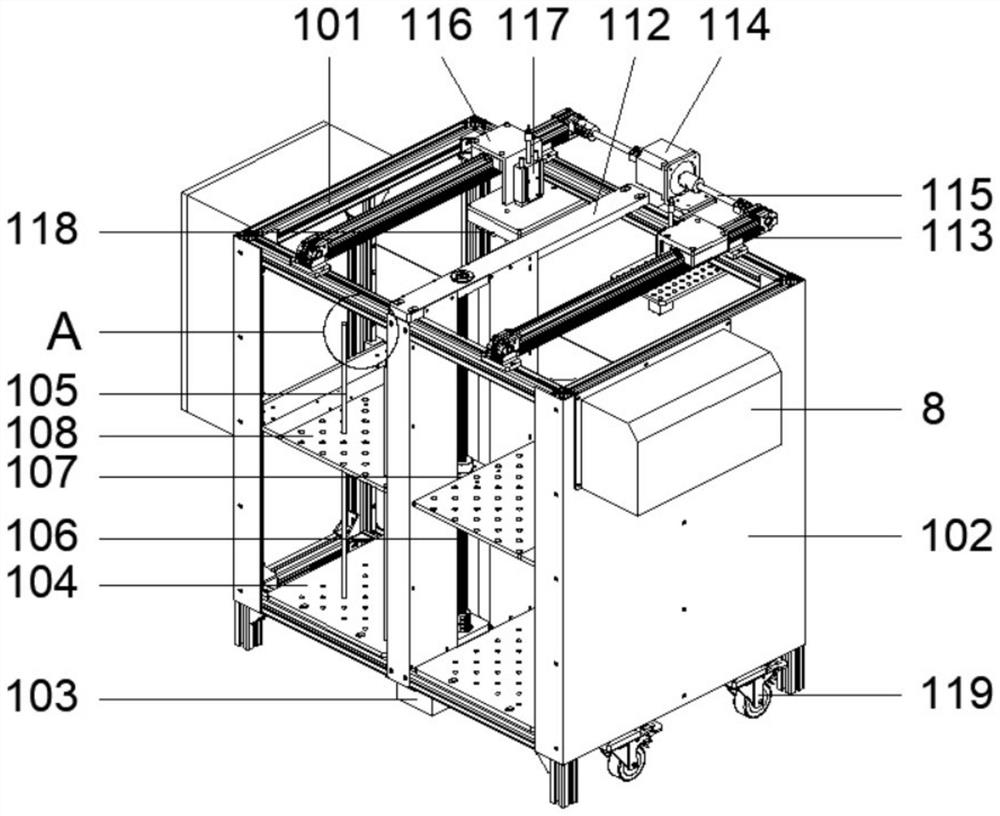

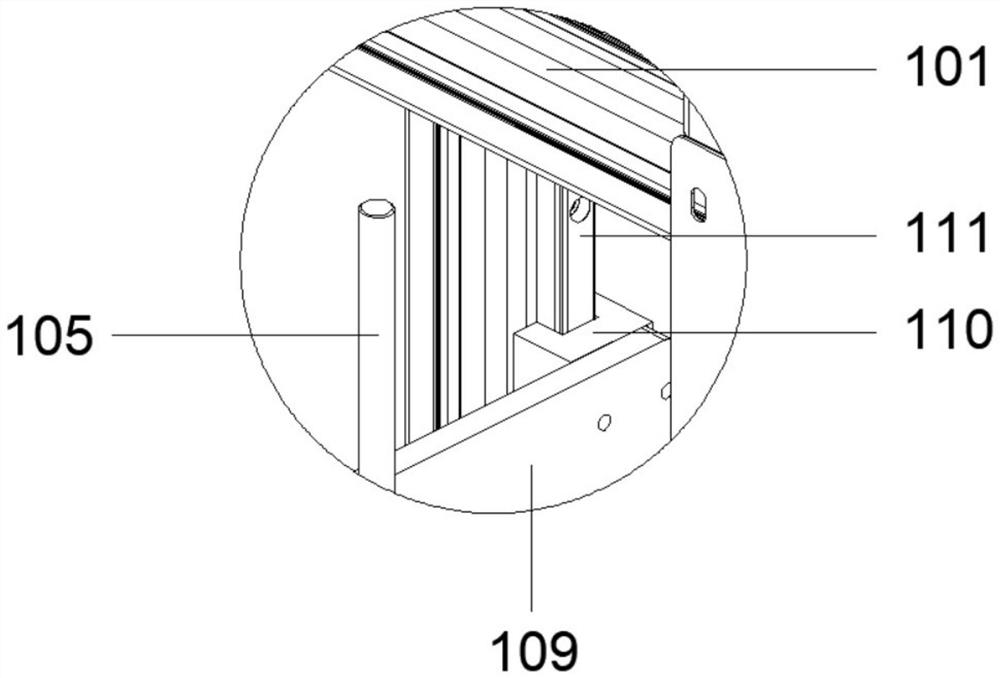

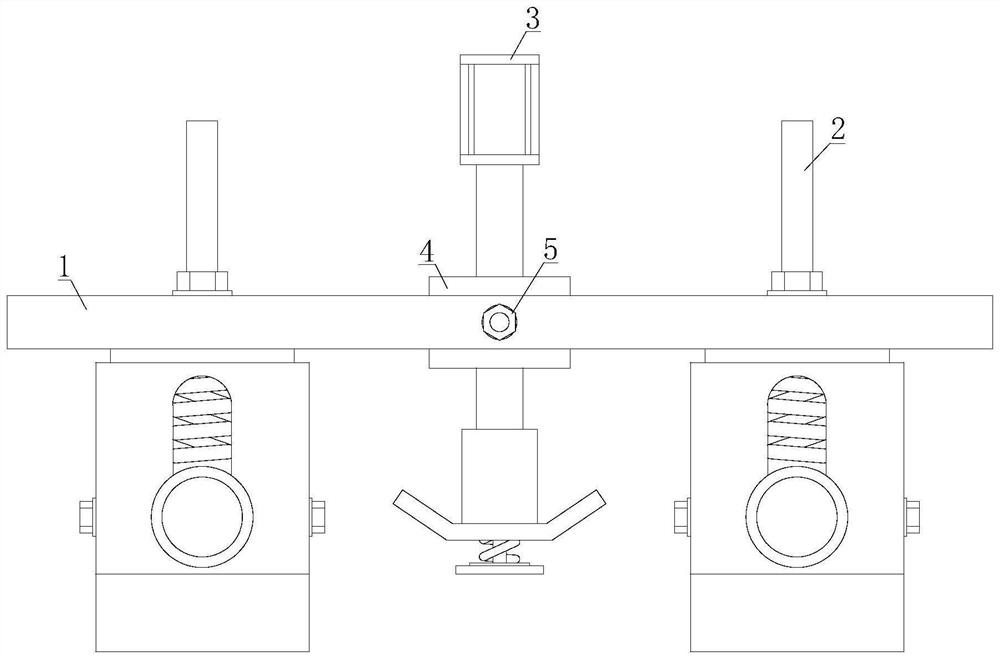

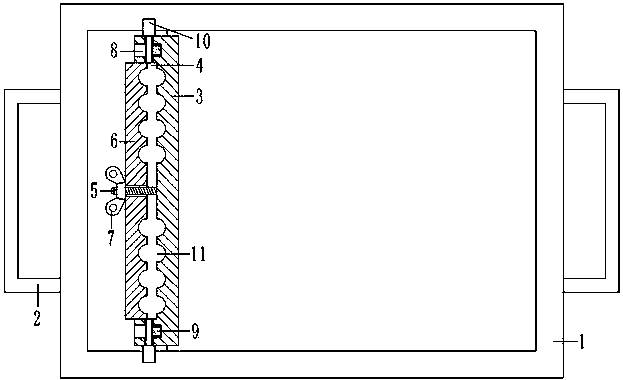

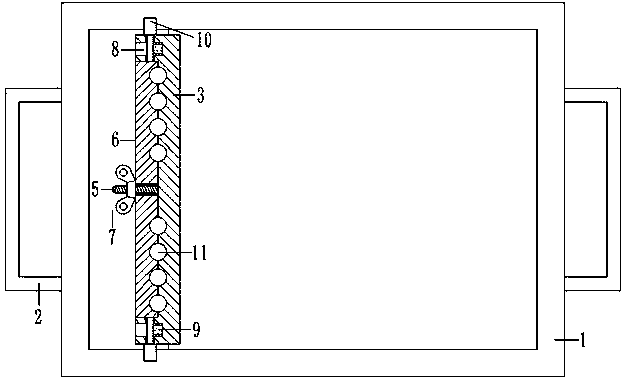

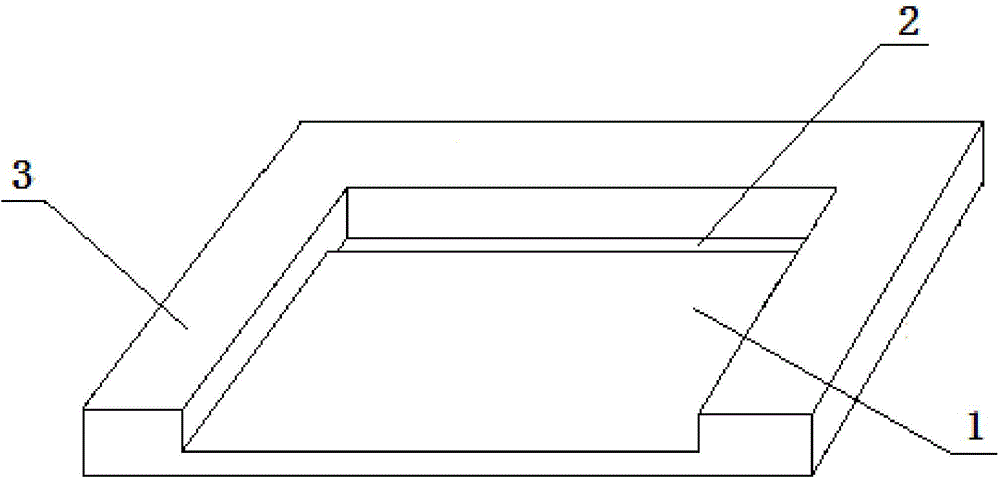

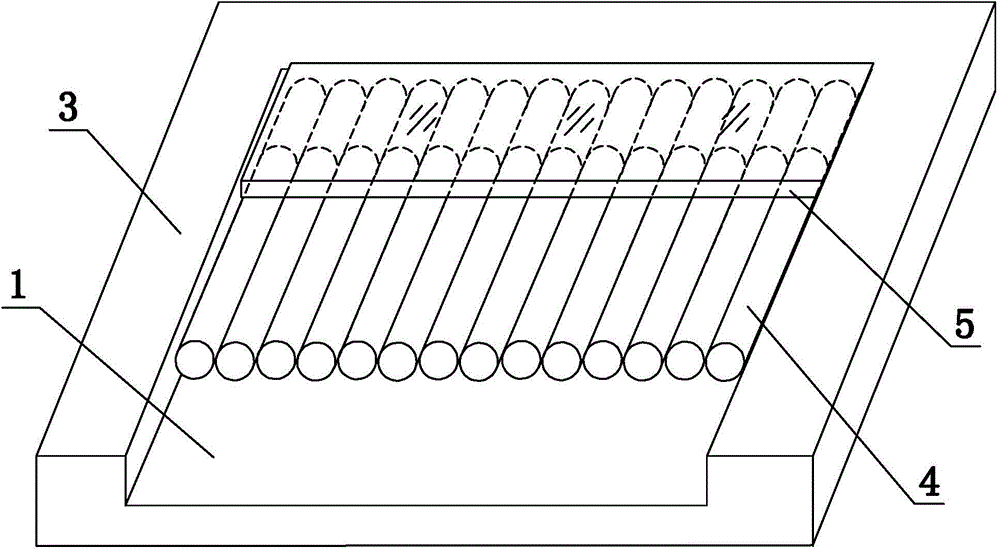

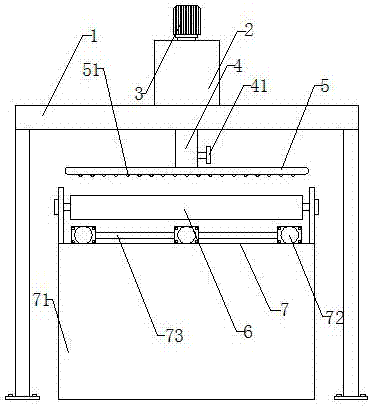

Layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials

ActiveCN104708689AFast processingSpread evenlyOther plywood/veneer working apparatusAdhesive application devicesProduction lineEngineering

