Patents

Literature

35results about How to "Avoid affecting work progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

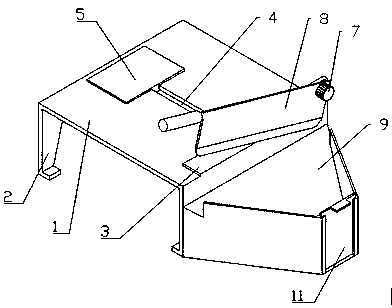

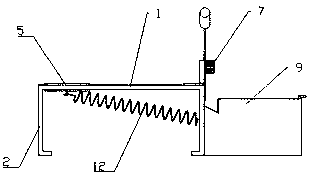

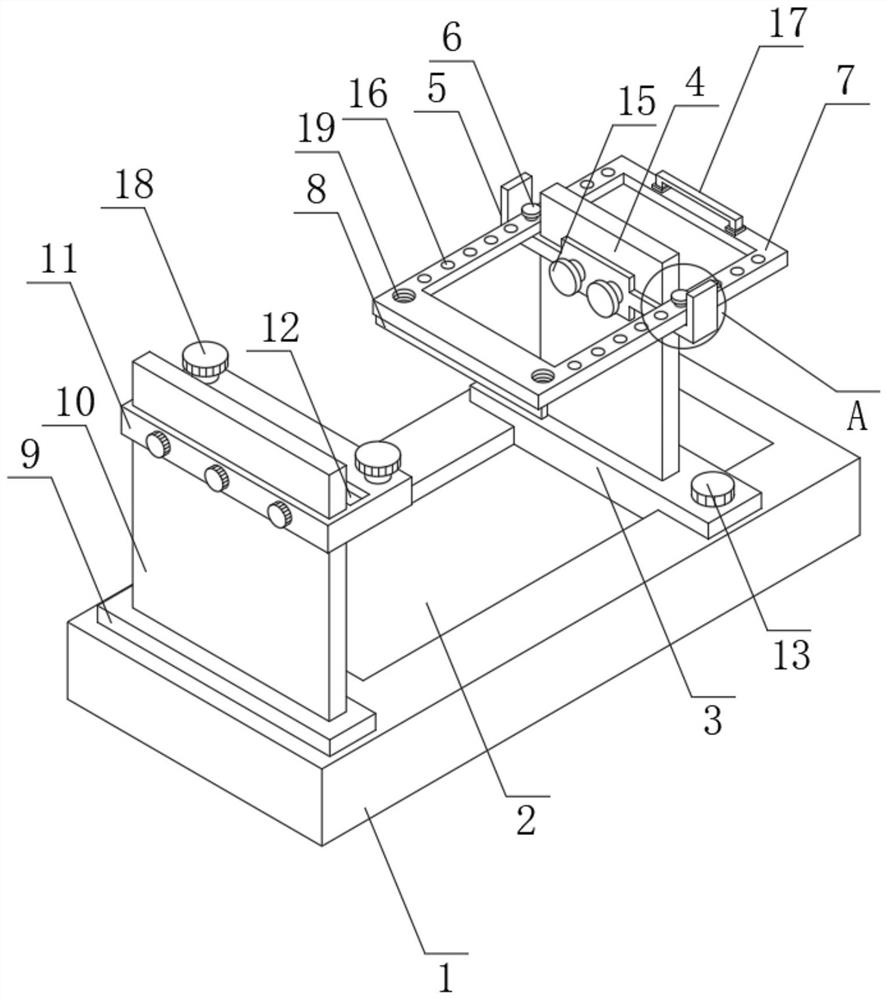

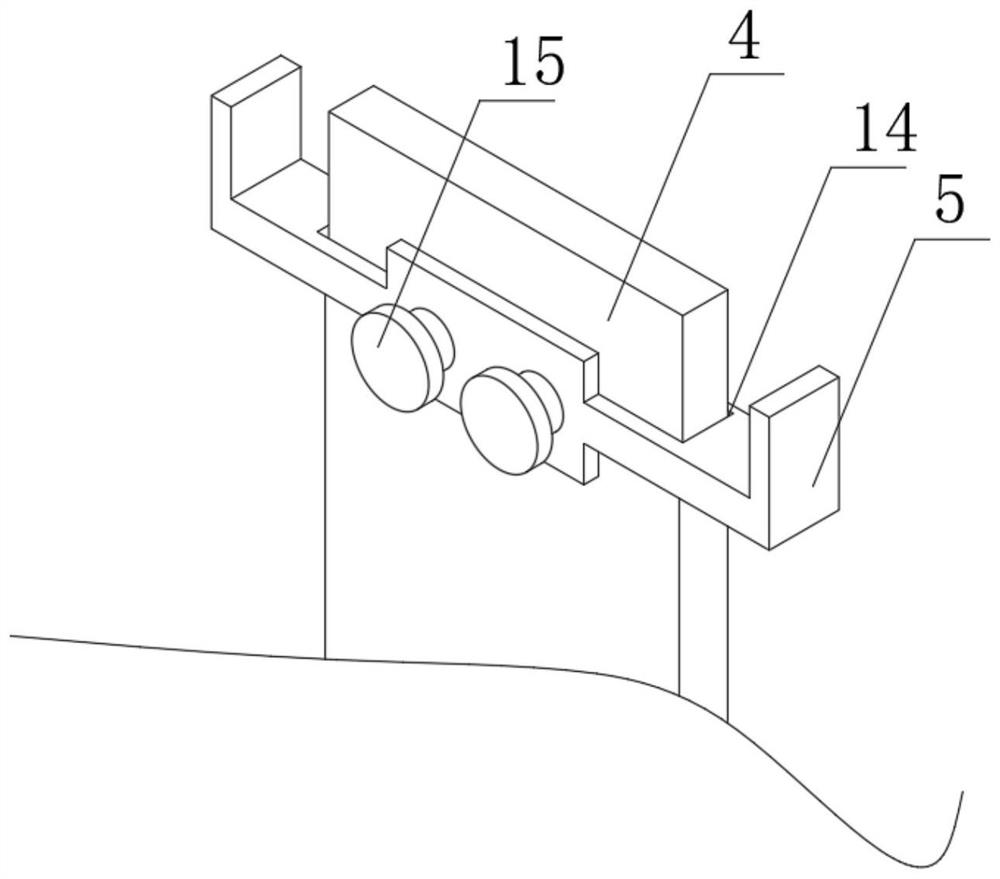

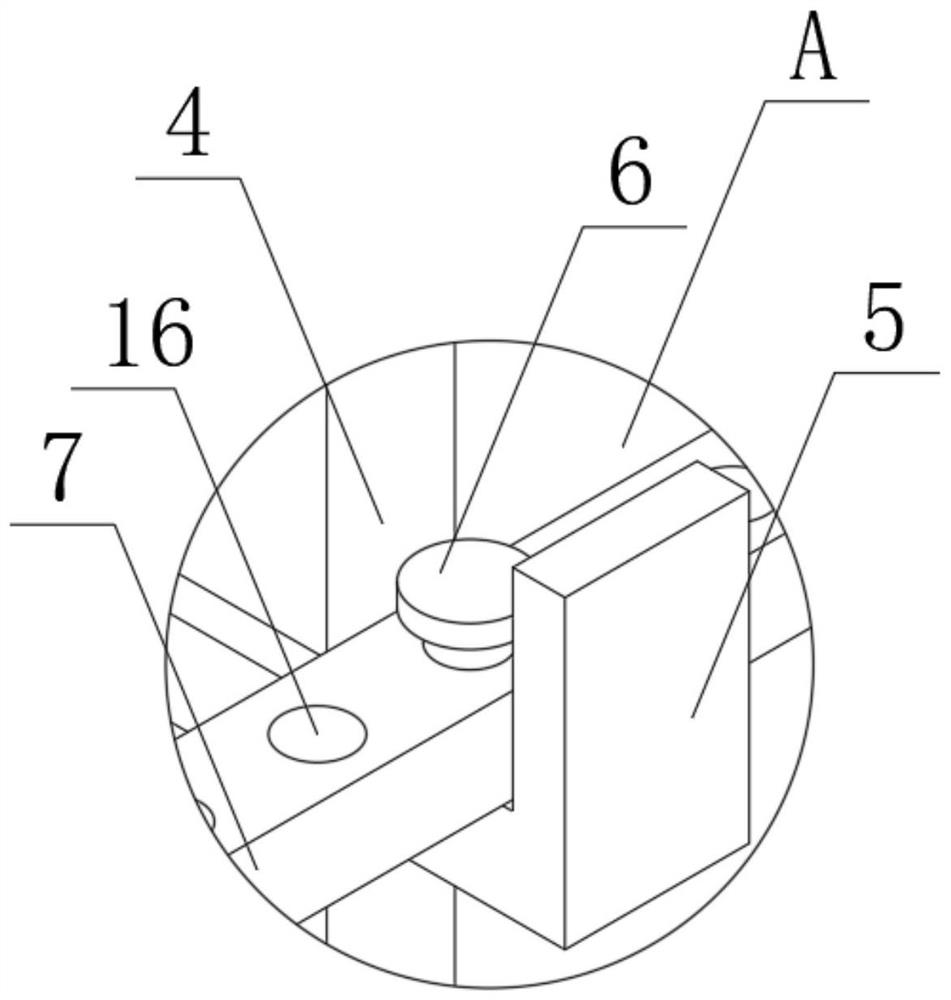

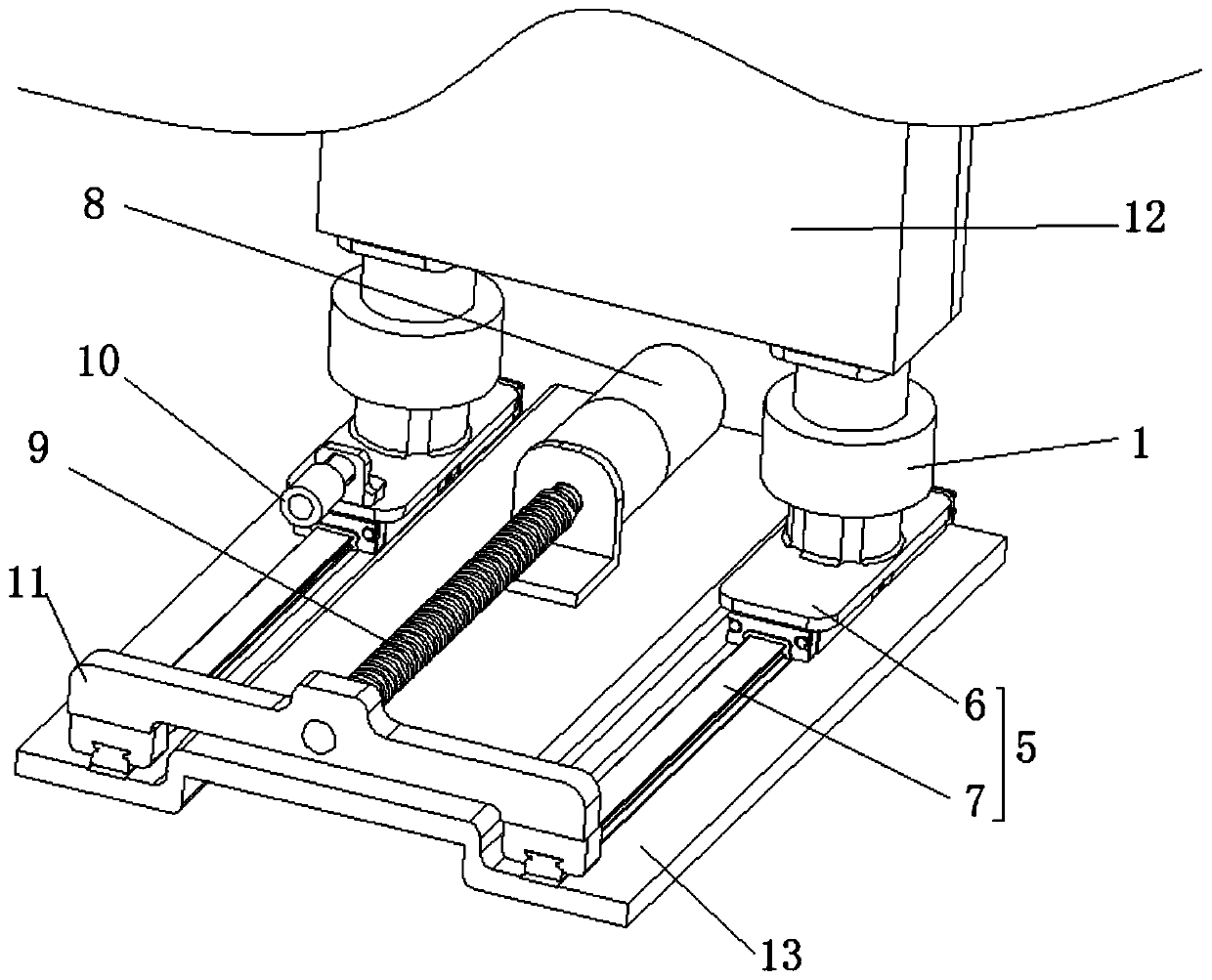

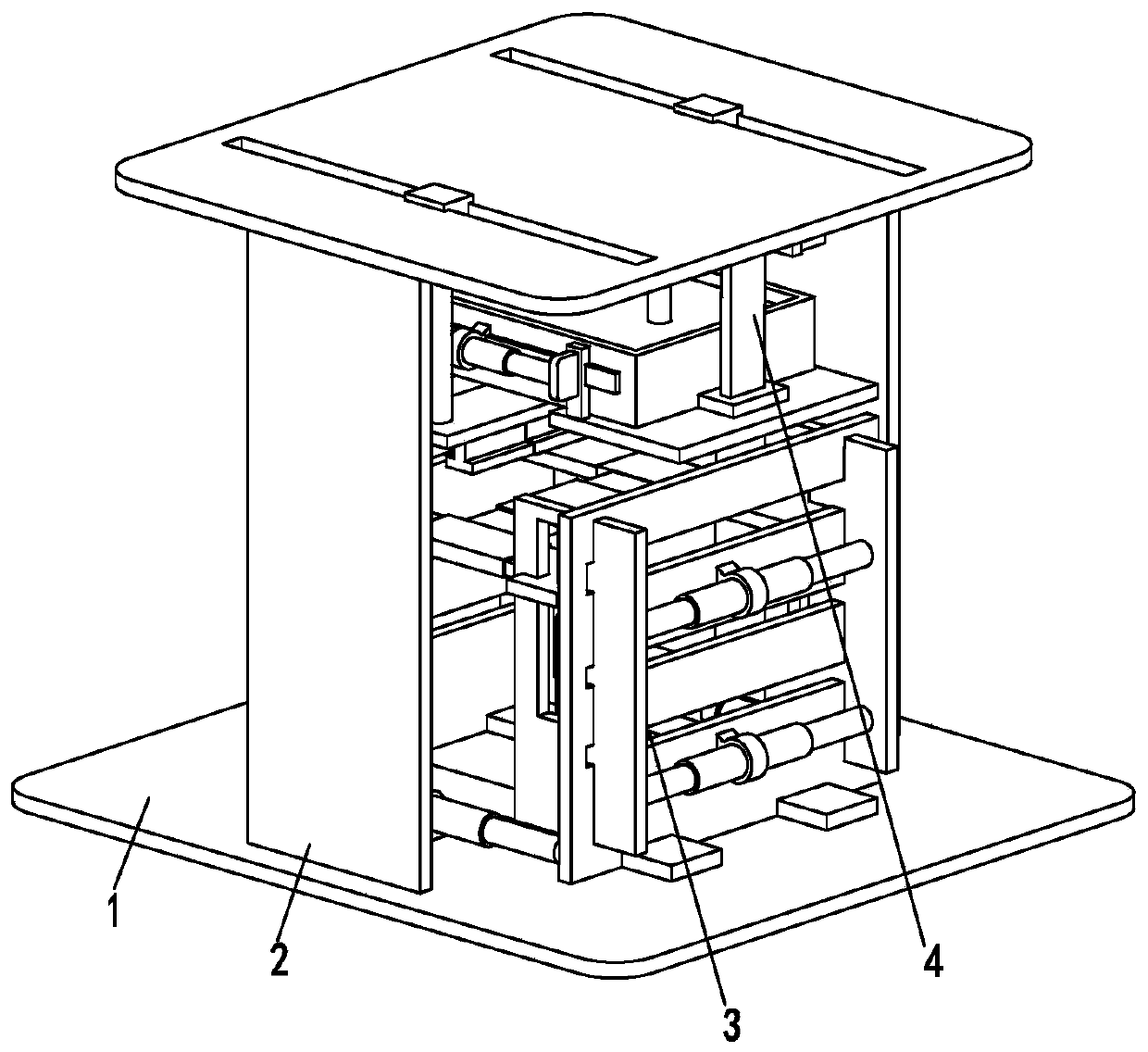

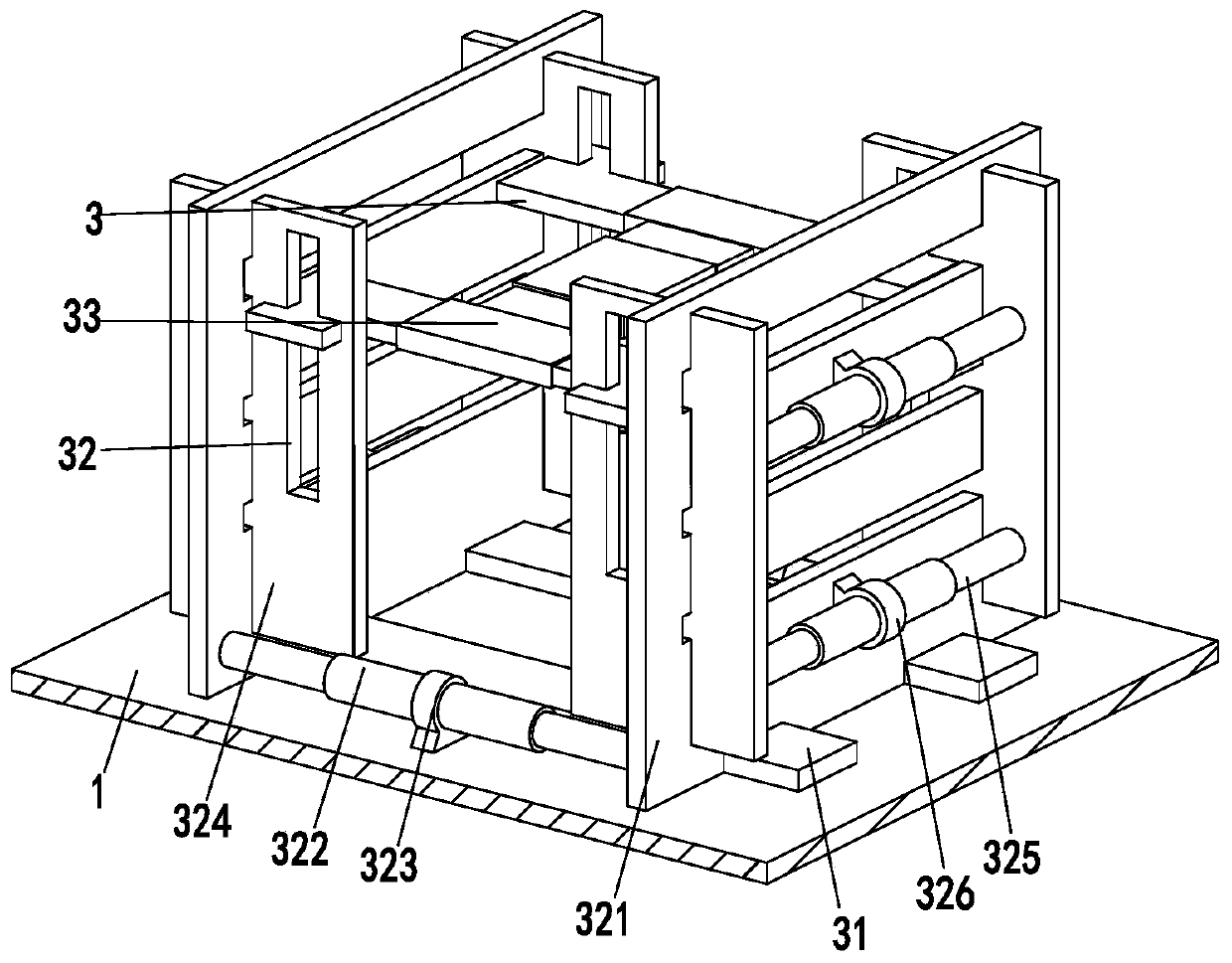

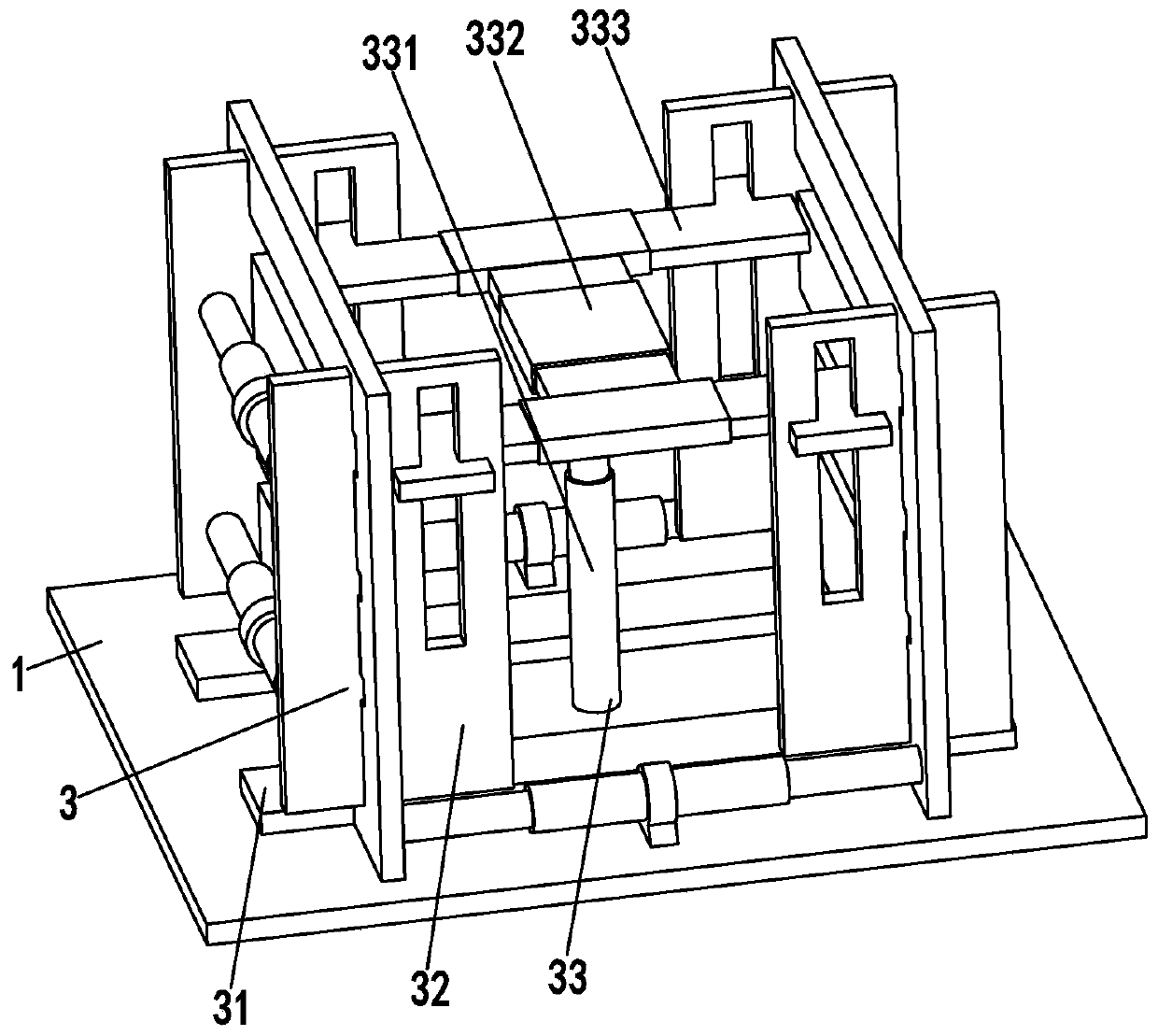

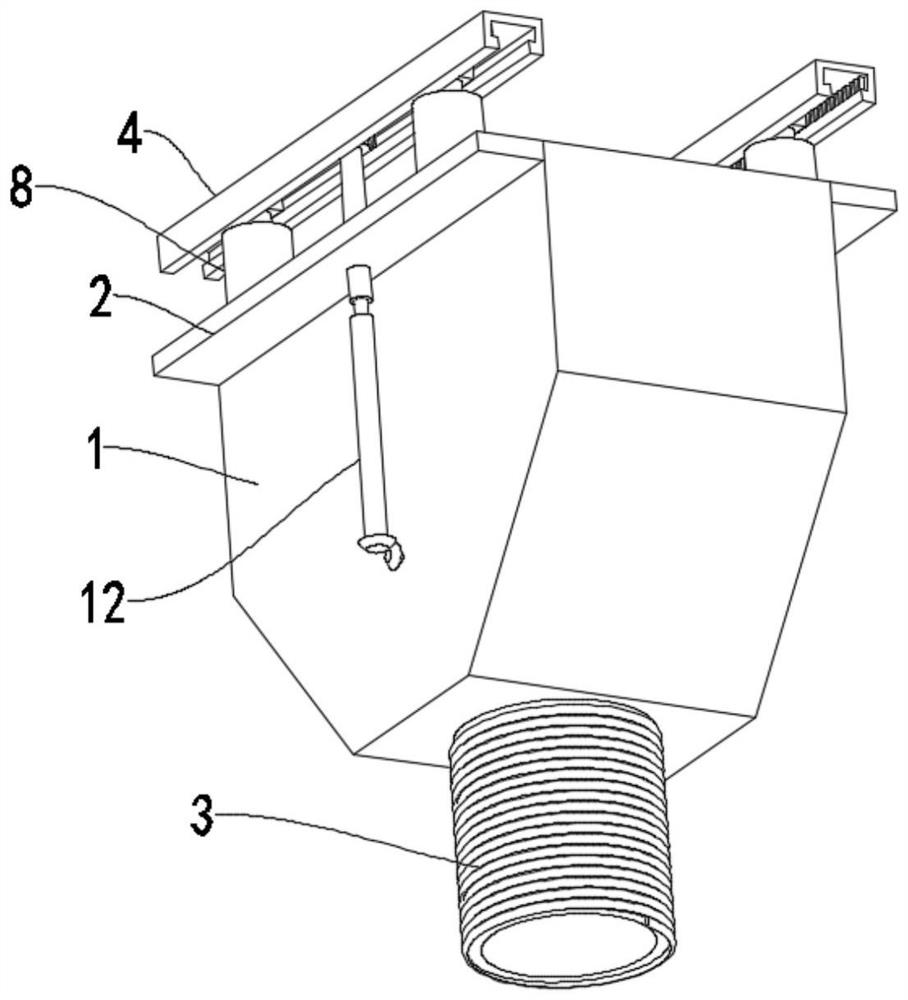

Composite board automatic gluing device

ActiveCN108656260AMeet work needsAvoid affecting work progressAdhesive application devicesEngineeringMechanical engineering

