Machine vision-based automatic leather lineation method and apparatus

A technology of automatic scribing and machine vision, applied in instruments, image data processing, computing, etc., can solve problems such as slow speed, low precision, and difficult to meet the requirements of the process, and achieve the goal of fast speed, high precision, and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

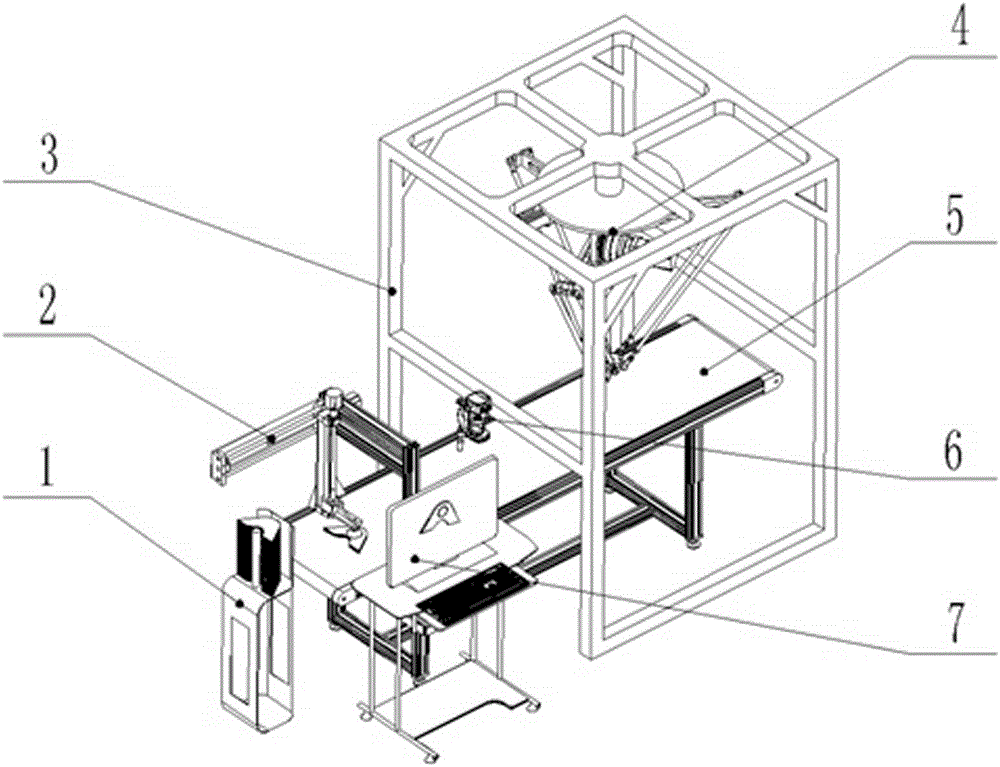

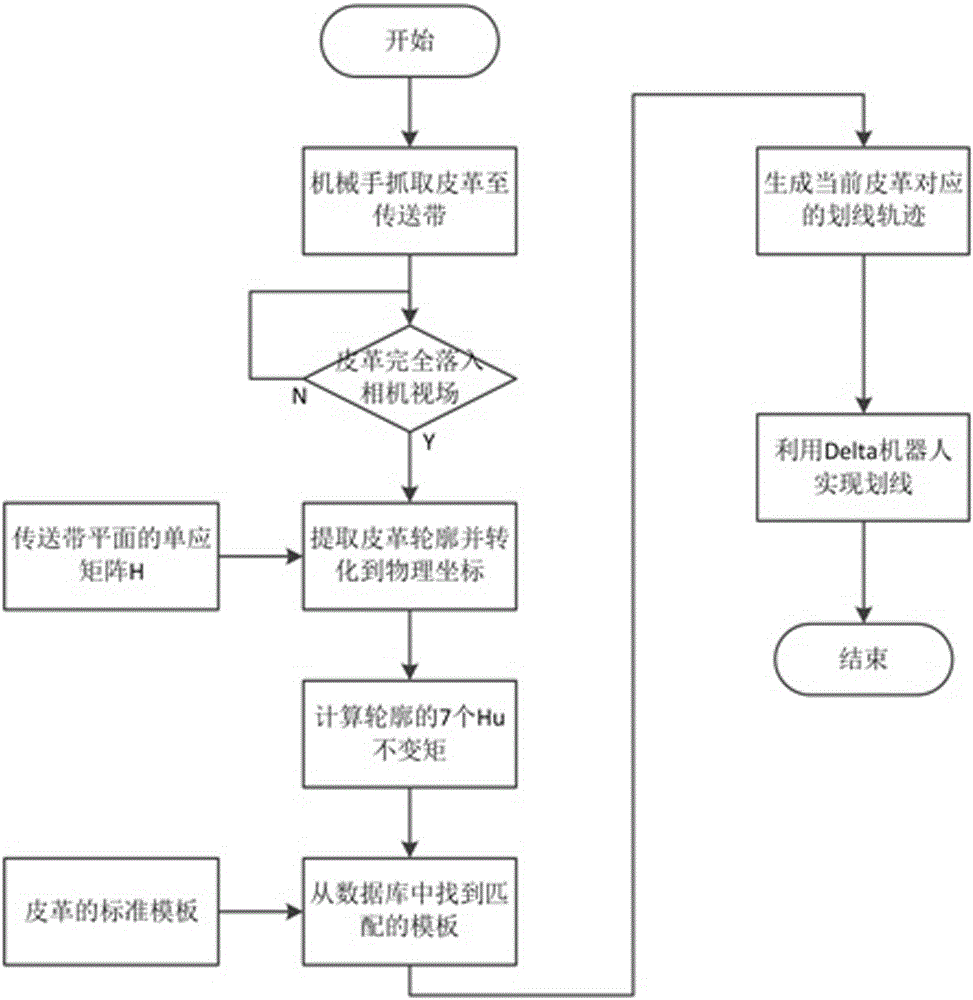

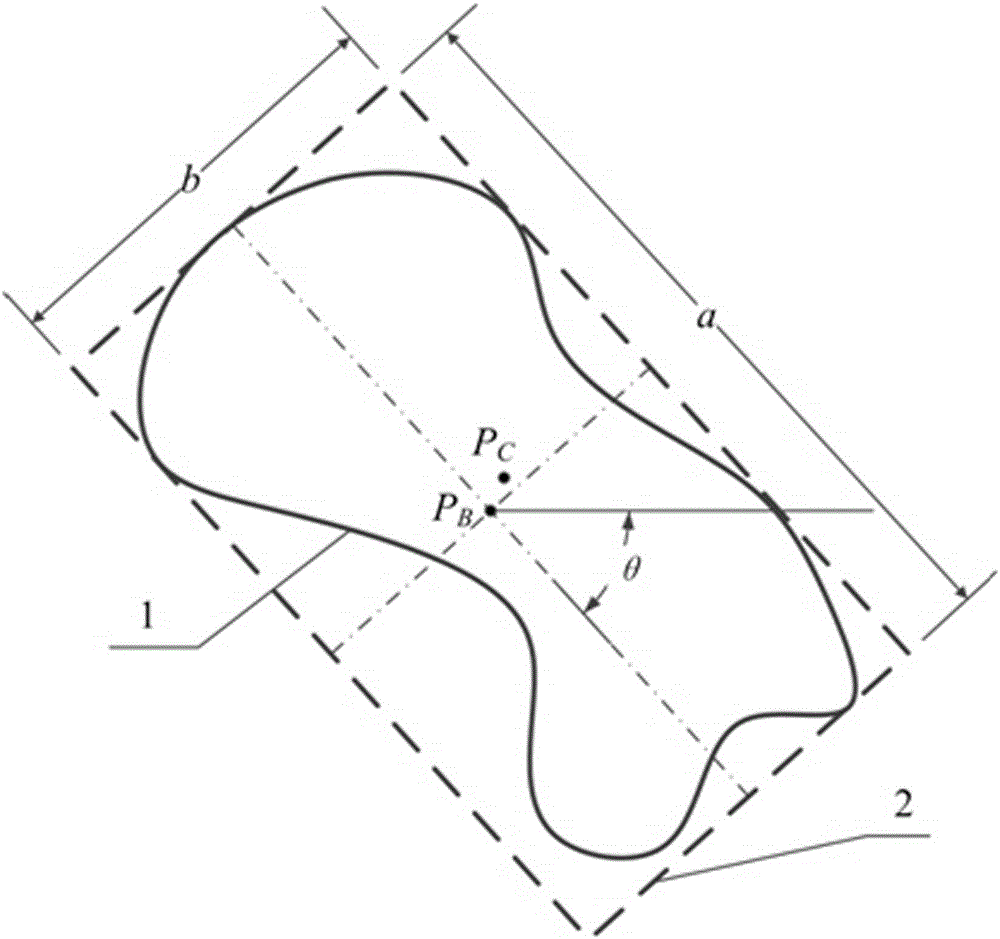

[0031] Such as figure 1 As shown, an embodiment of a leather automatic scribing device based on machine vision of the present invention includes a leather placing frame 1, a manipulator 2 with a suction cup at the end and movable in two degrees of freedom of up and down, left and right, a precision conveyor belt 5, Industrial camera 6, a Delta parallel robot 4 with a paintbrush at the end installed on the robot frame 3, and an industrial computer 7, the manipulator 2 grabs a single piece of leather from the leather placement rack 1 and places it on the left side of the precision conveyor belt 5, and the leather is transported to When the industrial camera 6 is below, the scribing trajectory of the corresponding leather is calculated through the image processing algorithm, and is used to control the Delta parallel robot 4 to realize the scribing of the leather. Its specific implementation method is as follows figure 2 Shown, a kind of method based on machine vision leather au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com