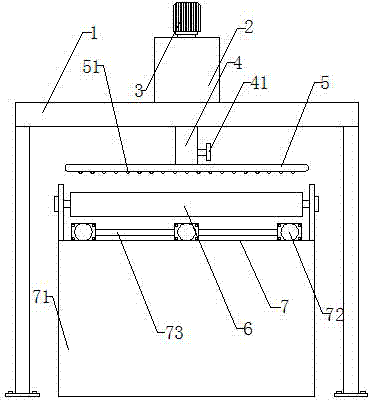

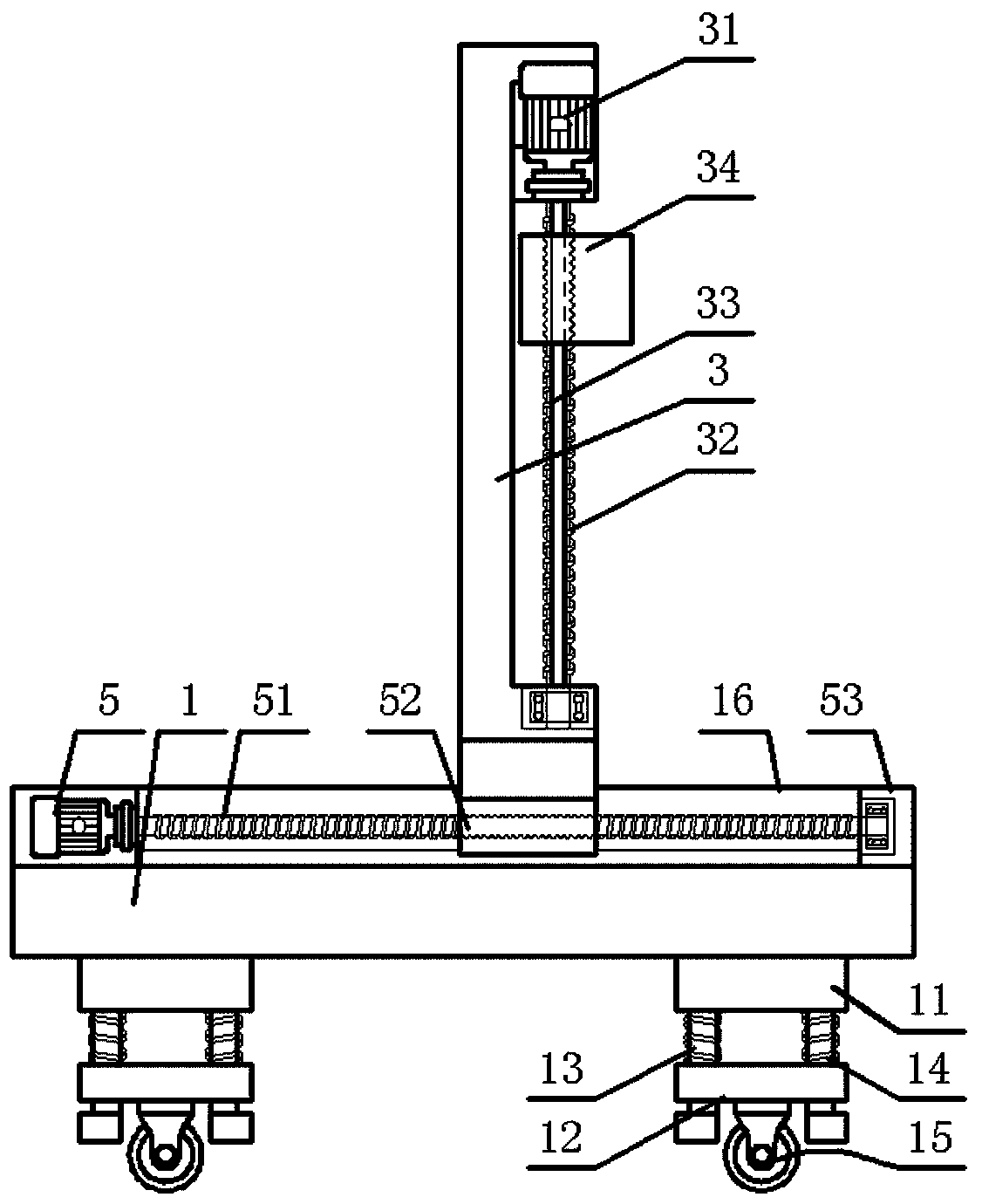

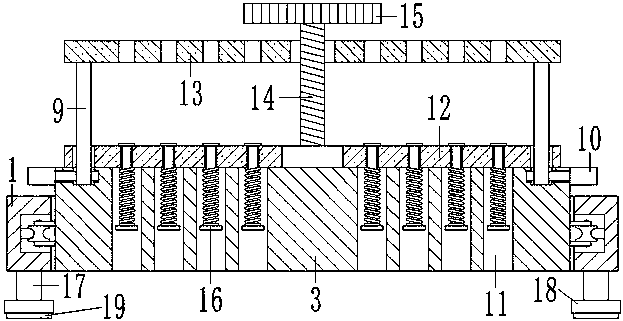

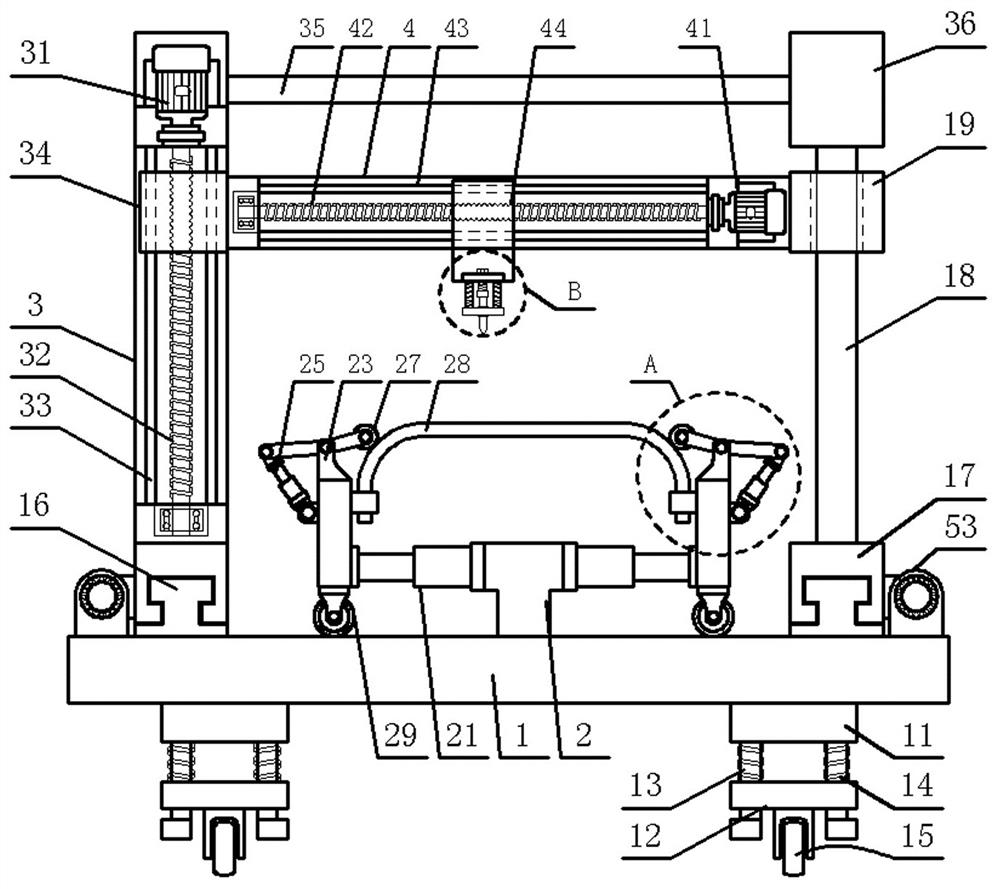

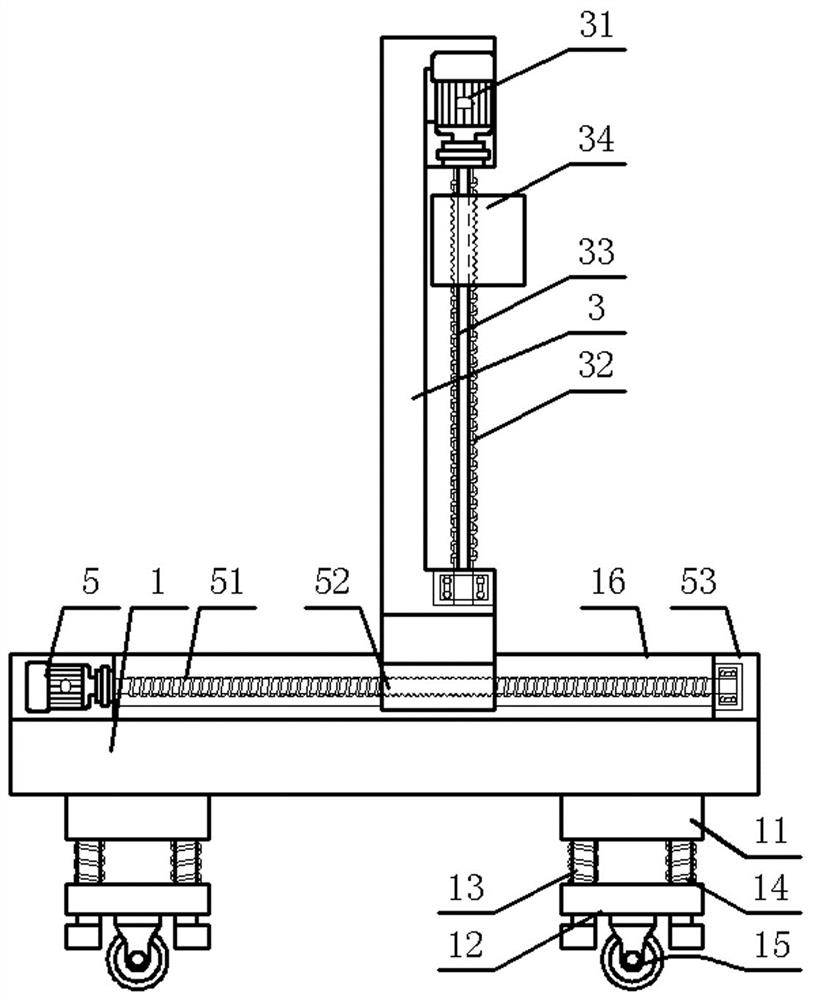

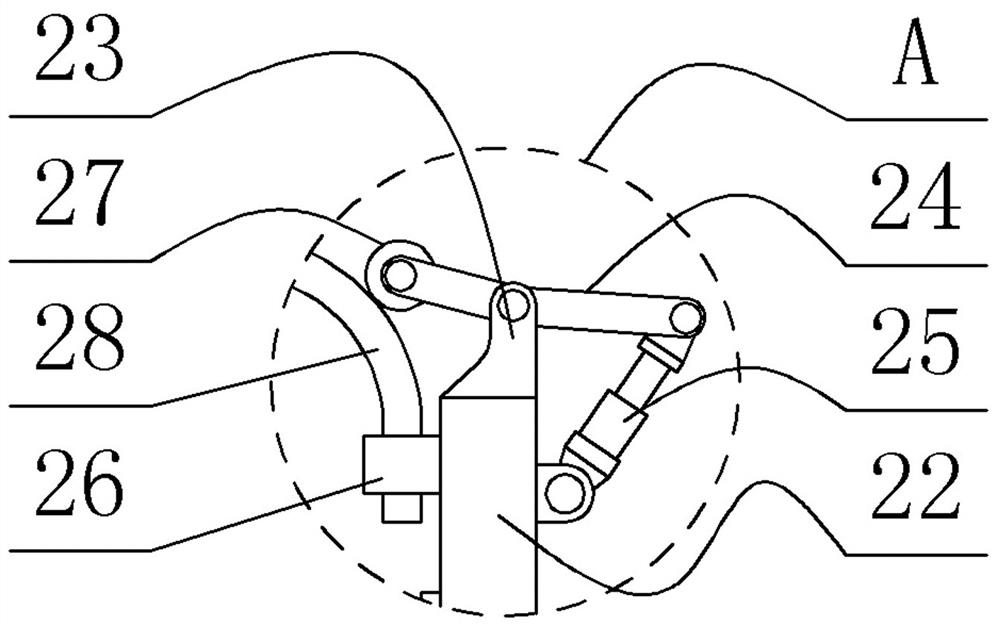

The invention discloses layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials. The layer-by-layer automatic feeding, marking and gluing integrated equipment for the sheet materials comprises a marking device and a gluing device; the gluing device is arranged on one side of the marking device and a layer-by-layer automatic feeding device is arranged on the other side of the marking device; the layer-by-layer automatic feeding device comprises a pushing mechanism, a hoisting mechanism and a sliding mechanism in sequence; and the gluing device comprises a supporting framework, a stirring mechanism arranged at the upper end of the supporting framework, a material scattering mechanism arranged at the bottom of a transverse beam of the supporting framework, and a compression roller gluing mechanism arranged under the supporting framework. According to the layer-by-layer automatic feeding, marking and gluing integrated equipment, marking and gluing are integrated, transmission and interruption of machines are reduced in the process and the consistency of a production line is improved; and the machining time of the whole sheet material is shortened, materials can be automatically fed layer by layer, the transmission is buffered, the gluing can be automatically realized and the gluing is uniform.

Owner:JIANGSU KENTIER WOOD

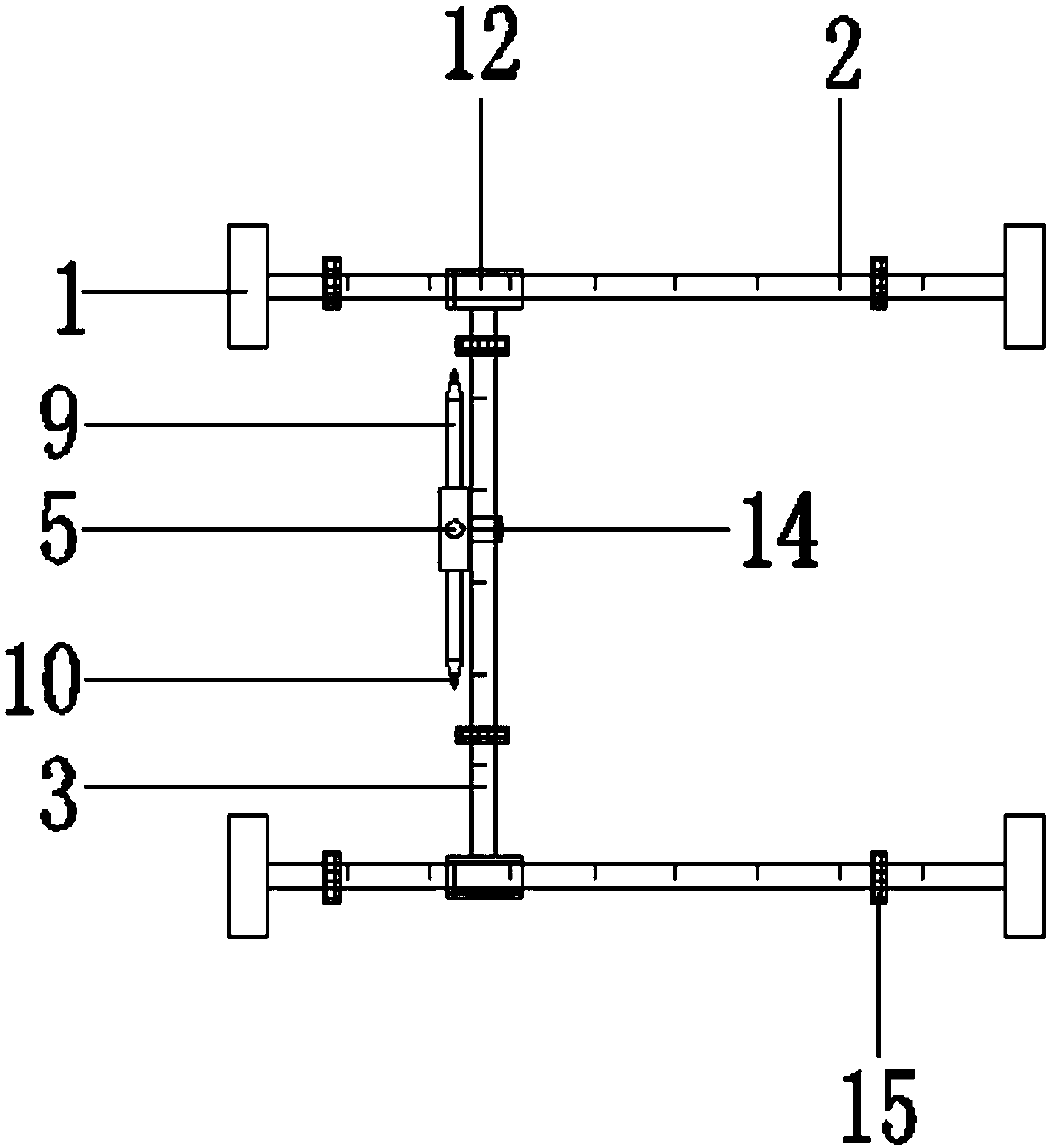

Round pipe end surface lineation machine

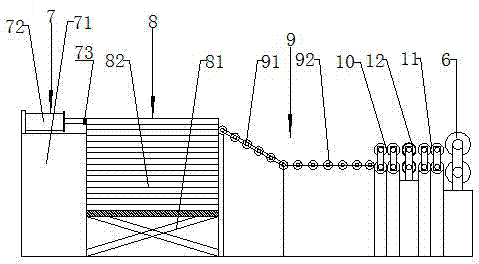

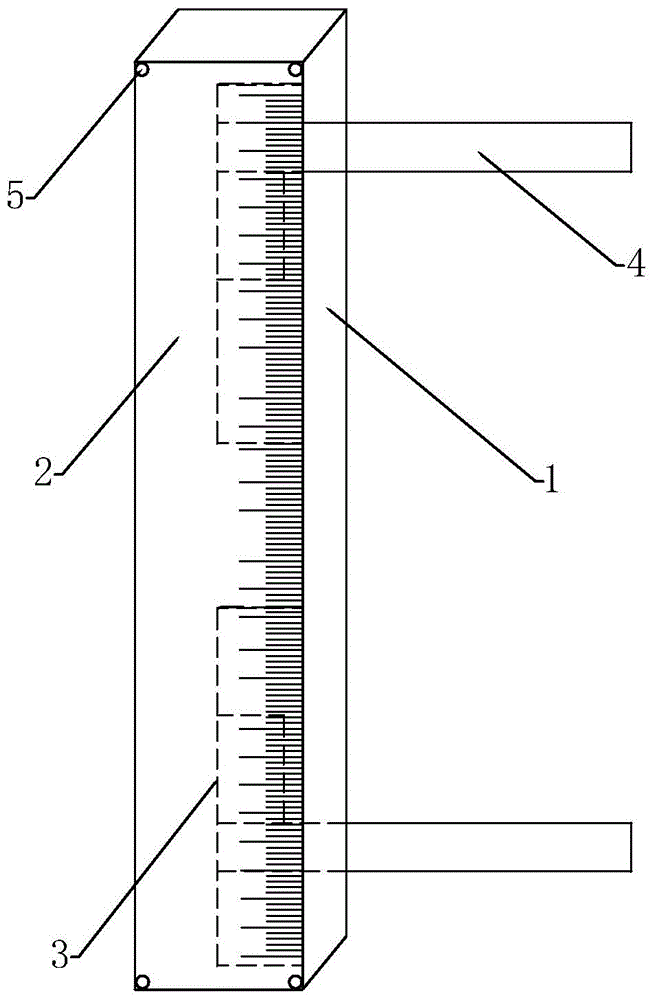

The invention discloses a round pipe end surface lineation machine. The round pipe end surface lineation machine consists of a turning plate, a main ruler, a secondary ruler, a lineation needle and a fastening screw; when a center line is drawn, the inner side of the turning plate is tangential to the side surface of a cylinder or a round pipe; the main ruler is tightly bonded on the end surface of the cylinder or the round pipe; and as the axis of the lineation needle mounted on the secondary ruler is intersected with the angle line of the turning plate, the secondary ruler can be pushed to draw the center line on the end surface of the cylinder or the round pipe. When a concentric circle is drawn, the inner side of the turning plate is tangential to the side surface of the cylinder or the round pipe; the main ruler is tightly bonded on the end surface of the cylinder or the round pipe; the diameter of an outer circle is measured by the main ruler and the secondary ruler; the secondary ruler is shifted according to the radius of the drawn circle to enable the lineation needle to locate in the position of the circle to be drawn; the fastening screw is tightened to relatively fix the secondary ruler with the main ruler; the lineation needle rotates to enable the needle tip to contact with the end surface of the cylinder or the round pipe; and the lineation machine and the cylinder or the round pipe relatively rotate to draw the requested circle on the end surface. The round pipe end surface lineation machine can used for conveniently, quickly and precisely drawing the center line and the concentric circle on the end surface of the cylinder or the round pipe.

Owner:CHINA MCC 2 GRP CO LTD

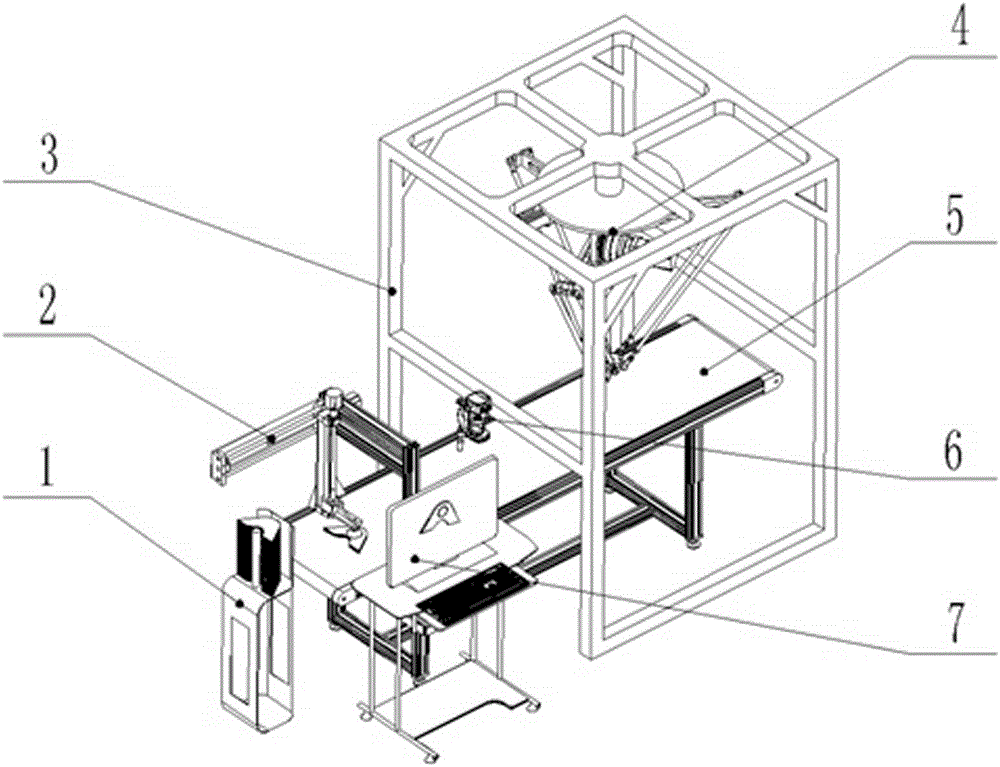

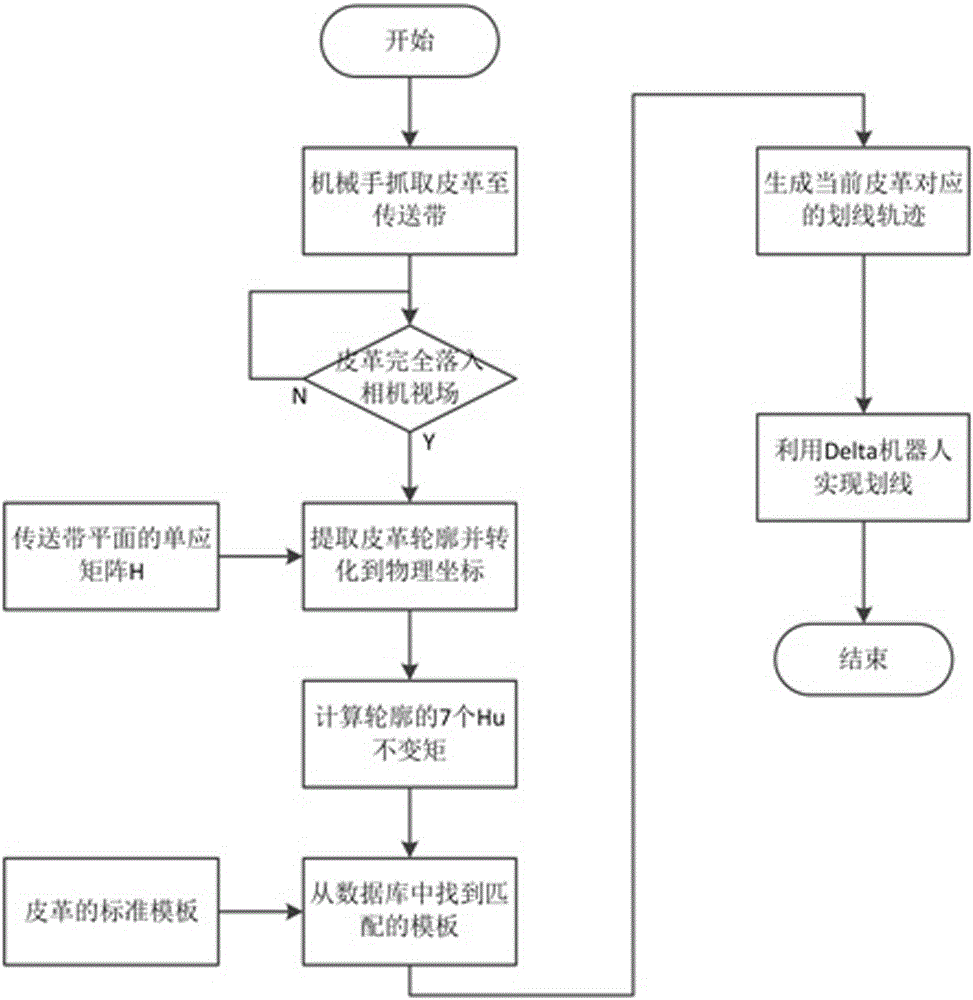

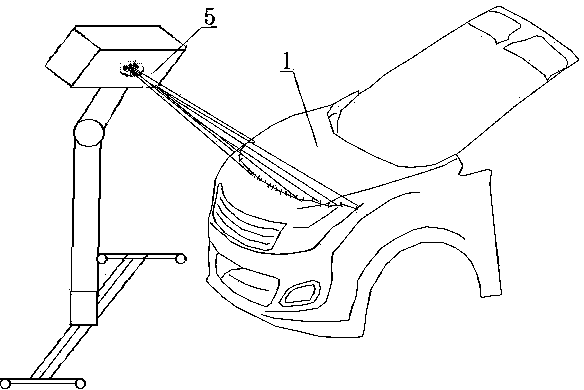

Machine vision-based automatic leather lineation method and apparatus

A machine vision-based automatic leather lineation method is characterized in comprising the following steps: step S1, leather capturing: quickly capturing leather from a leather placing rack to a conveyor by using a manipulator; step S2: real-time scanning: performing, by a camera placed above the conveyor, real-time scanning on an image on the conveyor, and determining, by using an algorithm, whether the leather completely enters a view field of the camera; step S3: leather contour data extraction: after the leather completely enters the view field of the camera, analyzing an edge contour of the leather by using an image processing algorithm, and transforming the edge contour into an actual physical coordinate; step S4: lineation track determining: according to actual extracted contour data of the leather, searching a database for a template matching the data, and correspondingly determining a lineation track; and step S5: lineation: after determining the lineation track, performing leather lineation by using a Delta parallel robot. The Delta parallel robot is used to implement lineation, and the present invention has advantages of being high in accuracy and fast in speed.