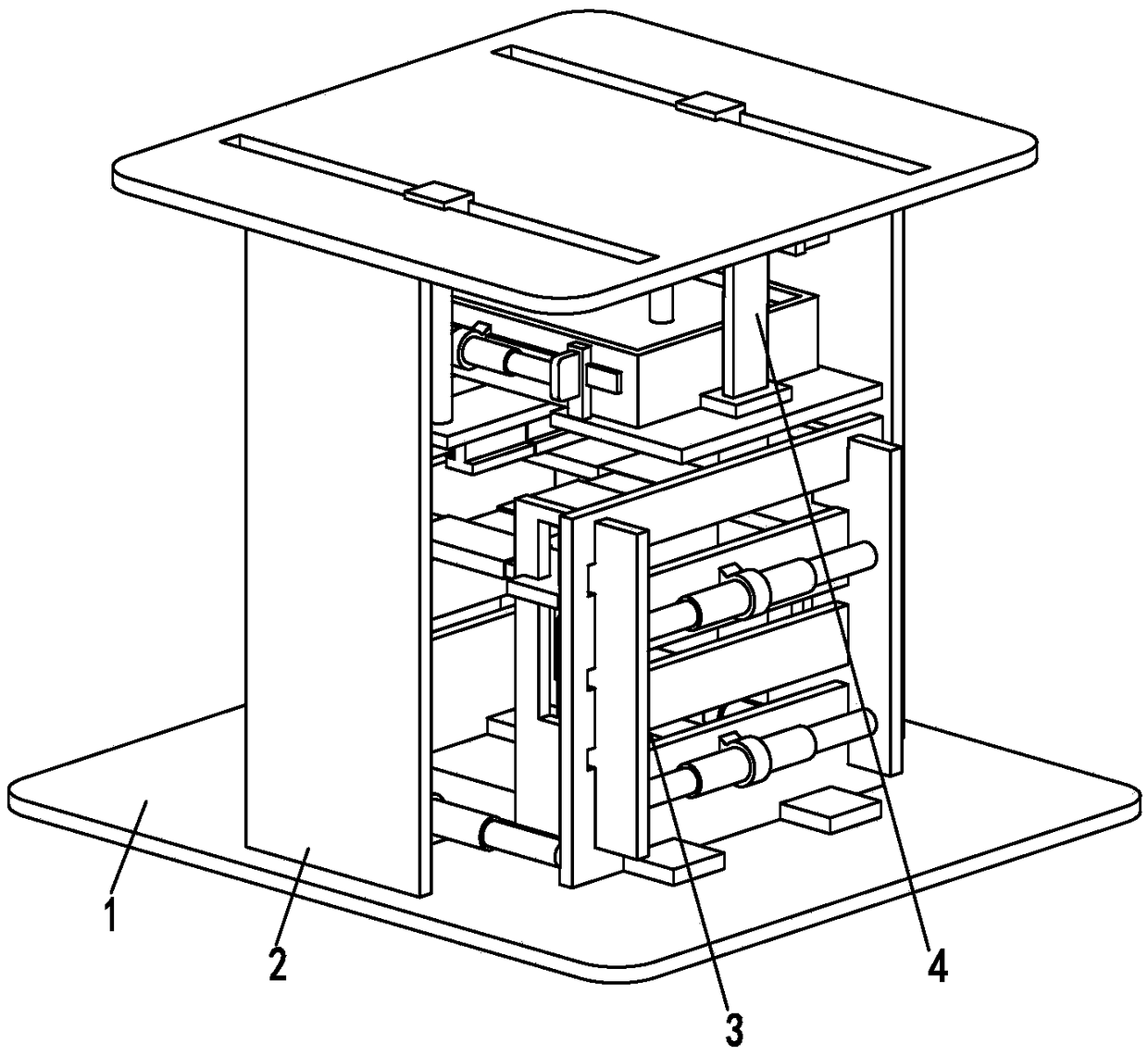

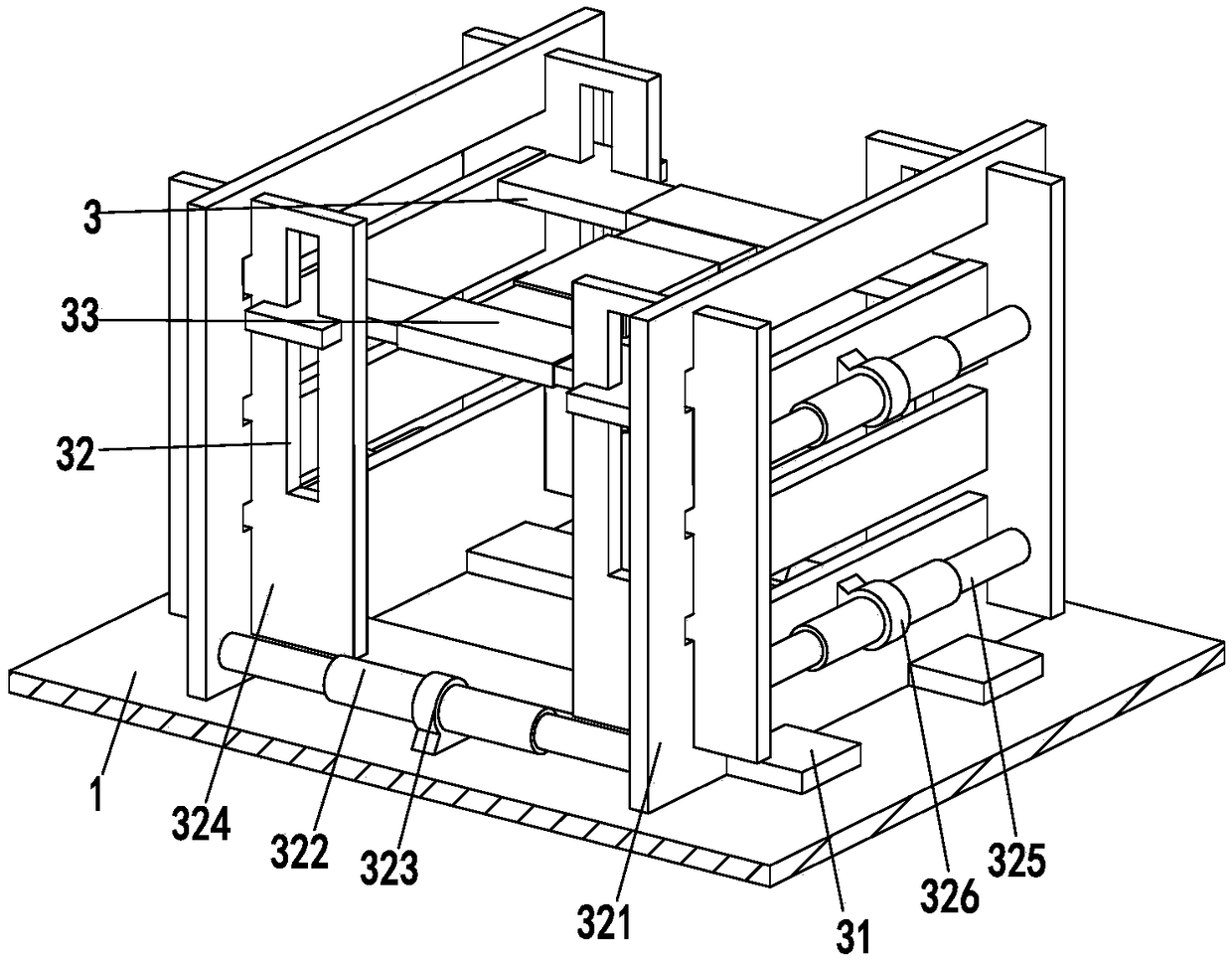

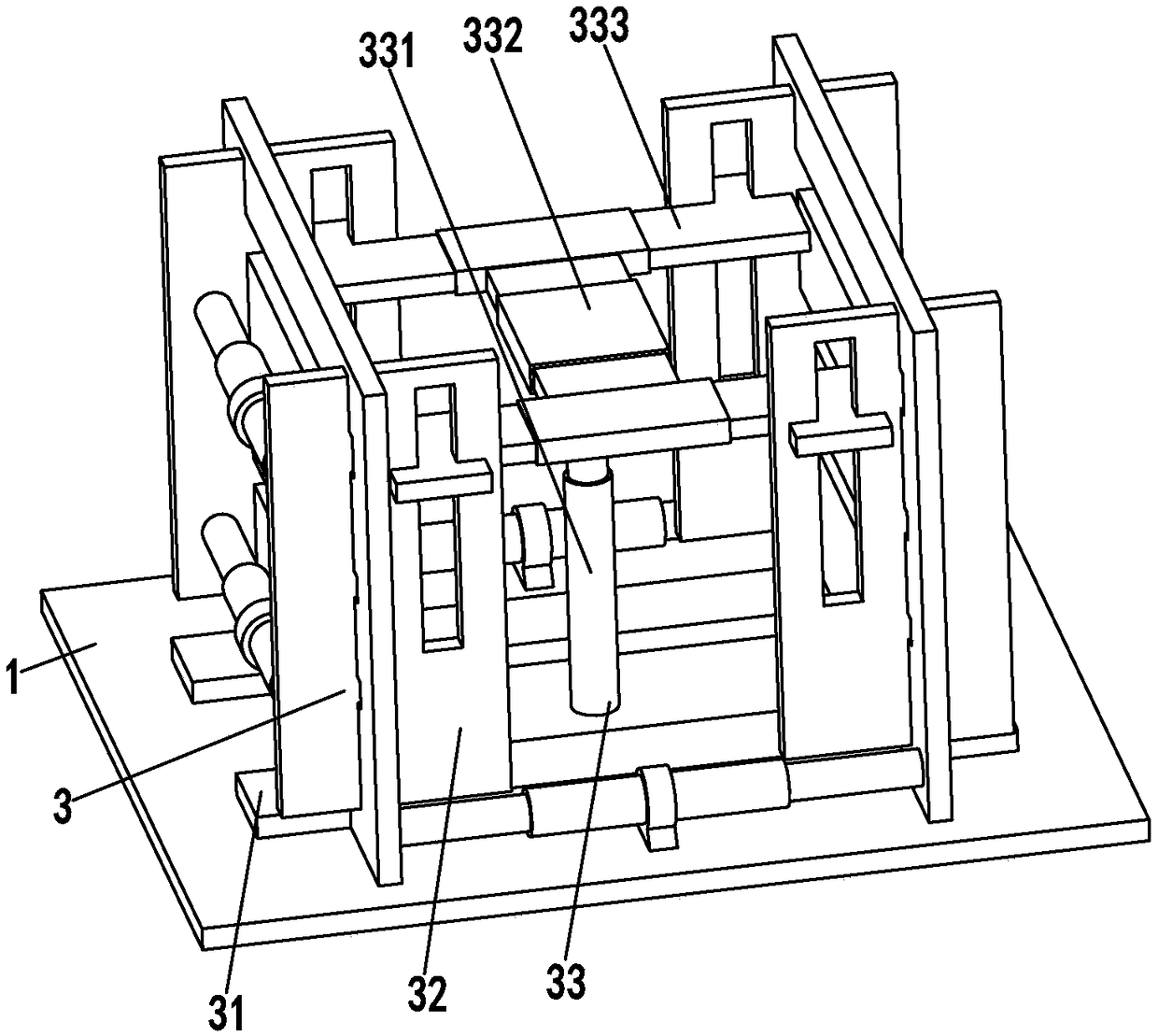

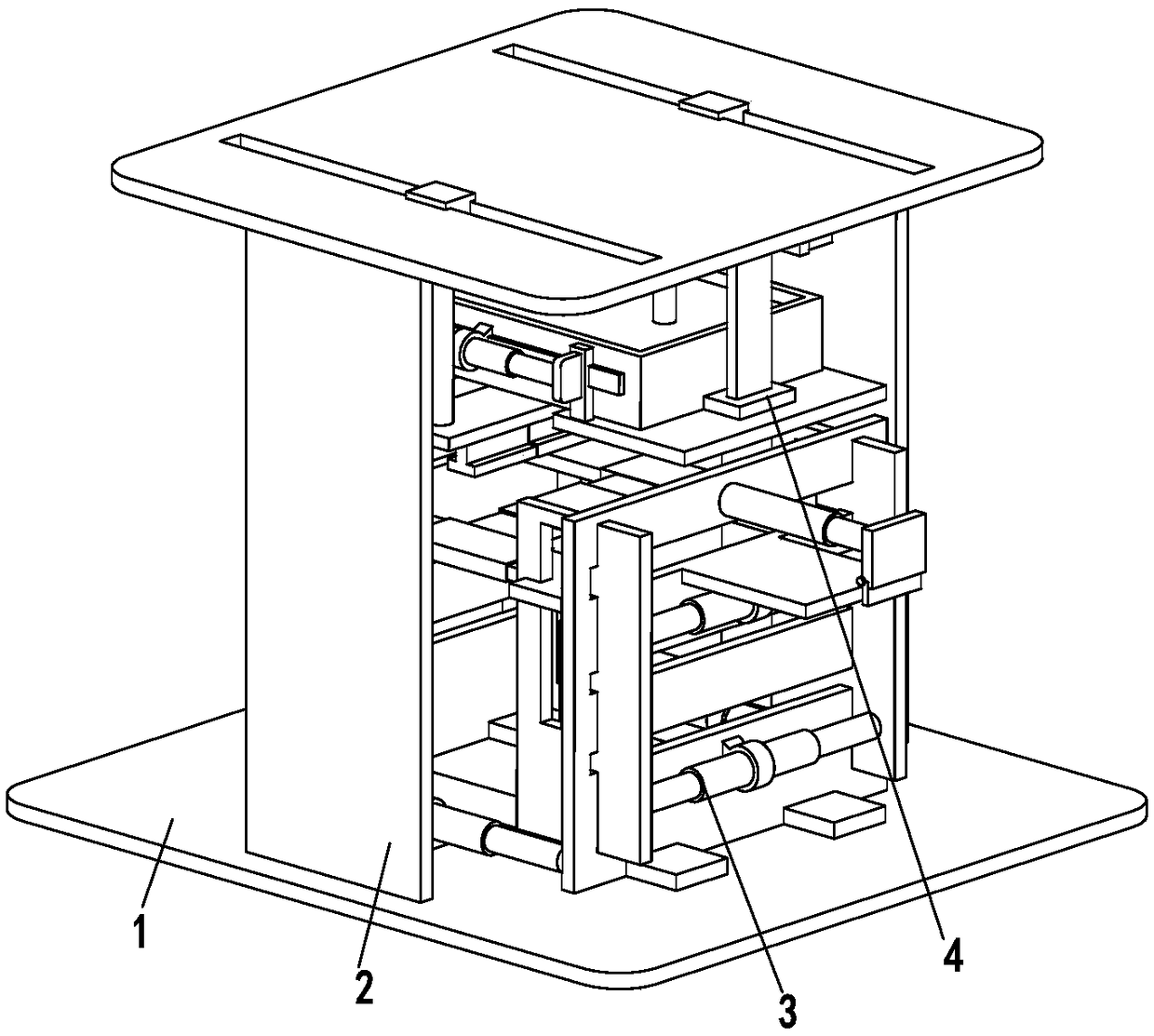

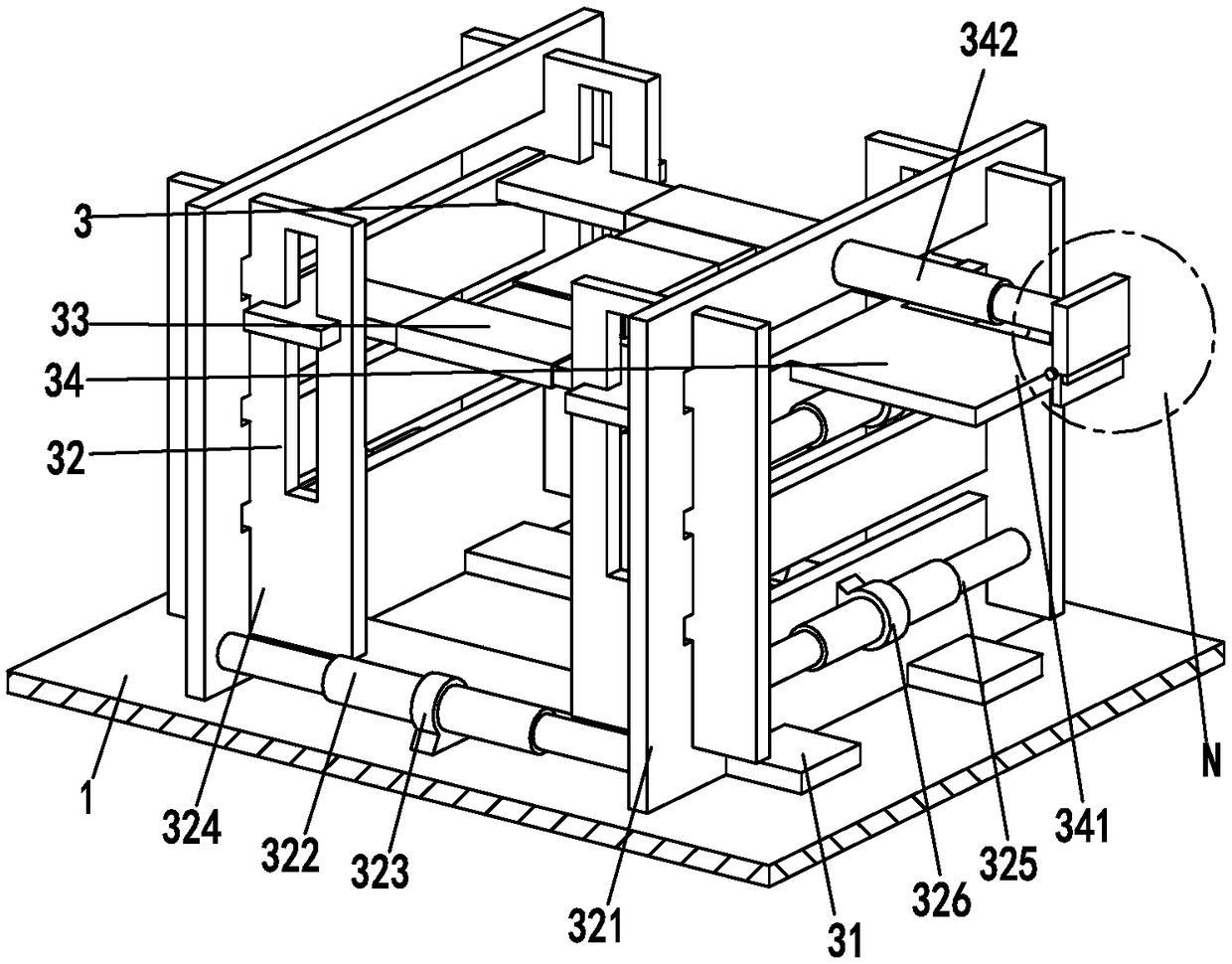

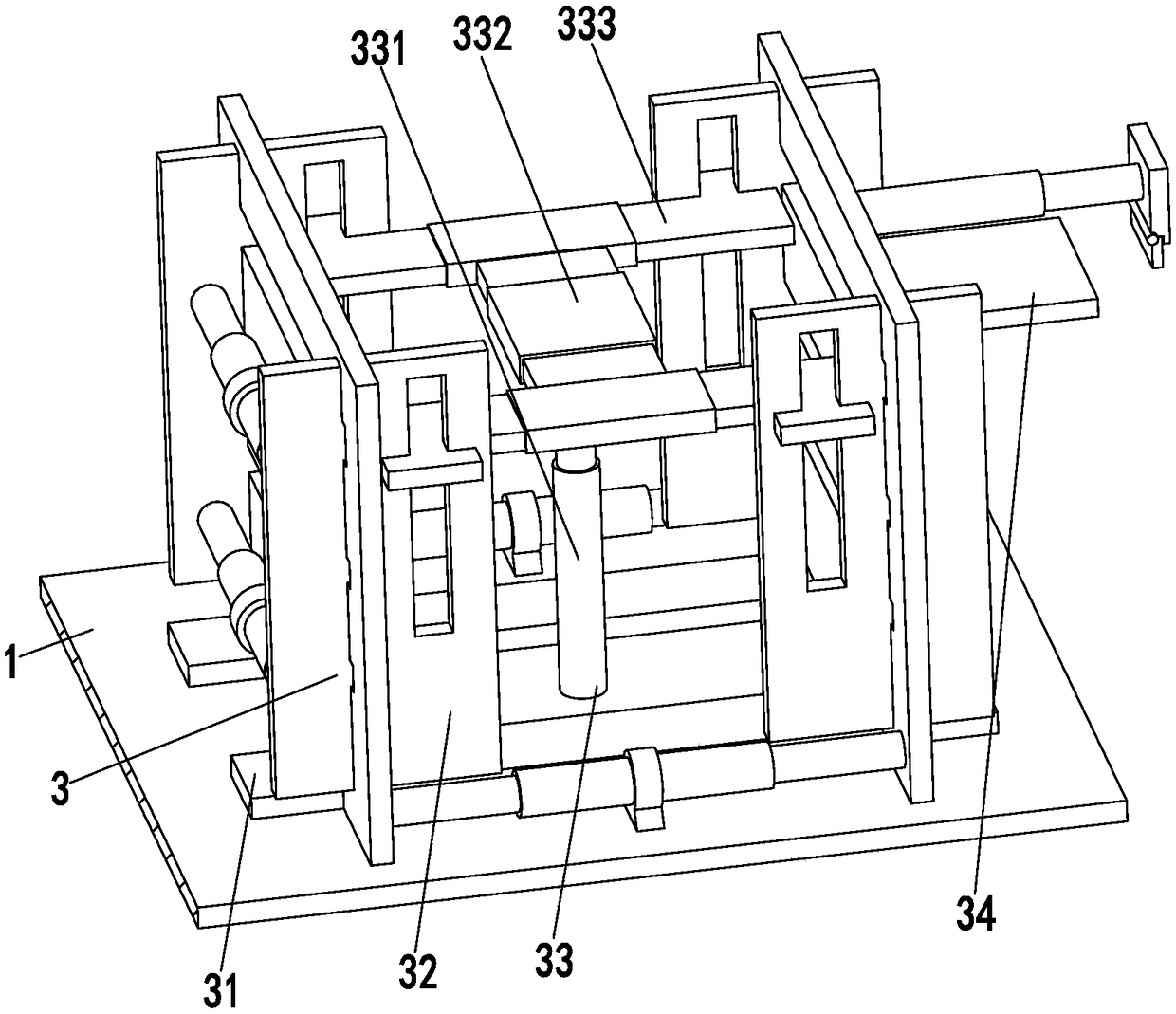

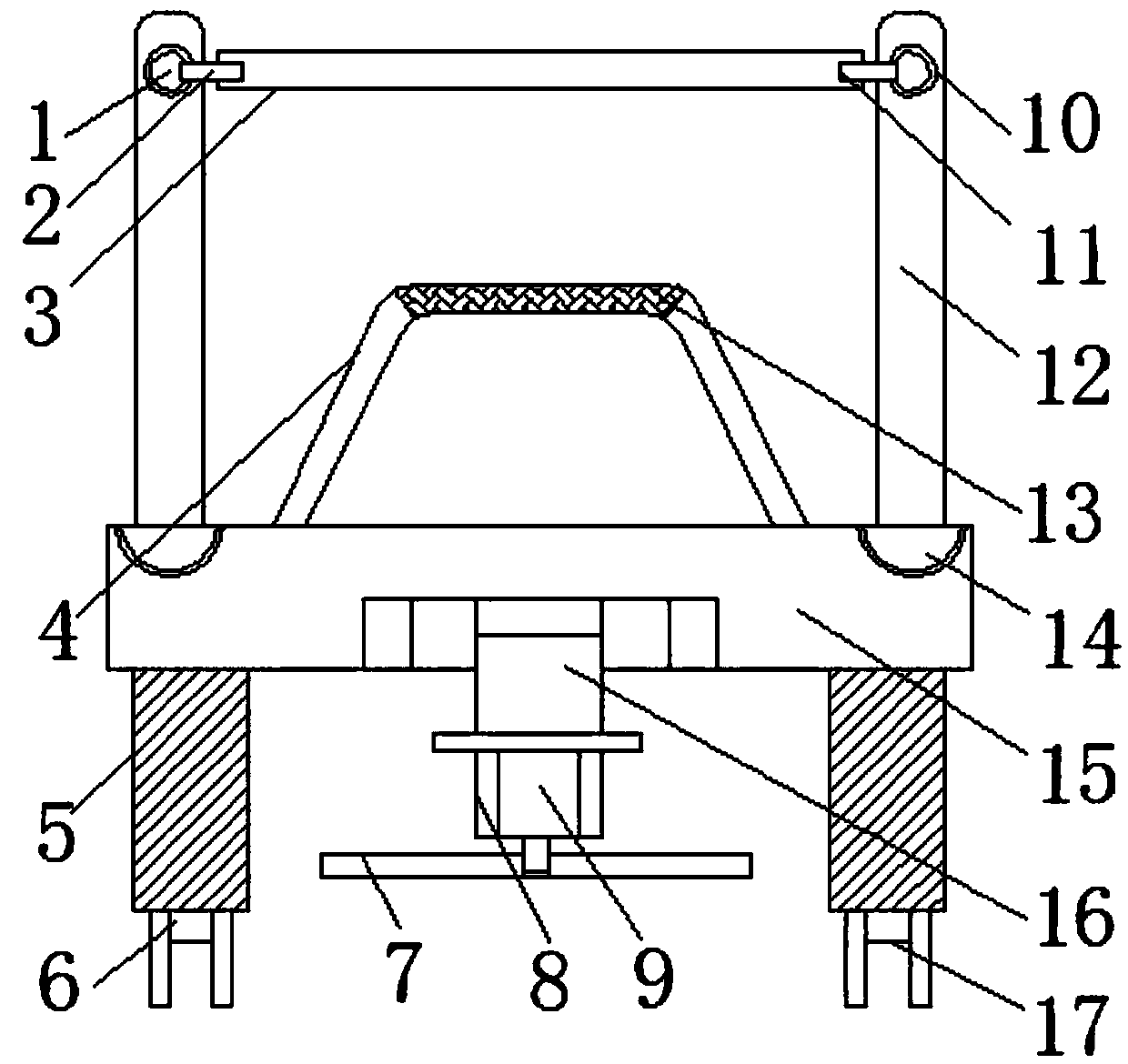

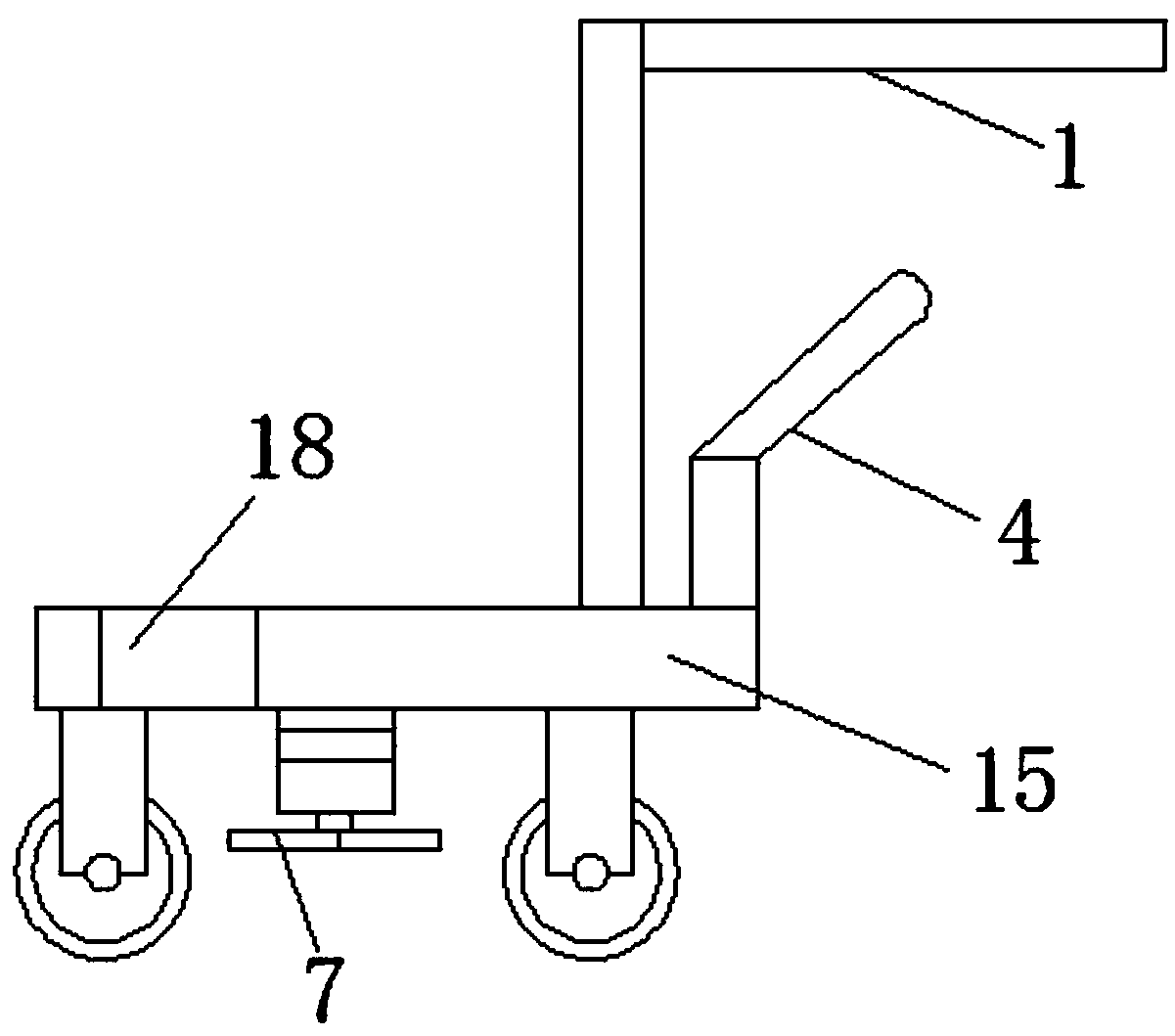

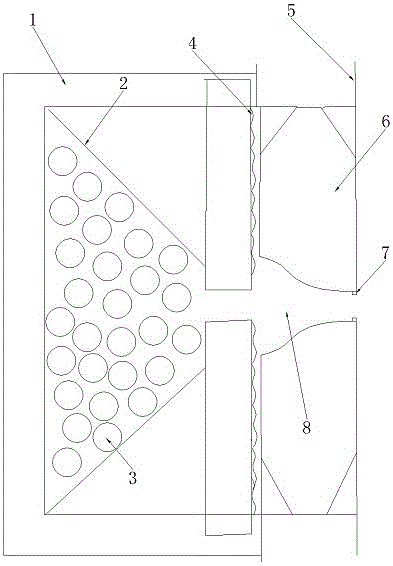

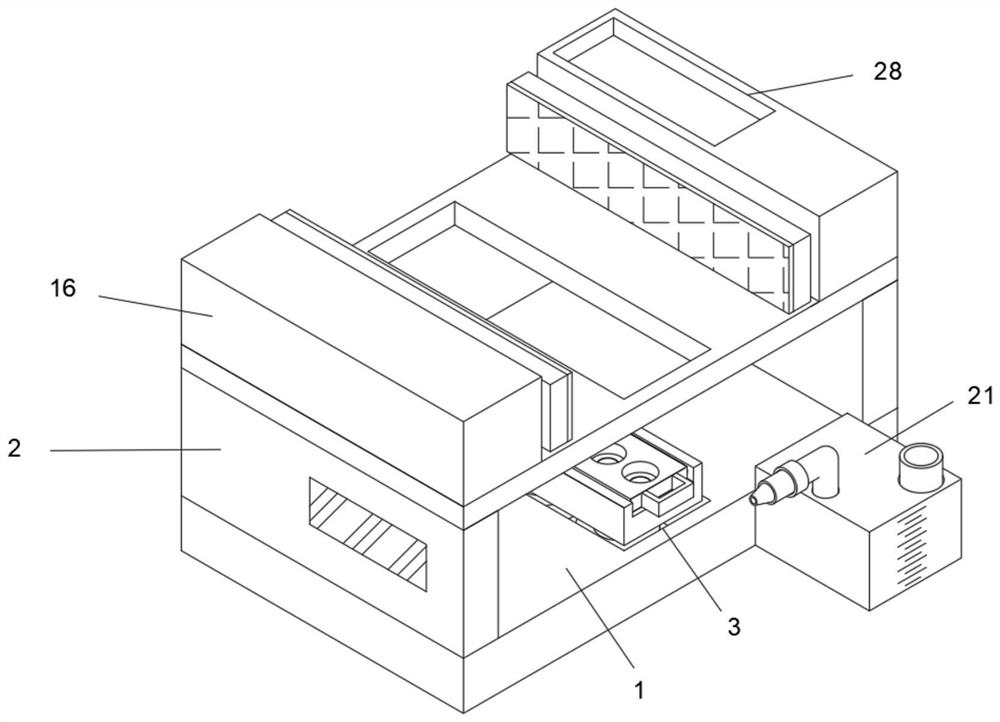

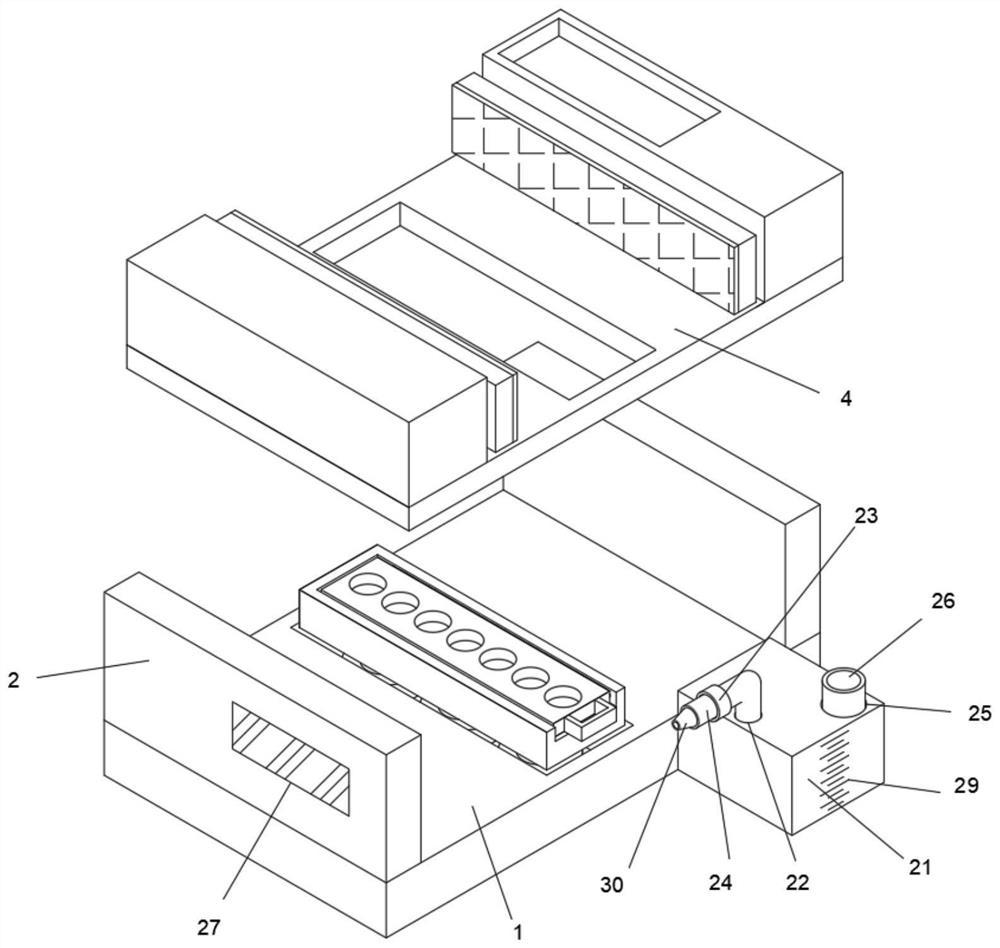

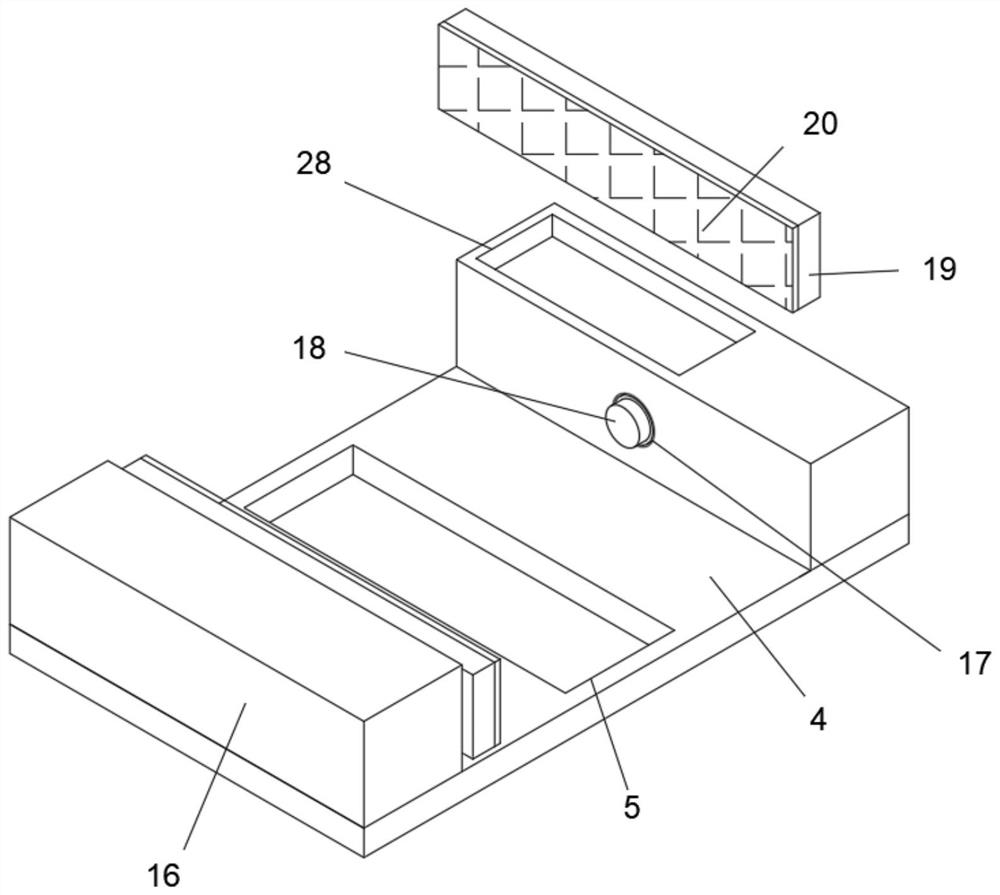

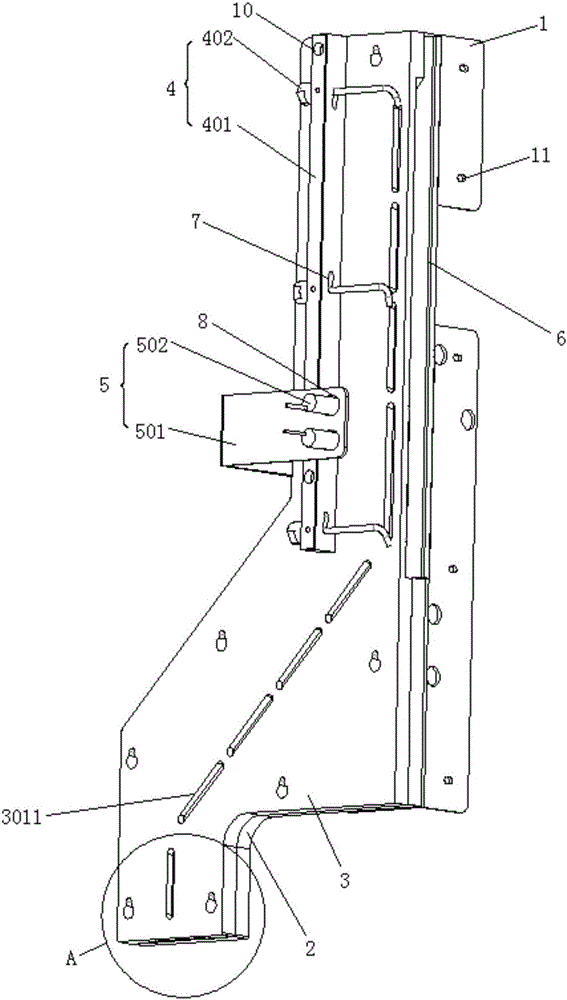

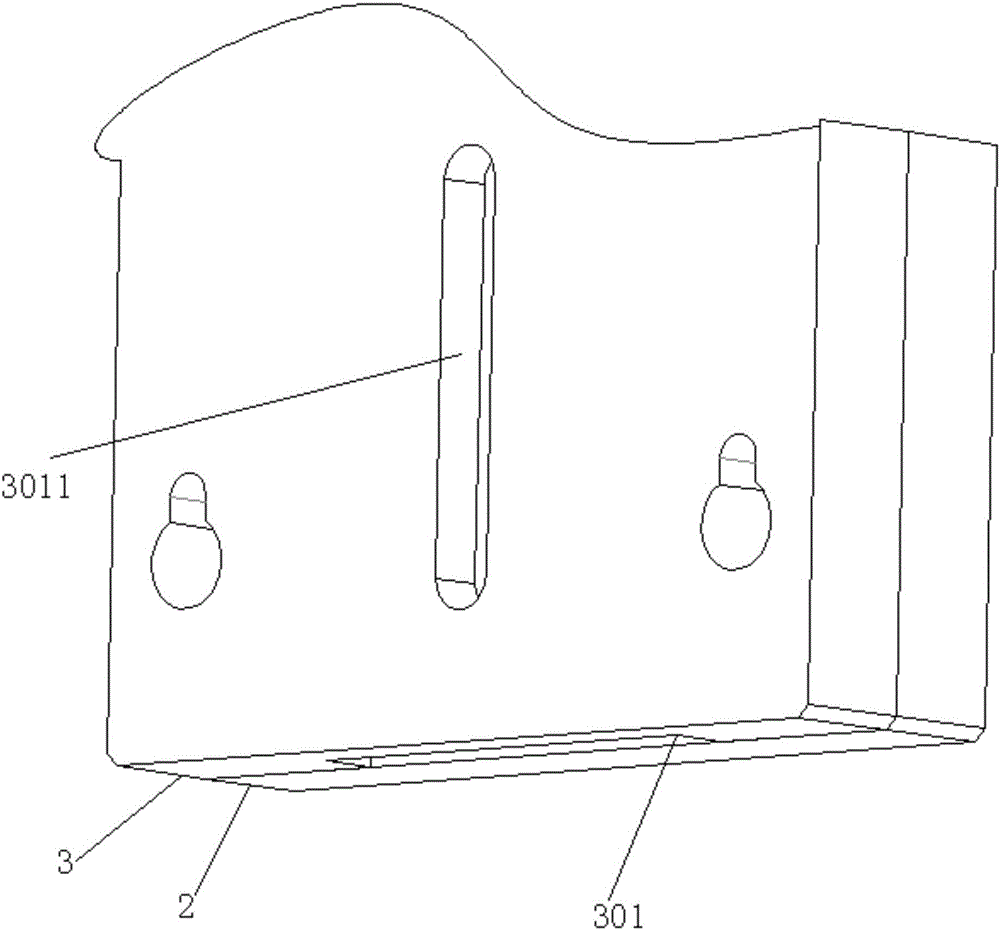

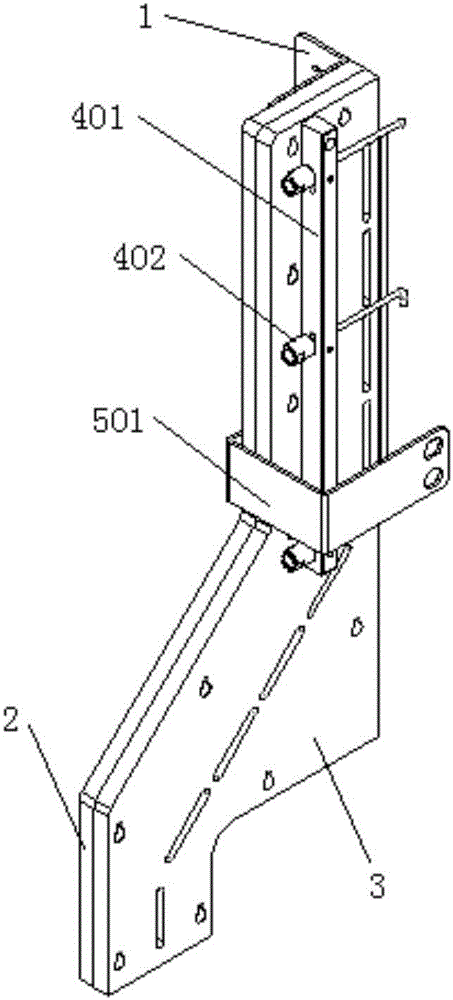

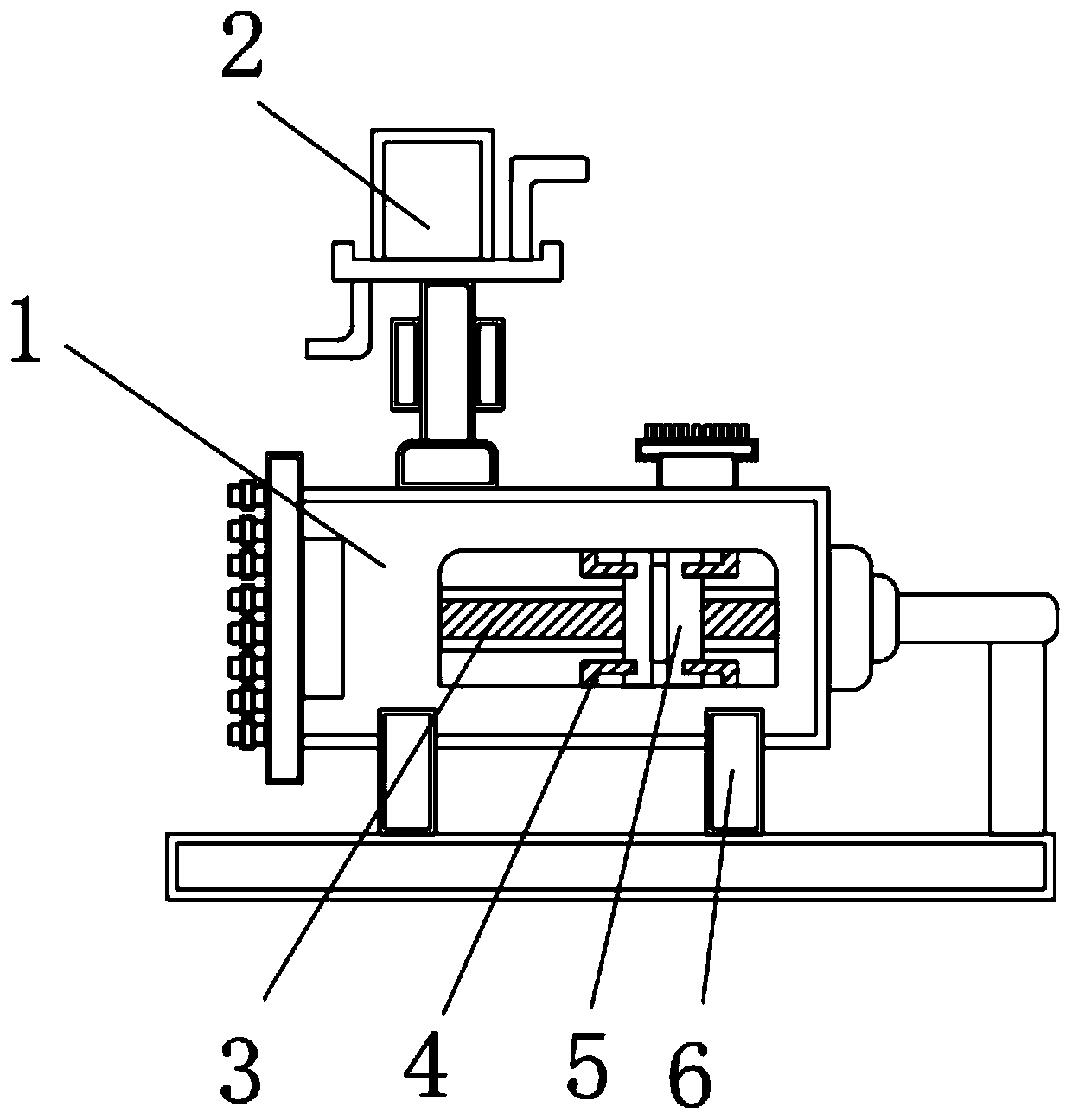

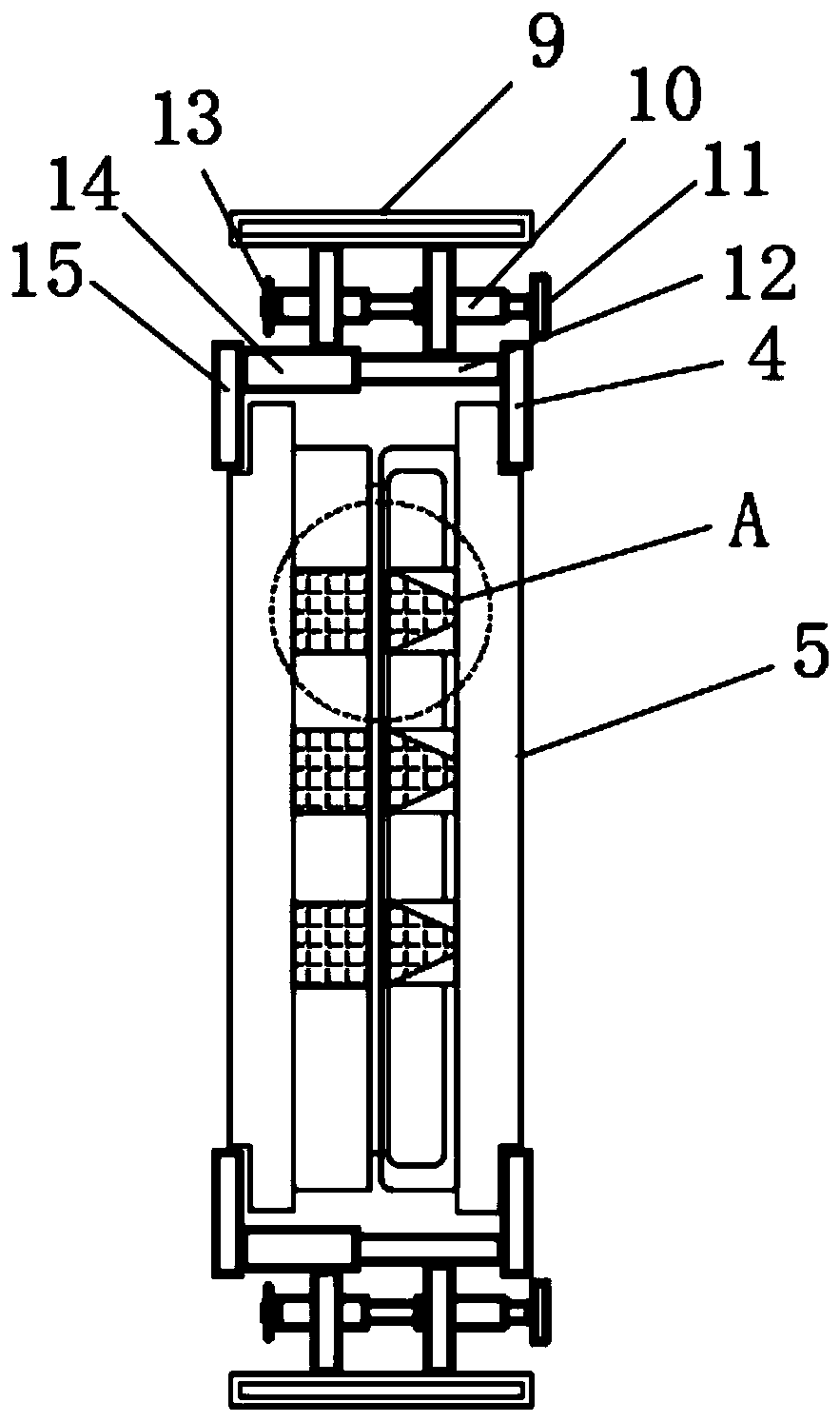

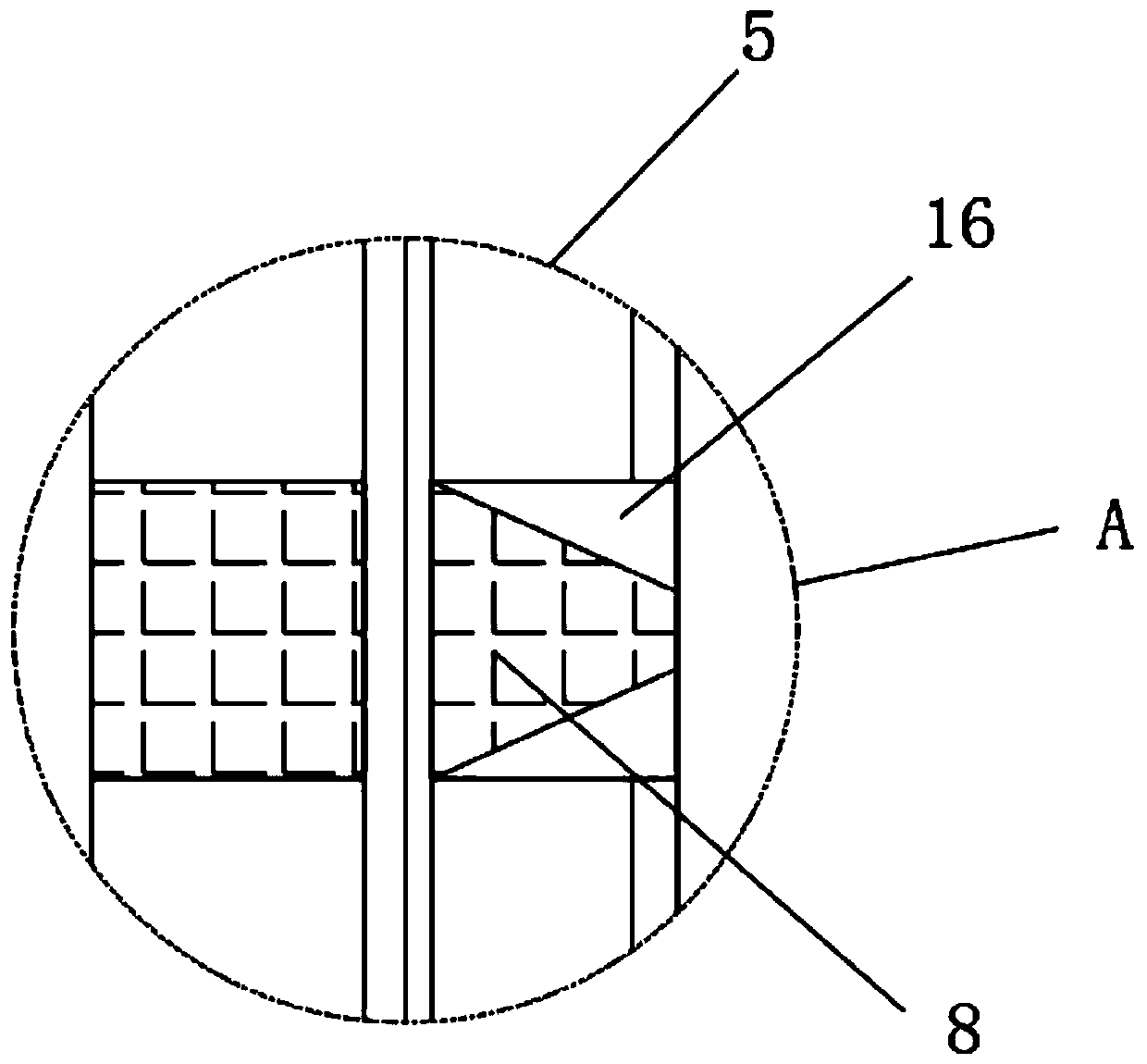

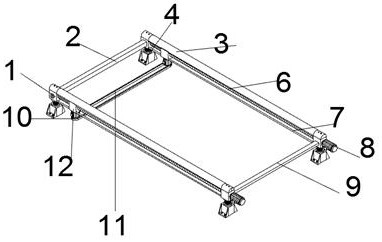

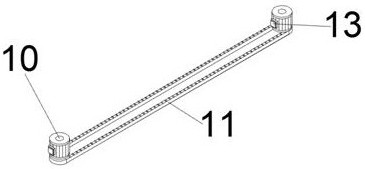

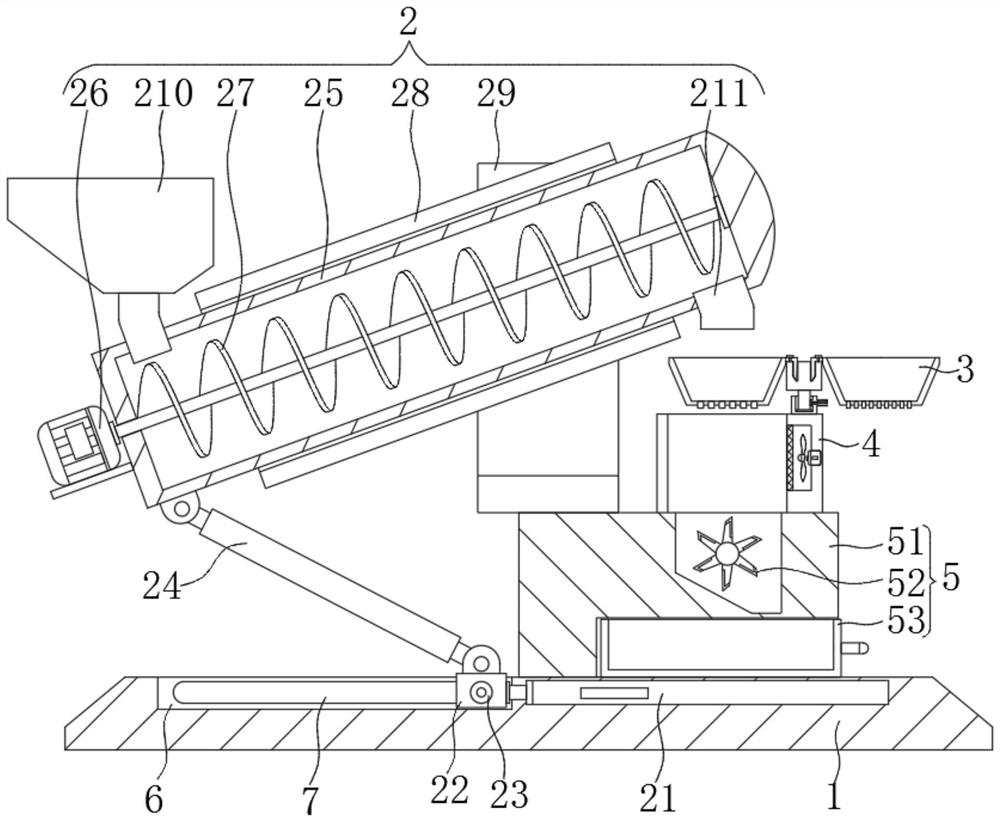

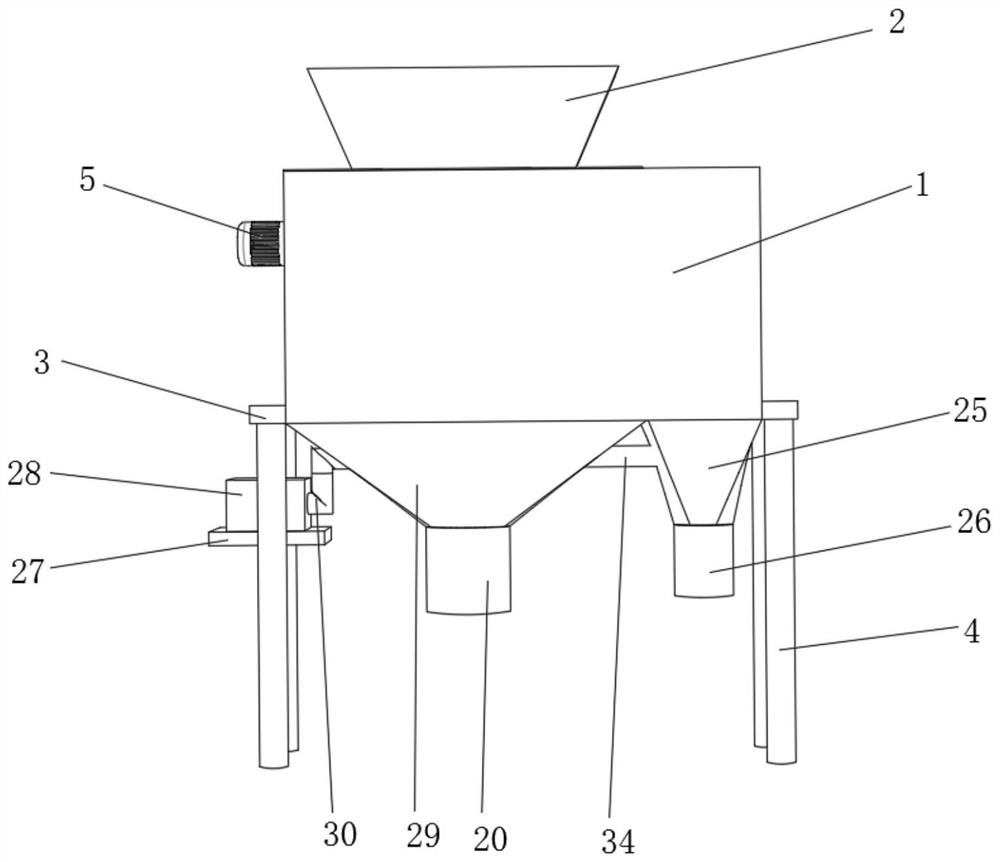

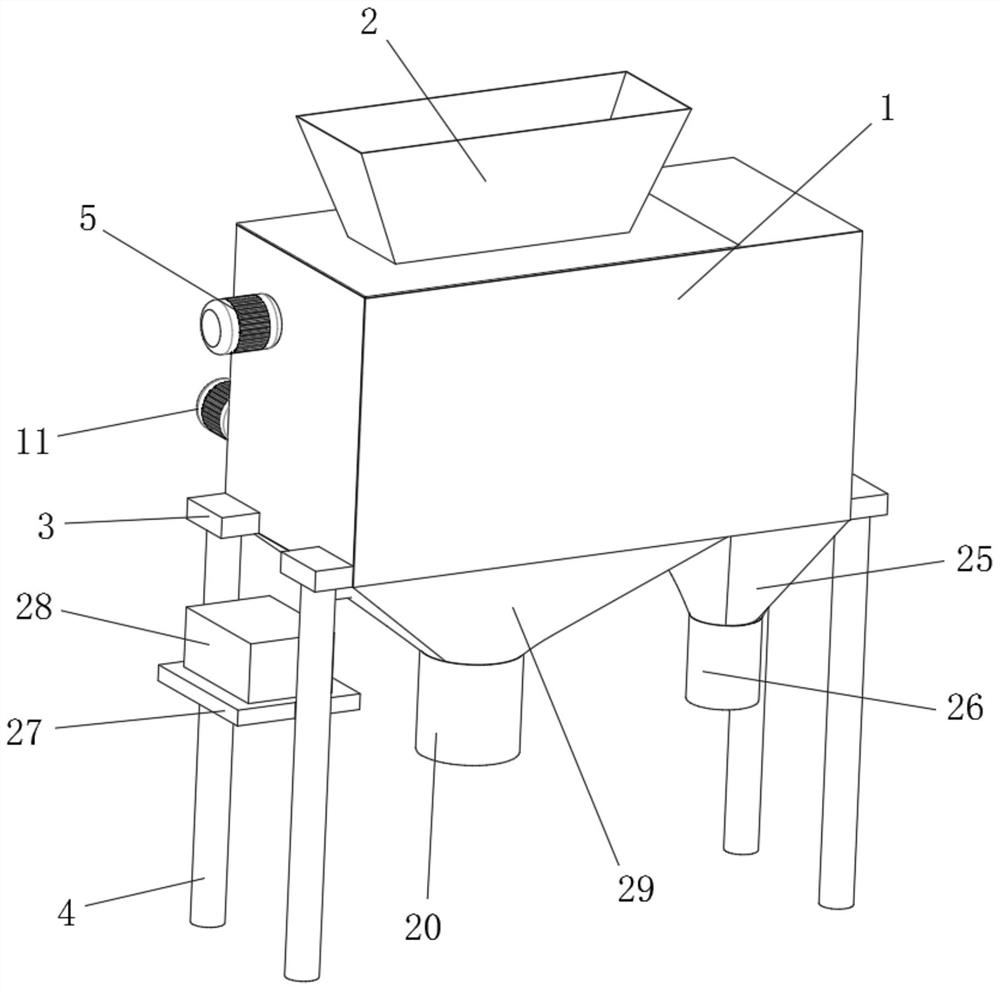

