Auxiliary device and auxiliary method for scribing before beveling of steel plate

An auxiliary device and beveling technology, which is applied to the field of scribing auxiliary devices before steel plate beveling, can solve the problems of unsatisfactory weld quality and large steel plate beveling error, so as to ensure the quality of beveling and facilitate the marking. Lines, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

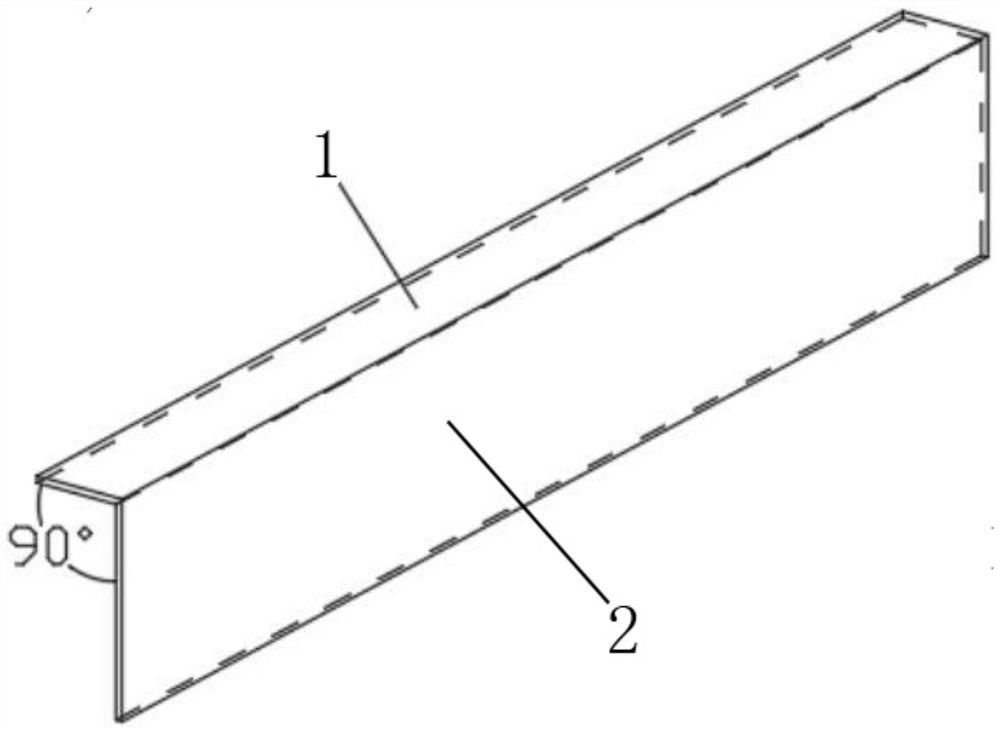

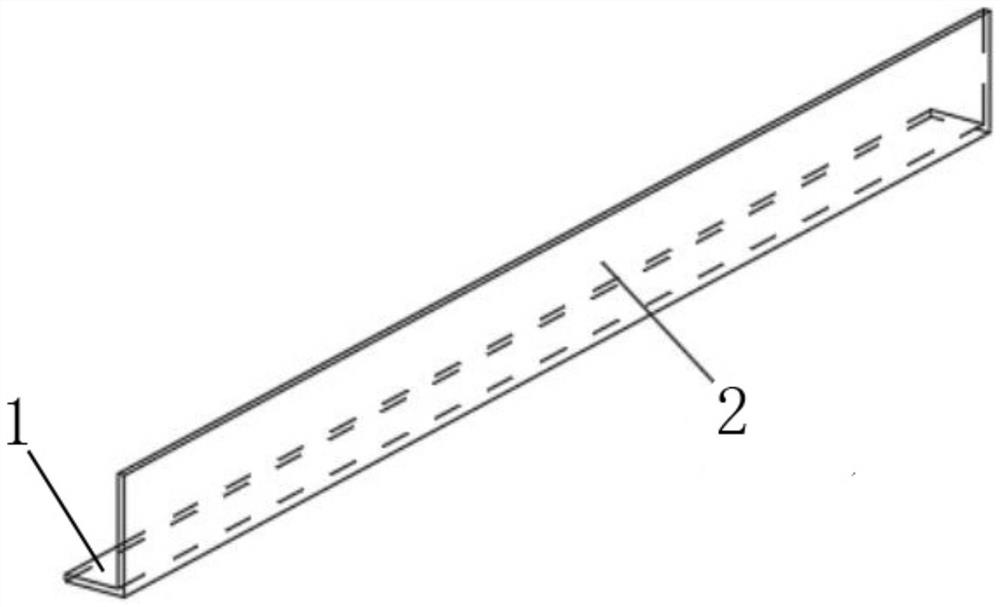

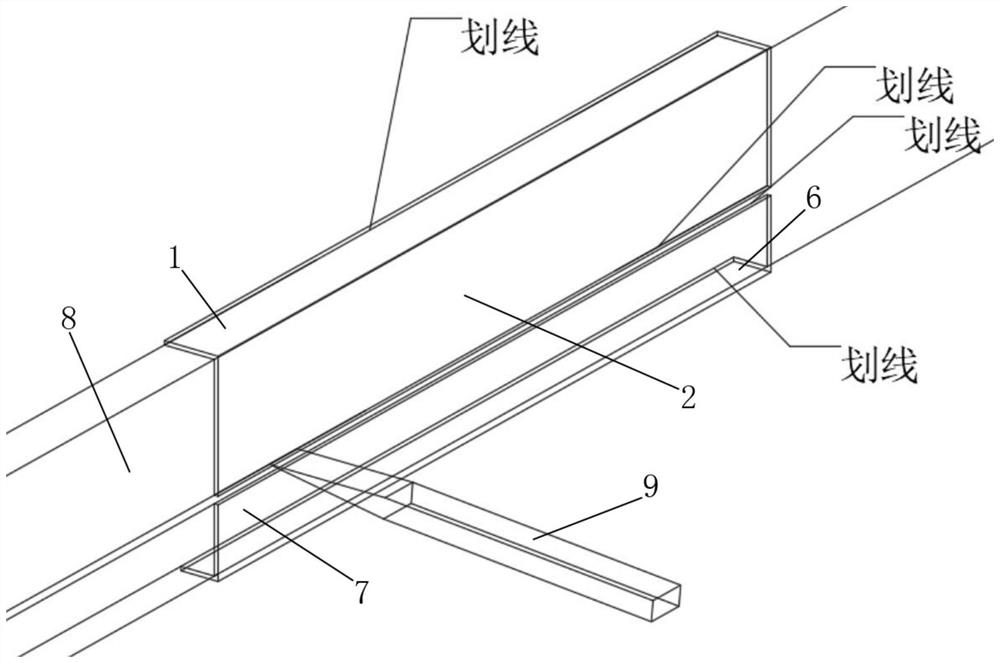

[0036] Example 1, as Figure 1-5 As shown, the present invention provides an auxiliary device for scribing before beveling of a steel plate, including a plate A1 for laminating the top surface 3 of the steel plate, and a plate B2 for laminating the thickness surface 4 of the steel plate, the plate A1 and the plate A1 B2 is a one-piece structure, the outer long side of the plate A1 coincides with the upper groove line on the top surface 3 of the steel plate, and the outer long side of the plate B2 coincides with the upper groove line on the thickness surface 4 of the steel plate.

[0037] The invention has the advantages of simple structure, scientific and reasonable design, and convenient use. , to ensure the quality of the steel plate beveling, further ensure the quality of the weld, used for fast and convenient scribing, improve work efficiency, simple and practical, with low material cost, simple and efficient use.

[0038] According to the groove angle required by the pro...

Embodiment 2