Owner:浙江城电科技有限公司

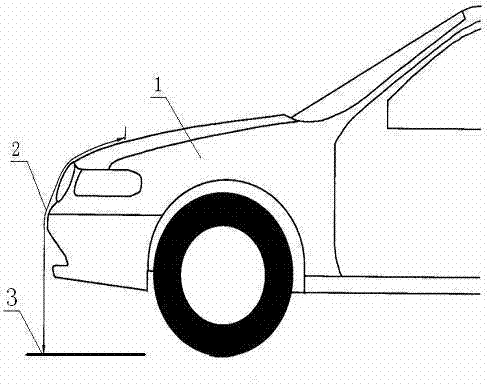

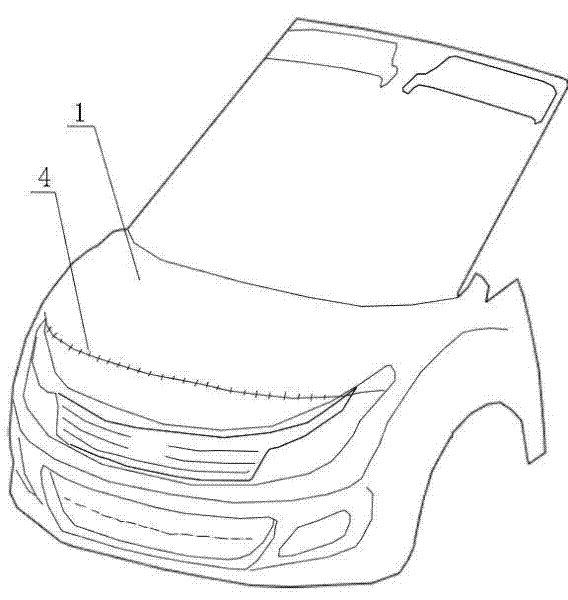

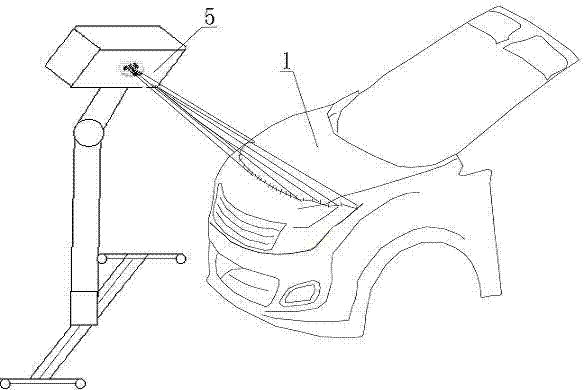

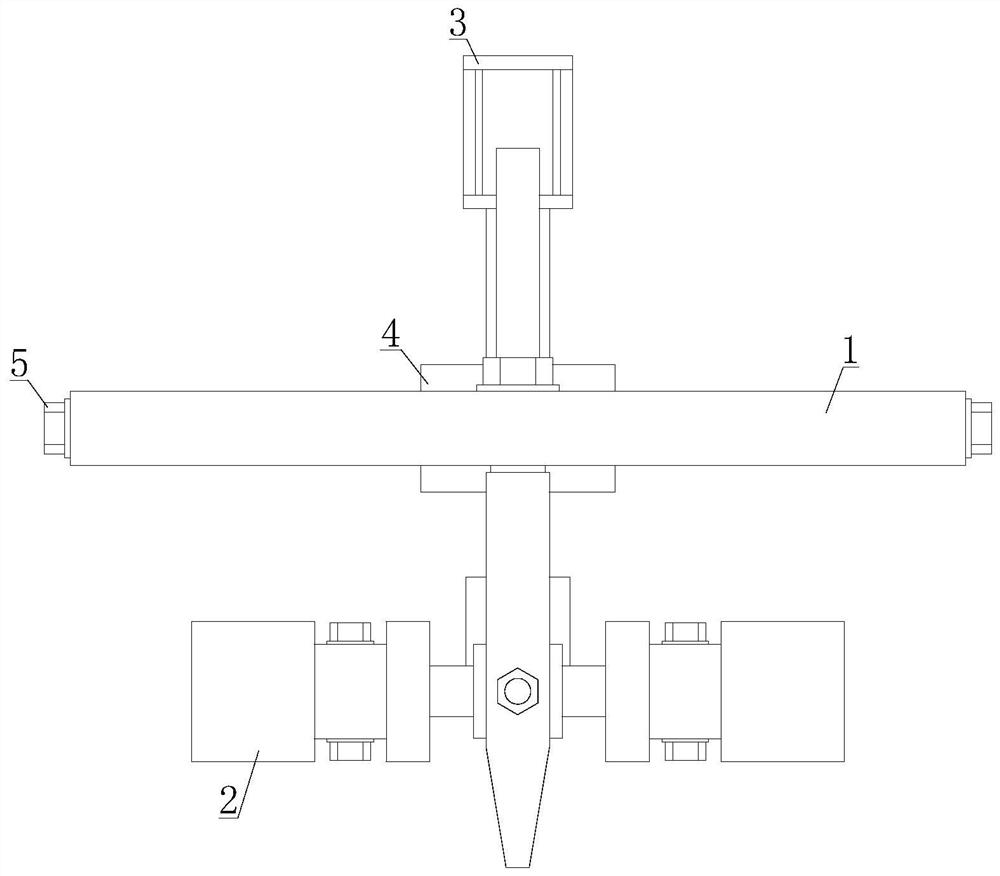

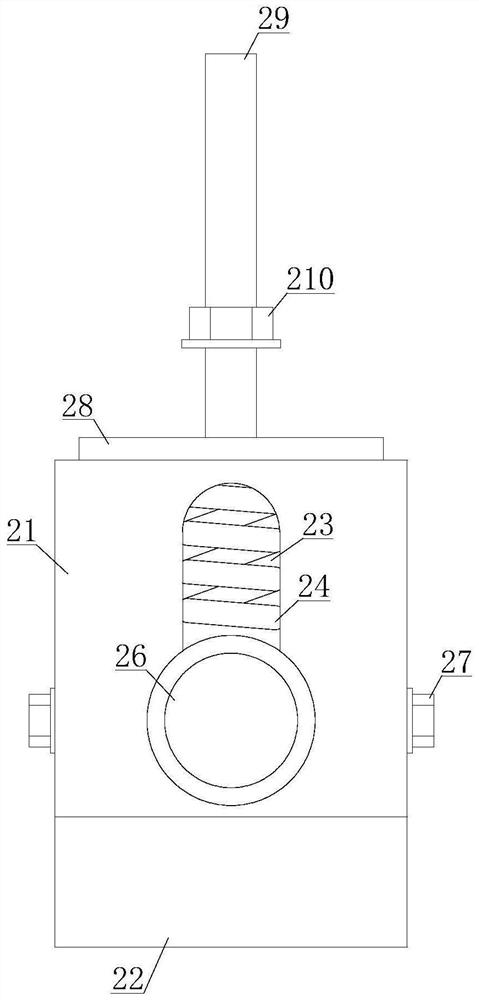

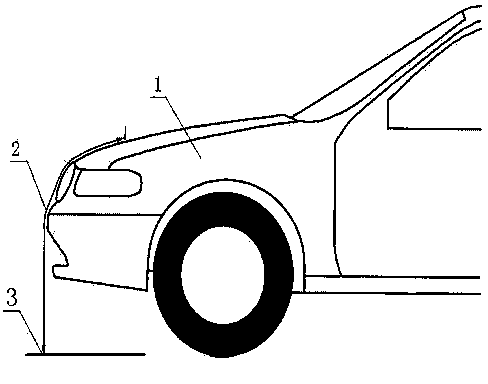

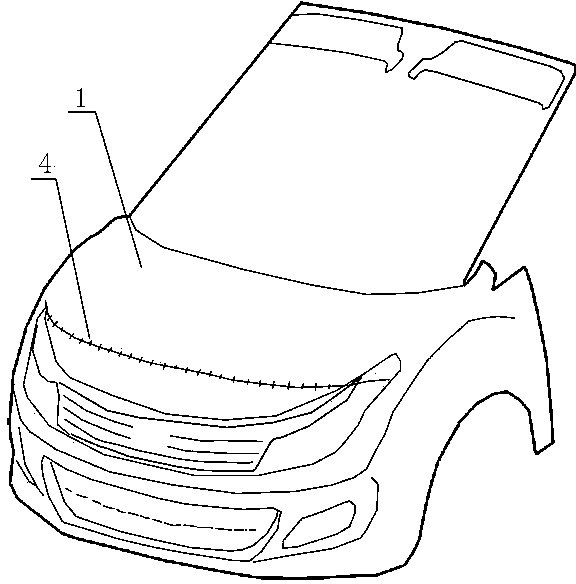

Marking device for pedestrian protection test

ActiveCN102463570AMeet the needs of protection markingQuick dashOther workshop equipmentSimulationComputer aid

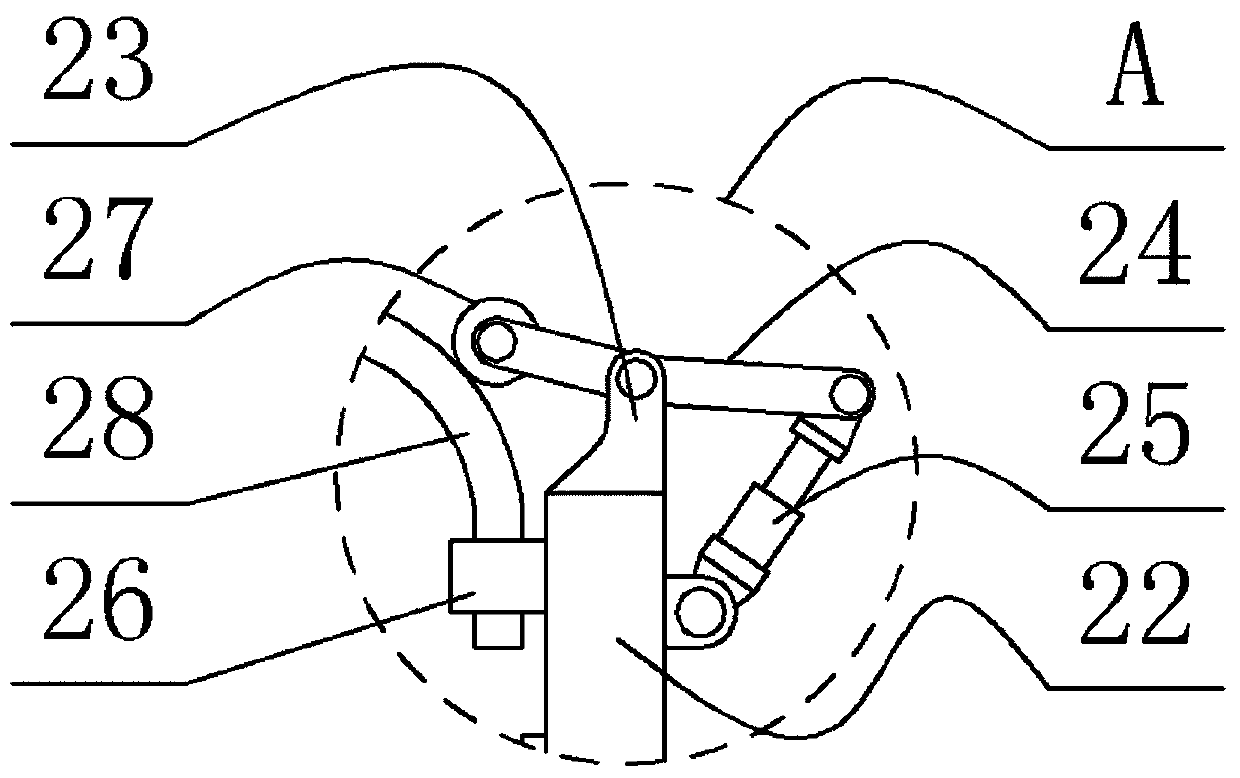

The invention relates to the technical field of a vehicle safety test, in particular to a marking device for a pedestrian protection test, solving problems that various technical index lines such as required reference lines of the front edge of an engine hood can be marked rapidly and accurately in a test of protecting pedestrians from automobile collision, wherein the rapid marking is realized and the marking precision is ensured by combining the computer-aided marking and the actual vehicle point-stroking; the rapid marking is realized and the marking precision is ensured, and moreover, the marking results can be stored in a computer for later check and use.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

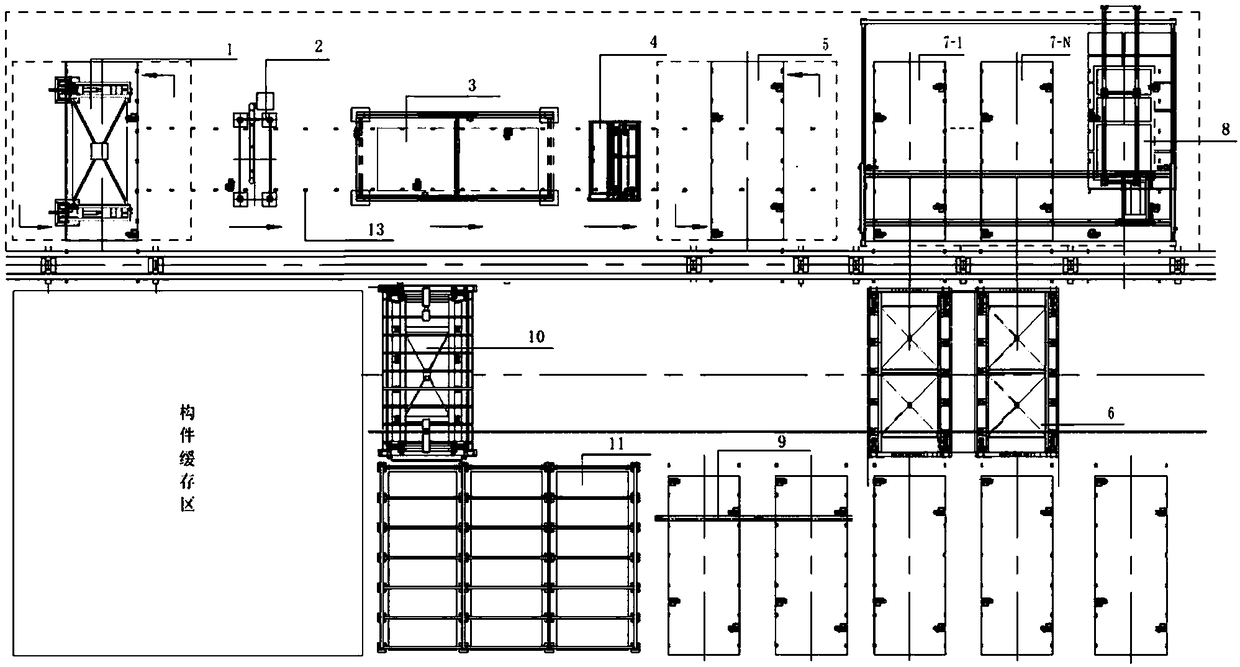

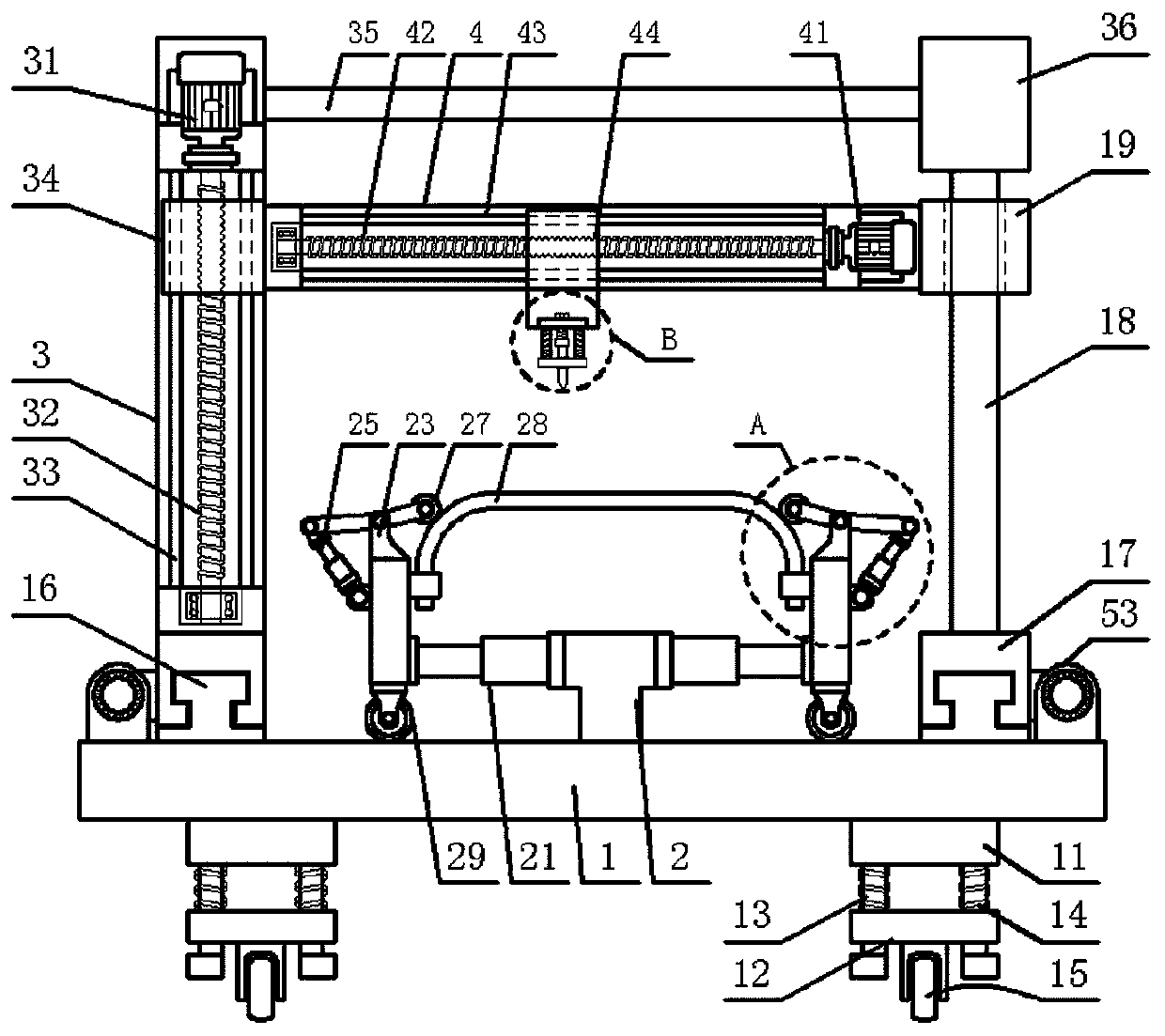

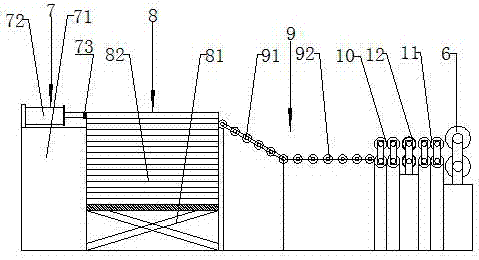

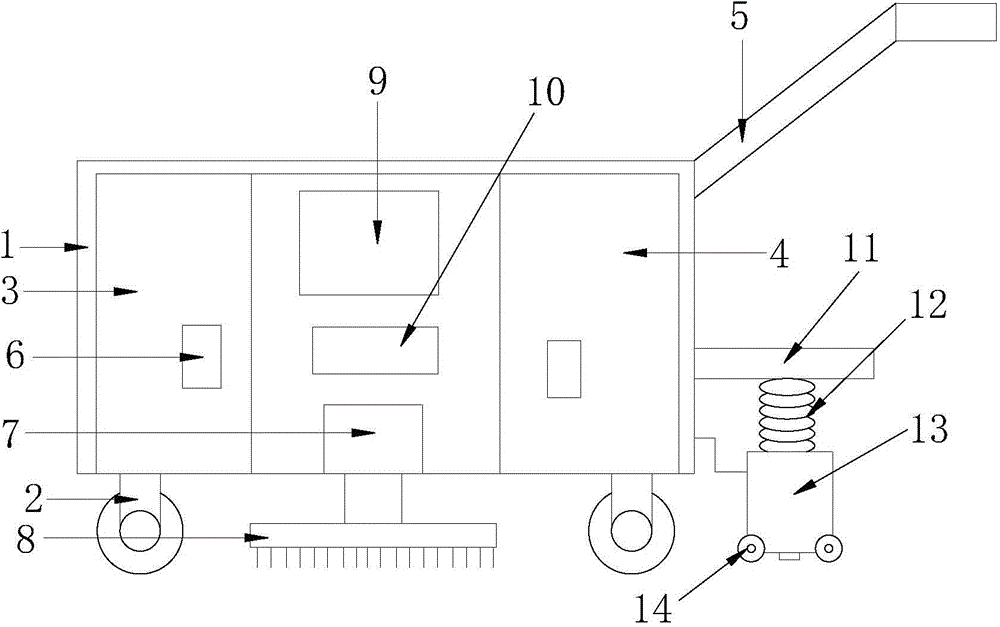

Ferry type all-purpose rhythm comprehensive assembly production line for assembly type components

InactiveCN108501197ASimple structureEasy to manufactureCeramic shaping plantsProduction lineDrive wheel

The invention belongs to the technical field of PC production lines in modern assembled buildings in the construction industry, in particular to a ferry type all-purpose rhythm comprehensive assemblyproduction line for assembly type components. The production line is characterized in that the downstream of a plate turning machine which is used for form stripping and is provided with a hydraulic rotating device is connected with an assembly production line stage through driving wheels, wherein the assembly production line stage comprises a cleaning machine, a ruling machine, a spraying machinewhich are sequentially connected to the driving wheels; the downstream of the spraying machine is connected with a mold table with a hydraulic rotating device through the driving wheels, and the moldtable is connected with idle mold table stations through rail type ferry vehicles to perform steel bar binding, mold supporting and embedded part remaining; and a material distributing machine is arranged at the downstream of one idle mold table station, the downstream of the material distributing machine is sequentially provided with the idle mold table stations and a napping machine, and the napping machine is used for conveying the components to a curing kiln for maintenance through a stacking machine. According to the production line, the structure is simple, manufacturing is convenient,the performance is stable, and the production line can be become a novel product of assembly type building PC production lines for producing a laminated plate, an outer wall plate, an inner wall plateand a special-shaped structure.