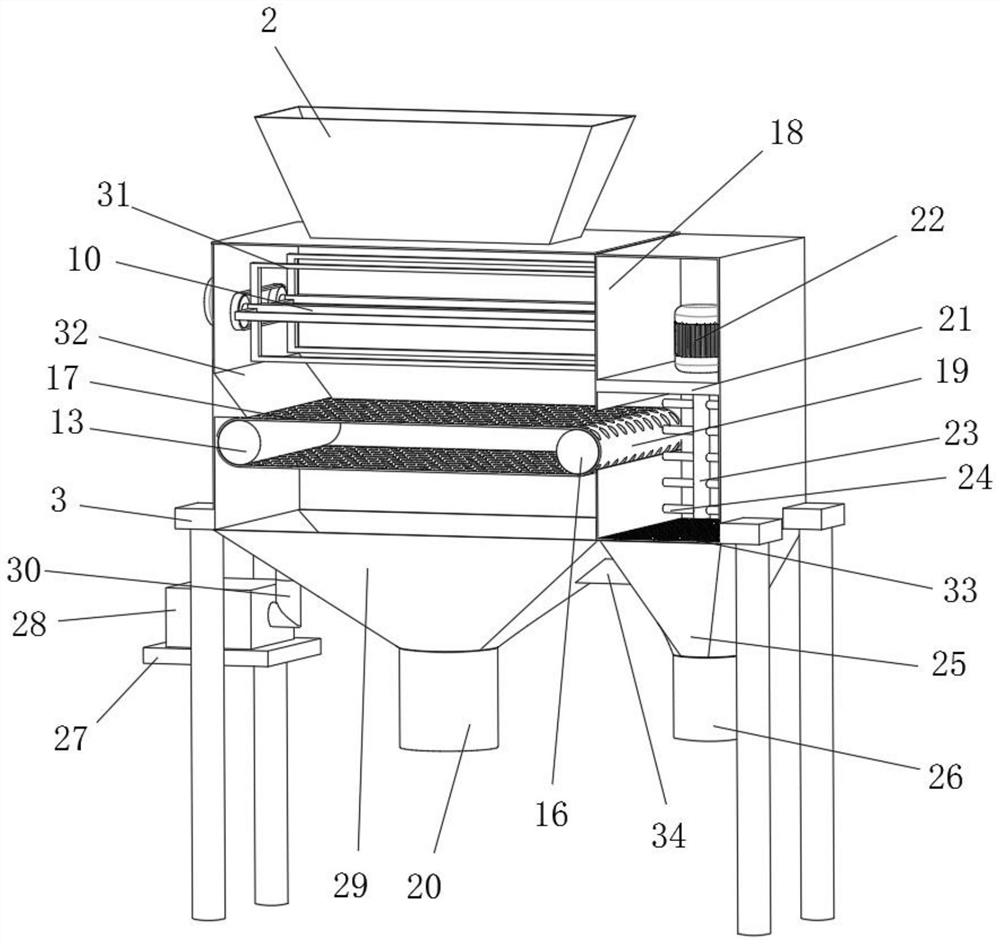

The invention relates to a composite board automatic gluing device. The device comprises a bottom plate, a mounting rack, a stacking device and a gluing device; the mounting rack is installed on the bottom plate, sliding chutes are formed in the mounting rack, the gluing device is installed in the sliding chutes, and the stacking device is installed at the lower end of the gluing device; the stacking device is installed on the bottom plate, and the stacking device comprises a linear guide rail, a limiting mechanism and a supporting mechanism; the gluing device comprises a glue discharging mechanism and a leveling mechanism; and the leveling mechanism comprises sliding blocks, sliding rods, a transverse plate, a telescopic leveling frame, a fixed supporting plate, an adjusting length air cylinder, a connecting ring and a driving branched chain. According to the composite board automatic gluing device, the problems that board codes are not even, gluing