Protective clothing structure for operation at high temperature and constructing method of protective clothing structure for operation at high temperature

A technology for high temperature operation and clothing, applied in clothing, protective clothing, clothing and other directions, can solve the problems of phase change material leakage, limited cooling protection range of protective clothing, etc. And the effect of moisture absorption and quick drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

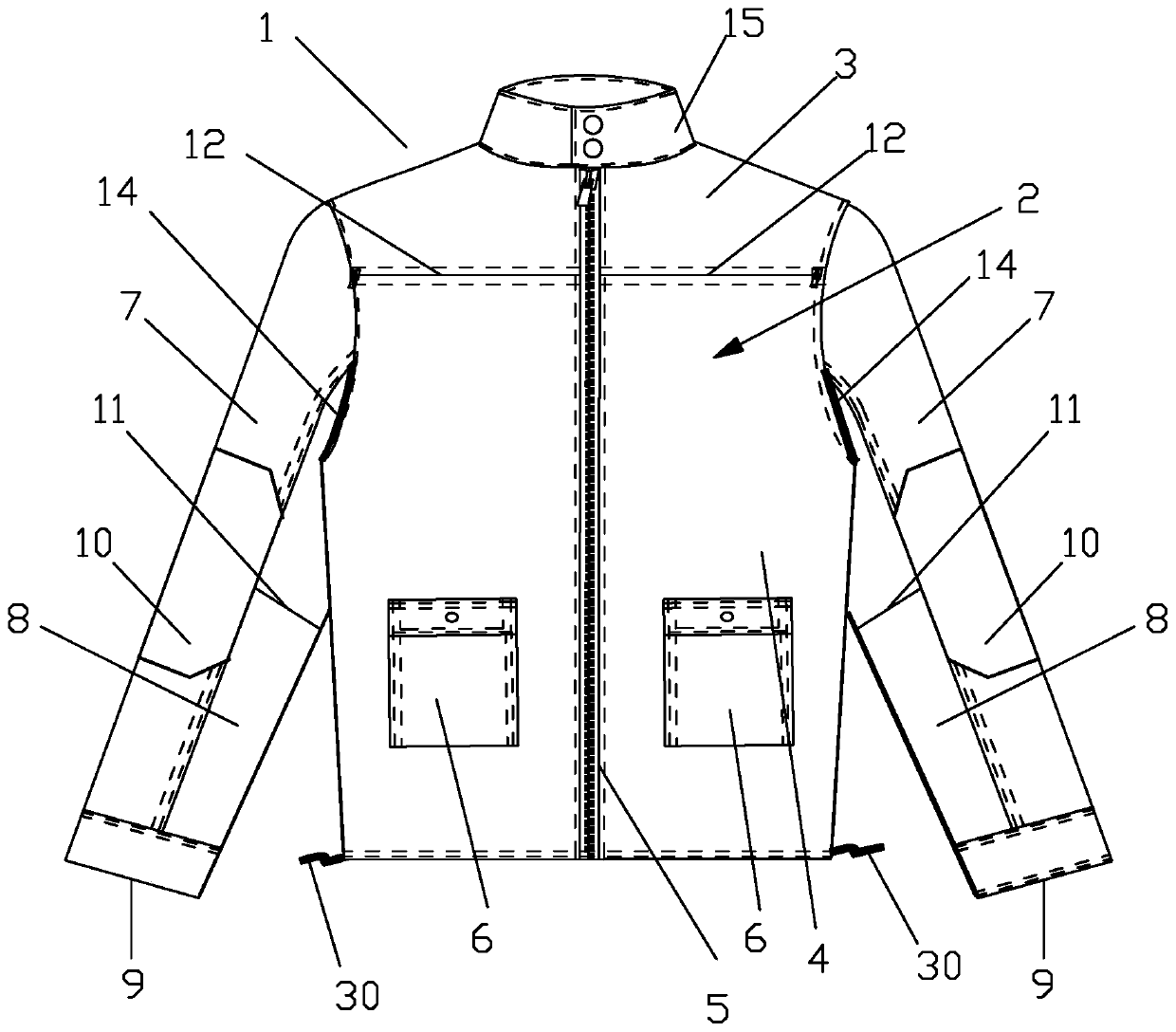