Owner:江苏旺材科技有限公司

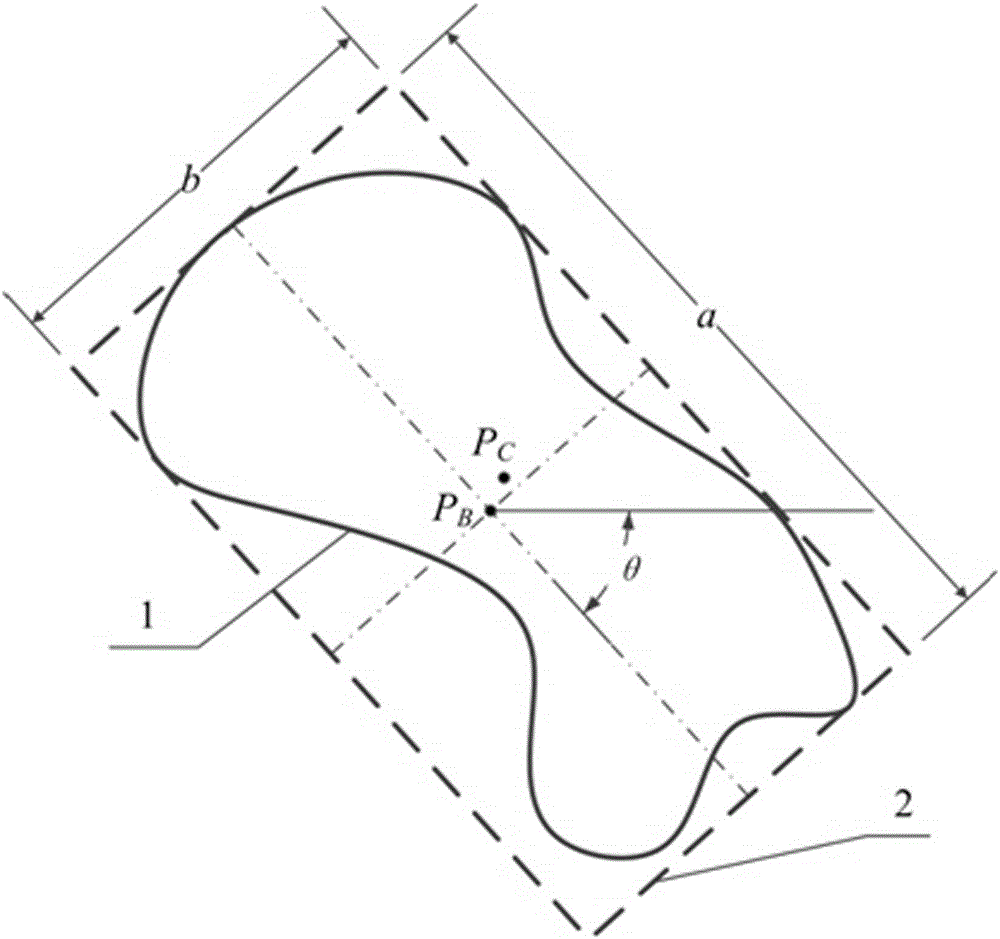

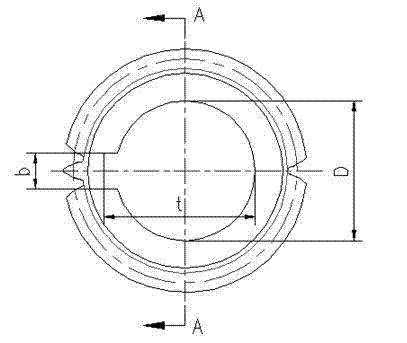

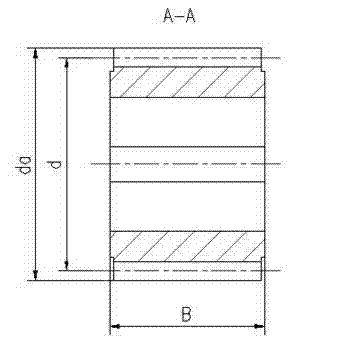

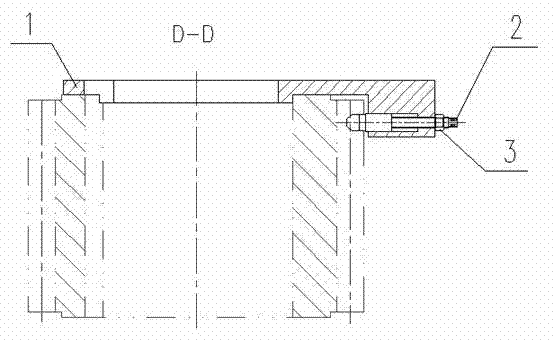

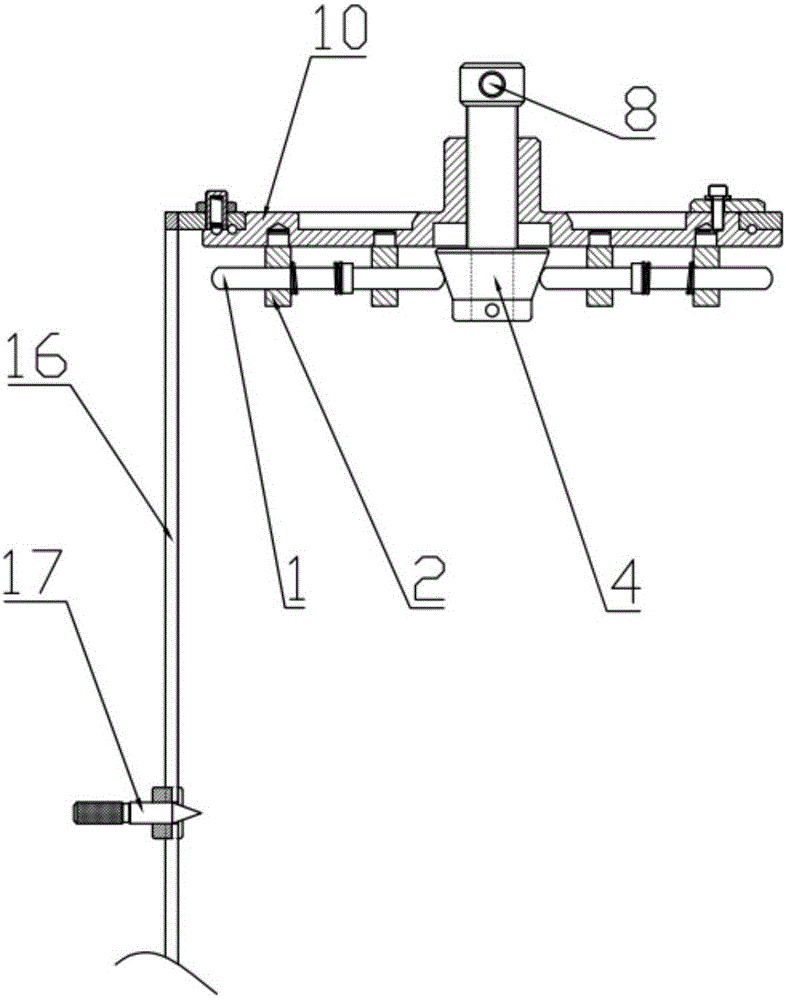

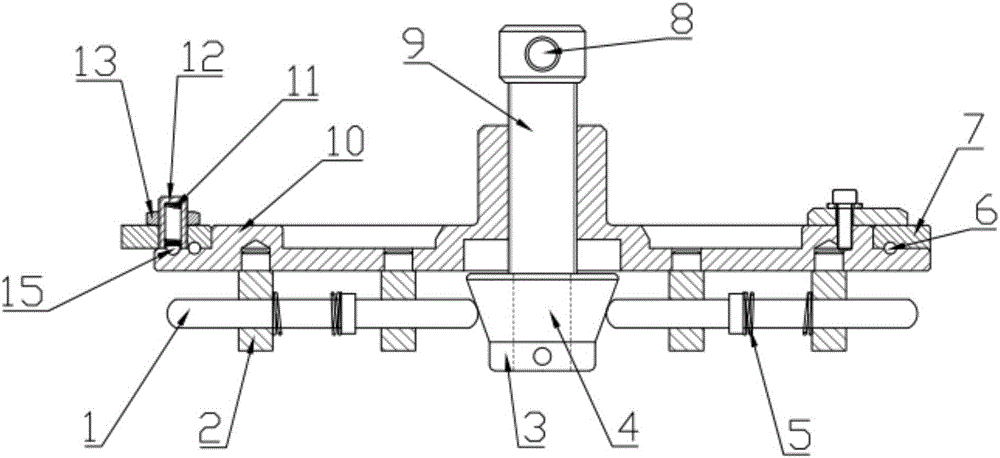

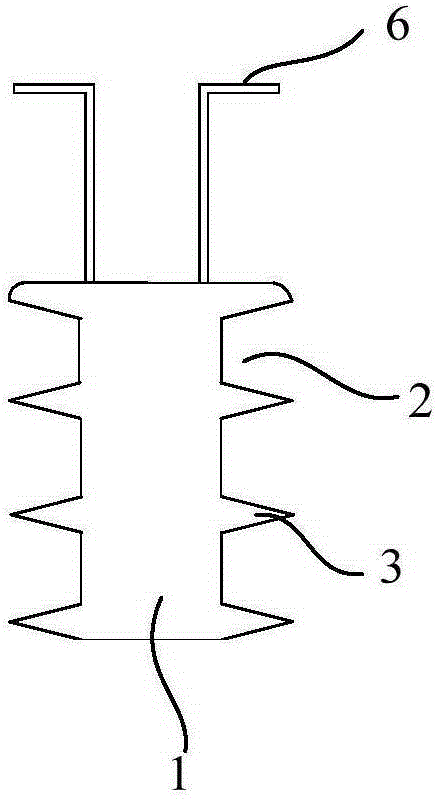

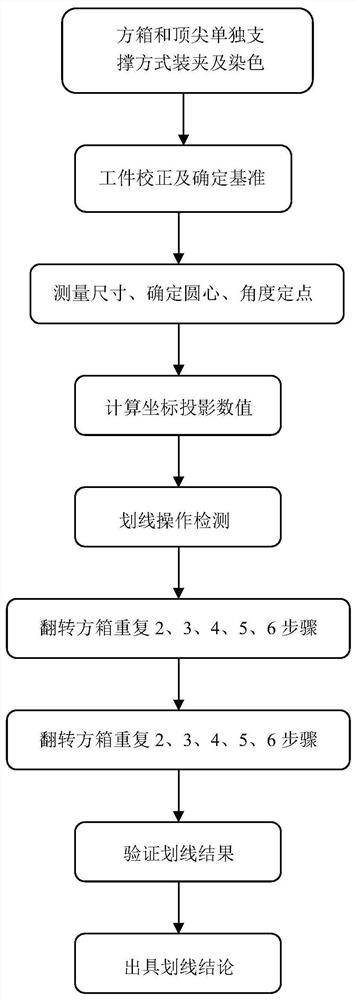

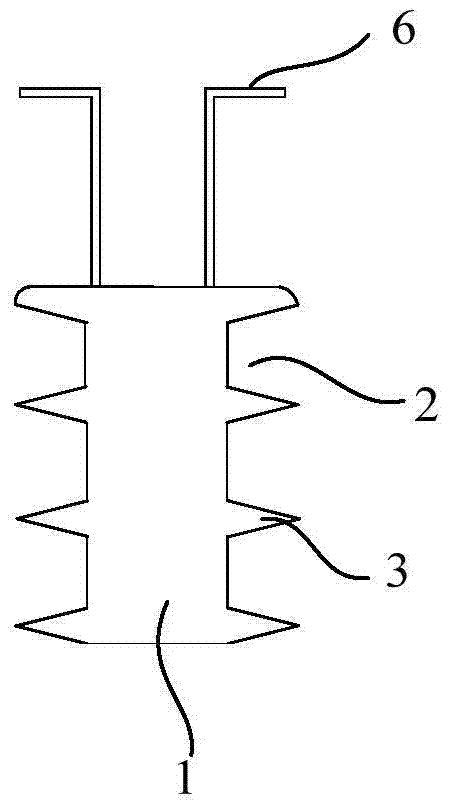

Key groove lineation method for making aligned tooth sample plate and used for helical gear with odd teeth

The invention discloses a key groove lineation method for making an aligned tooth sample plate and used for a helical gear with odd teeth. The aligned tooth sample plate consists of a sample plate body (1), a bulb moving rod (2) and a nut (3). The method comprises the following steps of: screwing a screw of the bulb moving rod into an internal thread hole of a stepped through hole of the sample plate body till the bulb of a sphere exceeds the end face A of a lug boss at the lower end of the right side of the sample plate body; arranging the sample plate body provided with the bulb moving rod into an inner hole of the helical gear with odd teeth; negatively screwing the bulb moving rod, gradually screwing the bulb moving rod into a tooth groove between two adjacent oblique teeth of the helical gear with odd teeth till complete contact with the tooth groove, and then tightening the bulb moving rod at the screw of the bulb moving rod through the nut; marking a key groove width b and a key groove depth t of the helical gear with odd teeth through a key groove formed at the left end face of the inside diameter of the sample plate body and by means of a lineation pen, wherein the key groove width b can correspond to the tooth outline of the end face of a random odd tooth; and then machining the helical gear with odd teeth according to the key groove width b and the key groove depth t.

Owner:CITIC HEAVY INDUSTRIES CO LTD

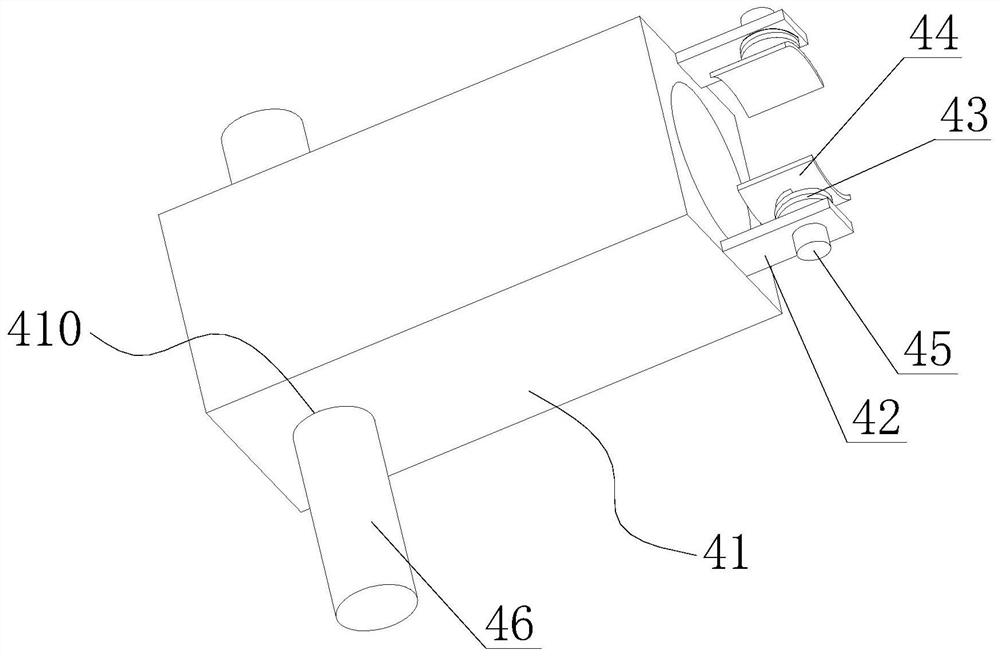

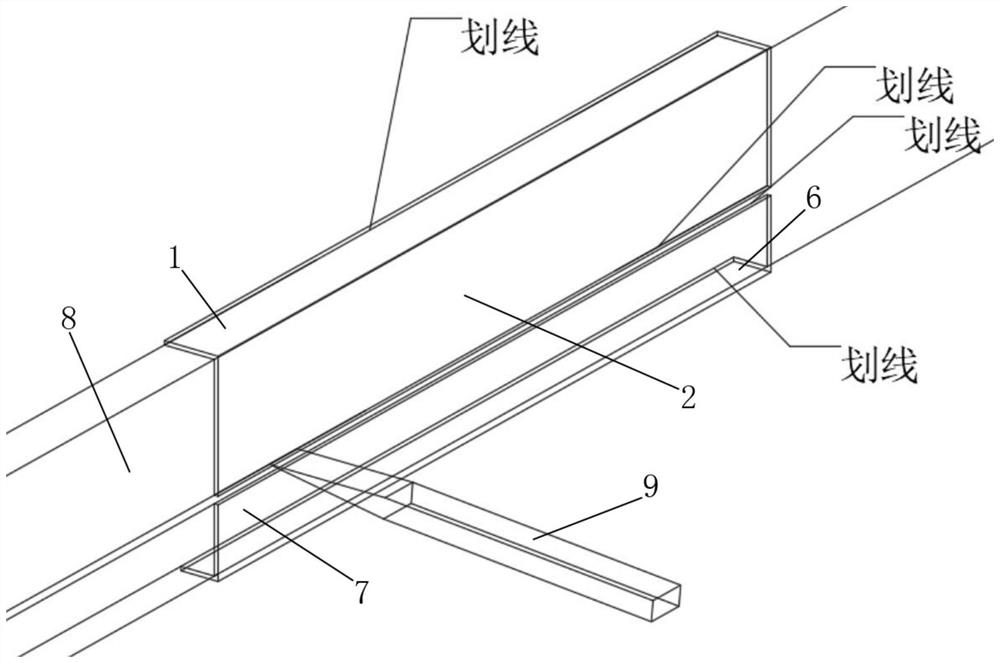

Intelligent tooling fixture for scribing carbon contact strip and operation method of tooling fixture

ActiveCN111055258AImprove free switchingImprove marking efficiencyWork holdersOther workshop equipmentEngineeringSlide plate

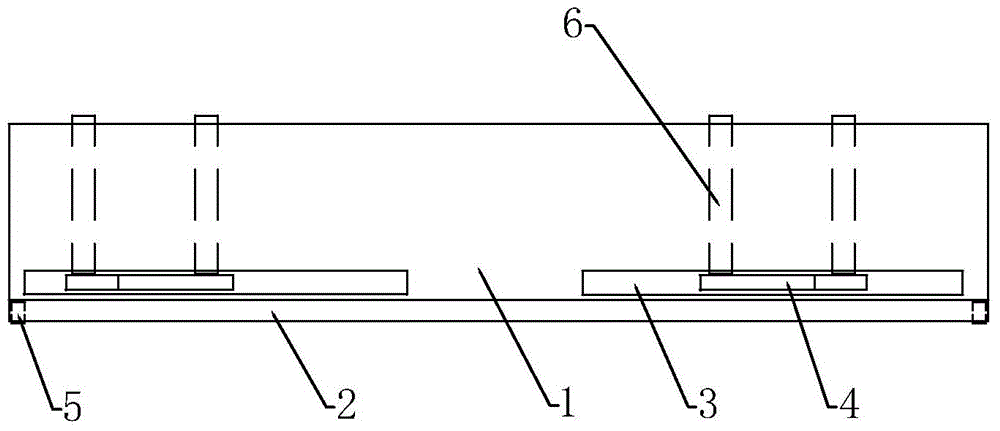

The invention discloses an intelligent tooling fixture for scribing a carbon contact strip. The fixture comprises a bottom plate, a vertical plate is arranged on the top surface of a slide plate located on one side, a first mechanism is vertically arranged on the front of the vertical plate, a vertical slide rod facing upwards is arranged on the top surface of a slide plate located on the other side, a rectangular block-shaped slide cylinder sleeves the top of the slide rod, one end surface of a first slide plate in the first mechanism is fixedly connected to one end surface of the slide cylinder through two ends of a horizontal plate, a second mechanism is horizontally arranged on the front of the horizontal plate, and the bottom surface of a second slide plate in the second mechanism isprovided with a scribing component; third mechanisms are arranged on the top surface of the bottom plate and located on the outer sides of the slide rails, and a screw cylinder in each third mechanismis fixedly connected to the outer end surface of one corresponding slide plate. The invention also discloses an operation method of the intelligent tooling fixture for scribing the carbon contact strip. The tooling fixture provided by the invention is simple in structure and convenient to operate, under the assistance of the tooling fixture, the carbon contact strip can be accurately and quicklyscribed, the scribing efficiency and precision can be improved, and the processing costs can be reduced.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Three-dimensional marking process for group holes of steel truss bar

ActiveCN105522555AHigh marking accuracyHigh degree of mechanizationOther workshop equipmentEngineeringDisplay device

The invention relates to a three-dimensional marking process for group holes of a steel truss bar. The process comprises the following steps: on a working platform of a three-dimensional marking machine, using a jack and a bar manufacturing center line to horizontally adjust the steel truss bar, and checking the coordinate system of a left marking measuring arm and a right marking measuring arm; then respectively operating the measuring arms to control handles according to a drawing size, moving on three coordinate directions of an X axis, a Y axis and a Z axis by utilizing the real-time numerical values of a three-axis digital displayer of the marking machine, and carrying out marking operation by utilizing marking needles at the end parts of the measuring arms. The process has the advantages that the process firstly introduces the three-dimensional marking machine to work in the marking line manufacturing work of the steel truss bar, adopts mechanized construction and utilizes high-precision three-dimensional marking machine to control the marking line precision, so that the marking line precision is high, and the degree of mechanization is high; the number of the needed operating persons is less; only one to two operating persons are needed, and the fast and efficient making can be realized.