are non-uniform, glue is easy to waste, the adjustability is poor and the like in an existing composite board gluing process are solved; and the function of automatically gluing the composite board can be achieved, and the device has the advantages of being neat in stacking, uniform in gluing, not easy to waste glue, and flexible to adjust.

Owner:江苏林德曼新材料科技有限公司

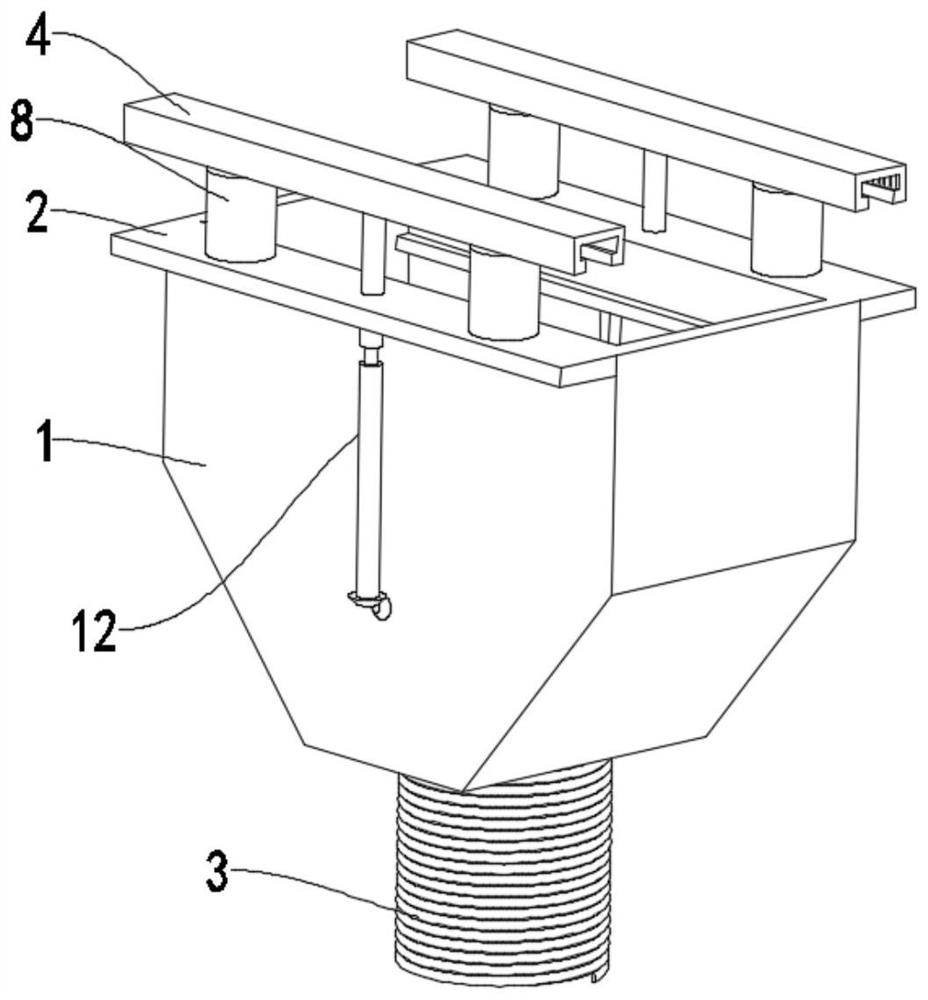

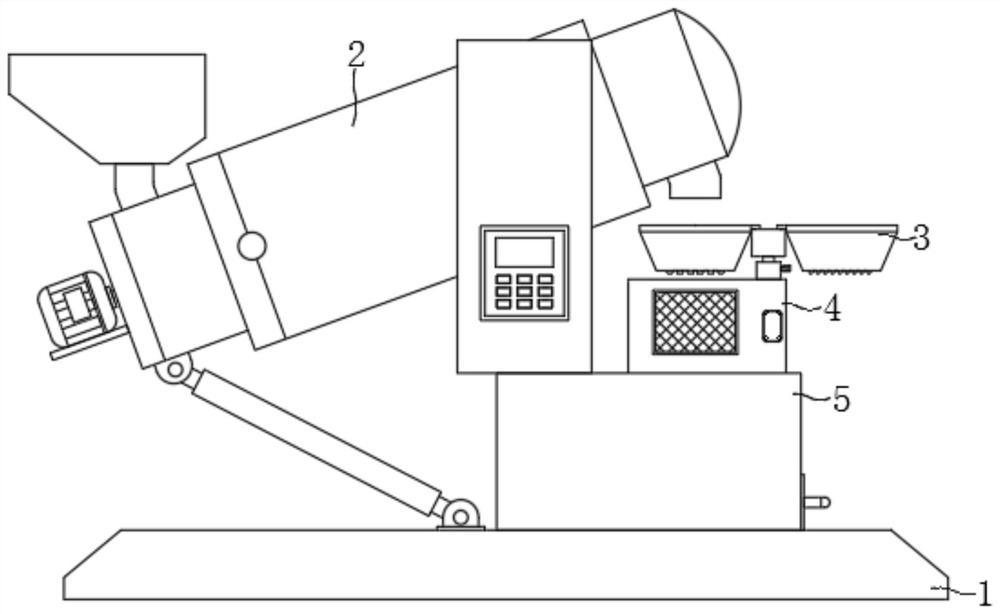

Composite wood board gluing machine

ActiveCN108687893ARealize automatic gluingWasteful realizationAdhesive application devicesPulp and paper industryWood panel

The invention relates to a composite wood board gluing machine. The composite wood board gluing machine comprises a bottom plate, an installing frame, a stacking device and a gluing device; the installing frame is installed on the bottom plate, and provided with a slide groove; the gluing device is installed in the slide groove, and the stacking device is arranged at the lower end of the gluing device, and installed on the bottom plate; the stacking device comprises a linear guide rail, a limiting mechanism, a supporting mechanism and a feeding mechanism; the gluing device comprises a glue outflow mechanism and a uniform smearing mechanism; and the uniform smearing mechanism comprises a sliding block, a sliding rod, a cross plate, a telescopic uniform smearing frame, a fixed supporting plate, a length adjusting cylinder, a connection ring and a driving branched chain. The composite wood board gluing machine can solve the problems that in the existing composite wood board gluing process, wood boards are stacked in disorder, gluing is not uniform, glue waste can be caused easily, and adjustability is poor, the function of performing automatic gluing on composite wood boards can be achieved, and the beneficial effects that stacking is in order, gluing is uniform, glue waste is not likely to be caused, and adjusting is flexible are achieved.

