Round pipe end surface lineation machine

A scriber and end face technology, which is applied in the field of round pipe end face scribers, can solve the problems of cumbersome work and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

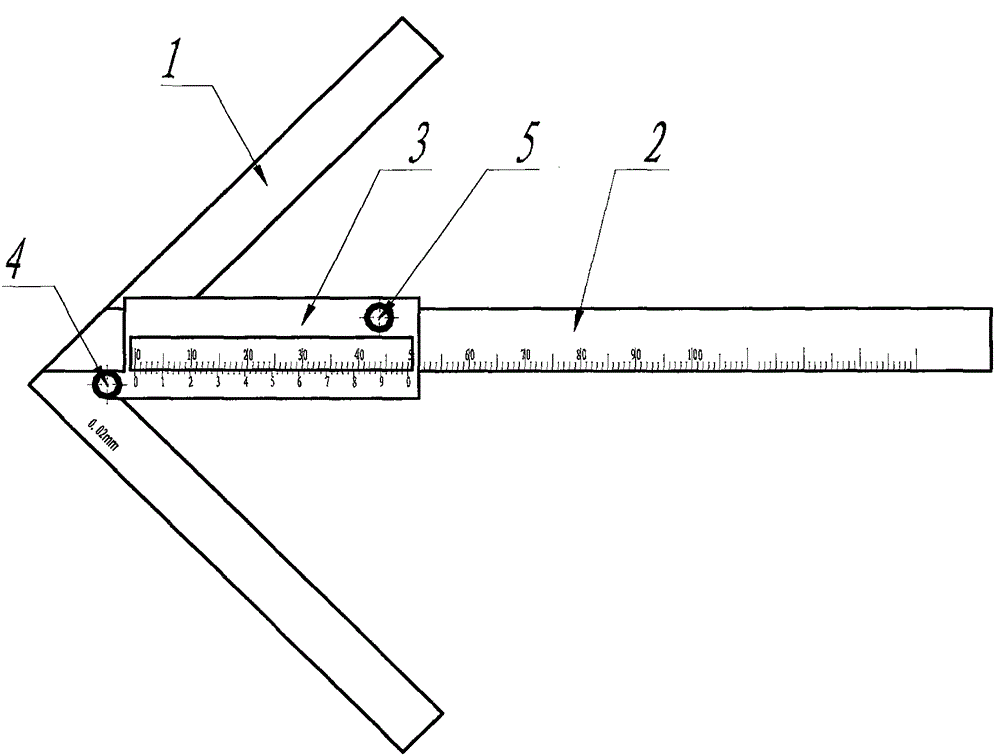

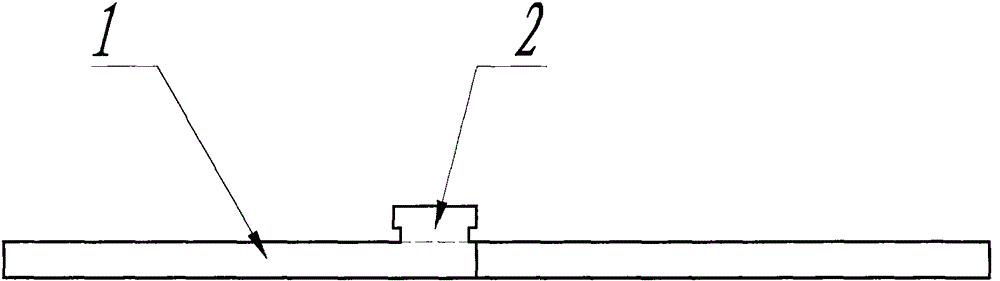

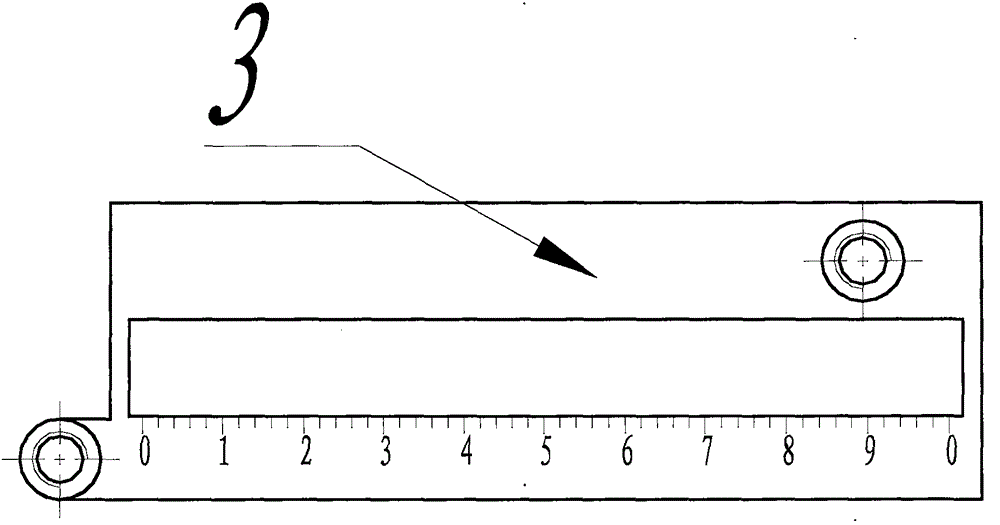

[0016] figure 1 and Figure 4 It can be seen that the present invention is made of turning plate 1, main ruler 2, auxiliary ruler 3, marking needle 4 and fastening screw 5. The main ruler 2 is fixed on the surface of the turning plate 1 and there is a scale in mm on the main ruler. The bisector of the angle is parallel; the main ruler 2 slides and fits with the T-shaped groove of the auxiliary ruler 3 with a T-shaped cross section. The auxiliary ruler 3 has a scale with a unit of 0.98mm and a window. The central line of the screw hole intersects the angle bisector of the turning plate 1; the auxiliary ruler 3 is threadedly connected with the marking needle 4; the fastening screw 5 is threaded with the auxiliary ruler 3 and then contacts the main ruler 2.

[0017] The working principle of the present invention is described in further detail below:

[0018] The basic principle of the present invention is: in an angle, the centers of all circles tangent to the two sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com