Owner:SHANGHAI ZHENHUA HEAVY IND

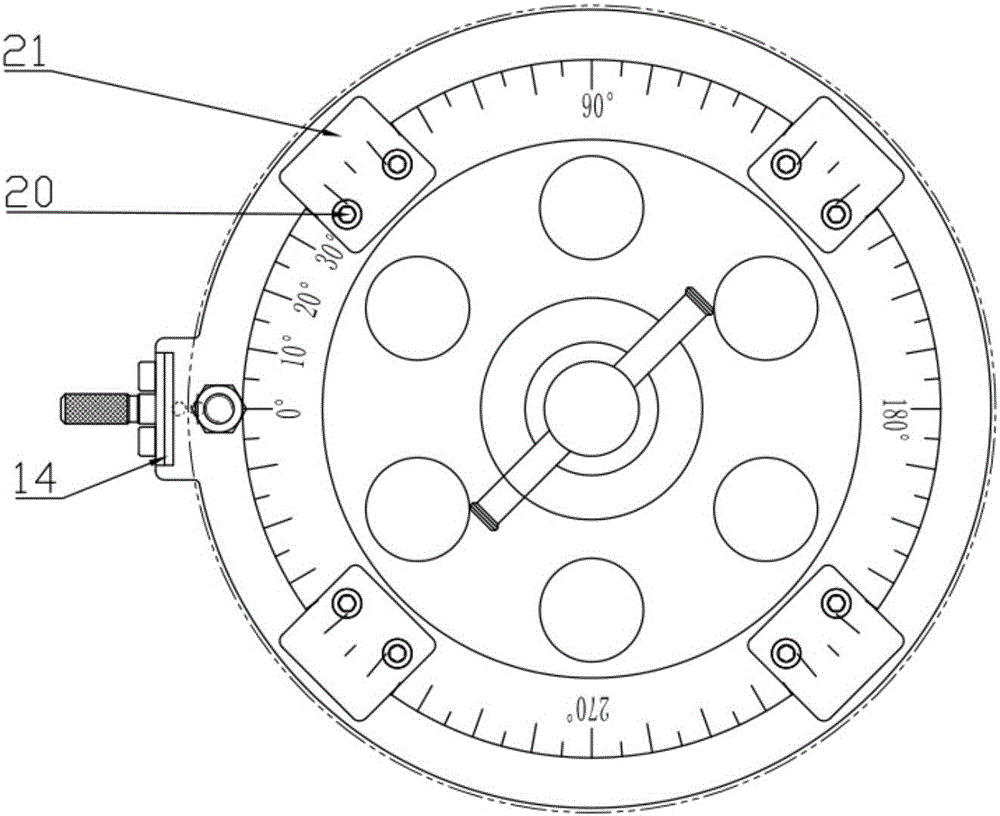

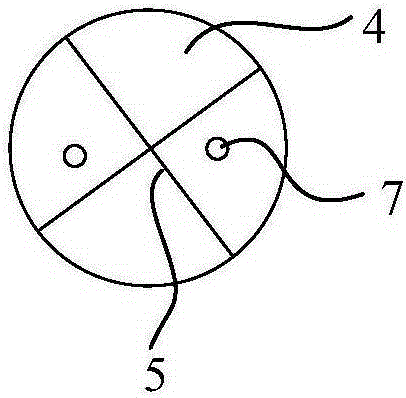

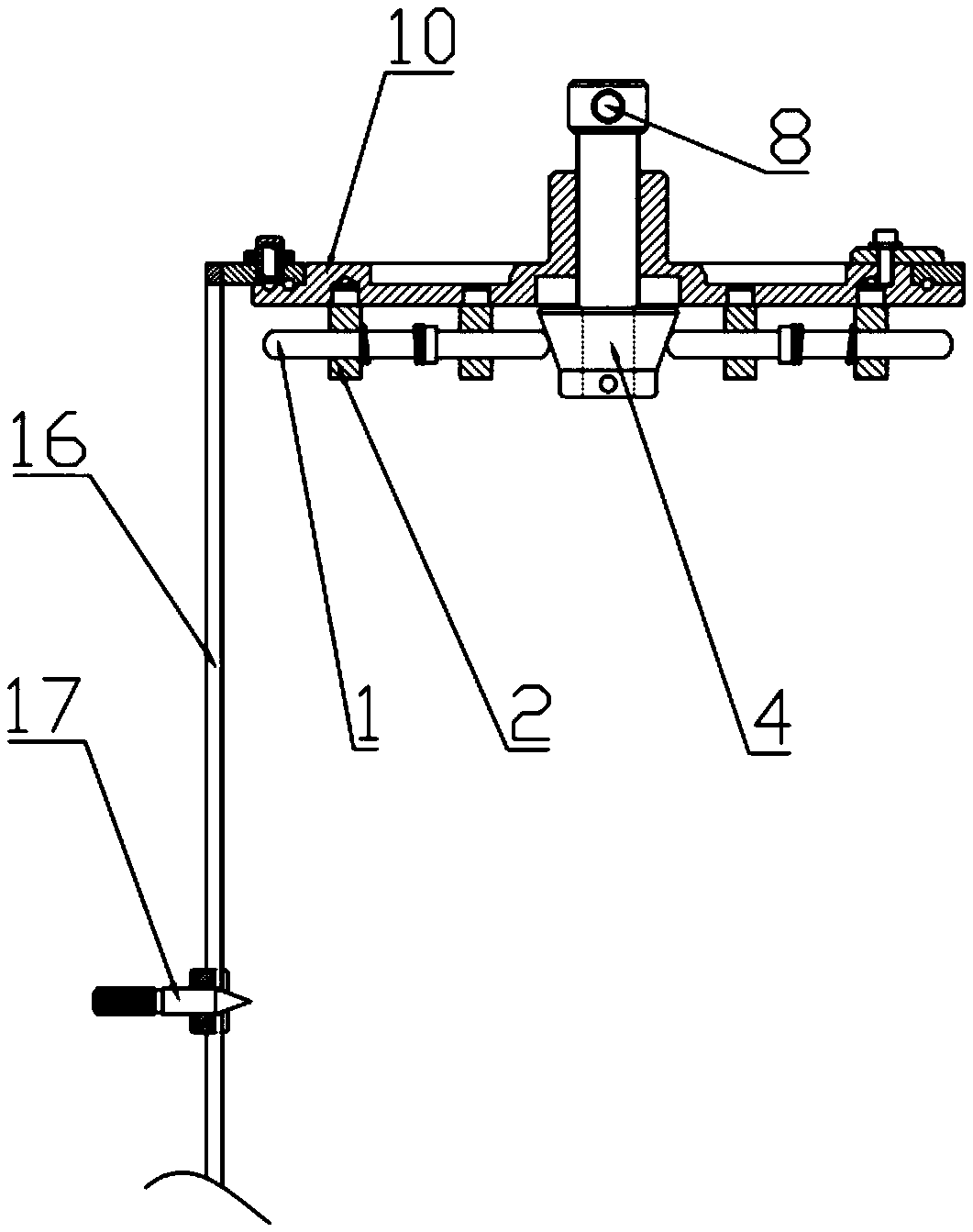

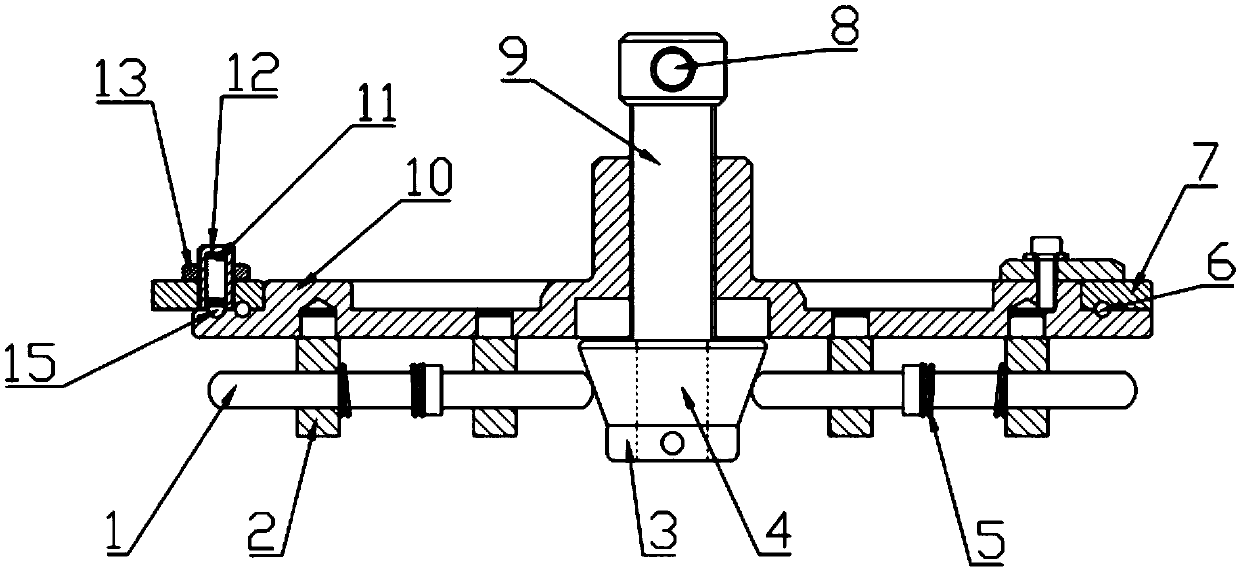

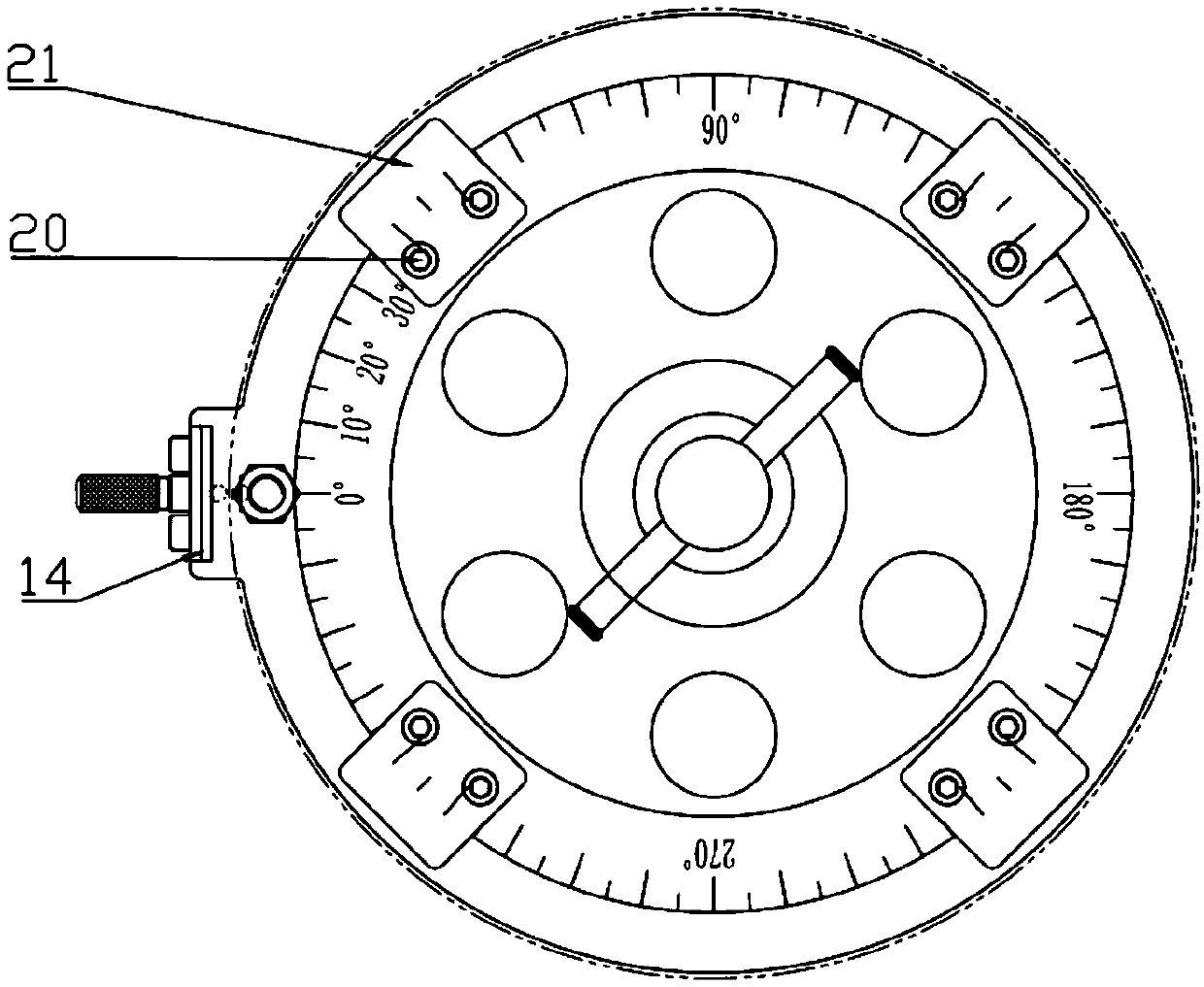

Universal device for marking barrel

ActiveCN106181952AHigh marking accuracyImprove marking efficiencyOther workshop equipmentEngineeringRotating disc

The invention discloses a universal device for marking a barrel and belongs to the field of mechanical marking equipment. The universal device for marking the barrel comprises a positioning disc which is provided with a rotating disc. Marking ruler guide strips are arranged on the circumference of the rotating disc in the vertical direction. The rotating disc drives the marking ruler guide strips to rotate. The marking ruler guide strips are provided with marking pins moving along the marking ruler guide strips. The universal device is a multifunctional combined marking tool and can achieve marking of crossed center lines of different heights and different angles through one-time clamping of workpieces; and by using the device for marking, the labor intensity of marking workers is greatly relieved, and the marking precision is improved.

Owner:山东豪迈重工有限公司

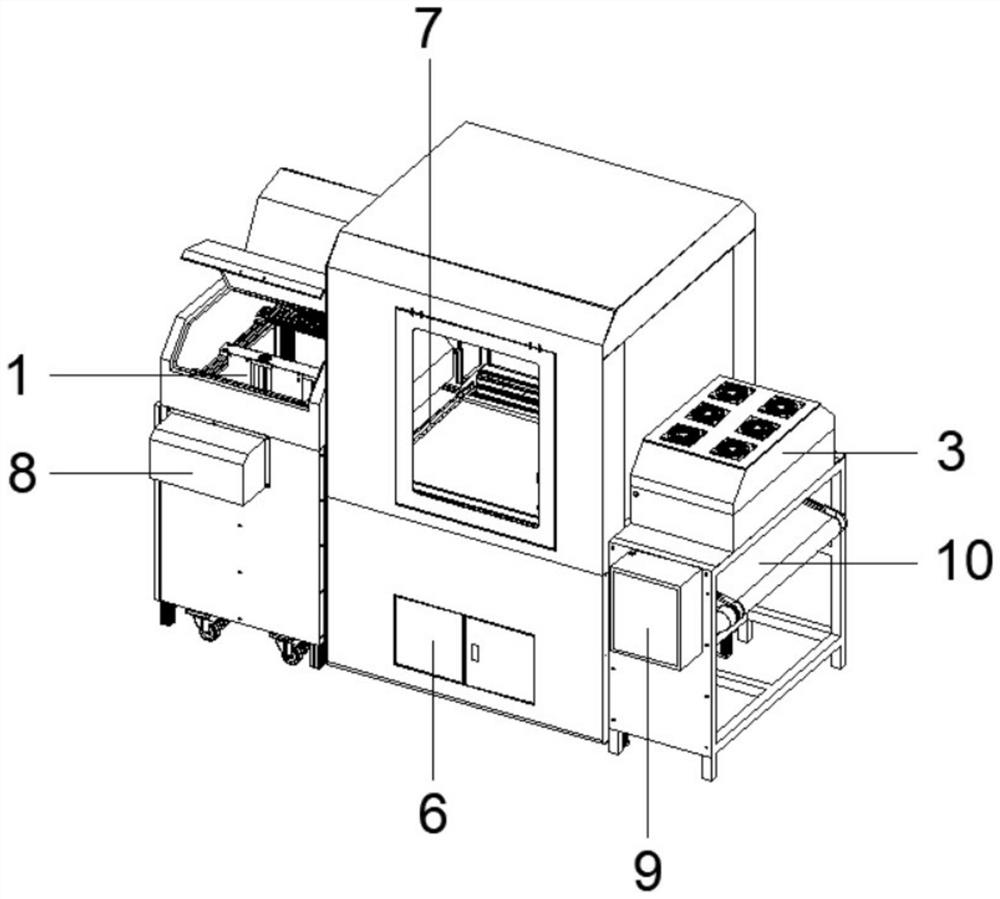

Full-automatic intelligent marking machine and working method thereof

ActiveCN112045653AGood pickupWith lifting functionOther workshop equipmentMechanical conveyorsGraphicsTemperature control

The invention provides a full-automatic intelligent marking machine. The full-automatic intelligent marking machine comprises an automatic feeding mechanism, a servo drawing mechanism, a drying mechanism, an industrial camera, a high-frequency injection valve, a system control box, a pressing device, a feeding mechanism control box, a temperature control box and a conveying belt device. Meanwhile,the invention further provides a working method of the full-automatic intelligent marking machine. The full-automatic intelligent marking machine has the beneficial effects that the high-frequency injection valve can move in the X-axis direction, the Y-axis direction and the Z-axis direction, marking is rapid and convenient, and a graph is presented at a moving position; the automation degree ishigh, plateless printing is achieved, manual operation is not needed, the labor cost is reduced, the spraying precision is high, the position precision of sewing marker lines is guaranteed, ink is used accurately, and therefore ink is saved; and in conclusion, one person can operate multiple machines, an operator does not need to conduct supervision all the time, the labor intensity is relieved, the labor efficiency is greatly improved, the product percent of pass is increased, and a favorable guarantee is provided for achieving an unmanned workshop.

