Sheet-by-step automatic feeding, marking and gluing integrated equipment

An automatic feeding and board technology, which is applied to other plywood/plywood appliances, wood processing appliances, adhesive application devices, etc., can solve the problems of reduced work efficiency, slow glue flow, uneven glue application, etc., and achieve fast scribing And gluing, reduce manual labor, improve the effect of gluing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

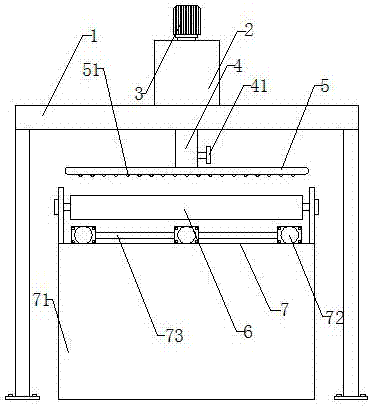

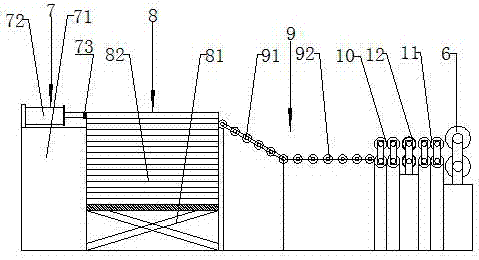

[0018] Embodiment: refer to attached Figure 1-2 The integrated equipment for scribing and gluing with step-by-step automatic feeding of boards shown includes a scribing device and a gluing device. Pressure roller 11 The function of the front pressure roller 10 and the rear pressure roller 11 is to ensure stable compression during the scribing process of the board; the gluing device is set on one side of the scribing device, and the other side is A step-by-step automatic feeding device, the step-by-step automatic feeding device includes a pushing mechanism 7, a lifting mechanism 8 and a sliding mechanism 9 in turn, and the pushing mechanism 7 consists of an operating table 71 and three The cylinder pushing assembly 72 is formed, and a push plate 73 is fixedly connected horizontally at the ends of the three push mechanisms 7. The height of the push plate 73 is the same as the thickness of the plate, so that when it is convenient for automatic feeding, the push plate 73 pushes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com