[0039] Example 2, as Figure 1-5 As shown, the present invention provides an auxiliary device for scribing before beveling of a steel plate, including a plate A1 for laminating the top surface 3 of the steel plate, and a plate B2 for laminating the thickness surface 4 of the steel plate, the plate A1 and the plate A1 B2 is a one-piece structure, the outer long side of the plate A1 coincides with the upper groove line on the top surface 3 of the steel plate, and the outer long side of the plate B2 coincides with the upper groove line on the thickness surface 4 of the steel plate. Plate A1 and plate B2 form an included angle of 90° with each other.

[0040] On the basis of Embodiment 1, this embodiment 2 provides a more preferred structure between the plate A1 and the plate B2, specifically: the plate A1 and the plate B2 form an included angle of 90° with each other. This design can make the plate A1 and the plate B2 adhere more closely to the base metal steel plate, and ensure...

Embodiment 3

[0041] Example 3, as Figure 1-5 As shown, the present invention provides an auxiliary device for scribing before beveling of a steel plate, including a plate A1 for laminating the top surface 3 of the steel plate, and a plate B2 for laminating the thickness surface 4 of the steel plate, the plate A1 and the plate A1 B2 is a one-piece structure, the outer long side of the plate A1 coincides with the upper groove line on the top surface 3 of the steel plate, and the outer long side of the plate B2 coincides with the upper groove line on the thickness surface 4 of the steel plate. Plate A1 and plate B2 are formed by integral bending of color steel tiles.

[0042] On the basis of Embodiment 1, this embodiment 3 provides a more preferred structure of the plate A1 and the plate B2, specifically: the plate A1 and the plate B2 are integrally formed by bending color steel tiles. Such a design, easy to manufacture, and strong practicability. The device is formed by bending and proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com