A Method for Checking Hole Center Offset

An inspection method and center-of-circle technology, applied in metal processing equipment, measuring/indicating equipment, metal processing mechanical parts, etc., can solve the problems of high requirements, long assembly time, waste, etc., and achieve the effect of low cost and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

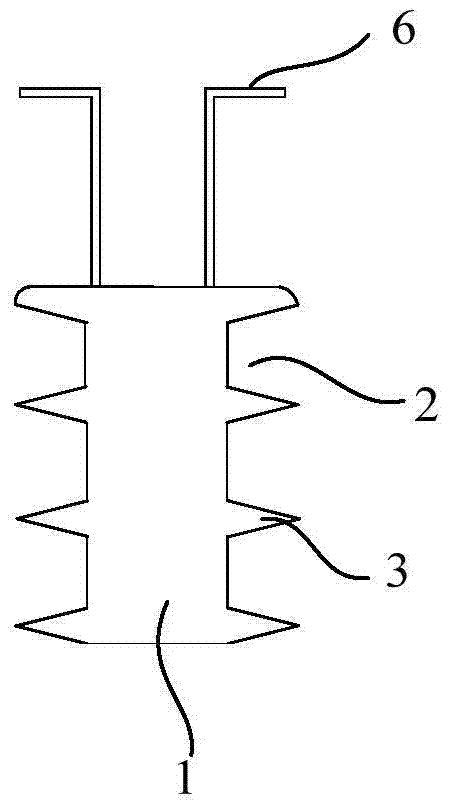

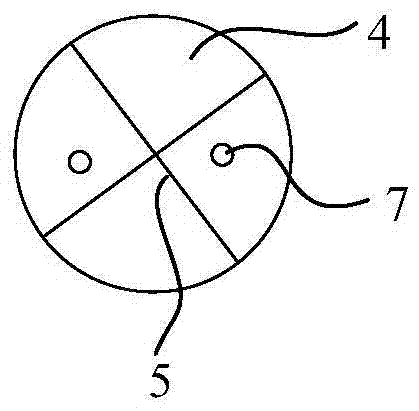

[0034] Such as figure 1 and 2 As shown, a fast marking and positioning device for the center of a hole includes a polyurethane round rod 1 that can be inserted into the hole 8. The outer diameter of the polyurethane round rod 1 is larger than the diameter of the hole 8, and the side wall of the polyurethane round rod 1 is provided with concave holes. Groove 2, because polyurethane material has flexibility, when inserting hole 8, even if the outer diameter of polyurethane round rod 1 is larger than the diameter of hole 8, under the situation that groove 2 exists, the side wall of polyurethane round rod 1 can realize deformation or Bending, so that the polyurethane round rod 1 can be inserted into the hole 8, and ensure a close fit with the hole 8. Specifically, the outer diameter of the polyurethane round rod 1 is 0-0.5mm larger than the diameter of the hole 8, which is easy to operate and has a good matching effect; The upper end surface 4 of the polyurethane round rod 1 is e...

Embodiment 2

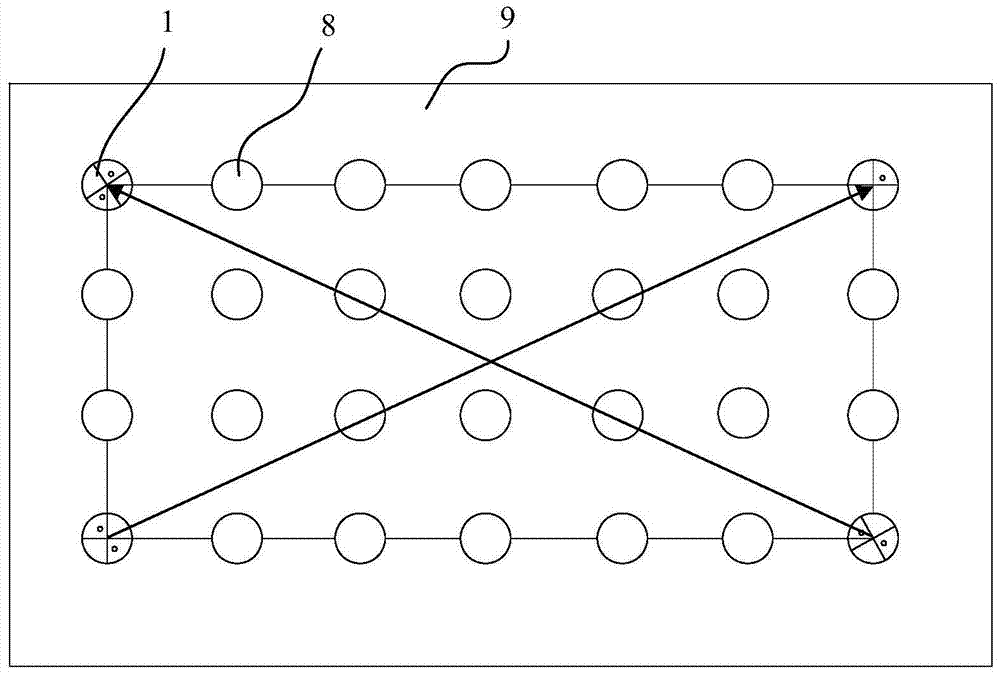

[0039] This embodiment protects a method for checking hole center offset, specifically using a hole center quick marking positioning device for checking, including the following steps,

[0040] Step 1, select at least two identical devices;

[0041] Step 2, inserting the devices into different holes 8 on the part 9 with holes, so that the upper end surface 4 of the device is flat with the surface of the part 9;

[0042] Step 3, according to the different arrangements of the holes 8, select the center of circle of the upper end surface 4 connected to the same row or the opposite device, and check whether the center of the hole on the same straight line as the two interconnected devices is offset;

[0043] Step 4, repairing the offset holes 8 to meet application requirements.

[0044] Further, in step 2, the specific arrangement of the device is not limited, it is only necessary to check whether the center of the hole is offset, specifically, as image 3 As shown, any two devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com