Side binding device of binding machine

A side-gluing and glue-binding technology, which is applied in book binding, binding adhesives, printing, etc., can solve inconvenience and other problems, and achieve the effect of reducing wire drawing and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

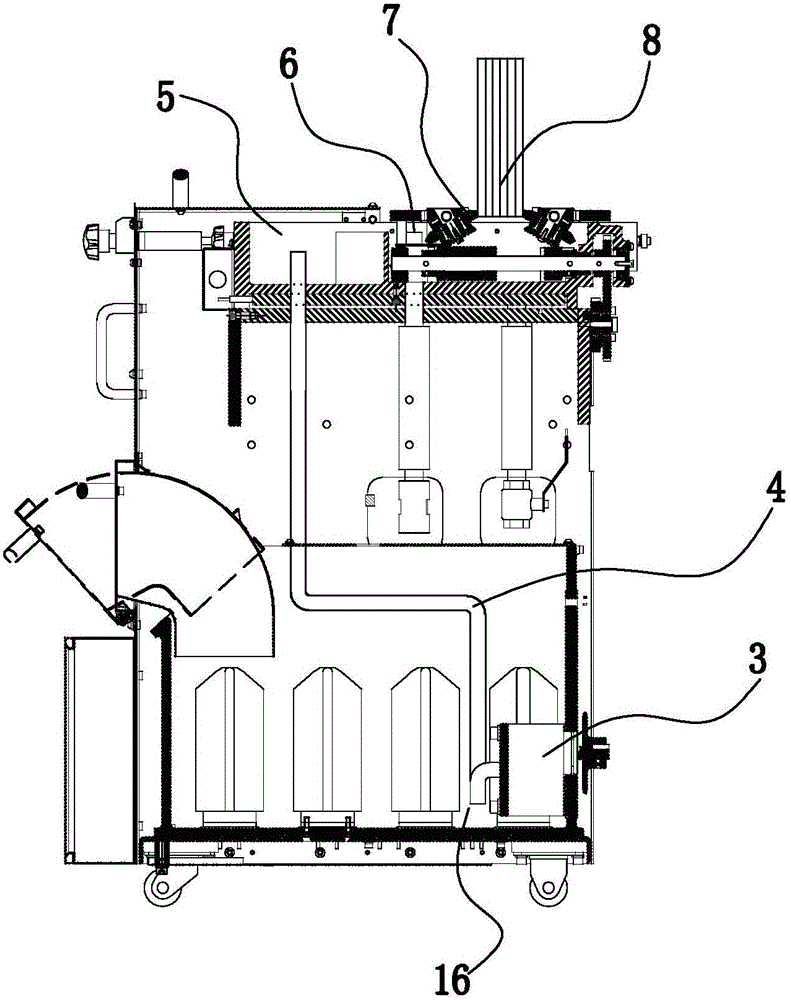

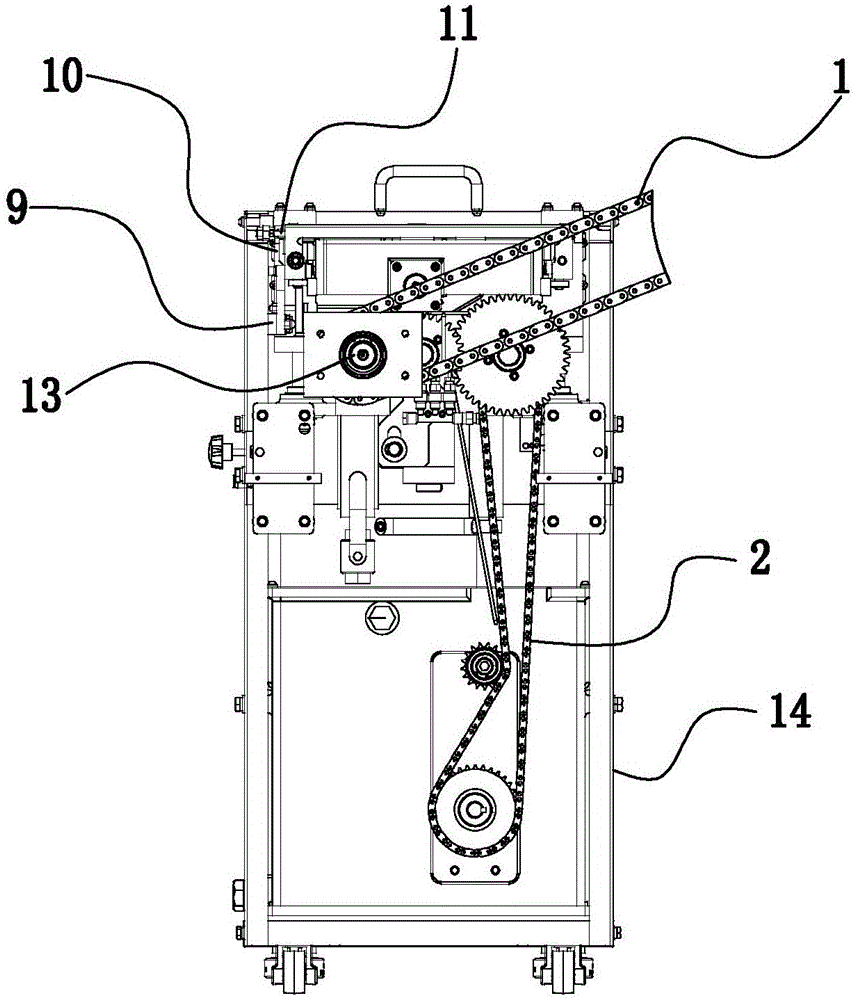

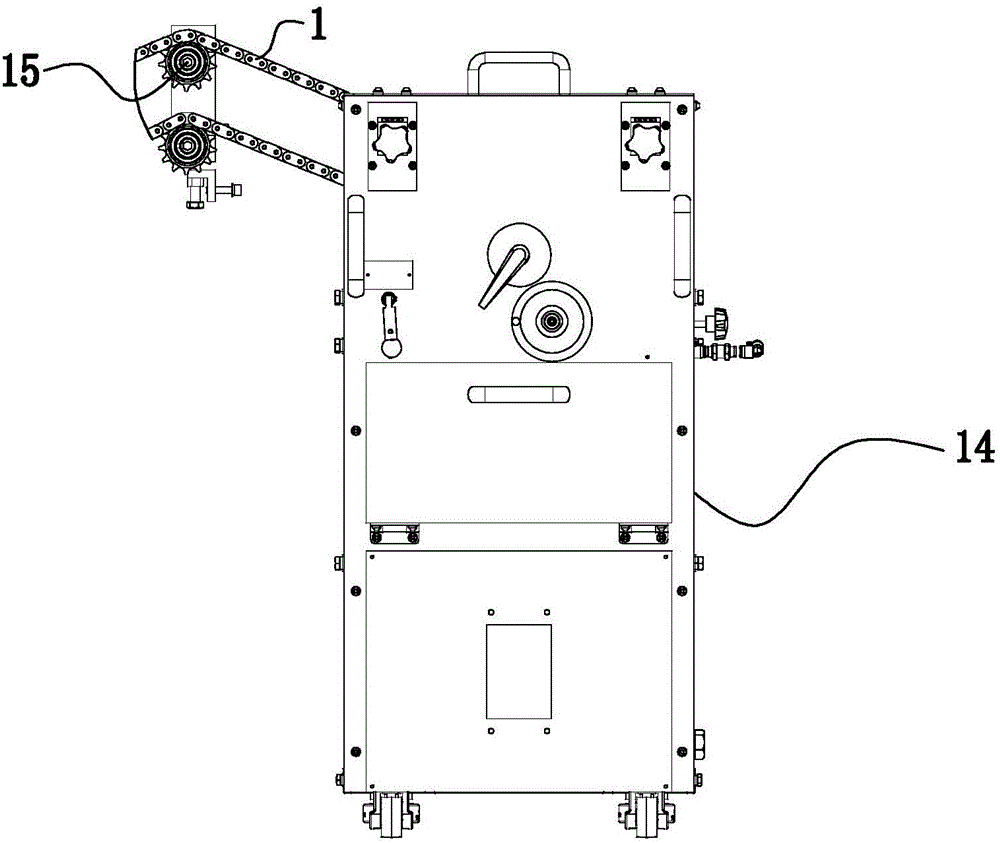

[0018] Example: such as Figure 1-4 As shown, a side glue device of a glue binding machine includes a side glue device body 14; and a sprocket shaft 13 mounted on the upper end of the side glue device body 14; the sprocket shaft 13 is equipped with a sprocket 15 on the outer end of the side glue device body 14 The drive gear shaft 13 rotates; the sprocket 15 and the sprocket shaft 13 are rotationally connected by a first chain 1; a number of transmission gear assemblies are provided at the lower end of the sprocket shaft 13; the first chain 1 drives the second chain 2 to rotate through the transmission gear assembly; The side glue device body 14 is provided with a gear pump 3 at the bottom, the second chain 2 is rotatably connected with the gear pump 3, and drives the gear pump 3 to rotate; the side glue device body 14 is provided with a glue pot 5; the glue pot 5 passes through a bellows 4 is connected to the gear pump 3.

[0019] The glue preheating bucket 16 with a side glue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com