Full-automatic intelligent marking machine and working method thereof

A fully automatic, scribing machine technology, applied in the field of garment processing, can solve the problems of ink odor endangering artificial health, no obvious improvement in labor intensity, difficulty in ensuring printing consistency, etc. The effect of printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

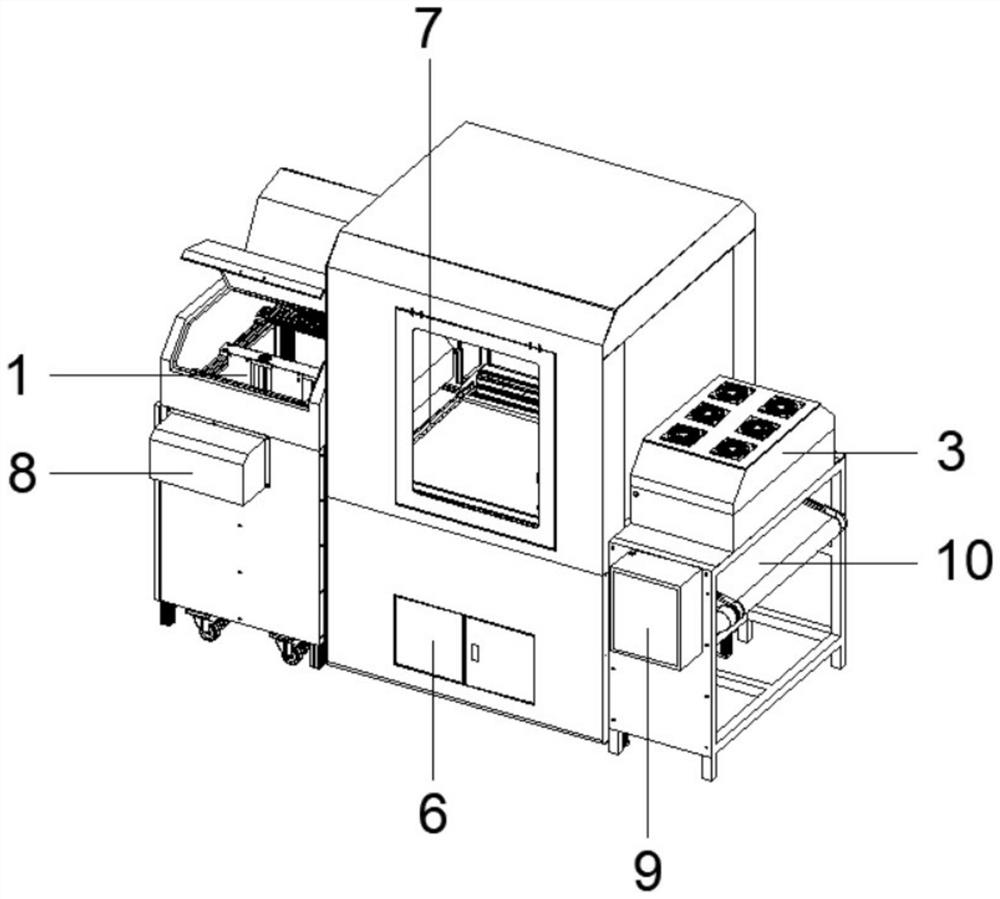

[0048] Fully automatic intelligent marking machine, including: automatic feeding mechanism 1, servo drawing mechanism 2, drying mechanism 3, industrial camera 4, high-frequency injection valve 5, system control box 6, pressing device 7, feeding mechanism control box 8. Temperature control box 9, conveyor belt device 10; conveyor belt device 10 is a non-reflective conveyor belt;

