Key groove lineation method for making aligned tooth sample plate and used for helical gear with odd teeth

A technology of helical gears and templates, applied in manufacturing tools, workshop equipment, etc., can solve the problem of low accuracy of manual scribing, and achieve the effects of high scribing accuracy, simple production and accurate scribing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

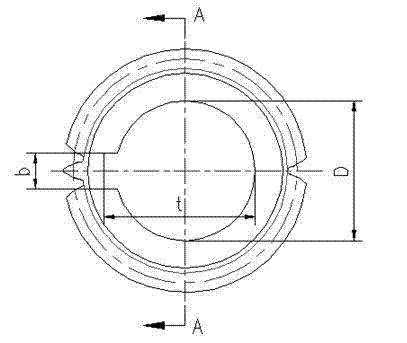

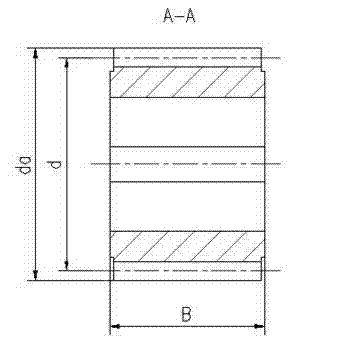

[0041] Taking the cylindrical involute helical gear XC240-9 in the 3500 steckel rolling mill as an example, the basic design parameters of the helical gear XC240-9 are shown in the table below (with Figure 1-2 The label code in the document shall prevail):

[0042] name code name value normal modulus mn 40 Number of teeth Z 27 Normal profile angle αn 25° Pitch circle helix angle β 12° spiral direction Right-handed Normal Variation Coefficient x 0.20446 Pitch circle diameter d 1104.128mm tooth width B 800mm

[0043] The design parameters of the helical gear XC240-9 keyway are: inner hole diameter D=690mm, keyway width b=177.8mm, keyway depth (including inner hole) t=744mm.

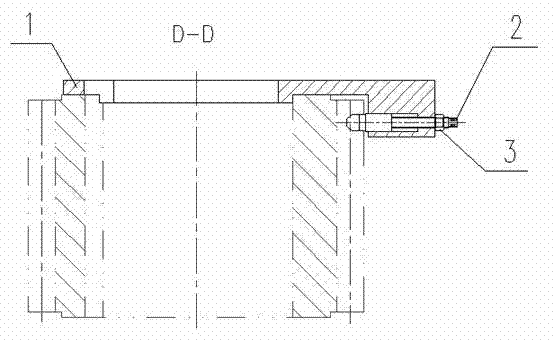

[0044] combine Figure 3-4 , the tooth template is composed of a template body 1, a ball head moving rod 2 and a nut 3, and a stepped through hole is arranged in the lower end boss on the right side of the template body 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com