Owner:NOBOT INTELLIGENT EQUIP (SHANDONG) CO LTD

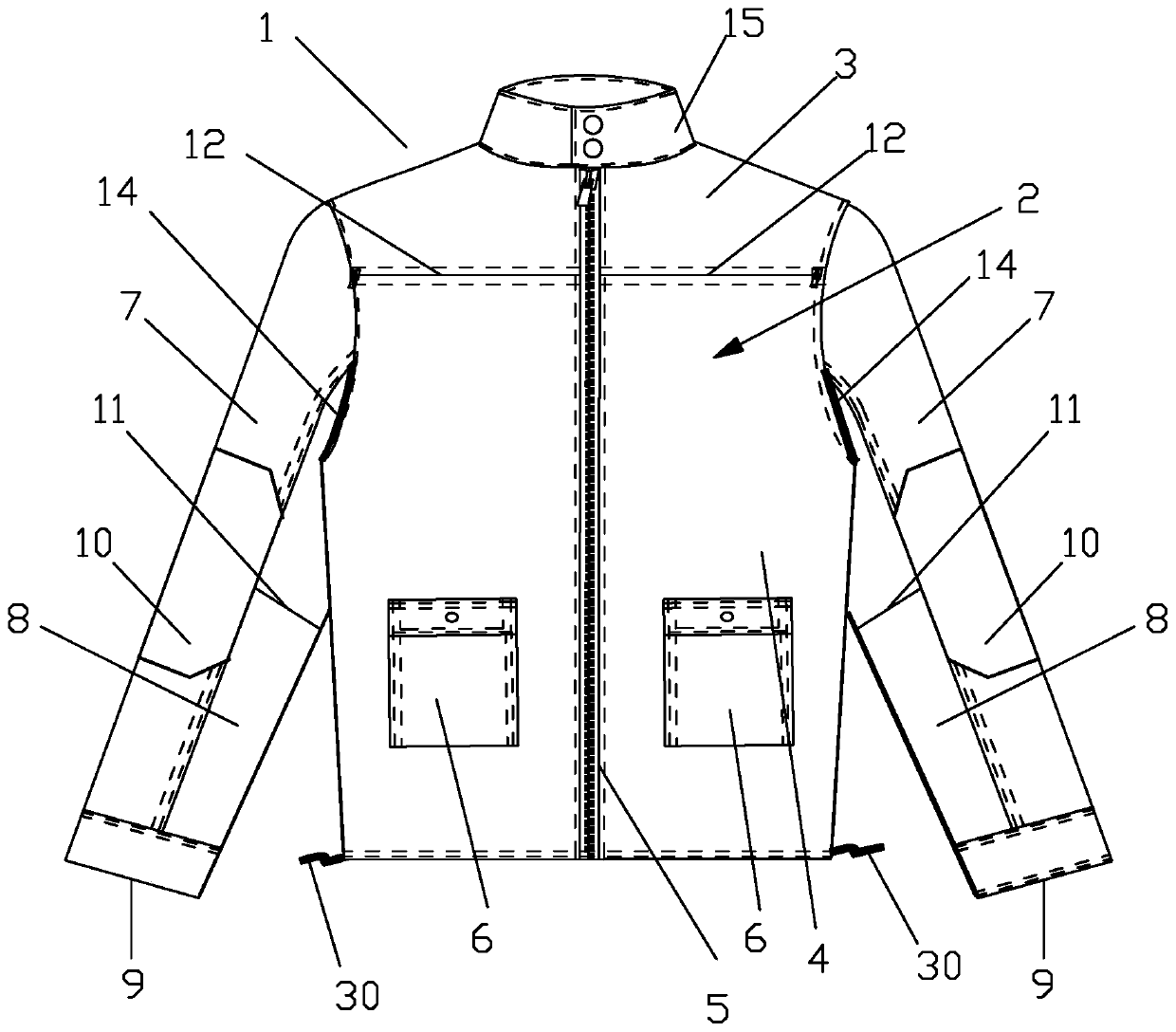

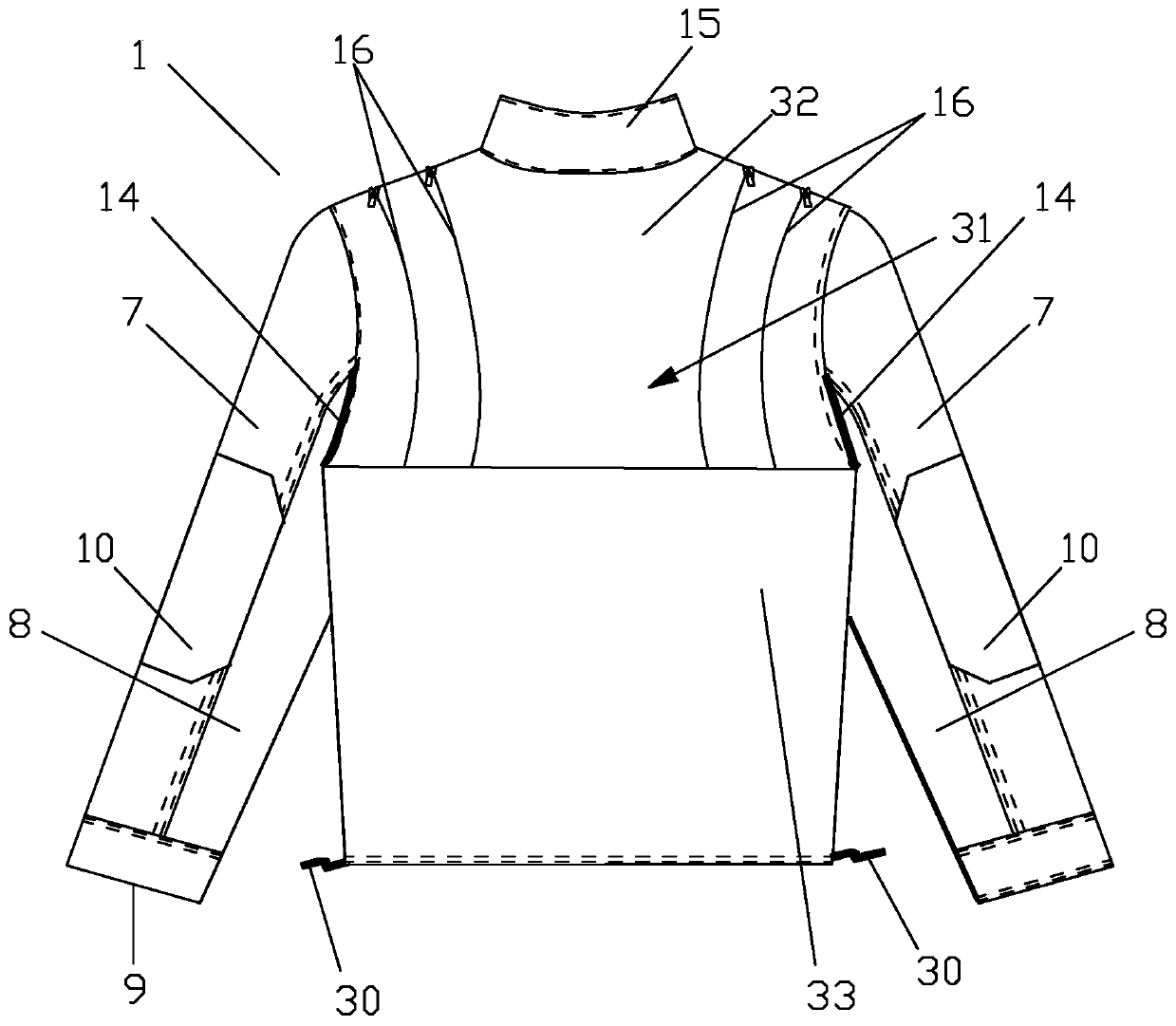

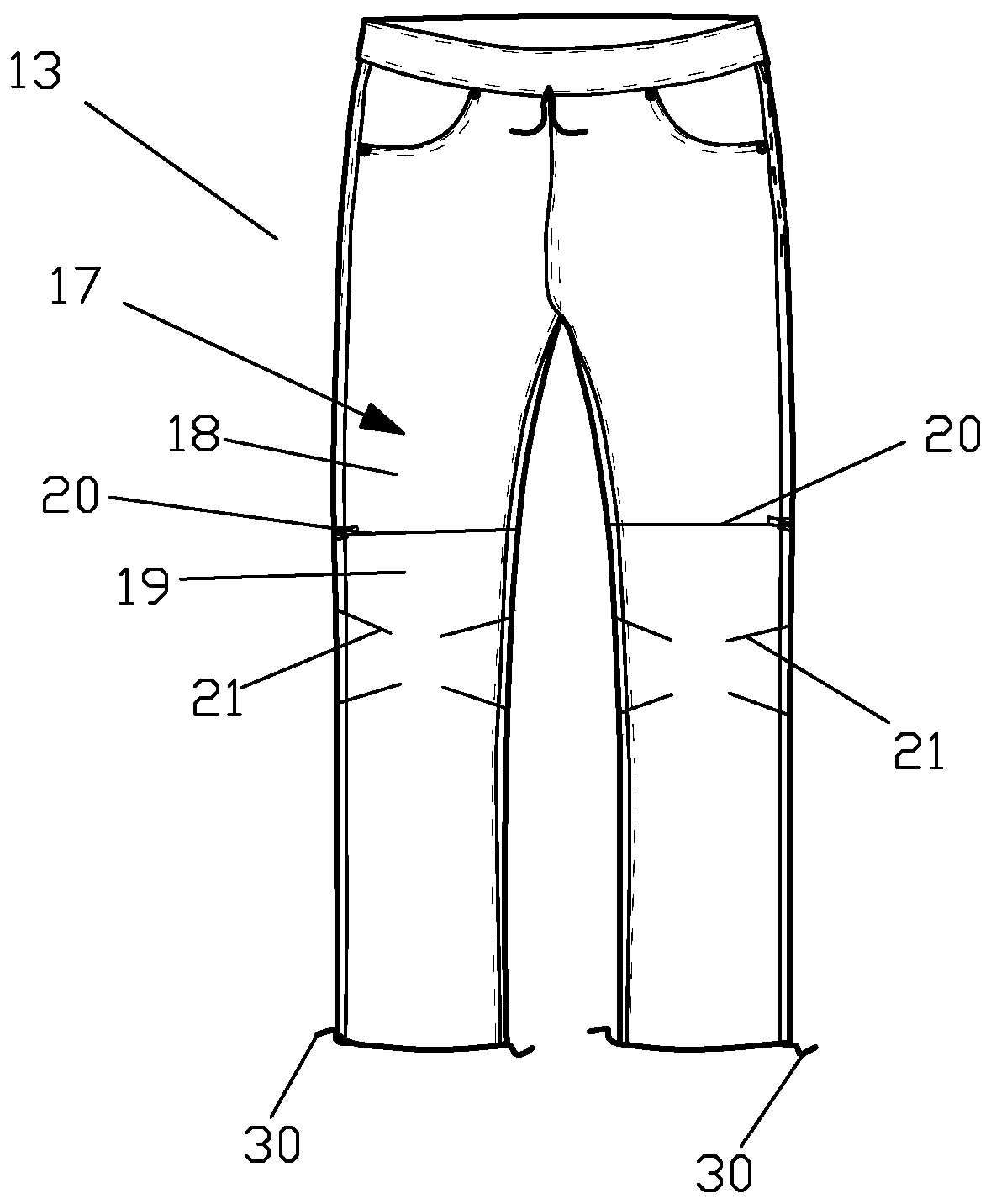

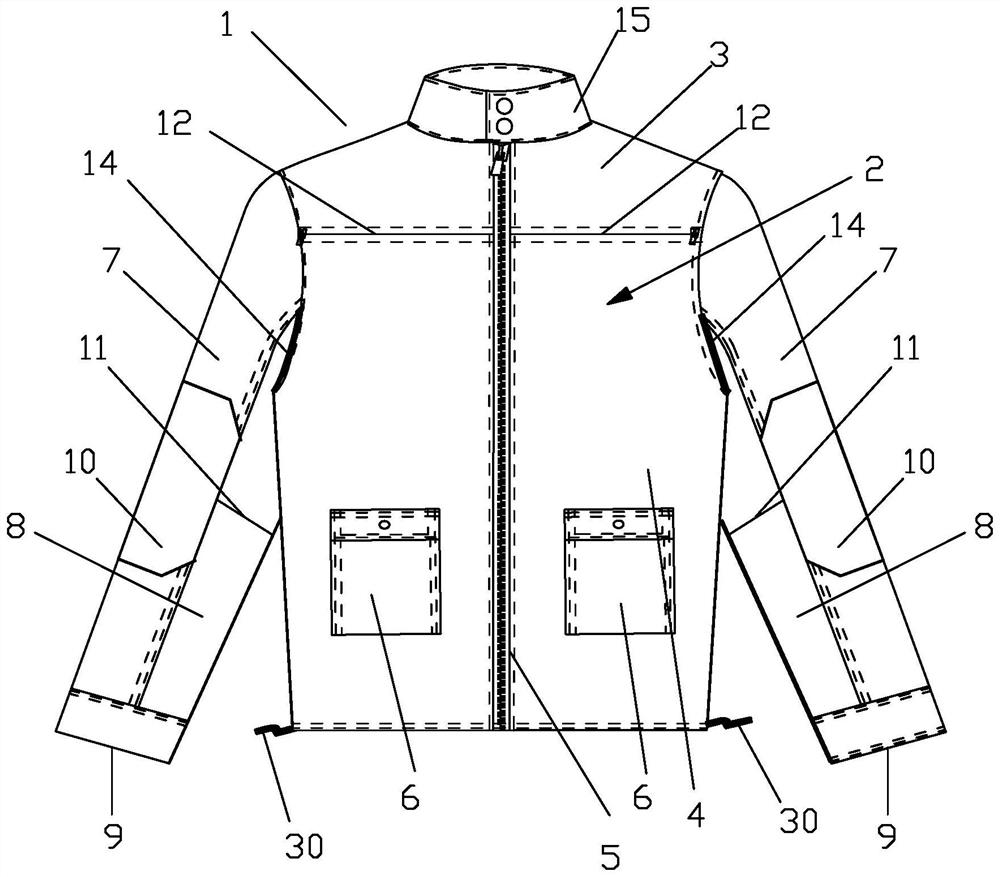

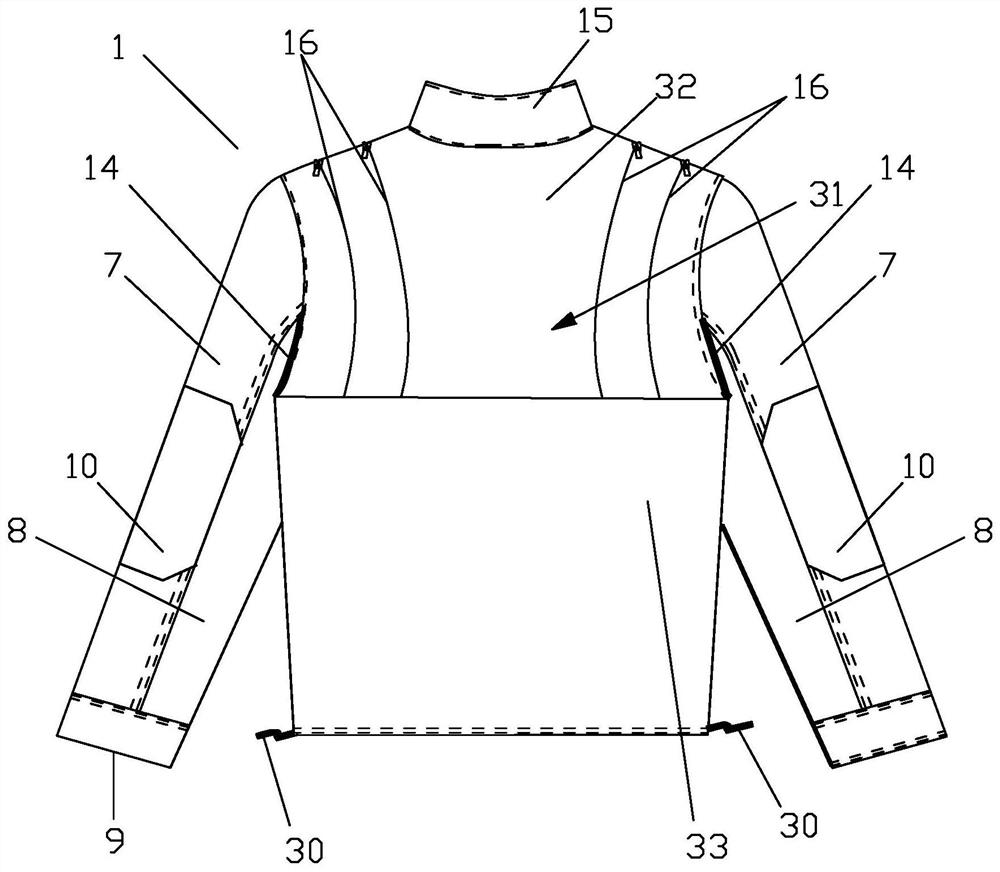

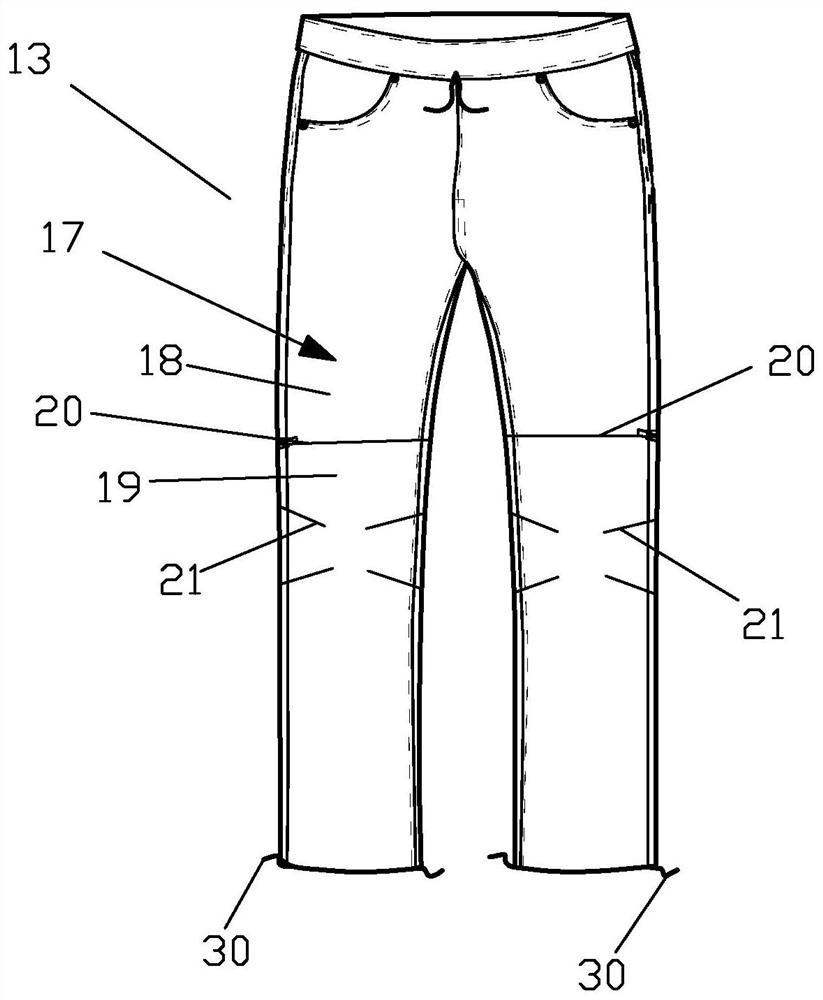

Protective clothing structure for operation at high temperature and constructing method of protective clothing structure for operation at high temperature

ActiveCN110638121AGuaranteed wearing comfortReduce heat radiationProtective garmentSpecial outerwear garmentsInfraredHuman body

The invention discloses a protective clothing structure for operation at high temperature and a constructing method of the protective clothing structure for operation at high temperature. The protective clothing structure for operation at high temperature includes a top and a pair of trousers, invisible zippers are arranged on both the top and the trousers, meshed cloth pieces are arranged on thepositions of the inner sides of the invisible zippers, and the top and the trousers are opened by the invisible zippers; and the fabric of the top and the trousers include a first thermal insulating layer, a second thermal insulating layer and a moisture transmission layer from outside to inside. By opening the invisible zippers, the air in the protective clothing can exchange with the external environment by forced convection, which can effectively accelerate the loss of the heat produced by a human body. The first thermal insulating layer can reduce thermal radiation to the human body at high temperature by using the ability of a nanomaterial to reflect near-infrared rays; the second thermal insulating layer uses an immobile air layer in an aerogel porous structure to isolate the external high-temperature environment from the human body, phase change microcapsules absorb the heat produced by the human body during a phase change process, and the microcapsule structures can prevent leakage of a phase change material; and the moisture transmission layer has good effect of single-way moisture transmission, moisture absorption and fast drying. The protective clothing is convenient touse and comfortable to wear with good protective performance.

Owner:浙江蓝天制衣有限公司

Soil compaction device for vegetable planting and implementation method

InactiveCN113366950AFast compaction operationShort processSpadesPlantingHydraulic cylinderSoil treatment

The invention discloses a soil compaction device for vegetable planting and an implementation method. The soil compaction device comprises a main panel, a marking compaction assembly, a vertical compaction assembly, a penetrating base and a fixing bolt. The height of a vertical adjusting screw rod in the marking compaction assembly is adjusted, so that a marking plate is embedded in soil, meanwhile, the surface of a compaction roller is in contact with the surface of the soil, the position of the whole soil compaction device is adjusted, the marking plate is used for marking out a gully on the soil surface, meanwhile, soil on the two sides of the gully is flattened and compacted through the compaction roller, plant seeds or plant seedlings are scattered in the soil gully, the height of the vertical compaction assembly is adjusted, and the position of the vertical compaction assembly is fixed through the fixing bolt; and a driving hydraulic cylinder is started, the driving hydraulic cylinder drives a hydraulic inner rod to move downwards, an auxiliary pressure plate compacts soil on the two sides of the gully, a vertical compaction plate compacts soil in the gully, rapid marking, sowing and soil compaction operation is achieved, the soil treatment process is greatly shortened, and the device is suitable for large-area soil treatment and vegetable planting.

Owner:HEXIAN LVYUAN VEGETABLE PLANTATION CO LTD

Four-line grid quick drawing device in English teaching board

The invention discloses a four-line grid quick drawing device in an English teaching board. The device comprises a frame board, wherein U-shaped handles are symmetrically and fixedly connected to theleft side and the right side of the frame board; a clamping strip board is slidably connected to an inner cavity of the frame board; a clamping groove is formed in the left side of the clamping stripboard; a bolt column is fixedly connected to the right side of the inner cavity of the clamping groove; a locking strip board is connected with the bolt column in a sleeving mode; a butterfly nut is screwed on the bolt column; hinge grooves are formed in the upper end and the lower end of the front side wall of the clamping strip board; guide rods are movably connected to the right sides of the inner cavities of the two groups of hinge grooves; prism stop pins are symmetrically inserted into the upper and lower sides of the clamping strip board; one ends, close to each other, of the two groupsof the prism stop pins extending into one sides, close to the bolt column, of the inner cavities of the hinge grooves; and four groups of chalk accommodating holes are formed in the upper end and thelower end of the front side wall at the joint of the clamping strip board and the locking strip boards at equal intervals. According to the device, the structure design is reasonable; and four-line grid can be quickly drawn conveniently to facilitate standardization of the writing of students, and both the learning efficiency of the students and the teaching quality of teachers are improved.

Owner:JIANGSU MARITIME INST

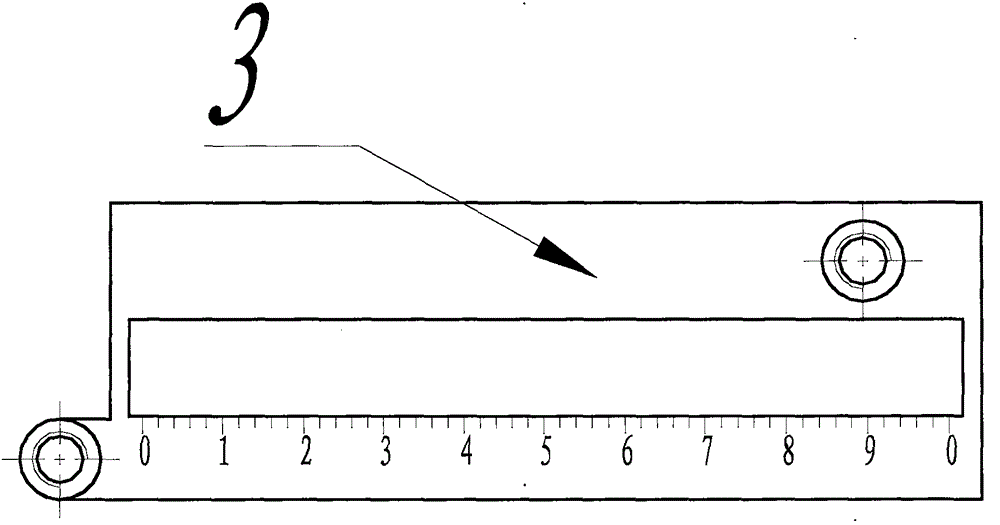

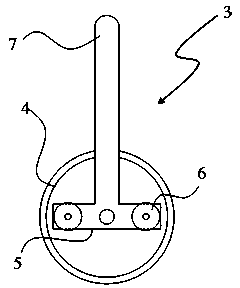

Polycrystal minority carrier lifetime detection back lineation measuring tool

InactiveCN104972450AQuality assuranceLower requirementOther workshop equipmentWorkloadMechanical engineering

The invention relates to a polycrystal minority carrier lifetime detection back lineation measuring tool. The polycrystal minority carrier lifetime detection back lineation measuring tool comprises a wood base, wherein the front end of the wood base is connected with a dividing ruler bonded with the wood base; grooves are respectively formed in one side of the front part of the wood base corresponding to the upper and lower ends of the dividing ruler; right-angled rulers are respectively arranged in the grooves in a vertical sliding manner; and first fastening screws for fixing the right-angled rulers are respectively arranged at the two ends of the bottom edges of the right-angled rulers corresponding to the back part of the wood base. The polycrystal minority carrier lifetime detection back lineation measuring tool has the advantages of reasonable structure, convenience, practicability, simple operation, time and labor saving, precise lineation, low workload and capability of improving the working efficiency.

