Ferry type all-purpose rhythm comprehensive assembly production line for assembly type components

A production line and assembly technology, which is applied in the field of the ferry-type universal beat integrated assembly-type component production line, can solve the problems of low production efficiency, low failure rate of the central ferry-type production line, and large influence of the production efficiency failure of the assembly line production line. To achieve the effect of simple structure, stable performance and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

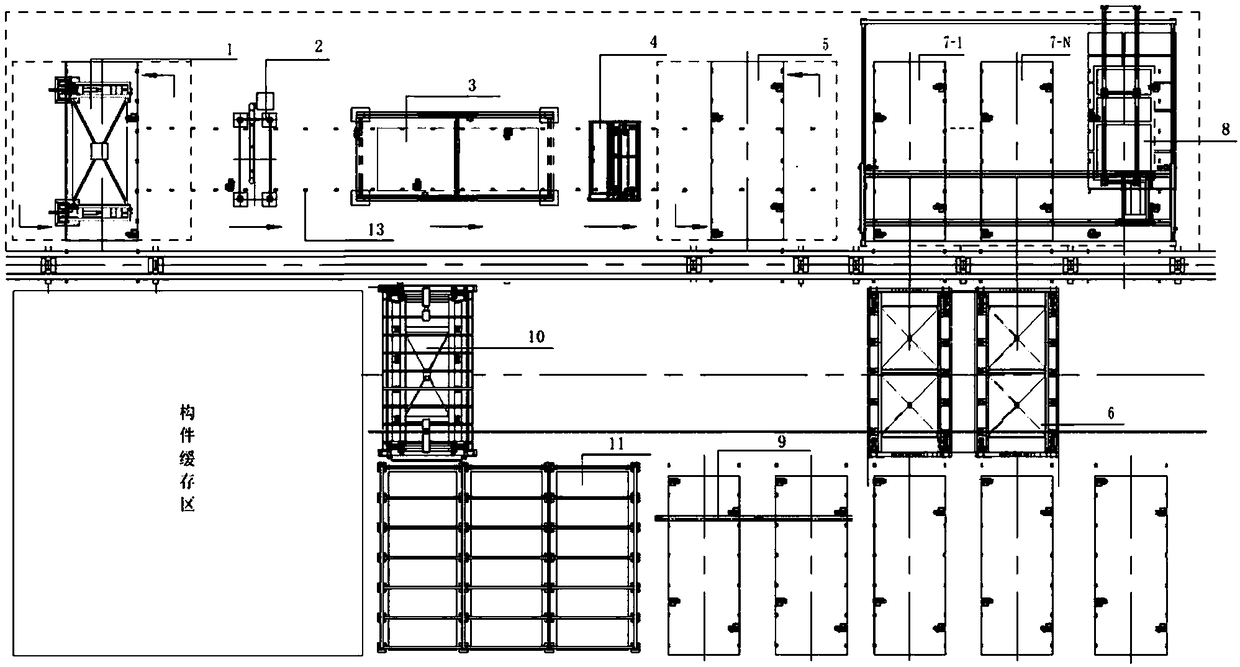

[0015] Such as figure 1 As shown in the figure, the ferry-type universal rhythm integrated flow assembly component production line is used for mold removal and has a hydraulic rotating device. The downstream of the turning machine 1 is connected to the assembly line stage through the drive wheel 13. The cleaning machine 2, the marking machine 3, and the spraying machine 4 on the wheel 13, the downstream of the spraying machine 4 is connected to the mold table 5 with a hydraulic rotating device through the driving wheel 13, and the mold table 5 is connected to the idle mold table through the rail-type ferry car 6 From station 7-1 to idle mold table station 7-n, carry out steel bar binding, formwork support, and retain embedded parts. The downstream of idle mold table station 7-n is the distributing machine 8, and the downstream of distributing machine 8 is the idle mold table worker in turn. position, the napping machine 9, and the napping machine 9 transports the components to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com