Intelligent tooling fixture for scribing carbon contact strip and operation method of tooling fixture

A technology of tooling fixtures and carbon skateboards, which is applied in the direction of manufacturing tools, workpiece clamping devices, workshop equipment, etc., can solve problems such as inaccurate and inconvenient straight lines, affect marking efficiency, and increase processing costs, so as to improve marking efficiency and precision, accurate scribing, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

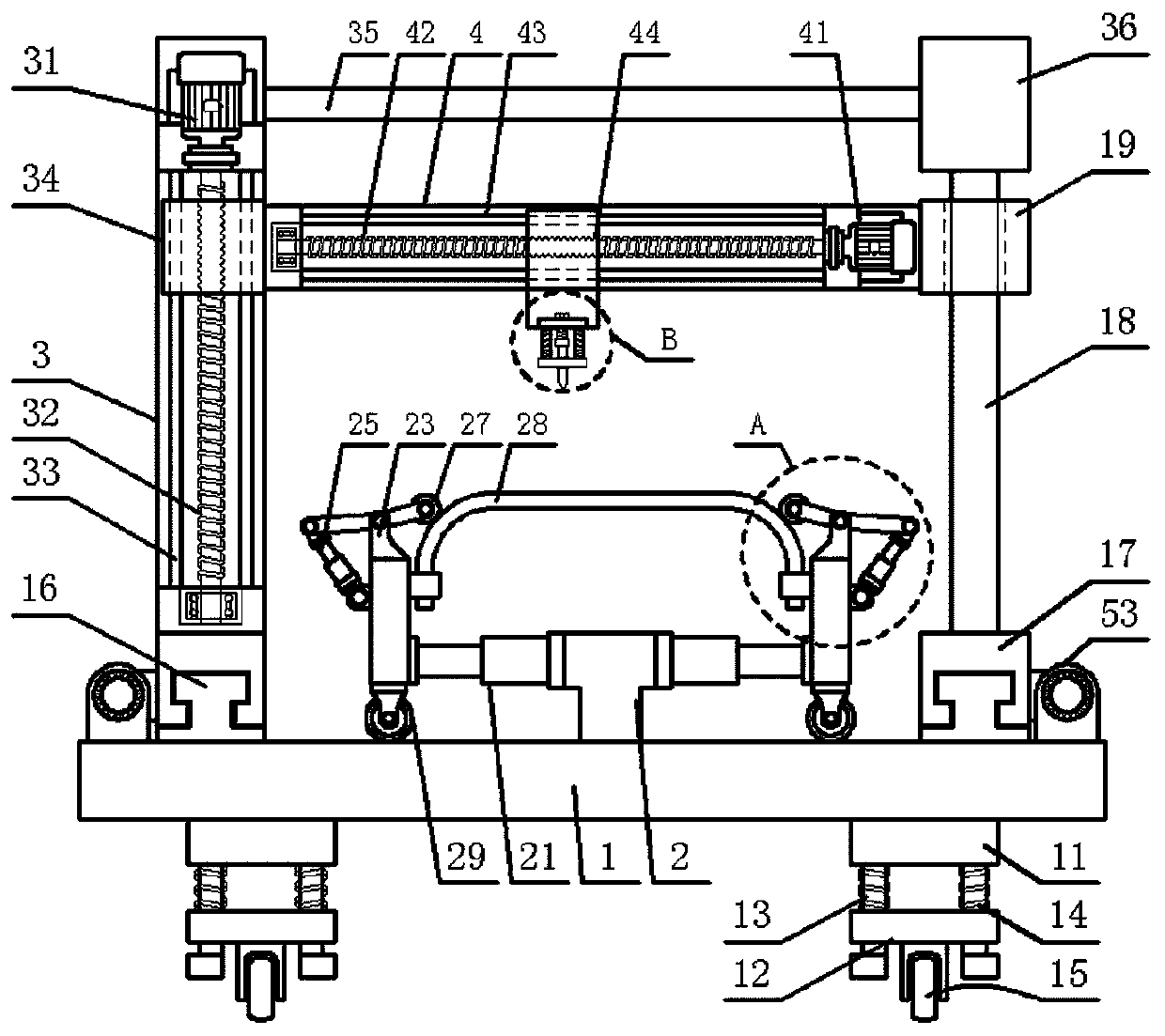

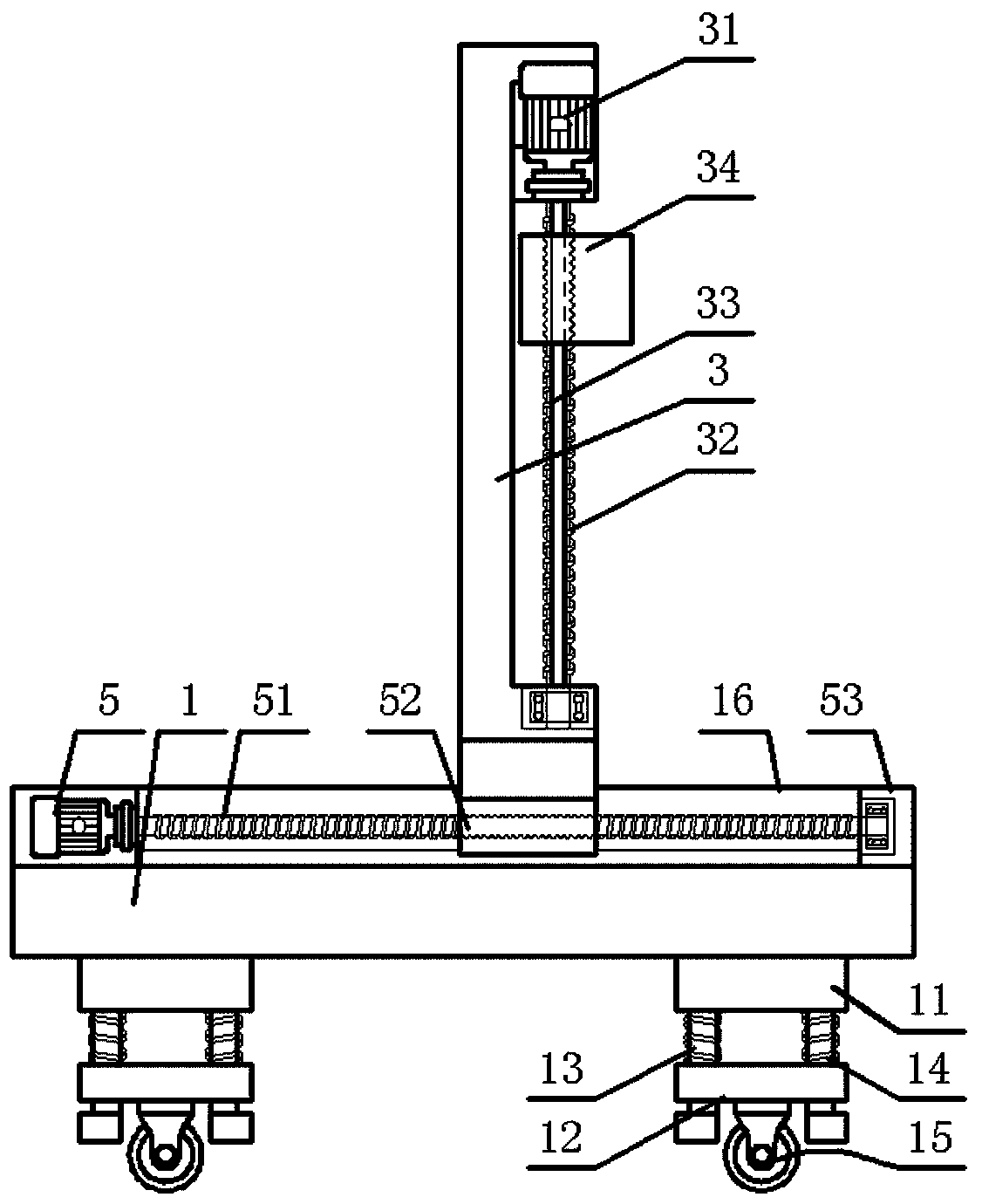

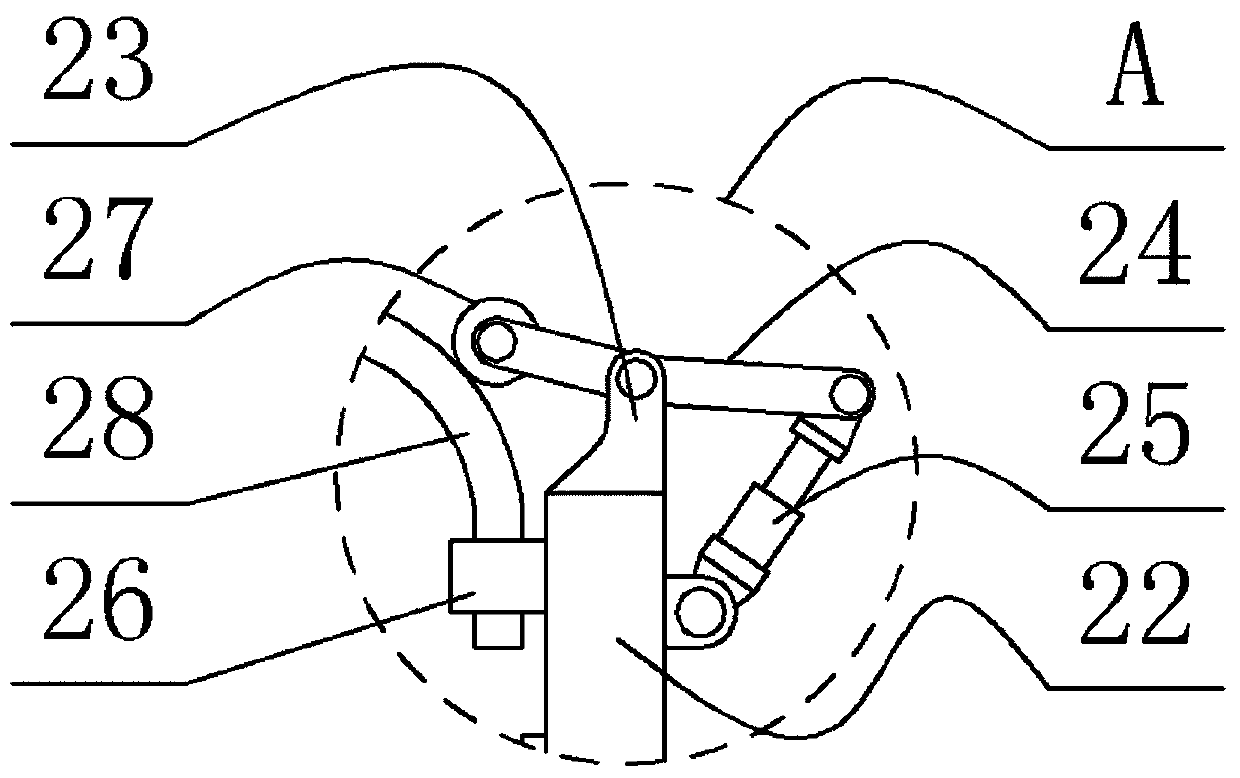

[0034] Embodiment 1: see Figure 1-4 , a tooling fixture for marking lines on an intelligent carbon skateboard, comprising a base plate 1, the base plate 1 is a horizontally placed rectangular plate, and both sides of the top surface of the base plate 