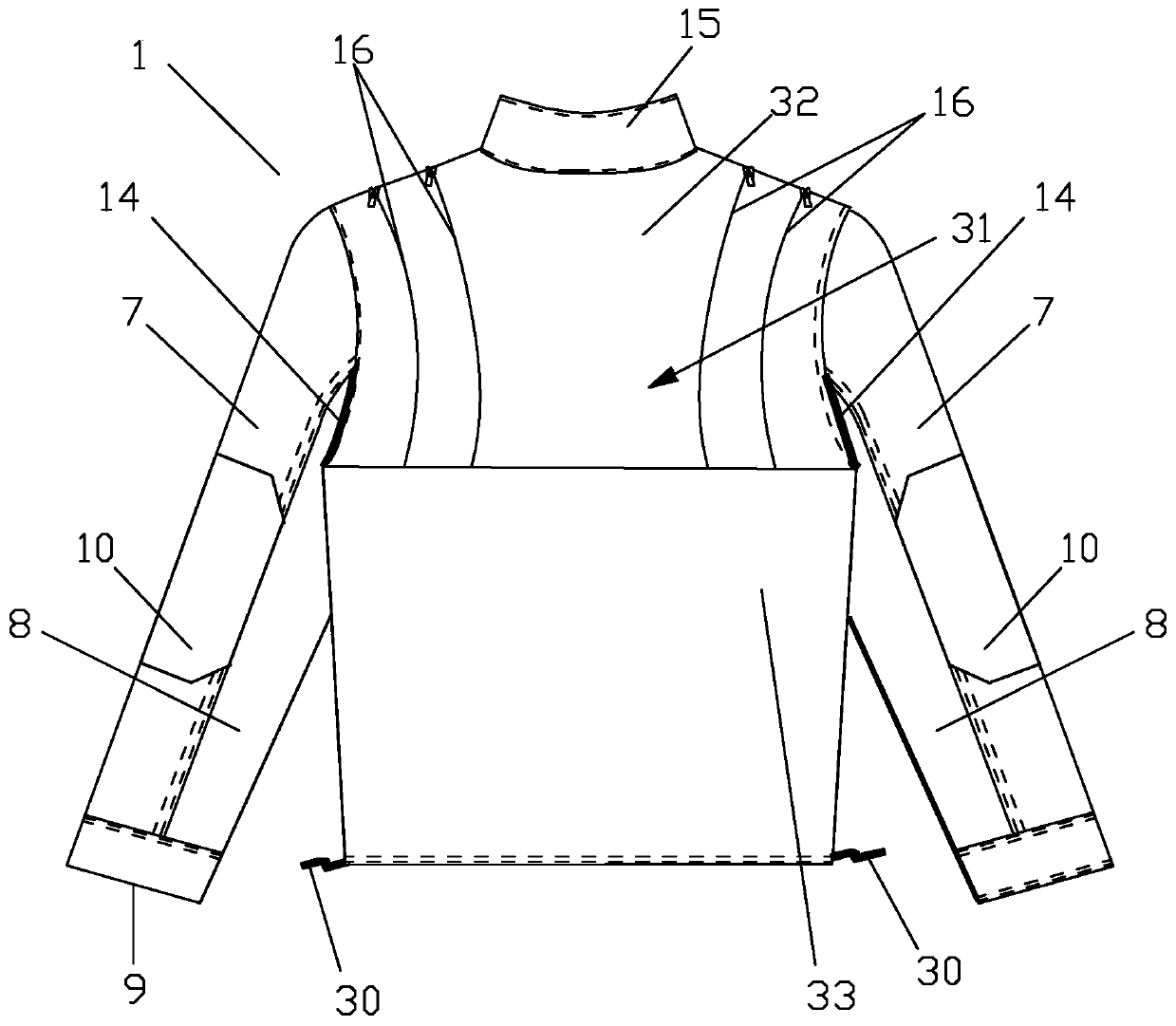

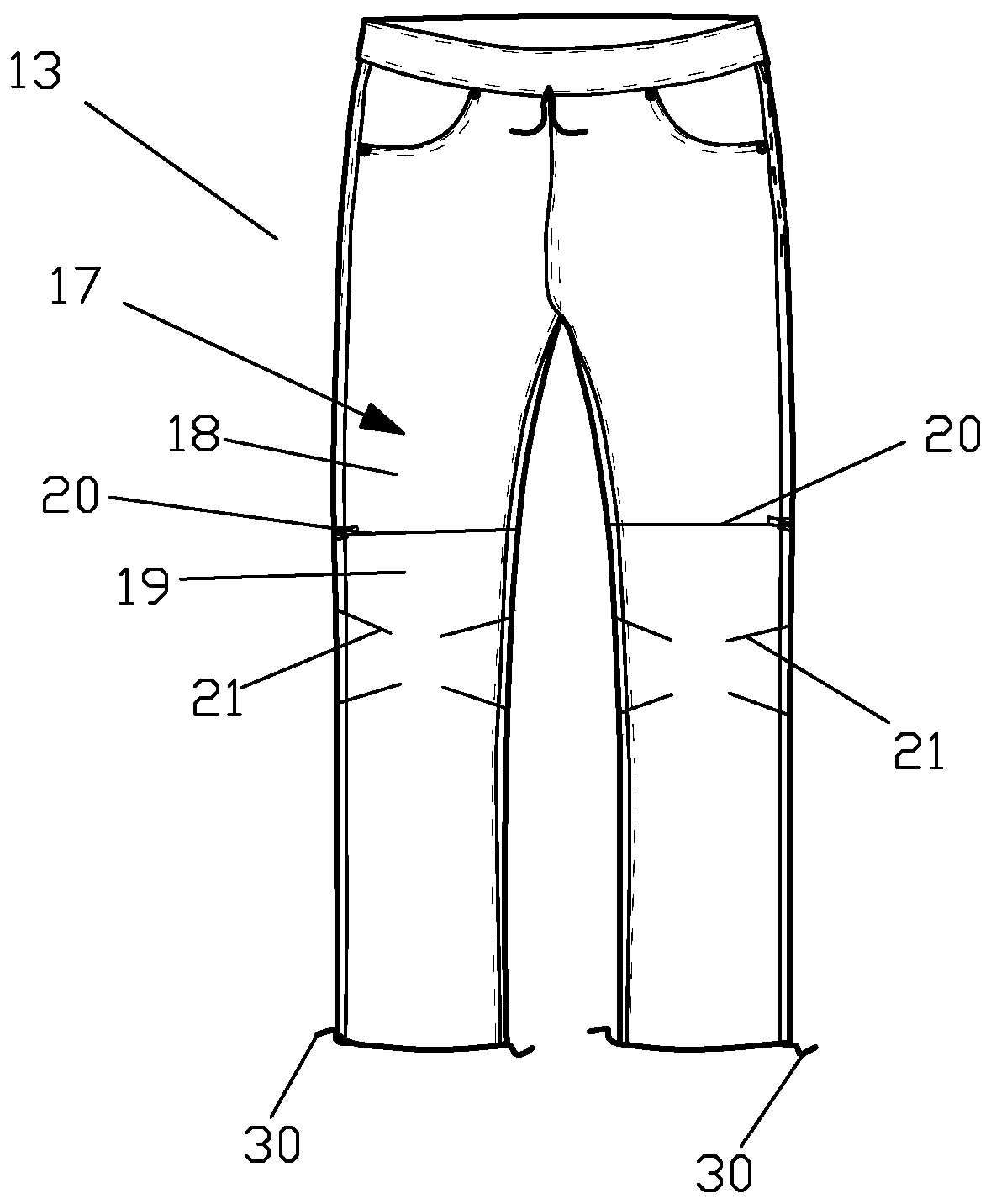

[0042] Such as Figure 1 to Figure 7 As shown, a protective clothing structure under high-temperature operation includes a top 1 and trousers 13. The top 1 includes a front garment 2, a rear garment 31, a collar 15, a large sleeve 7, a small sleeve 8 and cuffs 9 , the trousers 13 include a front trousers panel 17 and a rear trousers panel 22 . The collar 15 of the coat 1 is a stand-up collar, the bottom of the collar is larger than the collar circumference, and the collar height is increased to 6-8 cm, so as to reduce the high-temperature radiation of the neck and protect the neck, while avoiding that the collar height is too high to affect the neck movement. The middle position of front garment piece 2 is provided with jacket zipper 5, and jacket zipper 5 is convenient for the user to put on and take off the protective clothing top. The jacket zipper 5 is a rubber zipper, which is light in weight and poor in thermal conductivity. Front clothing piece 2 is also provided with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com