Owner:桃江县万众木业股份有限公司

Building paint spraying device with purification function

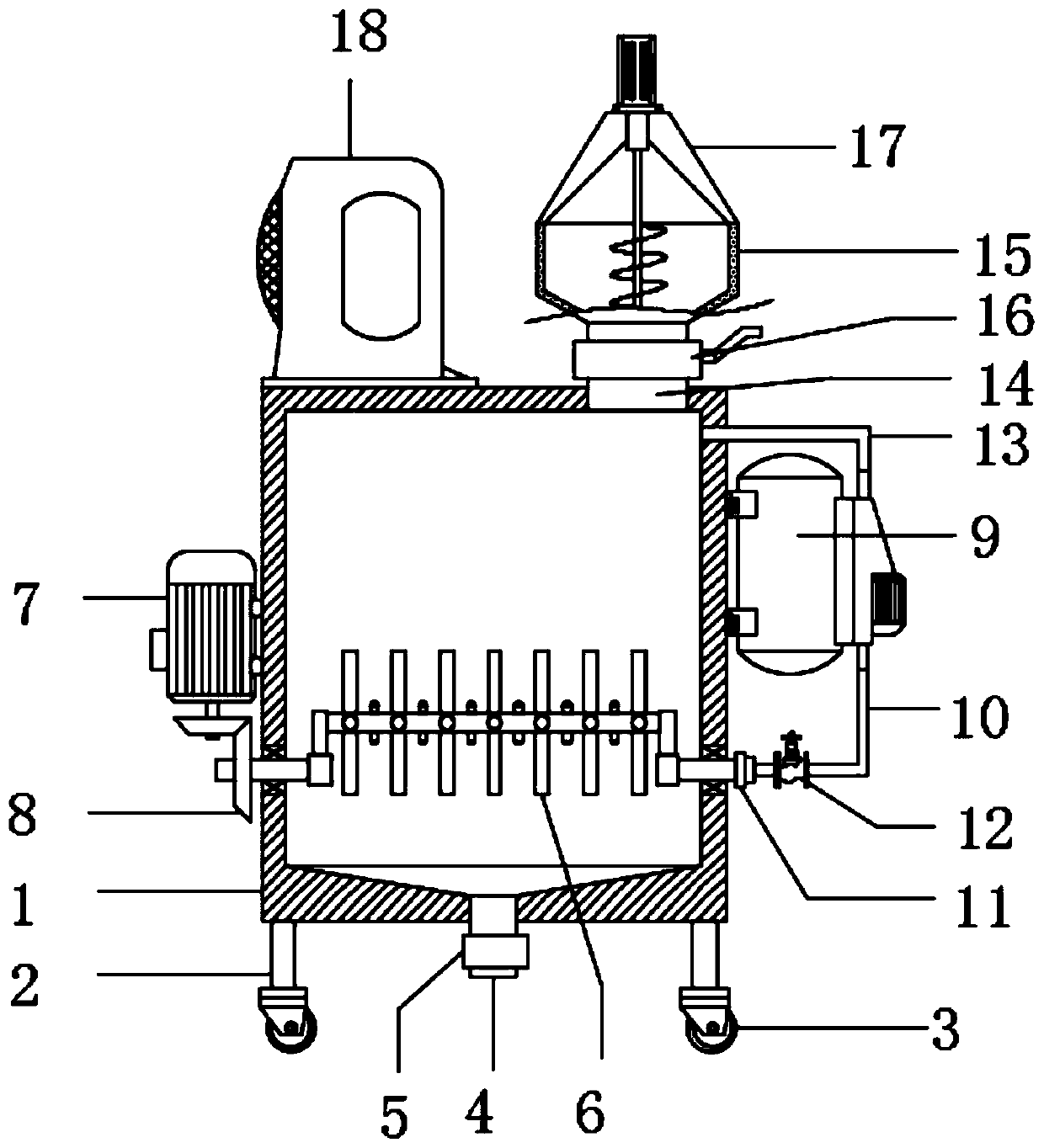

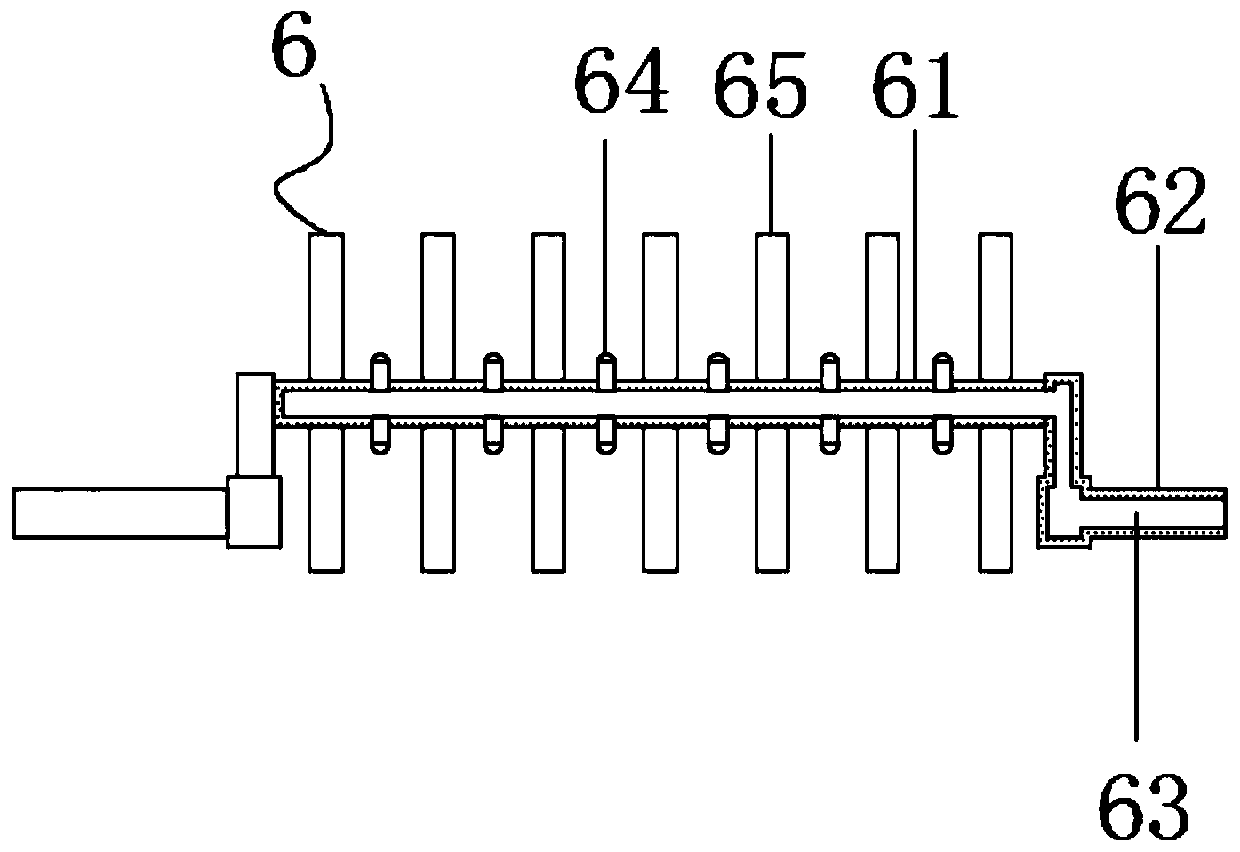

InactiveCN111482119AImprove stirring efficiencyIncrease finenessTransportation and packagingMixer accessoriesArchitectural engineeringAir cleaning

The invention discloses a building paint spraying device with a purification function, and belongs to the technical field of building paint. The device comprises a stirring box, universal wheels, a first motor and a small air compressor; supporting columns are fixedly connected to four corners of the bottom of the stirring box; four sets of the universal wheels are arranged; the four sets of universal wheels are arranged at the bottoms of the four sets of supporting columns correspondingly. The bottom of the stirring box is fixedly connected with a discharge pipe communicated with an inner cavity of the stirring box; a first control valve is mounted on the discharge pipe; a stirring shaft assembly is horizontally, transversely and rotationally connected to the lower middle portion of the inner cavity of the stirring box, and the first motor is fixedly arranged on the left side wall of the stirring box. Through mechanical stirring and air injection stirring of the stirring shaft assembly, the stirring efficiency of paint can be improved, and the stirring fineness of the paint can also be improved; and through an air purification assembly, indoor air can be effectively purified, andthe situation that the health of a worker is affected due to the fact that the worker inhales a large amount of dust and harmful gas is avoided.

Owner:福清市景士兰涂料有限公司

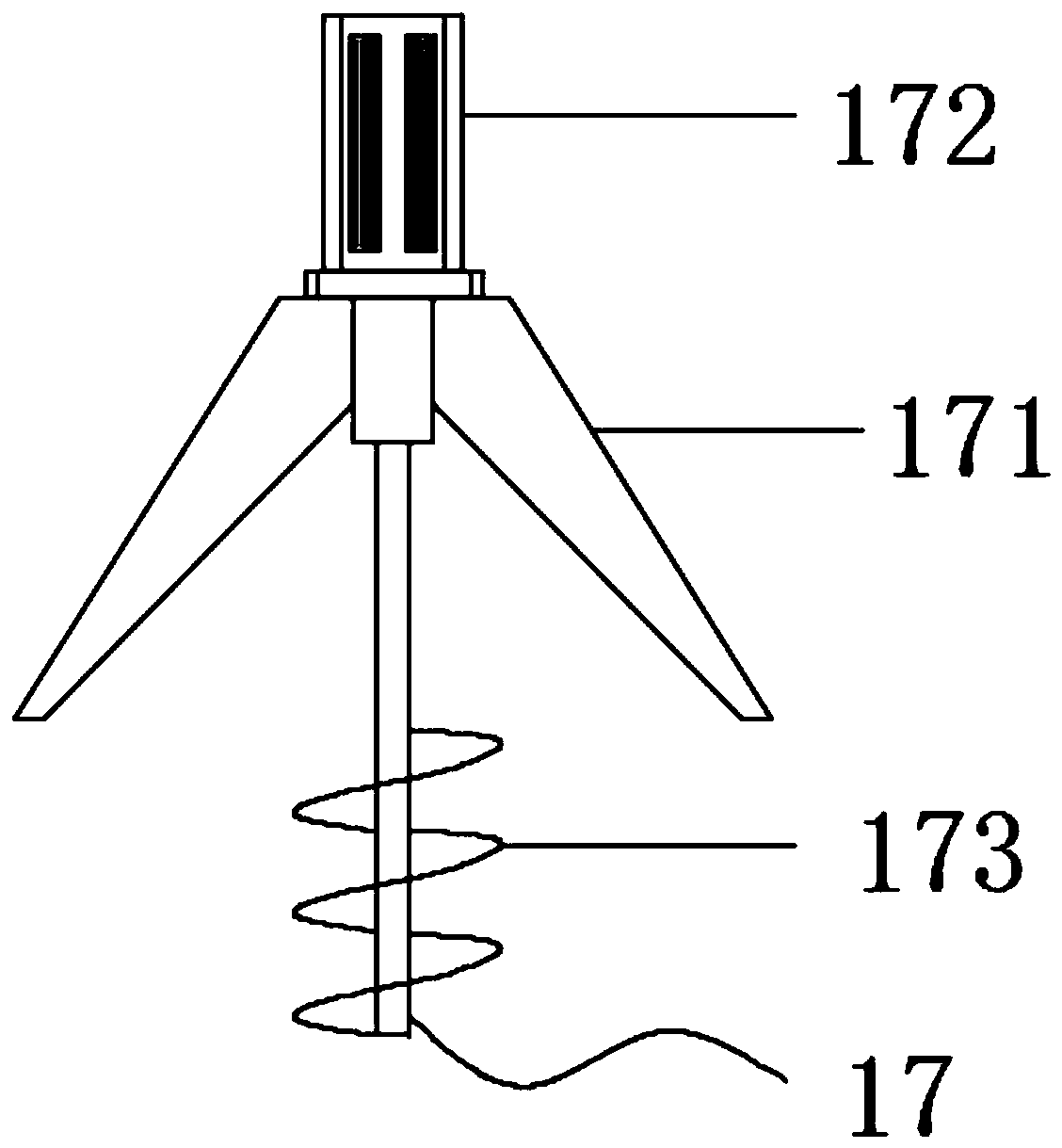

Hand push type environment-friendly lawn trimmer

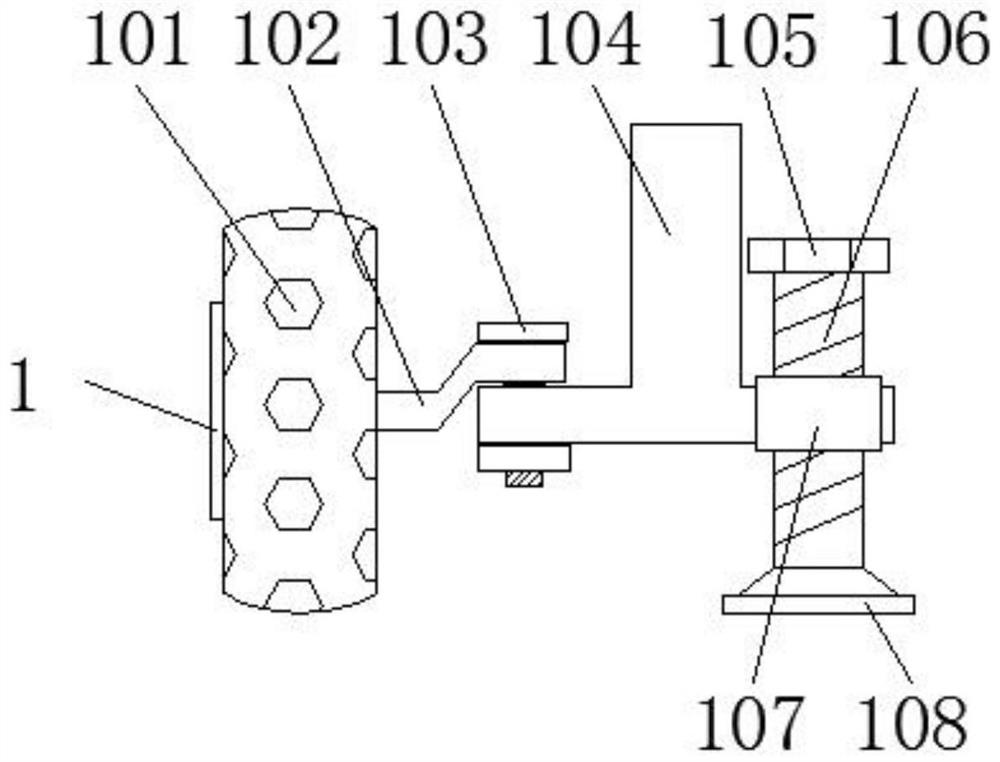

The invention discloses a hand-push type environment-friendly lawn trimmer. The lawn trimmer comprises an armrest, a stepping motor, a spiral lifter and annular grooves. The armrest is welded to the side of a fixed plate, second mounting holes are symmetrically formed in the top of the fixed plate, and vertical rods are screwed into the second mounting holes. First mounting holes are formed in theends, away from the second mounting holes, of the vertical rods, cross bars are fixed to the inner sides of the first mounting holes, and bumps are arranged on the inner sides of the cross bars. A sun-protective rain baffle plate is connected between the cross bars, and clamping slots corresponding to the bumps are formed in both sides of the sun-protective rain baffle plate. As the hand-push type environment-friendly lawn trimmer is provided with the spiral lifter and the stepping motor, when the trimmer is working, the height of a mounting groove from the ground is adjusted by the spiral lifter, thereby changing the height of the stepping motor in the mounting groove from the ground, facilitating the adjustment of a cutting blade to the trimming length of a lawn, and making the lawn betrimmed neatly without any unevenness.

Owner:HEFEI DONGLU MACHINERY MFG

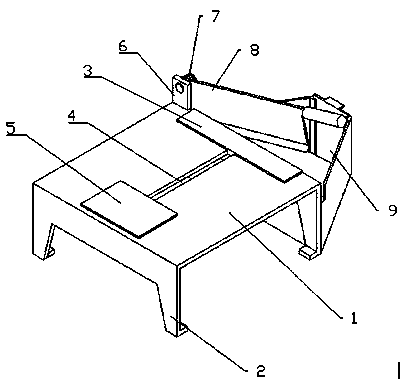

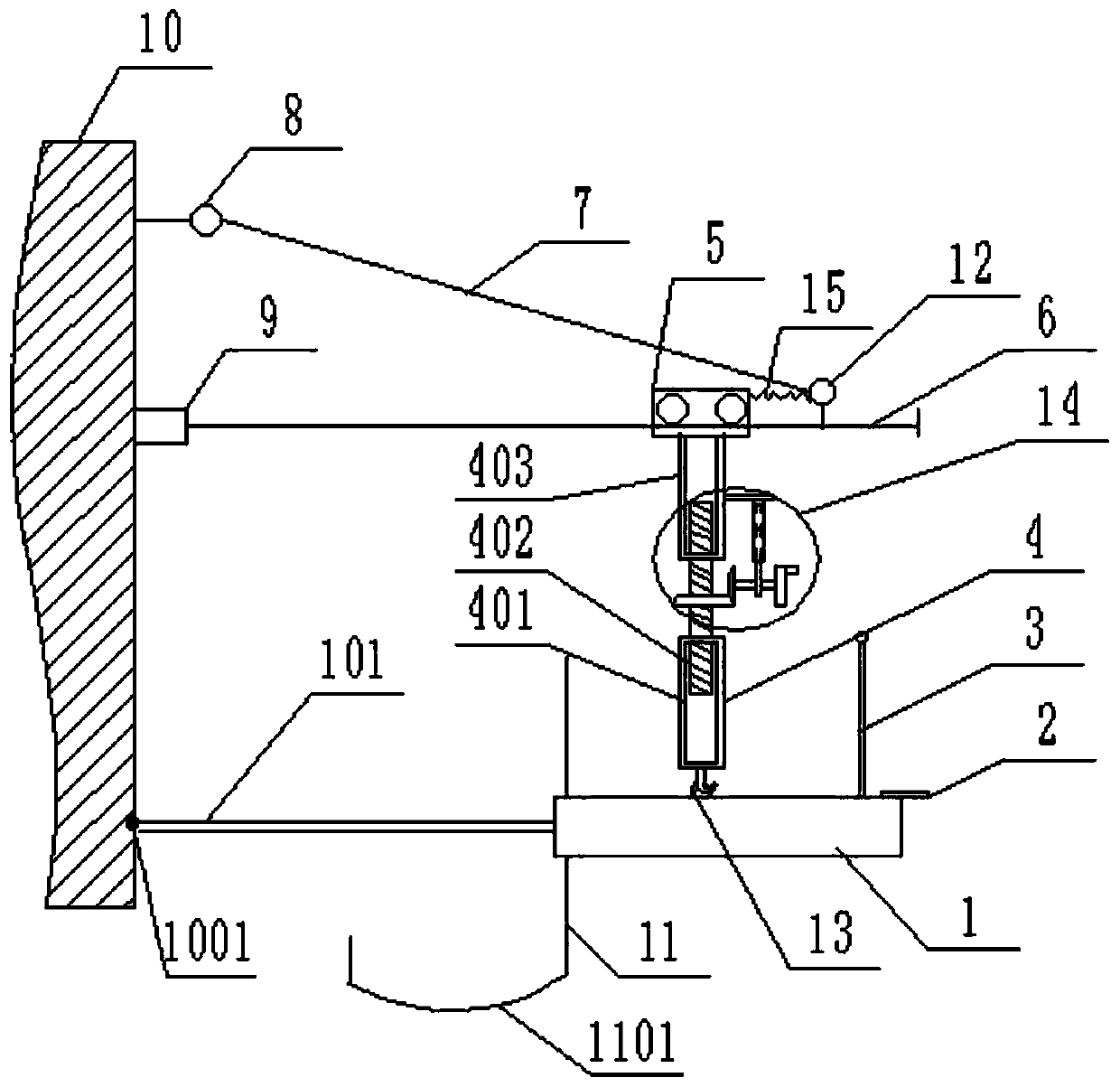

Preparation method of traditional Chinese medicinal materials

InactiveCN108656186AEasy to take out in pilesReduce frictionMetal working apparatusFixed frameEngineering

The invention discloses a preparation method of traditional Chinese medicinal materials. The device comprises a cutting frame, supporting legs, a base plate, a sliding groove, a sliding body, a fixedframe, a rotary knob, a cutter, a trapezoid-shaped groove, a sliding rail, a sliding plate and an extension spring. The cutting frame is a square table, the supporting legs are fixed to the four corners of the bottom face, the rectangular base plate is fixed to the right end of the cutting frame, the sliding groove is formed in the middle of the cutting frame, the sliding body is in sliding connection with the sliding groove, the fixed frame is perpendicularly fixed to the right rear end of the cutting frame, the cutter is hinged to the fixed frame through the rotary knob, the trapezoid-shapedgroove is fixed to the right side face of the cutting frame, the vertical sliding rail is arranged in an outlet of the right end of the trapezoid-shaped groove, the sliding plate is in sliding connection with the sliding rail, a sliding slope is arranged inside the trapezoid-shaped groove and slides from a cutting frame joint at a higher position to a sliding plate outlet at a lower position, theextension spring is arranged at the bottom of the cutting frame, the right end is fixed to the left side face of the trapezoid-shaped groove, and the left end is fixed to the sliding body. Accordingto the preparation method, operation saves time, and cut traditional Chinese medicinal materials can be placed in a concentrated mode conveniently.

Owner:山东小度智慧信息科技有限公司

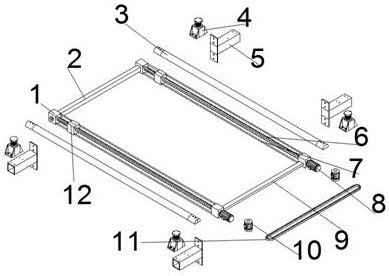

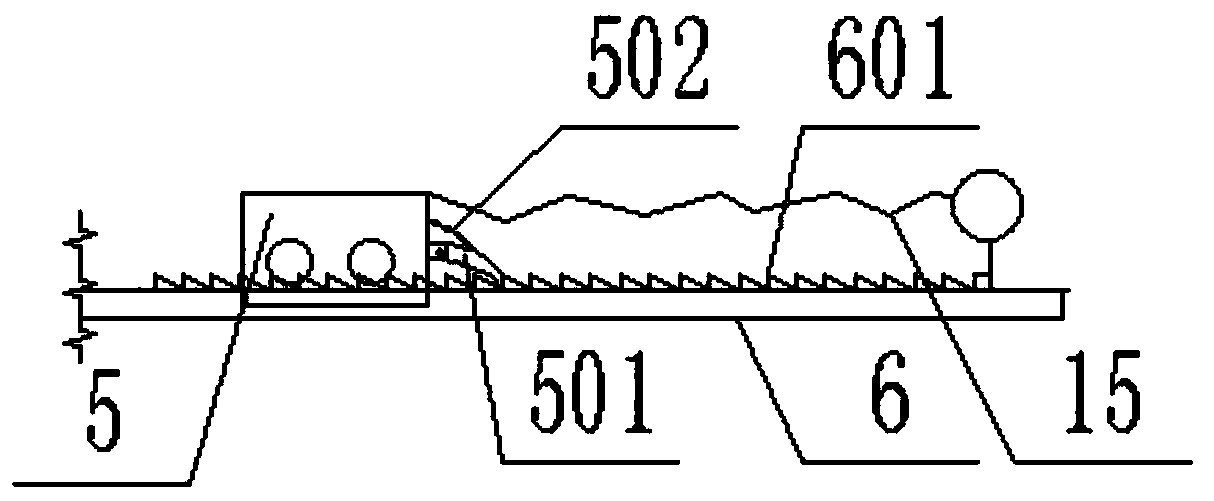

Pipe material cleaning device

InactiveCN106625092AAvoid affecting work progressEfficient and fast processing efficiencyEdge grinding machinesGrinding feedersPipe fittingEngineering

The invention belongs to the field of pipe fitting polishing and relates to a pipe material cleaning device. The pipe material cleaning device comprises a base; a taper type cavity allowing for pipe material stacking is formed in the base; the taper type cavity comprises an inlet end and an outlet end; friction layers are arranged on the outer walls of the outlet end of the taper type cavity; a guide rail is arranged on the position, outside the outlet end of the taper type cavity, of the base; a sliding block is connected with the guide rail in a sliding mode; a channel penetrating through the sliding block is arranged in the middle of the sliding block; elastic rings are fixedly mounted at the outlet end of the channel; and the diameter of each elastic ring is smaller than the diameter of each pipe material. According to the pipe material cleaning device, the shortcomings of slow machining cleaning and low machining efficiency of the pipe materials in the machining process can be overcome, and automatic cleaning and conveying of the pipe materials are achieved.

