Automatic arraying device for bearing retainers

A bearing cage and alignment device technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of irregular bearing cage structure, inconvenient automatic sorting, high error rate, etc., to achieve scientific and reasonable overall structure design, production The effect of low cost and low error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

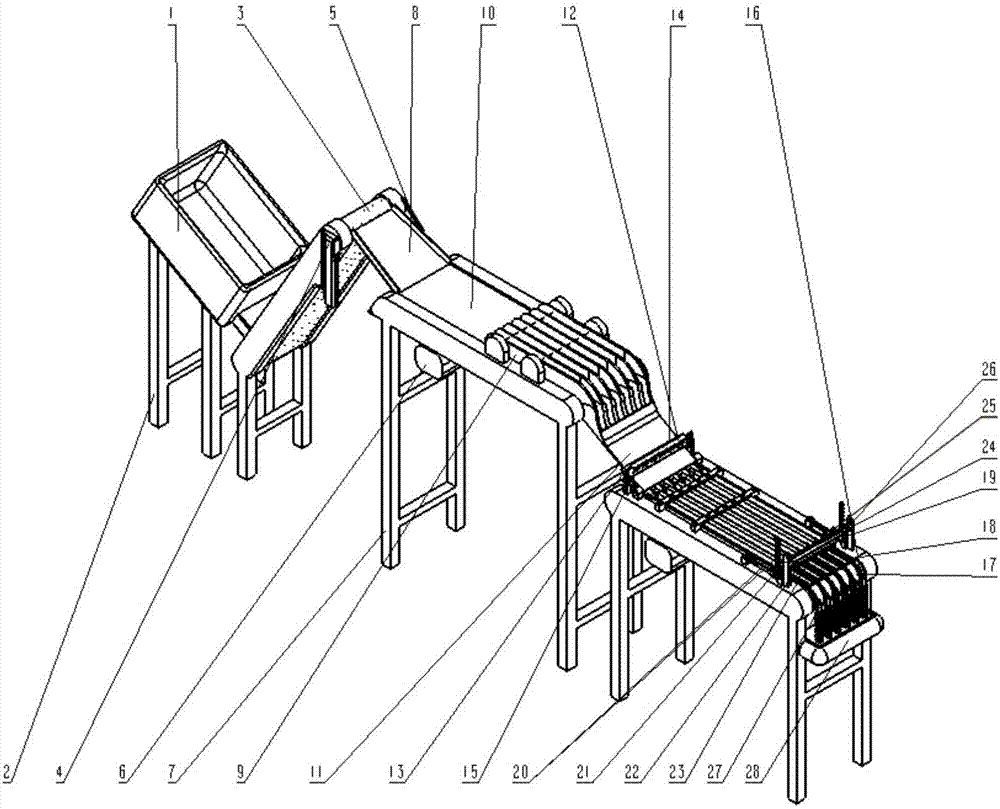

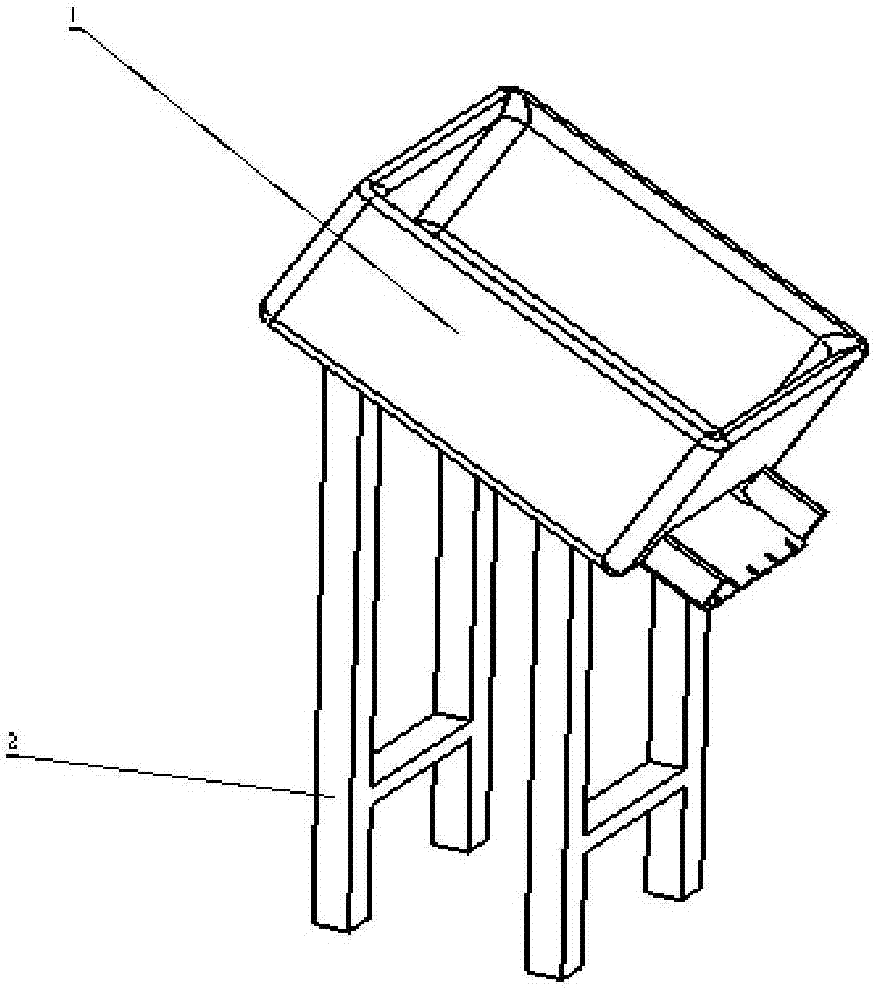

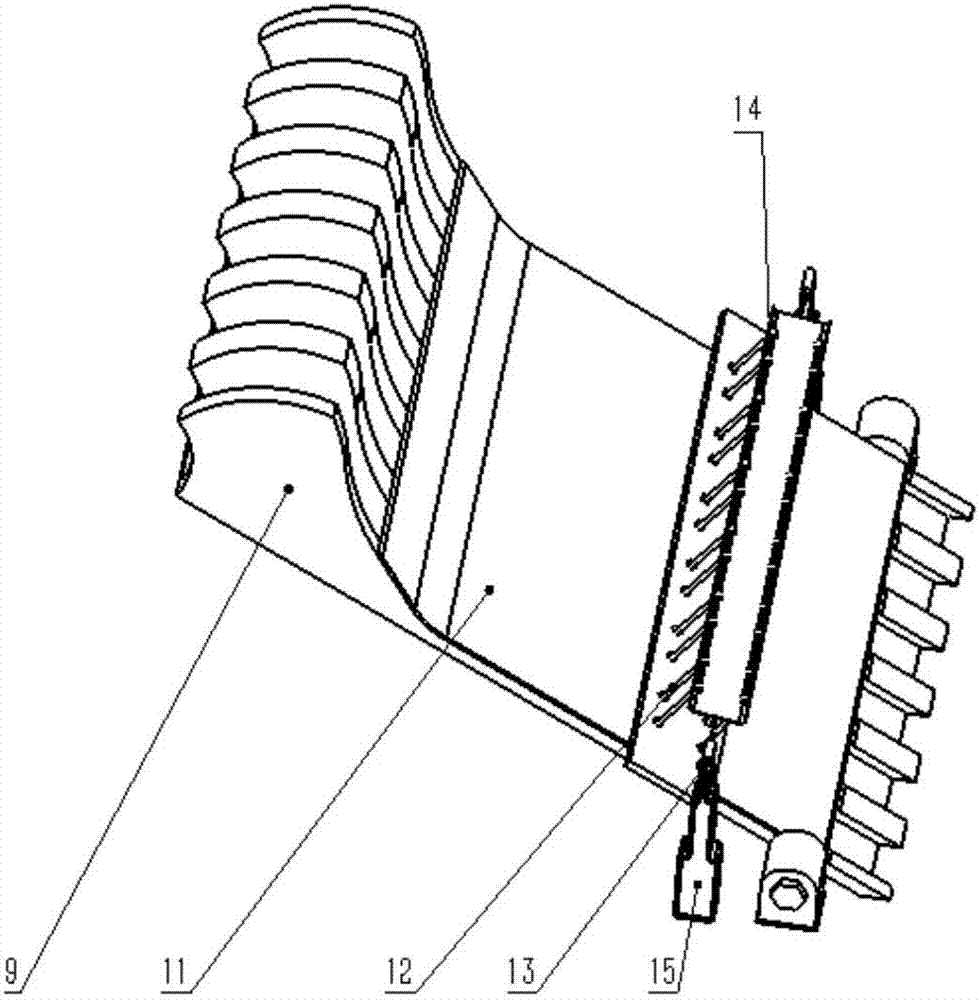

Embodiment

[0015] The main structure of the automatic alignment device for bearing cages involved in this embodiment includes: a hopper 1, a hopper support frame 2, a barb conveyor belt 3, a roller 4, a pulley 5, a speed regulating motor 6, a frame 7, a slide plate 8, a diverter Baffle plate 9, diverting conveyor belt 10, height-limiting slide plate 11, double-row pin 12, stepper motor 13, distance-limiting rotating shaft 14, distance-limiting support frame 15, round belt track 16, faceted conveyor belt 17, width-limiting baffle 18. Gear 19, rack 20, deceleration motor 21, height-limiting pin 22, reverse pick-up hook 23, pick-up hook support shaft 24, reverse collection rod 25, reverse collection rod support frame 26, front collection rod 27 and front collection rod Stopper 28; hopper 1 is the storage part of the bearing cage, which is fixedly connected with the hopper support frame 2 by bolts, the discharge port of hopper 1 is connected with the barb conveyor belt 3 at an angle of 90 deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com