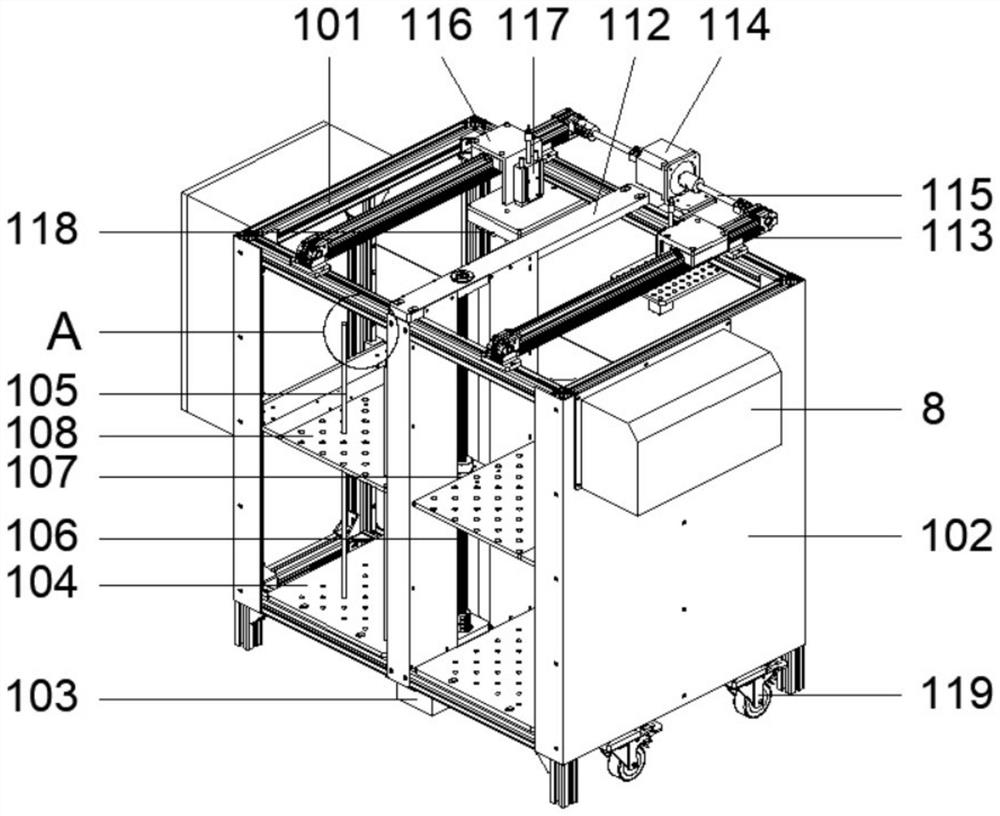

[0049] The automatic feeding mechanism 1 is installed on one side of the conveyor belt device 10. The automatic feeding mechanism 1 includes a feeding mechanism frame body 101, a shell 102, a material supporting structure and a transmission structure; the feeding mechanism control box 8 is installed on the automatic On the shell 102 of the feeding mechanism 1; universal wheels 119 are installed at the bottom of the feeding mechanism frame body 101;

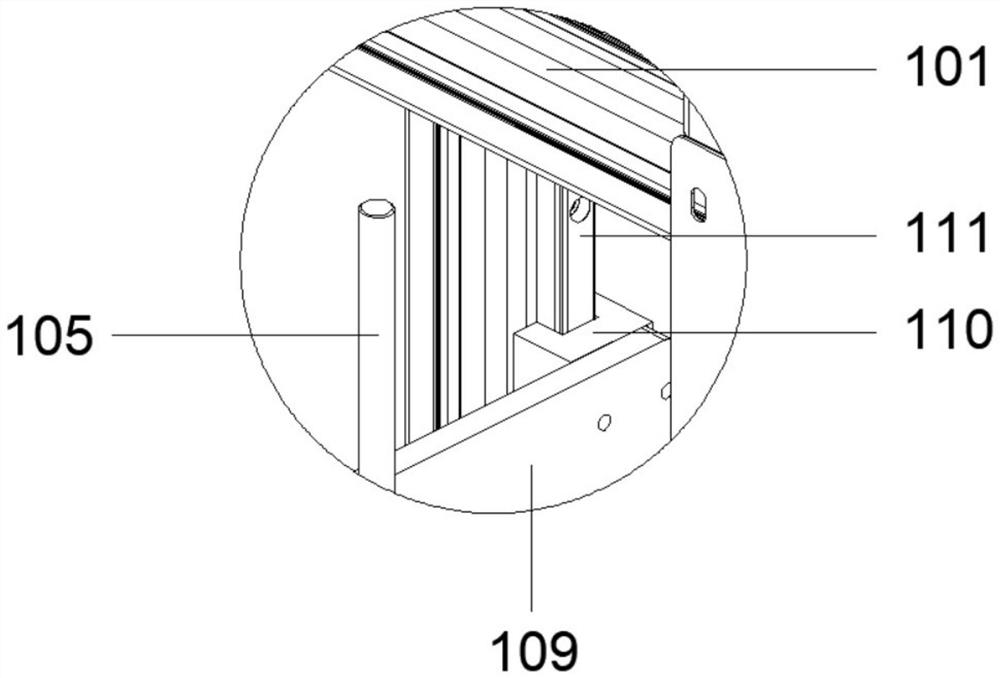

[0050] In the described supporting structure, a driving motor 103 is arranged at the bottom of the feeding mechanism frame body 101, and the driving moto...

Embodiment 2

[0061] The working method of fully automatic intelligent marking machine in embodiment 1 is characterized in that, comprises the following steps:

[0062] Step 1: The automatic feeding mechanism 1 grabs the material onto the conveyor belt device 10; the system control box 6 sends a signal to the feeding mechanism control box 8, thereby controlling the driving motor 103 to work, and the driving screw 106 drives the bottom pallet 108 to rise upwards Lifting and lifting cylinder 117 pushes the vacuum suction cup 118 down to absorb the material and lifts it up. The walking stepper motor 114 drives the linear module 113 to move the material to the top of the conveyor belt device 10. Afterwards, the vacuum suction cup 118 discharges the material so that the material is on the conveyor belt. on device 10;

[0063] Step 2: The conveyor belt device 10 transports the material to the working range of the industrial camera 4. The industrial camera 4 precisely positions the material, takes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com