Owner:ERA PIPELINE (CHONGQING) CO LTD

Bending equipment for machining protective aluminum part in construction field

The invention discloses bending equipment for machining a protective aluminum part in the construction field, and relates to the technical field of aluminum machining. The bending equipment a workbench, a first sliding groove is formed in the workbench, a box body is fixedly mounted at the top of the workbench, a supporting plate is fixedly mounted at the bottom of the box body, a motor is fixedlymounted at the top of the supporting plate, an output shaft of the motor is fixedly provided with a first latch through a coupler, a second latch and a third latch are arranged over the supporting plate, the first clamping teeth, the second clamping teeth and the third clamping teeth are sleeved with a transmission chain, the first clamping teeth, the second clamping teeth and the third clampingteeth are in transmission connection through the transmission chain, a first rotating rod is fixedly installed on the second clamping teeth, a second rotating rod is fixedly installed on the third clamping teeth, and an installation plate is arranged over the box body. The bending equipment is easy to operate, energy output can be reduced, and materials can be saved conveniently.

Owner:马琴英

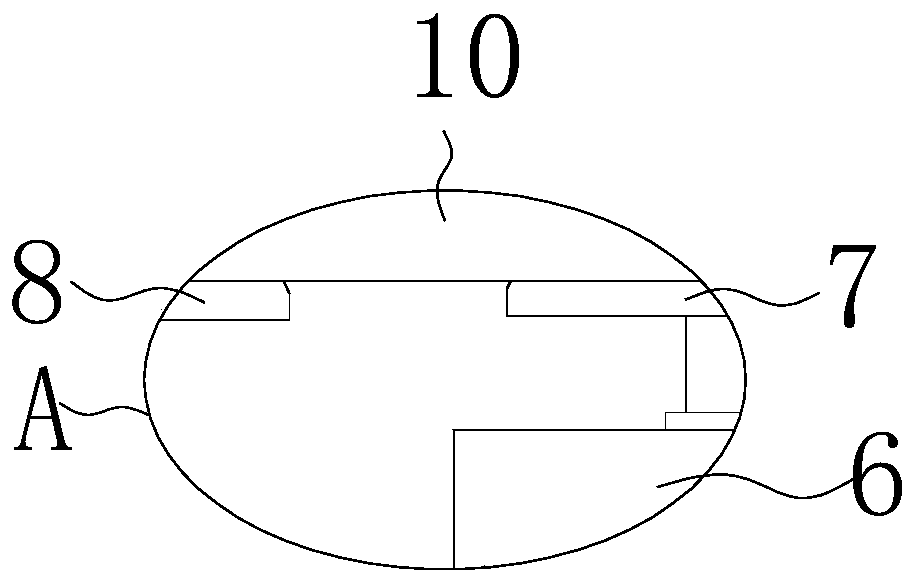

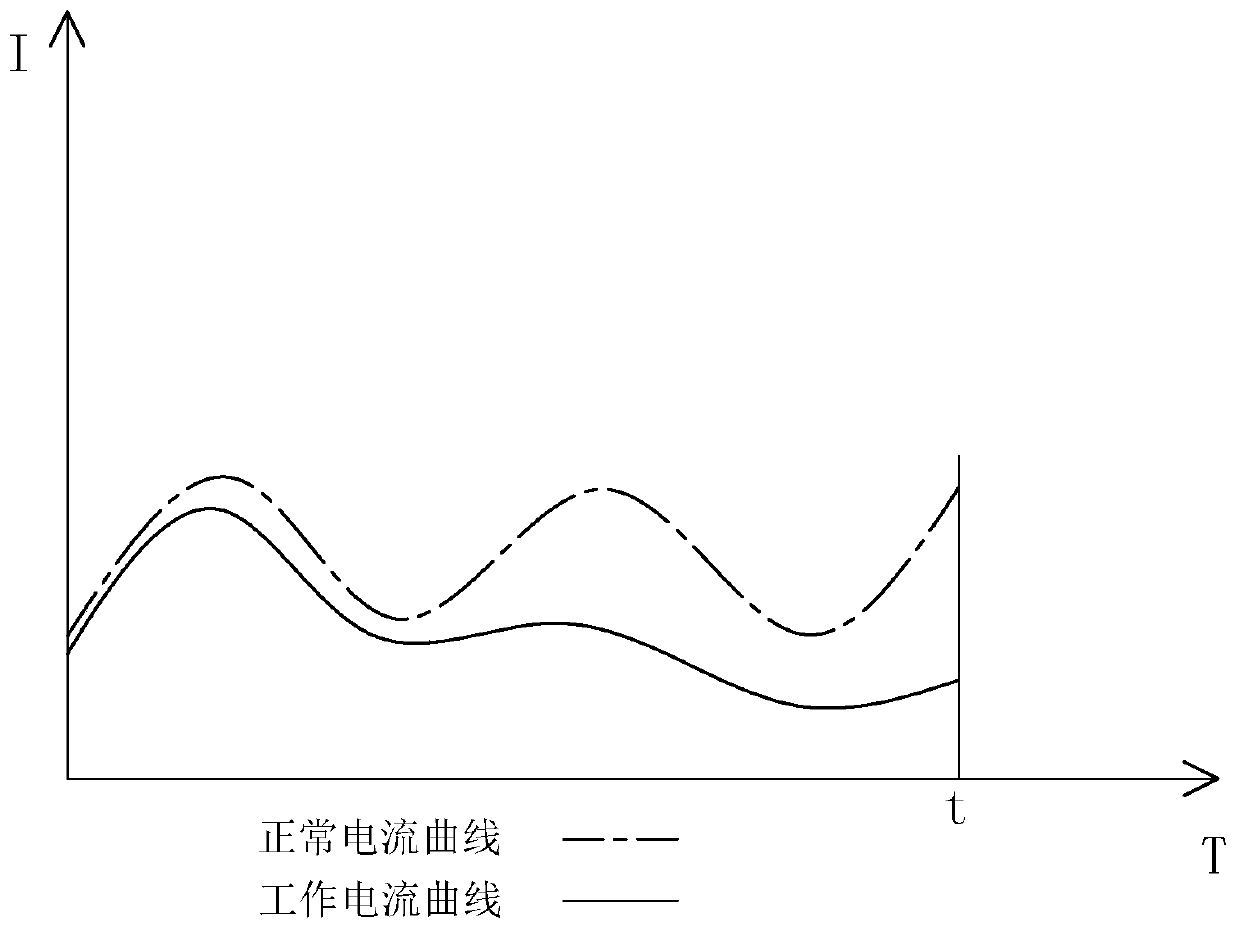

System and method for evaluating safety according to equipment data

ActiveCN109813956AAvoid affecting work progressReduce computationMeasurement using digital techniquesWork statusEngineering

The invention relates to the technical field of equipment safety, in particular to a system and method for evaluating safety according to equipment data. The method for evaluating the safety assessment according to the equipment data comprises the steps that 1, a database is established, and a normal current curve is formed; 2, a working current curve is monitored; 3, the working current curve iscompared with normal working current, and a low-risk signal of whether or not fire danger exists is judged and sent based on the similarity of the two curves. By establishing the database, the normalcurrent curve style is formed, the working current curve is formed after the working current of the equipment is monitored, and the working current curve is compared with the normal current curve. Based on the similarity judgment of the two curves, the difference degree of the two curves is calculated; when the difference of the two curves is small, it is judged that the equipment is in a normal working state, when the difference of the two curves is large, it is judged that the equipment is in an abnormal working state, and the low-risk signal is sent out. The equipment is repaired after thework on the day is finished.

Owner:CHANGZHOU TIANZHENG IND DEV CO LTD

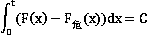

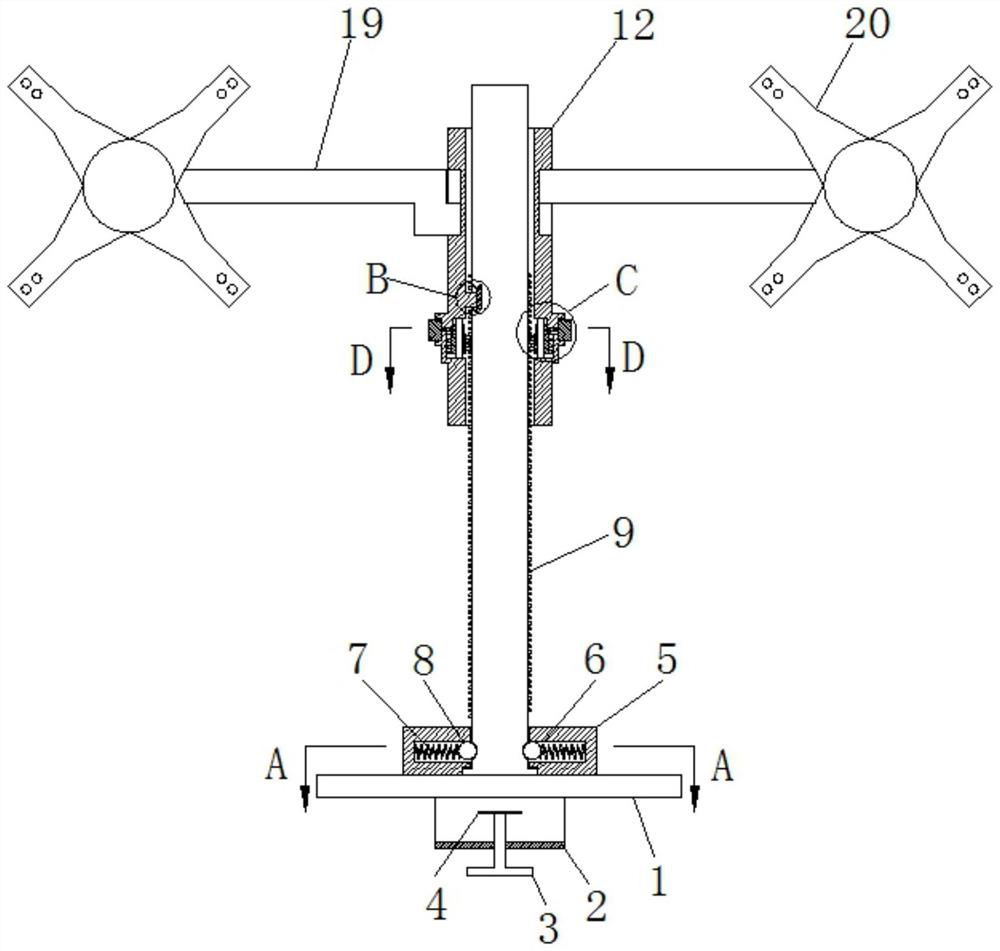

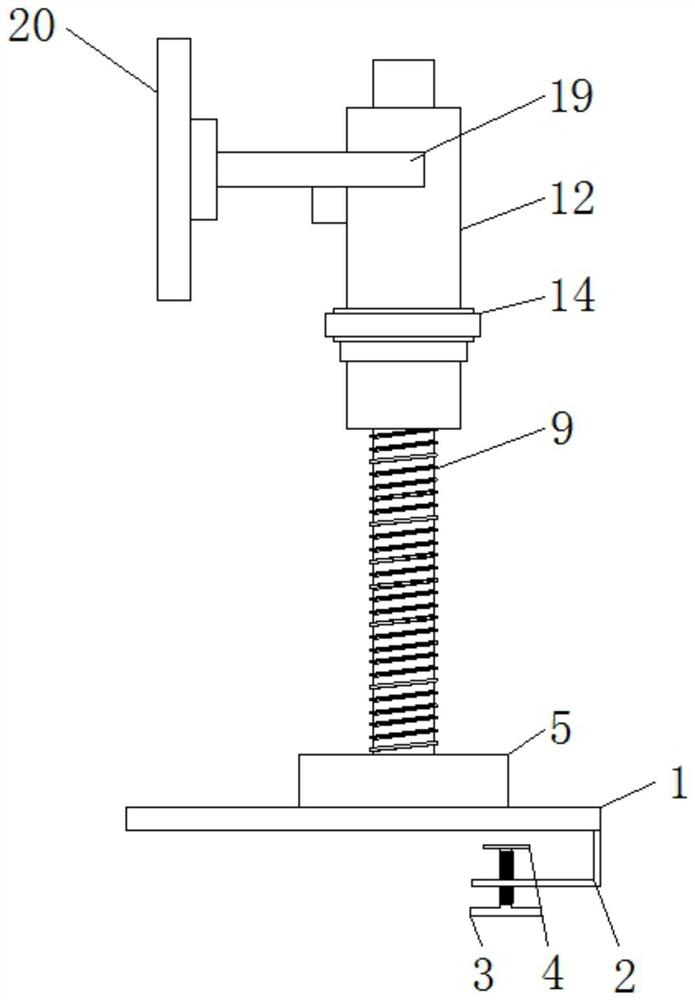

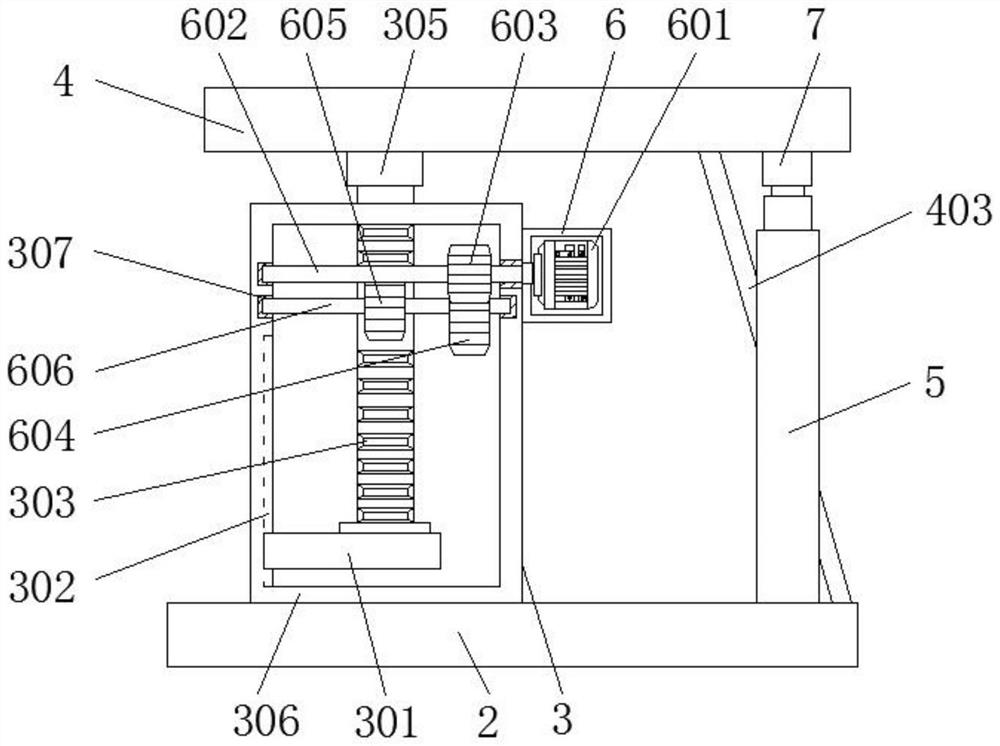

A multi-screen computer support frame based on the principle of screw rod lifting

The invention relates to the technical field of computer network development, and discloses a multi-screen computer supporting frame based on a screw rod lifting principle. The multi-screen computer supporting frame comprises a supporting plate, wherein the bottom of the supporting plate is fixedly connected with a fixing plate; the interior of the fixing plate is in threaded connection with a positioning pin; the top of the positioning pin is movably connected with a top plate; and the top of the supporting plate is fixedly connected with a base. According to the multi-screen computer supporting frame, the supporting plate, the fixing plate, the positioning pin and the top plate are used in a matched mode, the area of the supporting plate is large, the supporting bottom area is increased,the gravity center of the multi-screen computer supporting frame is reduced, and the stability of the multi-screen computer supporting frame is improved; and meanwhile, the top plate and the supporting plate clamp a working table top, so that the stability of the multi-screen computer supporting frame is further improved, the stability of a computer display screen is effectively guaranteed, the possibility that the computer display screen falls is avoided, the smooth operation of the work is guaranteed, the working progress is prevented from being influenced due to the fact that the display screen falls, and meanwhile, the situation that the maintenance cost is increased due to the fact that the computer display screen is broken is avoided.

Owner:安徽中恒威设计有限公司

Cutting mechanism for extrusion molding of CPVC pipe

InactiveCN111702850AEasy to holdEasy to moveMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a cutting mechanism for extrusion molding of a CPVC pipe. The cutting mechanism comprises a bottom plate. A sliding groove is formed in the upper surface of the bottom plate, asliding block is movably connected to the interior of the sliding groove, a supporting plate is fixedly connected to the upper surface of the sliding block, and a baffle is movably connected to the outer surface of the supporting plate. The upper surface of the baffle is movably connected with a pressing plate through an adjusting bolt, the lower surface of the pressing plate is fixedly connectedwith an inserting plate, and the upper surface of the bottom plate is fixedly connected with a fixing plate through a connecting plate. According to the cutting mechanism for extrusion molding of theCPVC pipe, the baffle, a pressing plate clamping groove and a fixing bolt are arranged on the outer surface of the supporting plate, the baffle slides on the outer surface of the supporting plate through the clamping groove by operating the fixing bolt, so that the height of the baffle is adjusted, the pressing plate is conveniently placed, the CPVC pipe can be clamped conveniently, and it is avoided that the CPVC pipe moves in the CPVC pipe cutting process and the work progress is influenced.

Owner:浙江长兴俊峰新材料科技有限公司

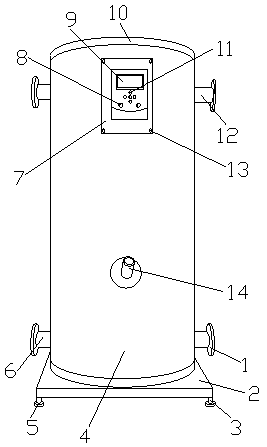

Biomass clean combustion boiler

PendingCN110469843AAvoid affecting work progressSolid fuel combustionLump/pulverulent fuel preparationCombustionHeat conducting

The invention discloses a biomass clean combustion boiler which structurally comprises a connecting plate, a supporting bottom plate, a connecting column, a boiler body, non-slip bottom feet, a feeding pipe, a buffer gasket, an indicator light, a display screen, a sealing cover, a control panel, an air outlet pipe, a limit screw and an observation pipe. According to the biomass clean combustion boiler, in the process that materials enter the boiler body, when the materials are piled up in the boiler body until a moving contact is pulled, a return spring deforms, the moving contact downwards and slantly touches a fixed contact under the action of a connecting shaft, a wiring port is energized to work, and a heat conduction pipe is energized to conduct heat to a heat-generating pipe, so thata heat-conducting cover automatically heats the materials, and gas generated after heating is discharged through the air outlet pipe; and when a worker uses the device, the boiler body on the devicecan automatically pull the moving contact through the materials to heat biomass, and the influences of inconvenient heating operation of the device on the working schedule are avoided.