Owner:SHANDONG DAHAI NEW ENERGY DEV

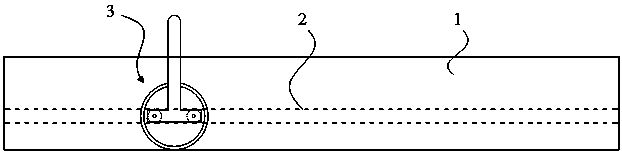

Marking device for sewing

The invention discloses a marking device for sewing, and belongs to the field of clothing for tailors. The device comprises a box body with an opening at the upper part, horizontal chutes formed in the inner walls of two side walls of the box body, and a sliding block device, wherein the sliding block device comprises a roller arranged in the box body, a support for fixing the roller, and an idler wheel arranged on the support and rolls in the chutes; and a solid coating board is arranged on the bottom of the box body. The device disclosed by the invention can be used for greatly improving the working efficiency of marking, and is low in cost, convenient to use and suitable for popularization.

Owner:南京宇盛羽绒制品有限公司

Scriber for cigarette butt

InactiveCN104964861AAccurately draw the lineQuick dashPreparing sample for investigationCigarette buttStructural engineering

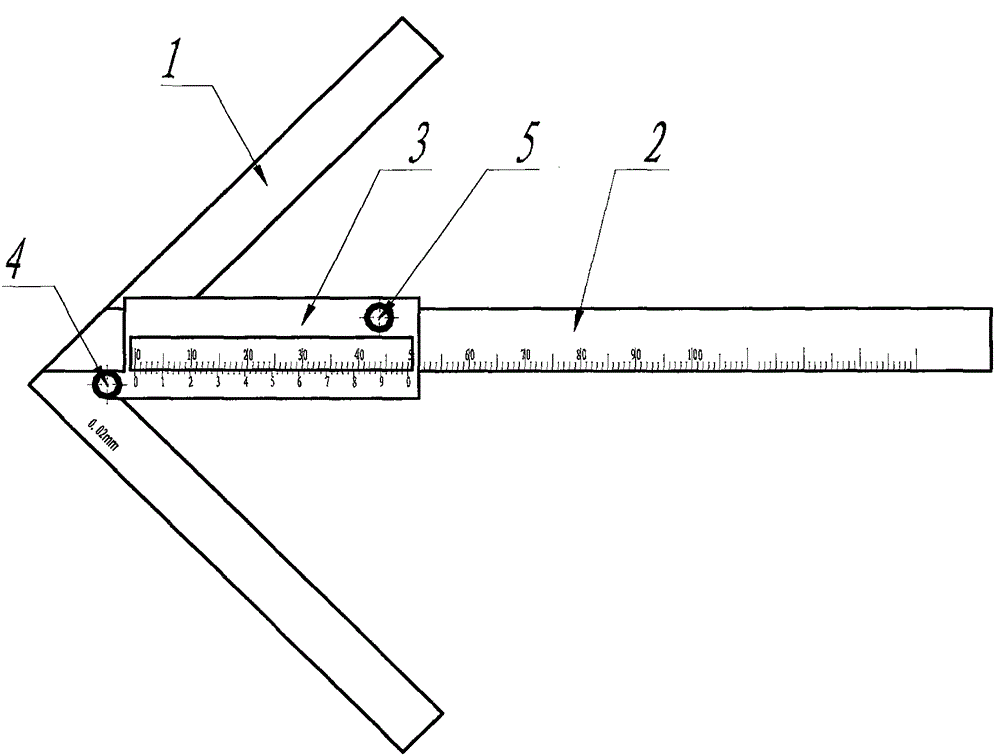

The invention discloses a scriber for a cigarette butt. The scriber is of a plate structure and is characterized in that three periphery sides of the plate protrude upward to form bosses respectively, the height of the bosses is larger than the diameter of a cigarette, a strip-shaped hole is formed in the part, along the inner wall of each boss, of the plate, and the width of the strip-shaped holes is smaller than the length of a cigarette filtering nozzle. By the adoption of the scriber for the cigarette butt, scribing can be accurately and rapidly performed on the cigarette butt of a cigarette sample in the process of scribing the cigarette, operation which wastes time and labor and is complex in process in the prior art is avoided, working efficiency is effectively improved, and meanwhile scribing errors are effectively reduced. Because the strip-shaped holes are formed in the plate, falling cigarette bits when the cigarette sample is pushed in the process of scribing can fall off along the strips-shaped holes, and the end of the cigarette filtering nozzle can make tight contact with the end of a sample tray; the defect that in the prior art, when the cigarette sample is scribed, the sample cigarette bits fall on the sample tray, so that the end of the cigarette sample butt will not remake tight contact with the top of the tray, and then scribing accuracy is affected is overcome.

Owner:CHINA TOBACCO HEBEI INDUSTRIAL CO LTD

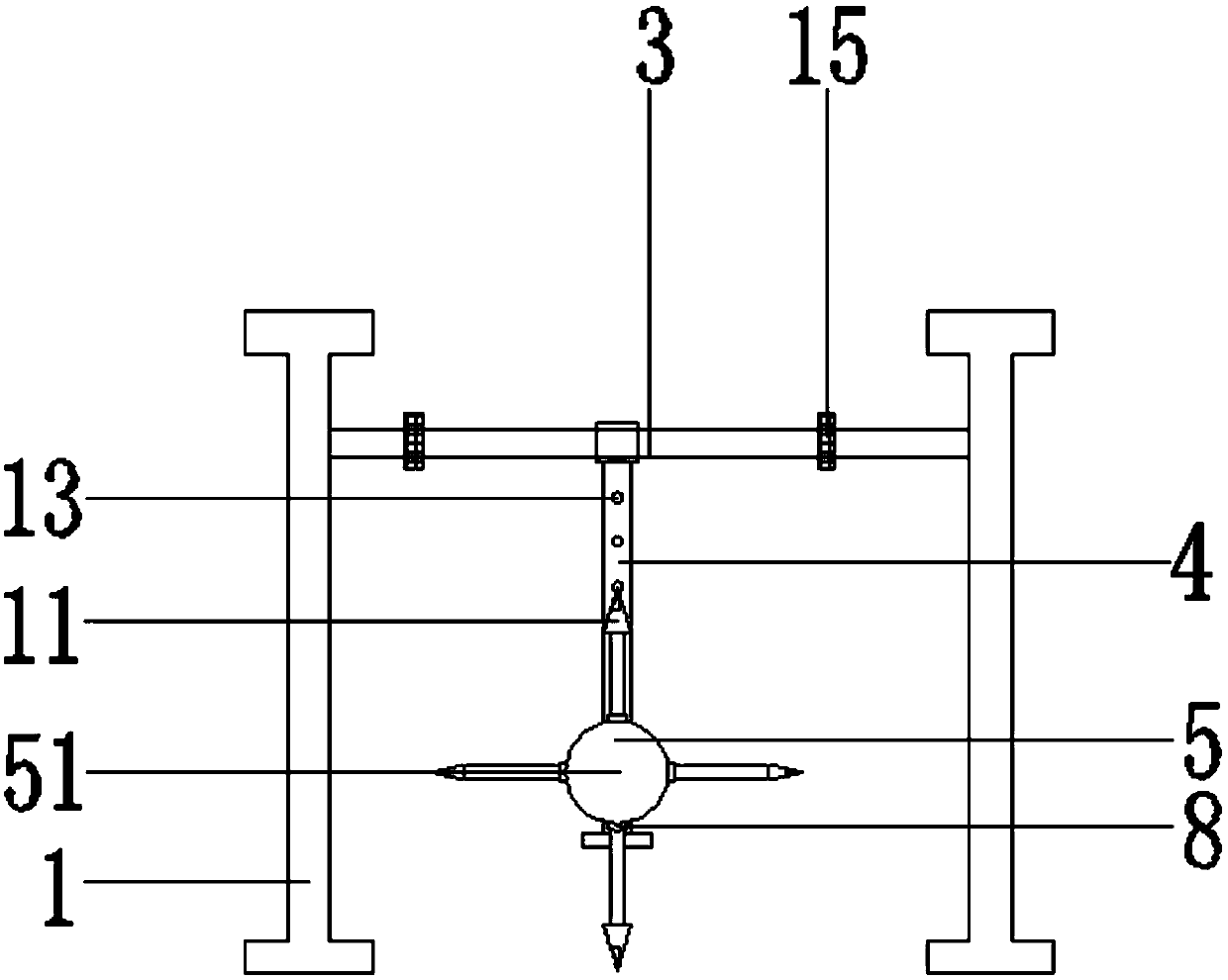

Positioning device for scribing and grooving in machining of mechanical parts

InactiveCN110962100AAccurate scribing and groovingFlexible moving processOther workshop equipmentCircular discGear wheel

The invention discloses a positioning device for scribing and grooving in machining of mechanical parts, and belongs to the technical field of machining of the mechanical parts. The positioning devicecomprises bases, every two bases form a group, an X-axis column is arranged in the middle of each group of bases, the X-axis columns are movably connected with a Y-axis column, the Y-axis column is movably connected with a vernier shaft, the vernier shaft is in threaded connection with a fixing disc, a gear is arranged in the fixing disc and connected with a disc ring, the outer wall of the discring is fixedly connected with a pen sleeve, the pen sleeve is connected with a pen holder in a threaded mode, a pen refill and a seal cutting pen point are arranged on the pen holder, transparent clamping sleeves are arranged at the two ends of the Y-axis column and the top end of the vernier shaft correspondingly, marking lines are arranged on the transparent clamping sleeves, threaded holes areevenly formed in the vernier shaft, screw rods matched with the threaded holes are fixedly arranged on the fixing disc, and movable clamps are arranged on the X-axis columns and the Y-axis column. According to the positioning device, accurate scribing and grooving can be carried out on the mechanical parts, the time is saved, and the working efficiency is improved.

Owner:扬州科迪机电制造有限公司

Sheet-by-step automatic feeding, marking and gluing integrated equipment

ActiveCN104708689BFast processingSpread evenlyOther plywood/veneer working apparatusAdhesive application devicesProduction lineMaterial scattering

The invention discloses layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials. The layer-by-layer automatic feeding, marking and gluing integrated equipment for the sheet materials comprises a marking device and a gluing device; the gluing device is arranged on one side of the marking device and a layer-by-layer automatic feeding device is arranged on the other side of the marking device; the layer-by-layer automatic feeding device comprises a pushing mechanism, a hoisting mechanism and a sliding mechanism in sequence; and the gluing device comprises a supporting framework, a stirring mechanism arranged at the upper end of the supporting framework, a material scattering mechanism arranged at the bottom of a transverse beam of the supporting framework, and a compression roller gluing mechanism arranged under the supporting framework. According to the layer-by-layer automatic feeding, marking and gluing integrated equipment, marking and gluing are integrated, transmission and interruption of machines are reduced in the process and the consistency of a production line is improved; and the machining time of the whole sheet material is shortened, materials can be automatically fed layer by layer, the transmission is buffered, the gluing can be automatically realized and the gluing is uniform.

Owner:JIANGSU KENTIER WOOD

A protective clothing structure and its composition method under high temperature operation

ActiveCN110638121BGuaranteed wearing comfortReduce heat radiationProtective garmentSpecial outerwear garmentsInfraredHuman body

The invention discloses a structure of protective clothing under high-temperature operation and a construction method thereof. It includes a coat and trousers. Both the coat and the trousers are provided with invisible zippers, and a mesh cloth piece is arranged on the inner side of the invisible zipper, and the coat is opened through the invisible zipper. and trousers; the fabrics of the coat and trousers include a first heat insulating layer, a second heat insulating layer and a moisture-conducting layer from outside to inside. By opening the invisible zipper, the air in the protective clothing can be exchanged with the external environment through forced convection, which can effectively accelerate the heat loss of the human body. The first heat insulation layer uses the performance of nanomaterials to reflect near-infrared rays to reduce heat radiation to the human body in high-temperature environments; the second heat insulation layer uses the static air layer in the airgel porous structure to isolate the external high-temperature environment from the human body and phase change microcapsules The phase change process absorbs the heat produced by the human body, and the microcapsule structure can prevent the leakage of the phase change material; the moisture-conducting layer has good one-way moisture-conducting and moisture-absorbing and quick-drying effects. The protective clothing is convenient to use, has excellent protective performance and good wearing comfort.

Owner:浙江蓝天制衣有限公司

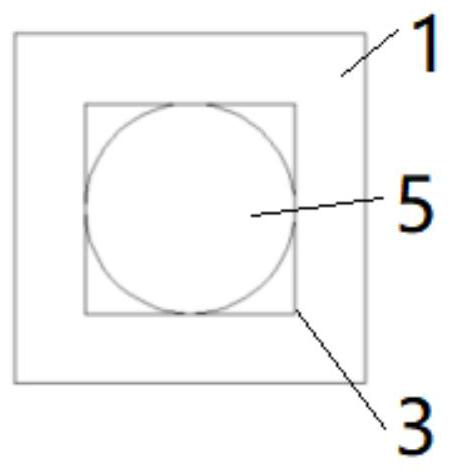

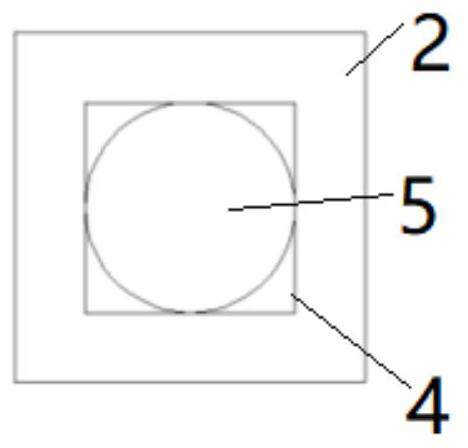

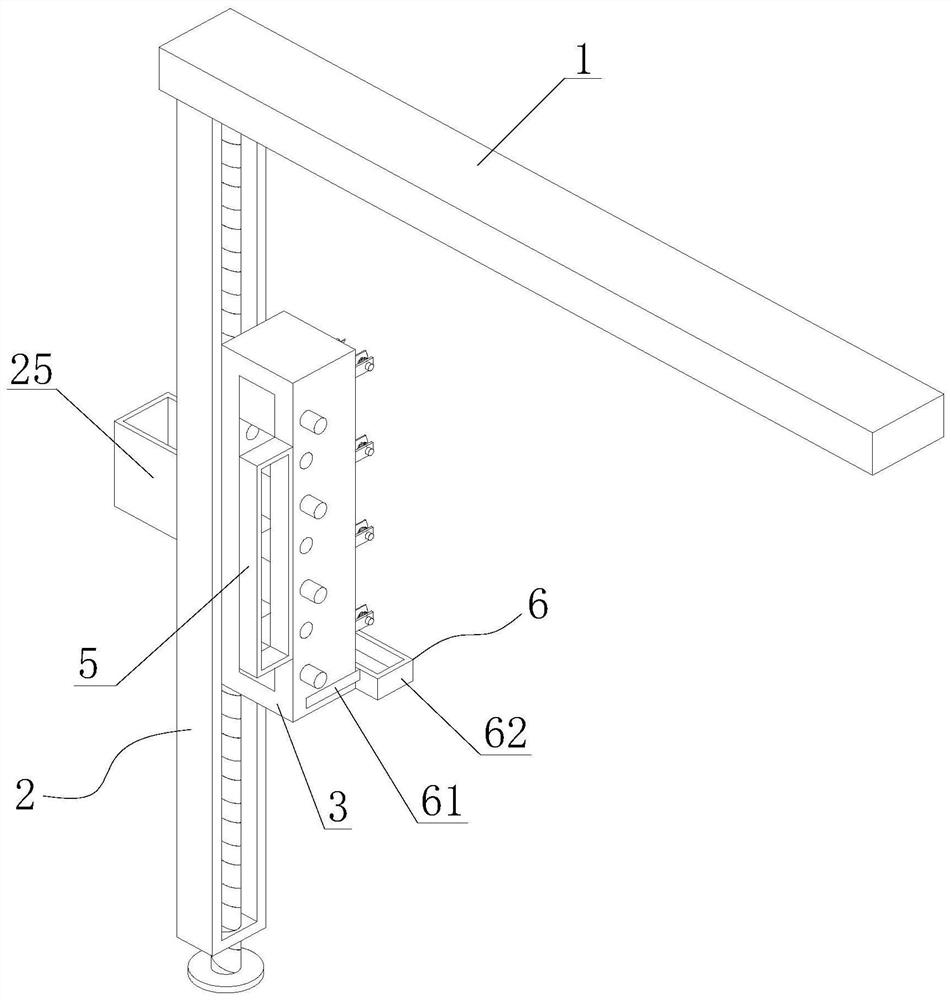

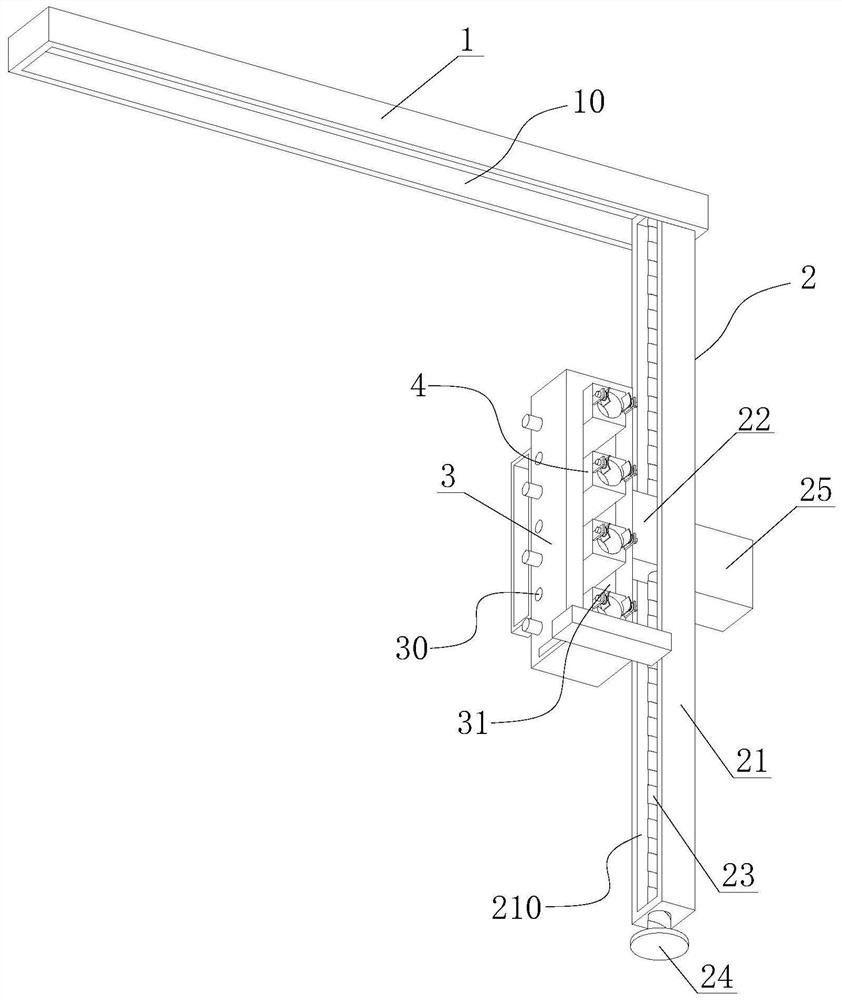

Rotary body positioning device and scribing method

PendingCN114434359AAddressing the easy-to-scroll featureEasy to draw linesWork holdersOther workshop equipmentEngineeringBody positions

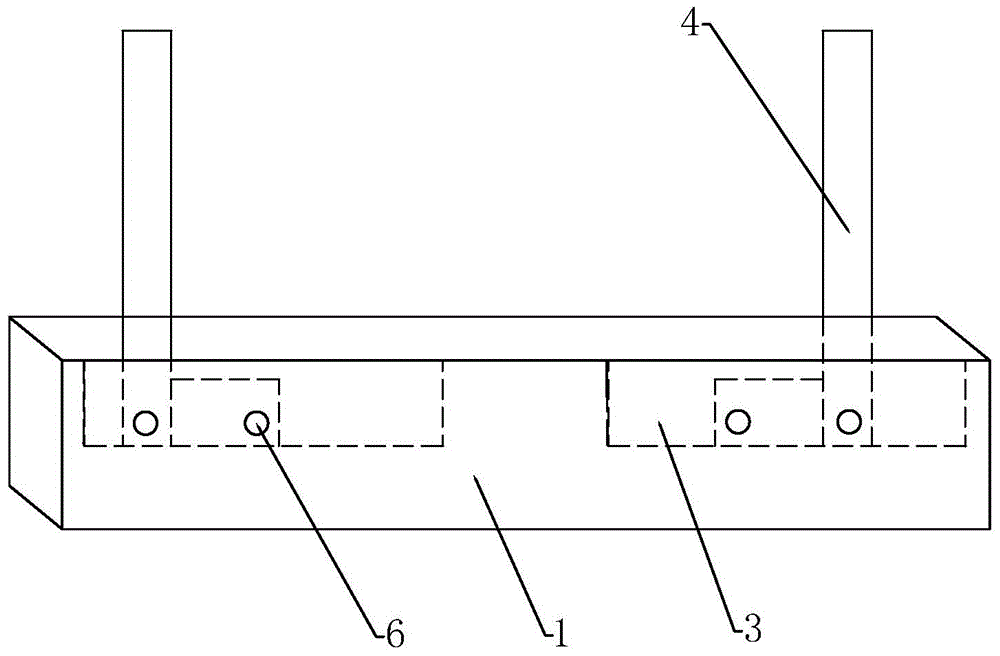

The invention discloses a rotary body positioning device and a scribing method. The rotary body positioning device comprises a first fixing block and a second fixing block which are used for fixing a rotary body. A first square with the diameter of the rotary body as the side length is marked on the first fixing block, and a second square with the diameter of the rotary body as the side length is marked on the second fixing block. One end of the rotary body is welded with the first square, and the other end of the rotary body is welded with the second square; the edge of one end of the revolved body is tangent to the first square, and the edge of the other end of the revolved body is tangent to the second square; the first square is parallel to the second square. The rotary body can be fixed through the rotary body positioning device, the problem that the rotary body is prone to rolling is solved, and scribing operation is facilitated; after the rotary body is positioned, the angle, needing to be marked, of the positioned rotary body is converted into the height; and according to the converted height, scribing is performed on the positioned rotary body through a height gauge. The method can be used for quickly aligning and scribing, simplifying the measurement process and realizing the aim of quickly scribing.

