Round and multi-angle shape forge piece lineation inspection method

An inspection method and multi-angle technology, applied in measuring devices, instruments, and mechanical devices, etc., to achieve the effects of low cost investment, reduced error accumulation, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

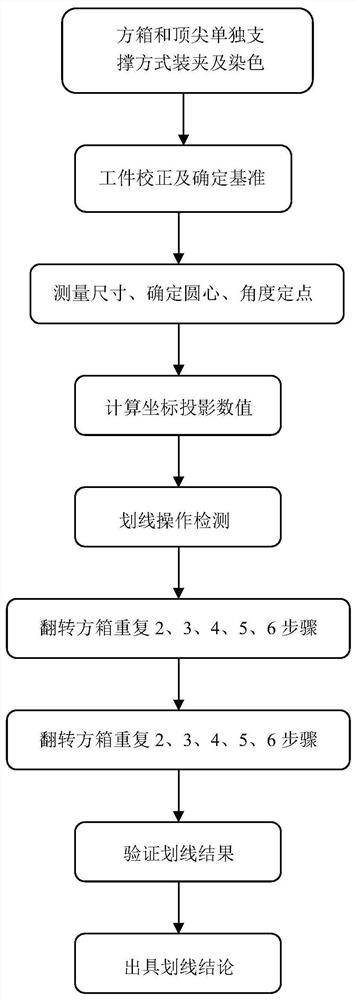

[0048] Specific embodiment 1: A method for inspecting marking lines of round and multi-angle shape forgings, which includes the following steps:

[0049] Step 1: Grind and burr the forgings that meet the marking requirements, paint the forgings with colored dye liquid, clamp the forgings by combining the square box and the top or by using the top alone, and fix the forgings on the marking inspection platform superior;

[0050] Step 2: Calibrate and level the workpiece with a height gauge, and draw a reference line on the forging according to the drawing;

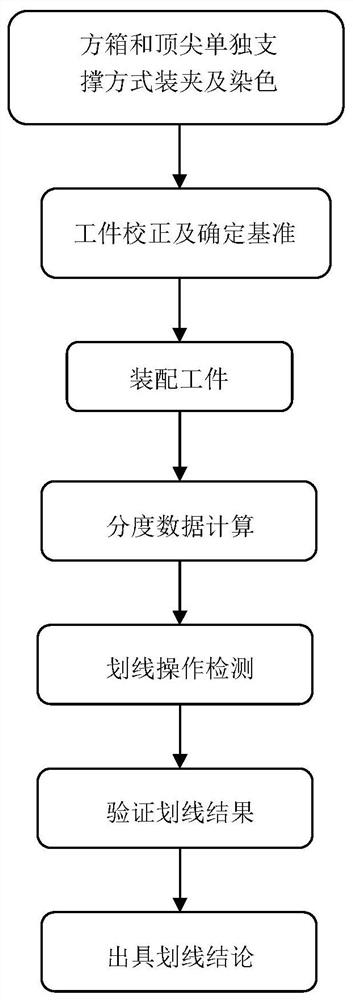

[0051] Step 3: Fix the workpiece on the universal indexing head on the platform with the inner and outer jaws of the workpiece shape. When the jaws cannot be assembled, punch the center of the workpiece and assemble it with a special assembly axis;

[0052] Step 4: Calculate all the indexing data according to the universal indexing head used, and record the number of revolutions of the required handle;

[0053] Step 5: Rotat...

specific Embodiment approach 2

[0057] Specific embodiment two: the colored dye in the step one is gentian violet dye.

[0058] Other implementation manners are the same as the specific implementation manner 1.

[0059] Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0060] Embodiment 3: The reference line in step 2 includes a height reference line, a circle center and a dimension line.

[0061] Other implementation manners are the same as the specific implementation manner 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com