Spacing-adjustable gluing mechanism capable of keeping gluing face upwards

A spacing and gluing technology, applied in container manufacturing machinery, paper/cardboard containers, box production operations, etc., can solve the problems of high processing cost, time-consuming and laborious, and low processing efficiency, and achieve the effect of energy-saving and environmental protection processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

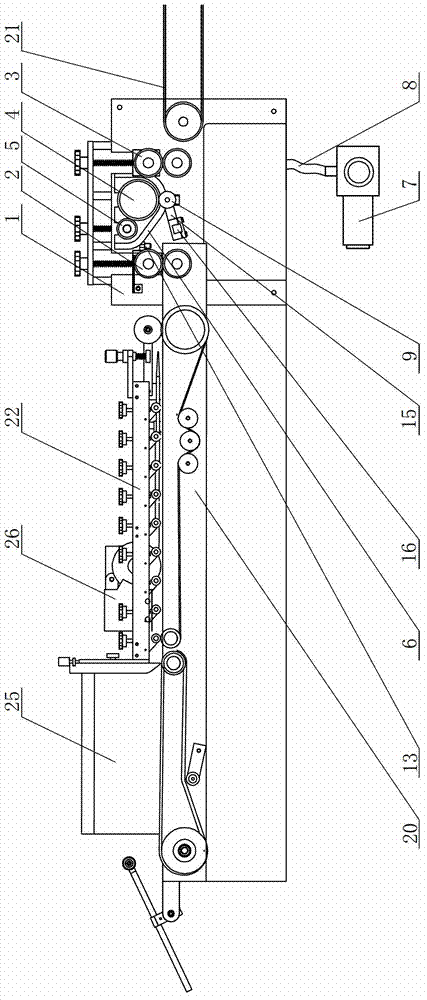

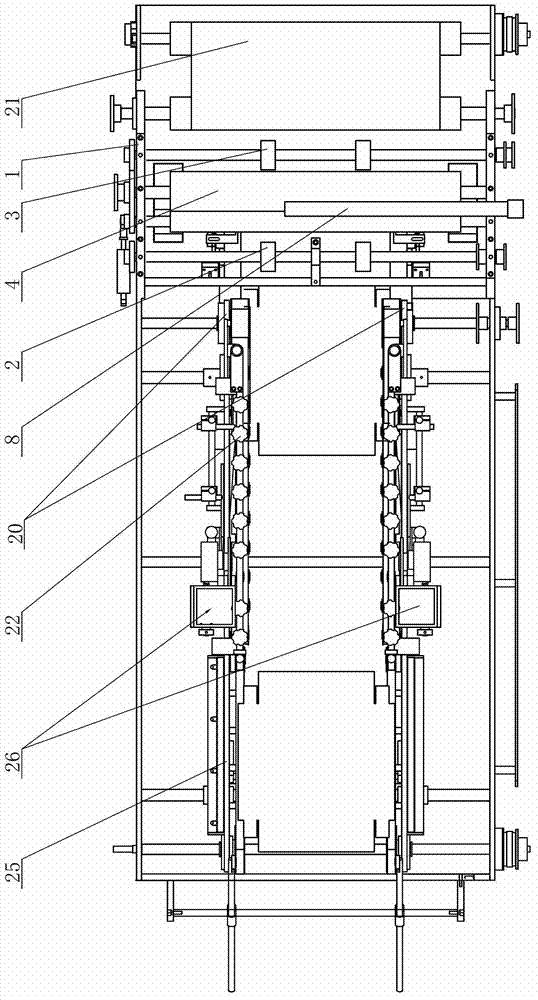

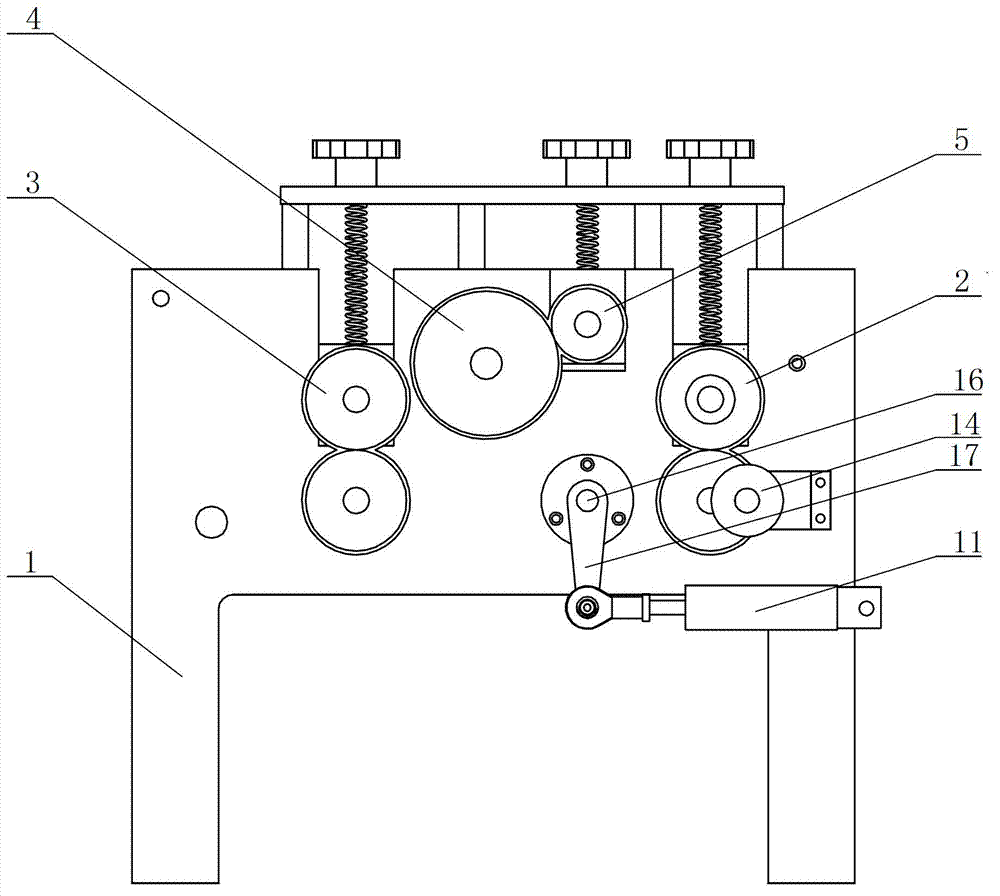

[0016] Such as figure 1 combine figure 2 , image 3 , Figure 4 , Figure 5 As shown in the figure, a glue-applied face-up spacing-adjustable gluing mechanism includes a frame 1 on which an input pressure roller set 2 and an output pressure roller set 3 are installed, and an input pressure roller set 2 and an output pressure roller set 3 are installed on the frame 1. The upper rubber roller 4 is installed on the frame 1 between them. The upper rubber roller 4 is located above the pressing surface of the input pressure roller group 2 and the output pressure roller group 3. One side of the upper rubber roller 4 is provided with a rubber adjustment roller 5. There is a glue funnel 6 under the upper rubber roller 4, and a rubber supply hose 8 connected to the rubber pump 7 above the upper rubber roller 4; the middle glue pressing wheel set 9 and two blade g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com