1 are longitudinally provided with slide rails 16, and the slide rails 16 are It is in the shape of "I" and has a slide plate 17 in the middle of each slide rail 16. The bottom surface of each slide plate 17 is longitudinally recessed with a T-shaped chute, and the top of each slide rail 16 is slided. Closed in the corresponding T-shaped chute; the top surface of the slide plate 17 on one side is provided with a vertical plate 3, and the front of the vertical plate 3 is vertically provided with a first mechanism, and the top surface of the slide plate 17 on the other side is provided with a vertical plate To the upward slide bar 18, the top of the slide bar 18 is provided with a connecting block 36, and the inner end surface of t...

Embodiment 2

[0043] Example 2: see Figure 5 , in this embodiment, the present invention also proposes an operation method of a tooling fixture for marking a smart carbon skateboard, comprising the following steps:

[0044] Step 1, according to the width between the two ends of the carbon skateboard 28, adjust the distance between the two limit cylinders 26, control the expansion and contraction of the telescopic rod of the first telescopic cylinder 21, and then drive the moving plate 22 and the pulley 29 to move laterally, thereby adjusting The distance between the two limit cylinders 26, and insert the two ends of the carbon slide plate 28 into the corresponding limit cylinders 26;

[0045] Step 2, control the expansion and contraction of the telescopic rod of the second telescopic cylinder 25, drive the outer end of the hinged rod 24 to rise through the hinge, and then drive the inner end of the hinged rod 24 and the clamping wheel 27 and the two sides of the top surface of the carbon s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com