Owner:SHANXI FENXI HEAVY IND

English scriber

The invention discloses an English scriber which comprises a transverse rail, a vertical frame, a mounting frame and multiple fixing assemblies. The vertical frame is slidably connected with the transverse rail; the mounting frame is slidably connected to the side edge of the vertical frame and provided with multiple first threaded holes and containing grooves; the fixing assemblies comprise chalk sleeves, multiple connecting columns, multiple first springs, multiple clamping plates, multiple guide columns and fixing bolts; the chalk sleeves of the fixing assemblies are arranged in the containing grooves; the multiple connecting columns are fixedly connected to the side edges of the chalk sleeves respectively; the multiple first springs are fixedly connected to the side edges of the multiple connecting columns respectively; the multiple clamping plates are fixedly connected to the side edges of the multiple first springs correspondingly; and the fixing bolts are in threaded connection with the mounting frame and the connecting columns correspondingly. During use, chalks are placed in the multiple chalk sleeves respectively, the clamping plates are pushed to fix the chalks through the return thrust of the first springs, and then the mounting frame is transversely pulled to enable the multiple chalks to move along the surface of the blackboard, so that four-line grids can be drawn quickly, and the line drawing time is saved.

Owner:TONGREN UNIV

Floor marking mechanism for construction engineering

InactiveCN104563510AQuick dashExtended service lifeBuilding material handlingArchitectural engineeringBuilding construction

The invention discloses a floor marking mechanism for construction engineering, and relates to the technical field of construction engineering. Traveling wheels are arranged at the bottom part of a framework, a liquid containing box I and a liquid containing box II are respectively arranged on the framework, a push handle is arranged at the right upper end of the framework, two heaters are respectively arranged in the liquid containing box I and the liquid containing box II, a rotary motor is arranged at the bottom end of the interior of the framework, a cleaning head is arranged on a rotary shaft of the rotary motor, an intelligent controller and a conveying pump are respectively arranged in the framework, a mounting plate is arranged at the back end of the framework, a spring is arranged at the bottom part of the mounting plate, a marking device is arranged at the lower end of the spring, anti-collision wheels are respectively arranged at the two ends of the bottom part of a casing of the marking device, one end of the conveying pump is respectively connected with the liquid containing box I and the liquid containing box II, and the other end of the conveying pump is connected with the marking device. The floor marking mechanism has the advantages that the quick marking is conveniently realized, the service life is prolonged, the operation is simple and convenient, and the working efficiency is high.

Owner:HENAN GAODUAN FLOOR ENG

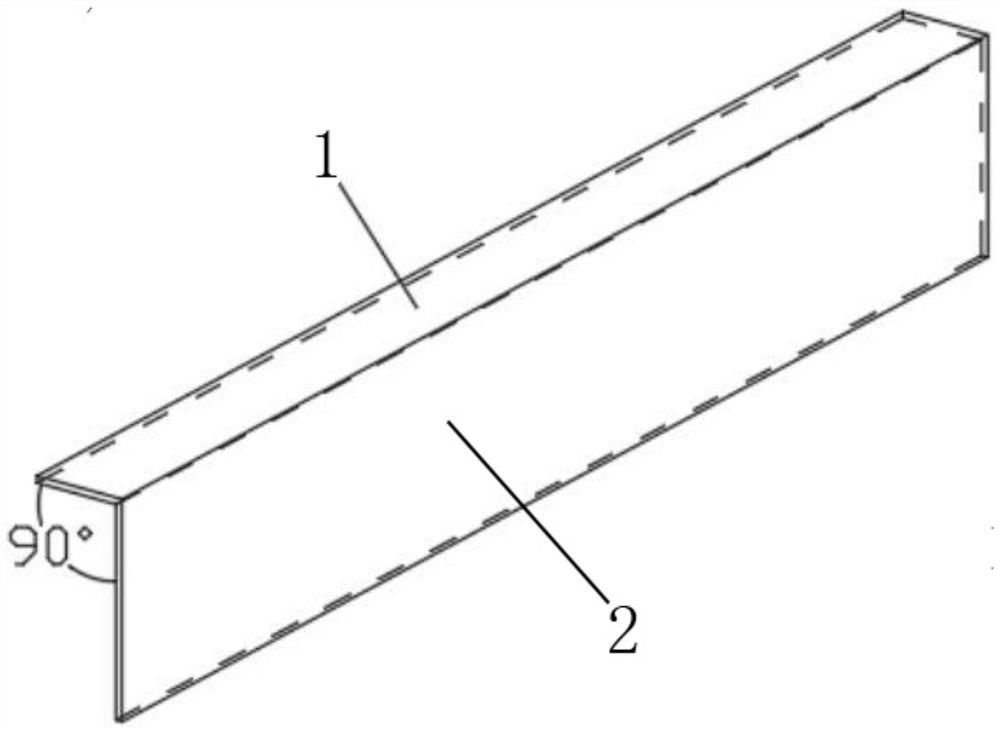

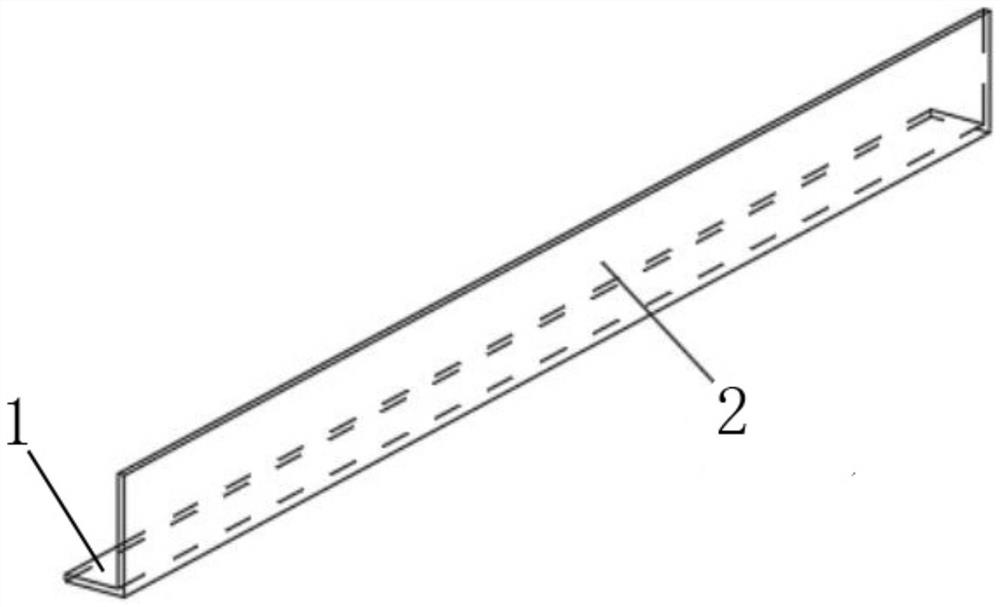

Auxiliary device and auxiliary method for scribing before beveling of steel plate

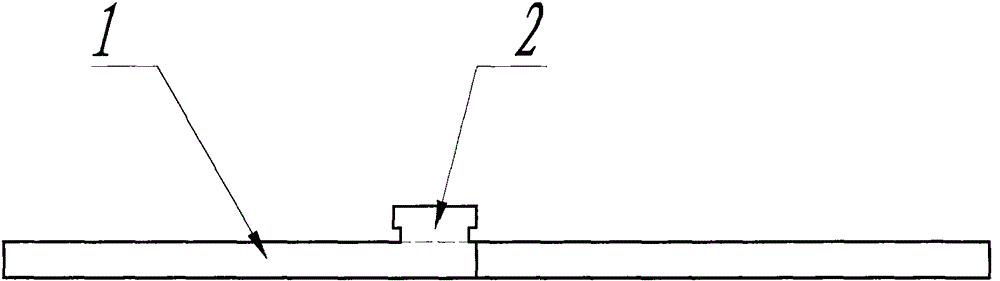

The invention discloses and provides an auxiliary device and an auxiliary method for scribing before steel plate beveling. The technical problem that in the prior art, the steel plate beveling error is large, and consequently the welding seam quality is not ideal is solved. The auxiliary device comprises a plate A and a plate B which are of an integrated structure, the long edge of the outer side of the plate A coincides with the groove line on the top surface of the steel plate, and the long edge of the outer side of the plate B coincides with the groove line on the thickness surface of the steel plate. According to the auxiliary method, a plate A, a plate B, a plate C and a plate D are machined to be attached to cutting lines according to the positions of the groove cutting lines, the surface of a base metal steel plate is cleaned up, the auxiliary device is arranged in the thickness direction of the steel plate to be closely attached, and the slate pencil and the auxiliary device are moved in the length direction of the steel plate to obtain the positions of the two cutting lines; and repeating the operation to obtain all required cutting line positions, and then using a flame cutting machine to align to the cutting lines for cutting. The device is formed by bending and processing the color steel tile, is used for quickly and conveniently grooving and scribing the steel plate, improves the working efficiency, is simple and practical, and ensures the grooving quality of the steel plate.

Owner:中冶西部钢构有限公司

Marking device for pedestrian protection test

ActiveCN102463570BMeet the needs of protection markingQuick dashOther workshop equipmentSimulationComputer aid

The invention relates to the technical field of a vehicle safety test, in particular to a marking device for a pedestrian protection test, solving problems that various technical index lines such as required reference lines of the front edge of an engine hood can be marked rapidly and accurately in a test of protecting pedestrians from automobile collision, wherein the rapid marking is realized and the marking precision is ensured by combining the computer-aided marking and the actual vehicle point-stroking; the rapid marking is realized and the marking precision is ensured, and moreover, the marking results can be stored in a computer for later check and use.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

A tooling fixture for intelligent carbon skateboard scribing and its operation method

ActiveCN111055258BImprove free switchingImprove marking efficiencyWork holdersOther workshop equipmentSlide plateProcessing cost

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

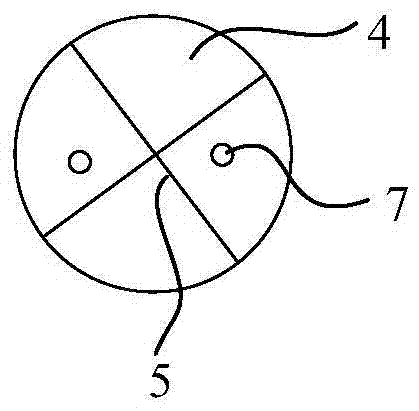

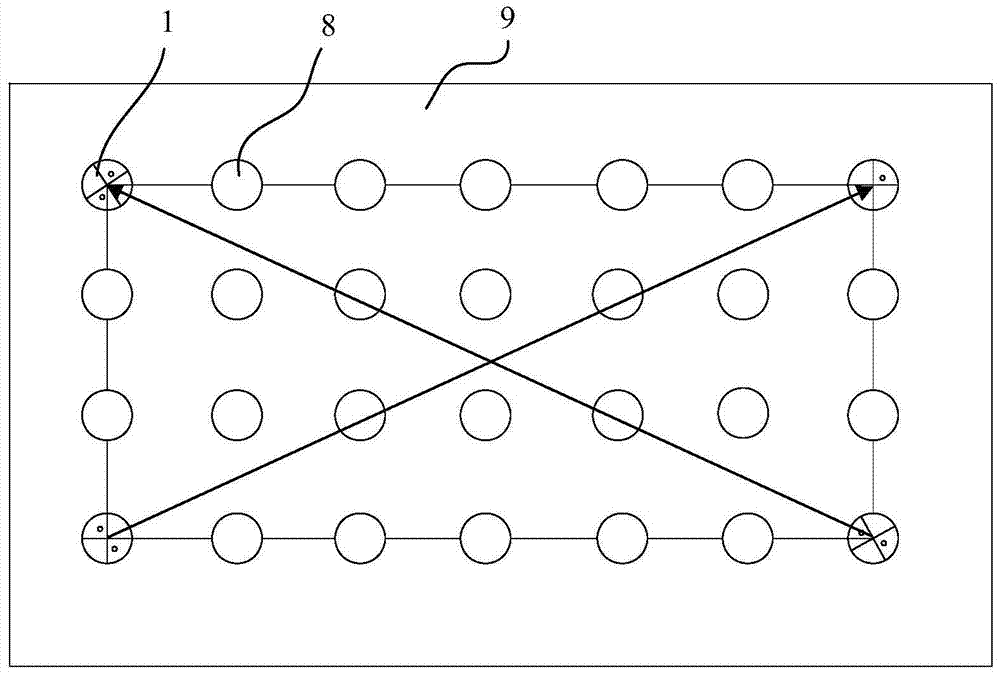

Hole centre rapid marking-positioning device and hole centre bias check method

ActiveCN105290884ADetermine the offset distanceEasy to insertMeasurement/indication equipmentsEngineeringPolyurethane

The invention discloses a hole centre rapid marking-positioning device and a hole centre bias check method, and relates to the technical field of hole centre marking. The hole centre rapid marking-positioning device comprises polyurethane round rods capable of inserting in holes, wherein the outer diameter of each polyurethane round rod is greater than the diameter of the corresponding hole; grooves are formed in the sidewall of each polyurethane round rod; and cross lines with an intersection point which passes through the circle centre of the upper end surface are engraved on the upper end surface of each polyurethane round rod. The invention further discloses a hole centre bias check method, and said hole centre check device is used for check. The hole centre rapid marking-positioning device and the hole centre bias check method, which are disclosed by the invention, are capable of realizing rapid marking-positioning for hole centres, capable of conveniently and rapidly detecting whether the hole centres are biased or not, high in detection accuracy, and suitable for being applied in various construction fields.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

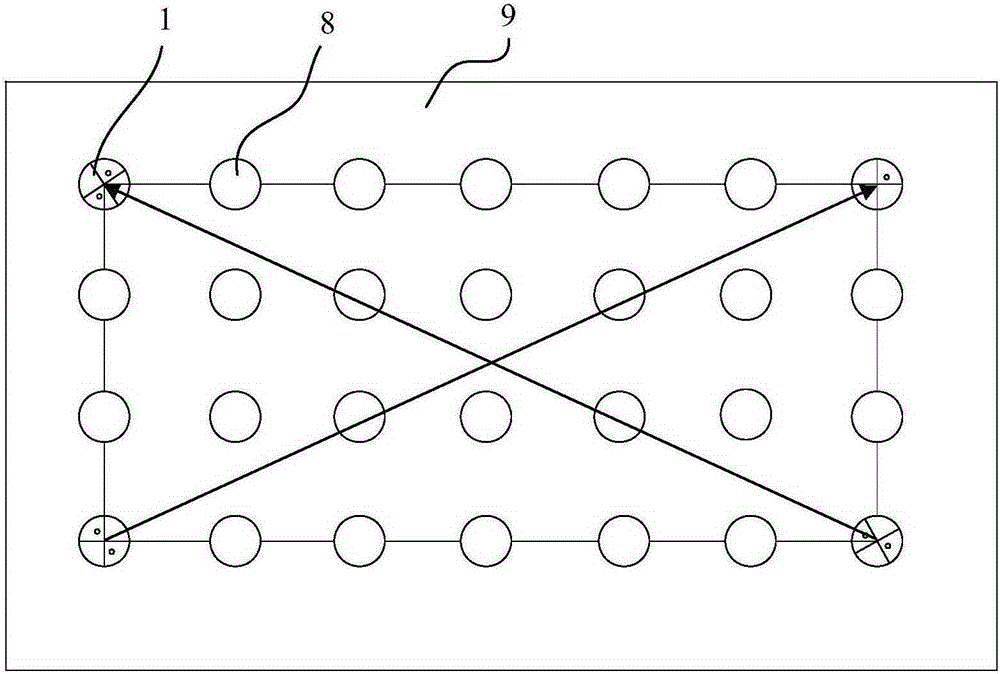

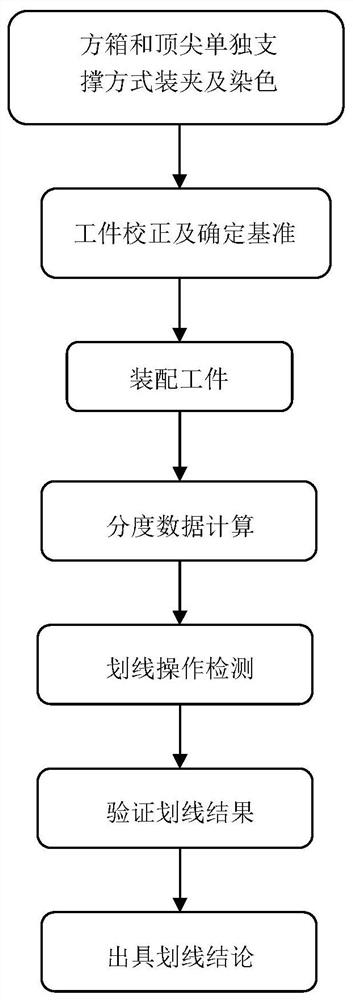

Round and multi-angle shape forge piece lineation inspection method

PendingCN112797863AOvercoming complexityOvercome operabilityMechanical measuring arrangementsIndustrial engineeringIndexing head

The invention relates to the field of outline dimension lineation detection of aluminum and aluminum alloy die forgings, and magnesium and magnesium alloy die forgings, in particular to a lineation inspection method for round and multi-angle outline forgings. The method comprises the following steps of: calculating all indexing data according to a universal indexing head during indexing calculation, and recording the number of revolutions of a required handle, and sequentially rotating the handle to a required degree, calculating according to the shaking turns of the handle of the universal dividing head, the equal score of the dividing head and the equal score of the workpiece, and drawing a required dimension line by using a height gauge. According to the invention, the method thoroughly changes the original method for checking such forgings by scribing, and effectively overcomes the complicated and cumbersome operation; some auxiliary accessories are designed and processed by using the original idle equipment, so that the cost investment is low, and the effect is quick; and the checking method for forgings with similar shapes is developed and extends, under the state that the workshop quality inspection task is heavy and the requirement is high, the lineation task of the die forgings of various specifications is completed, and a user identifies and accepts the inspection result.

Owner:NORTHEAST LIGHT ALLOY CO LTD

A Method for Checking Hole Center Offset

ActiveCN105290884BDetermine the offset distanceEasy to insertMeasurement/indication equipmentsEngineeringBuilding construction

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

A general device for cylinder marking

ActiveCN106181952BQuick dashSolve complex and cumbersomeOther workshop equipmentGeneral purposeEngineering

Owner:山东豪迈重工有限公司

A three-dimensional scribing process for group holes of steel truss members

ActiveCN105522555BReduce in quantityHigh marking accuracyOther workshop equipmentDisplay deviceEngineering

The invention relates to a three-dimensional marking process for group holes of a steel truss bar. The process comprises the following steps: on a working platform of a three-dimensional marking machine, using a jack and a bar manufacturing center line to horizontally adjust the steel truss bar, and checking the coordinate system of a left marking measuring arm and a right marking measuring arm; then respectively operating the measuring arms to control handles according to a drawing size, moving on three coordinate directions of an X axis, a Y axis and a Z axis by utilizing the real-time numerical values of a three-axis digital displayer of the marking machine, and carrying out marking operation by utilizing marking needles at the end parts of the measuring arms. The process has the advantages that the process firstly introduces the three-dimensional marking machine to work in the marking line manufacturing work of the steel truss bar, adopts mechanized construction and utilizes high-precision three-dimensional marking machine to control the marking line precision, so that the marking line precision is high, and the degree of mechanization is high; the number of the needed operating persons is less; only one to two operating persons are needed, and the fast and efficient making can be realized.

Owner:SHANGHAI ZHENHUA HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com