Owner:江苏台安迪环保科技有限公司

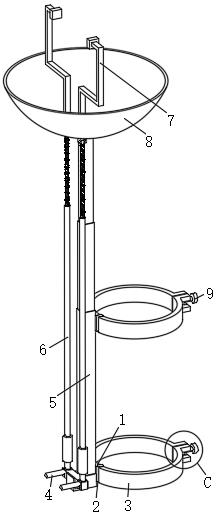

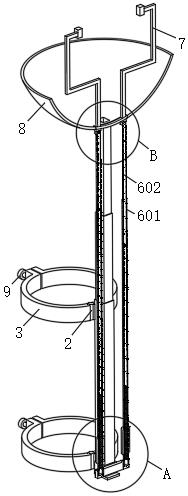

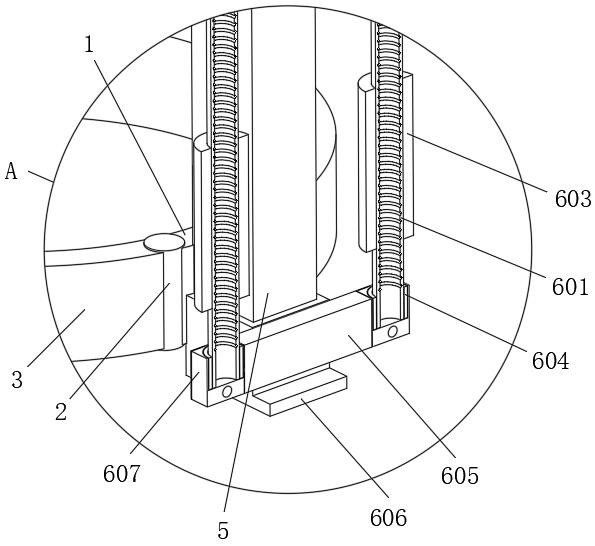

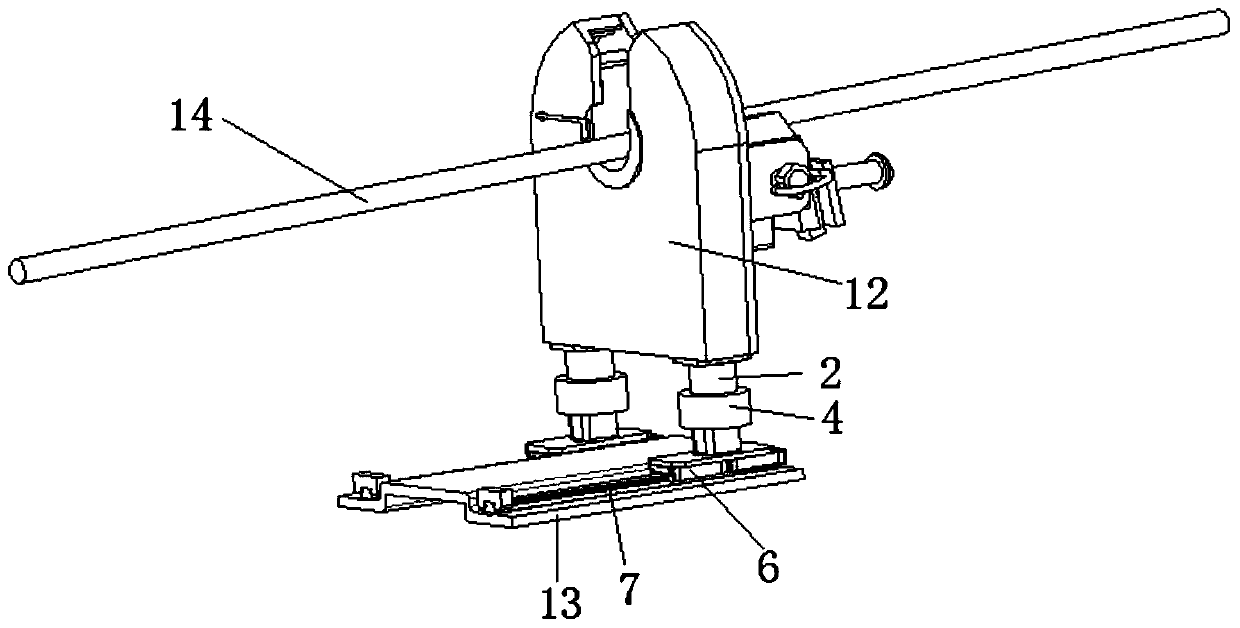

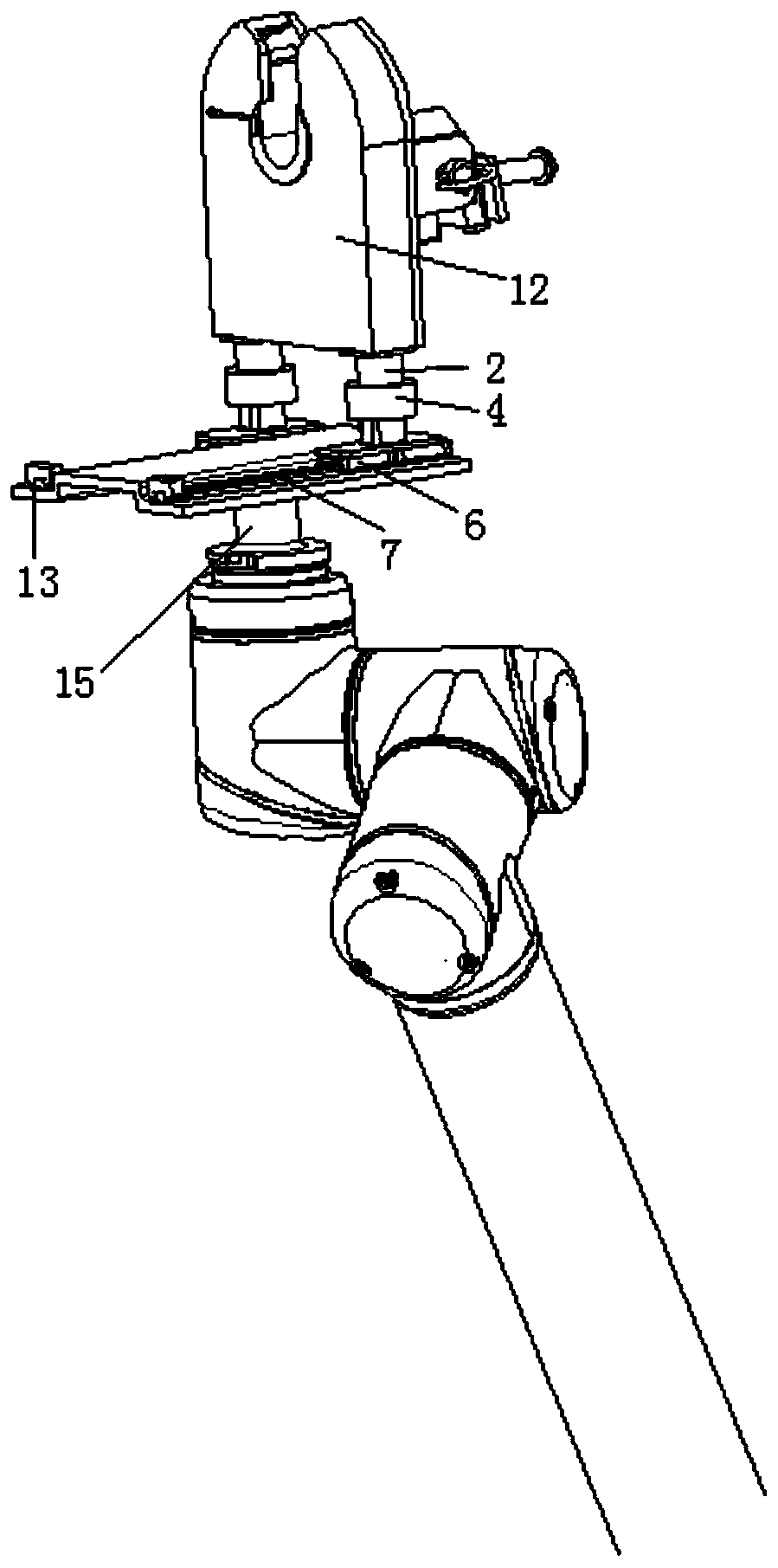

A bird's nest removal device on a power supply line

ActiveCN112467606BEasy to carryAvoid climbingOverhead installationApparatus for overhead lines/cablesAnimal scienceBird nest

A bird's nest removal device on a power supply line, which relates to the technical field of power supply line maintenance. There are two arc-shaped positioning plates. There are through grooves on the connecting plates, and a locking mechanism is installed in the through grooves on one of the arc connecting plates, and the locking end of the locking mechanism is located in the through grooves on the other arc connecting plate and snapped into place. The bird's nest removing device on a power supply line according to the present invention is convenient for the staff to carry, and the bird's nest removing device on the power supply line is fixed on the utility pole through the arc-shaped connecting plate and the locking mechanism, so as to prevent the staff from climbing , through the swing mechanism, the protective cover is raised to the bird's nest on the pole, and the bird's nest is removed by hitting the hitting rod, and the branches and soil that fall when hitting the bird's nest are collected through the protective cover to prevent the soil and branches from falling To the face of the staff, affecting the work progress.

Owner:国网河南省电力公司洛阳市孟津供电公司 +1

A cover outlet device for a cover unscrambling machine

The invention discloses a cap outlet device of a cap arrangement machine. A rear cover plate is detachably and fixedly connected with a front buckling plate. A concave guide groove which can contain bottle caps is formed in the inner side of the front buckling plate. Groove holes are formed in the concave guide groove. The concave guide groove serves as a space allowing the bottle caps to be conveyed smoothly and orderly. When being stuck, the bottle caps in the concave guide groove can be arranged in a manner that a tool penetrates into the groove holes; normal work is resumed; it is not needed to arrange multiple locating plates; the number of points needing to be fixed on the whole is relatively small; and a main body is mounted firmly, and the cap outlet device is provided with a small number of components. The cap outlet device has the beneficial effect of being simple in structure; the device is convenient to mount and detach; maintenance cost is lowered; and the problem that existing buckling plate structures are complex to mount or detach is solved.

Owner:海口尚维科技有限公司

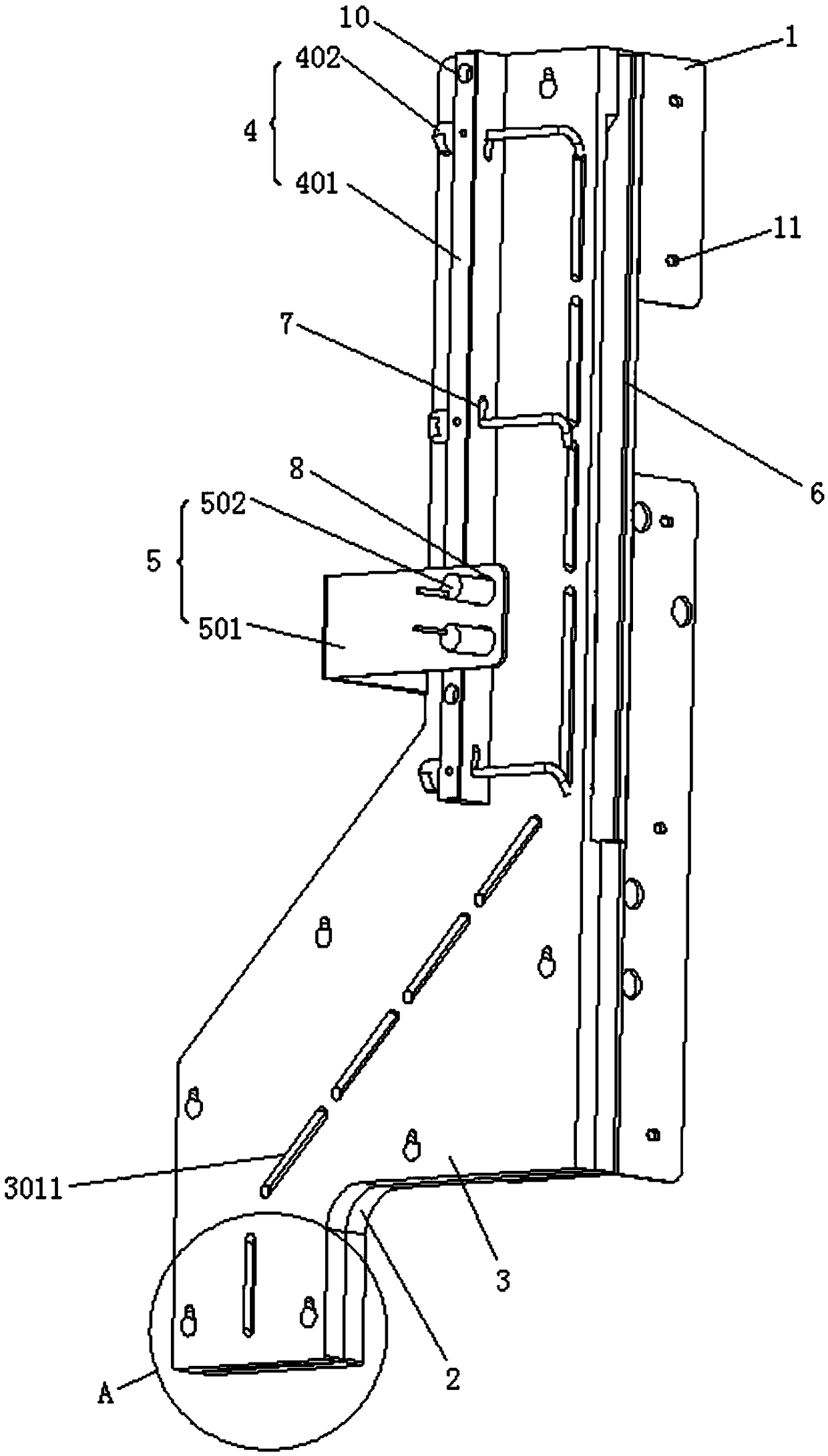

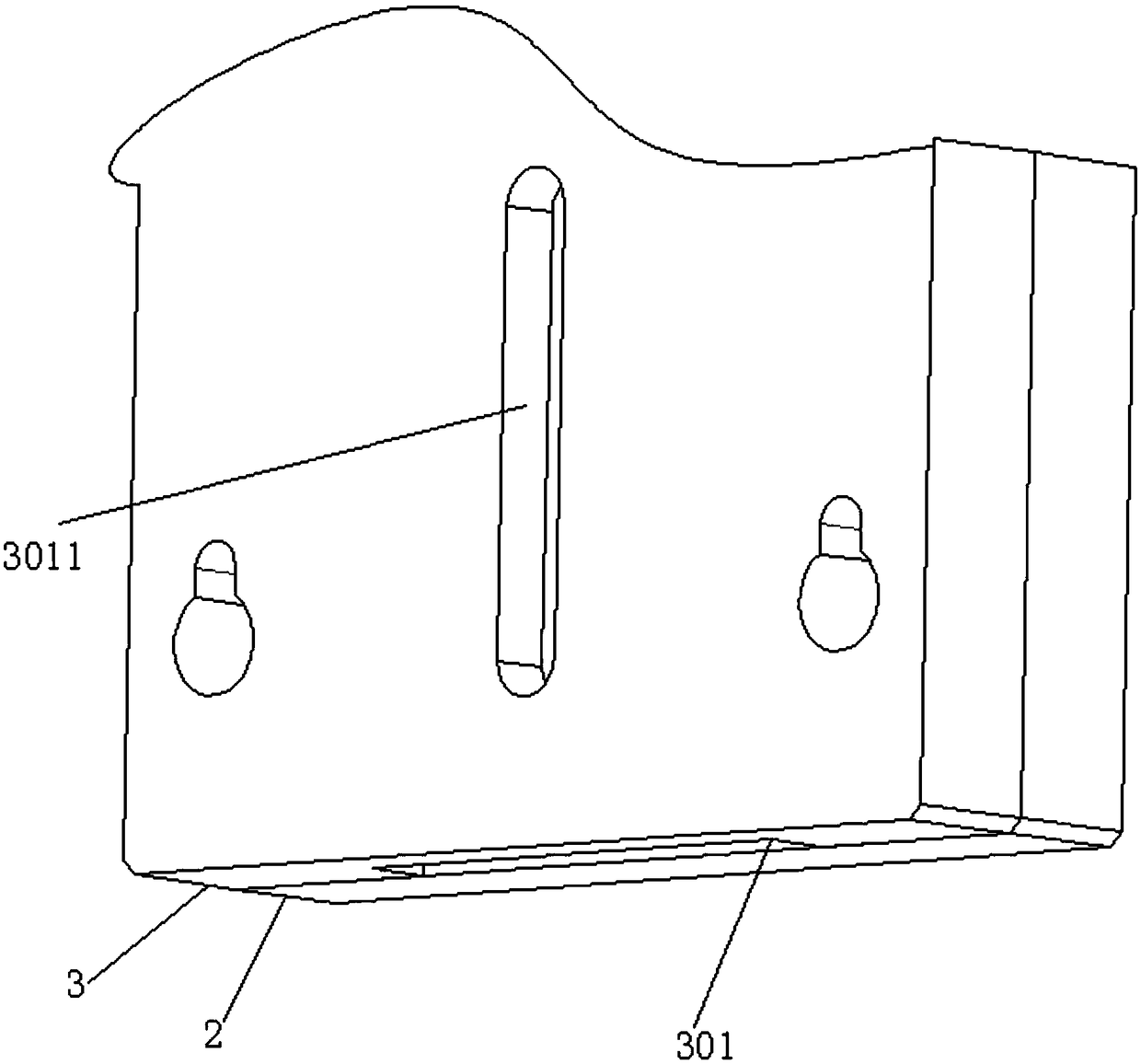

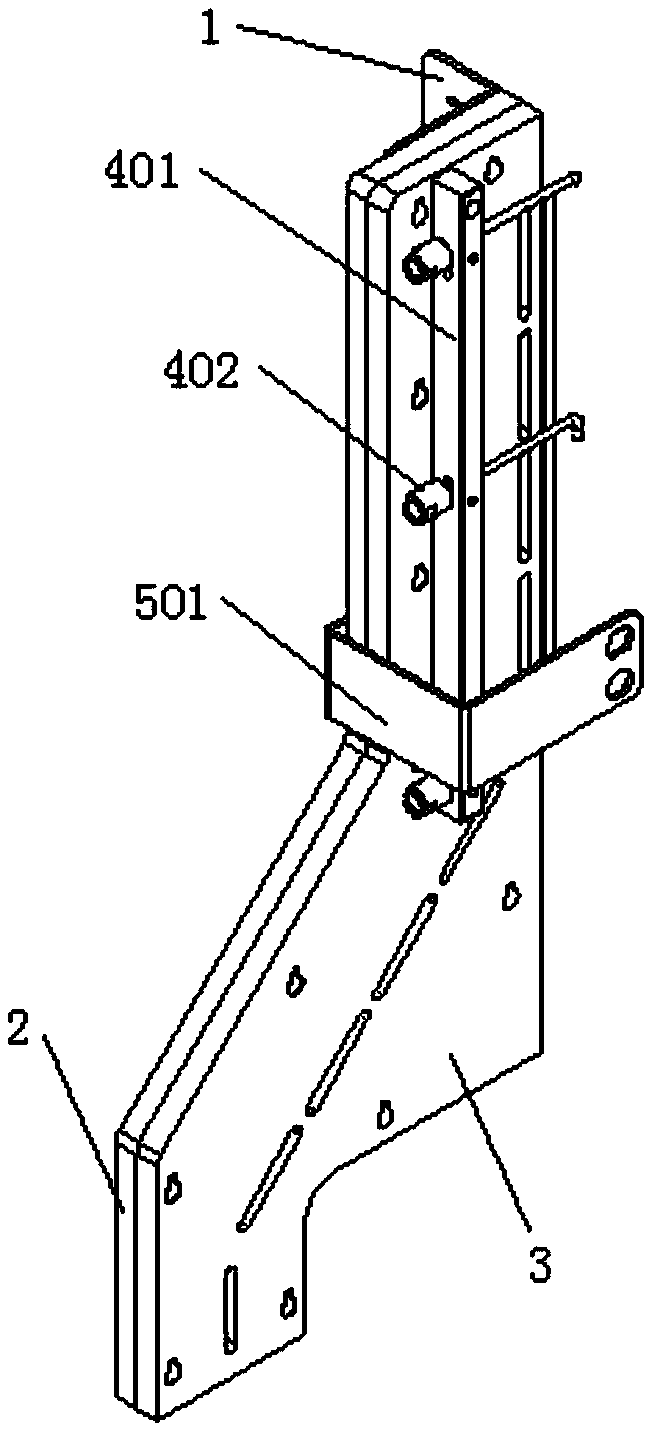

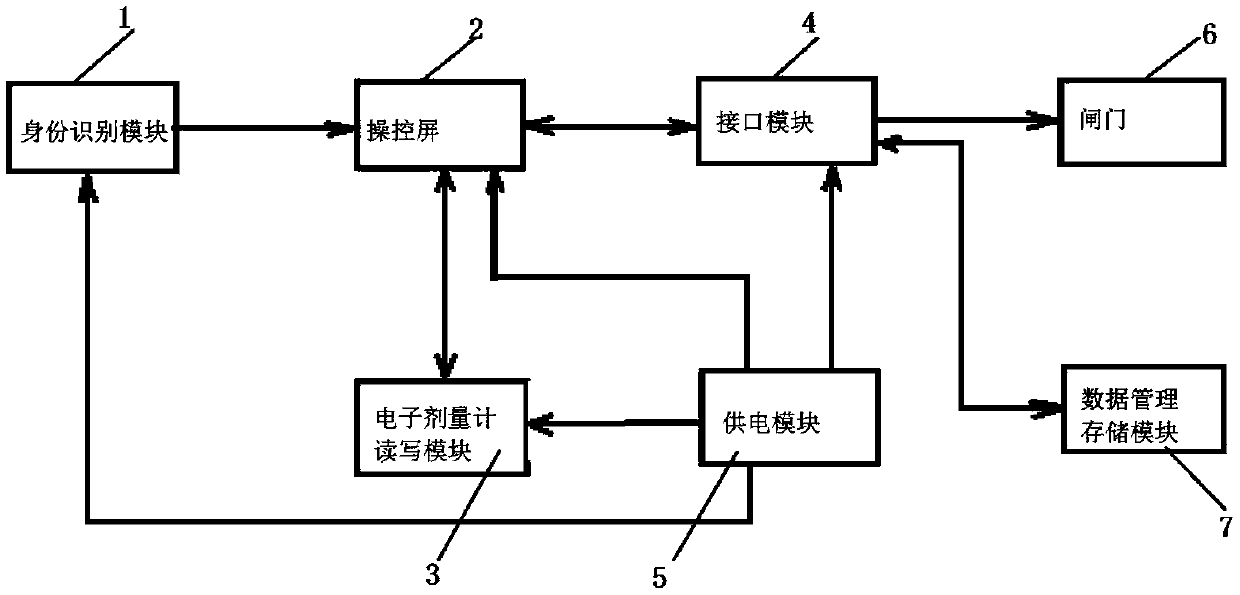

Complete equipment and method for nuclear power station identity recognition and electronic dosimeter gating

PendingCN111462372ARealize automatic identificationImprove pass rateIndividual entry/exit registersNuclear engineeringIdentity recognition

The invention belongs to the field of nuclear power station radiation control area personnel access control and management. The invention particularly relates to complete equipment and method for nuclear power station identity recognition and electronic dosimeter gating. The equipment comprises an identity recognition module, a control screen, an electronic dosimeter read-write module, an interface module, a power supply module, a gate and a data management storage module, the identity recognition module is connected with the control screen, and the other end of the control screen is connectedwith the electronic dosimeter read-write module and the interface module. According to the invention, automatic personnel identity identification can be realized, the radiation control area personnelaccess entity isolation control is realized, and before entering the radiation control area, management and control personnel must start a portable electronic dosimeter to enter the radiation controlarea, so that a personal dose file is established, the personnel passing rate, the radiation dose management level, dose statistical analysis and subsequent radiation dose optimization management areimproved, and personnel radiation irradiation accidents are avoided.

Owner:JIANGSU NUCLEAR POWER CORP

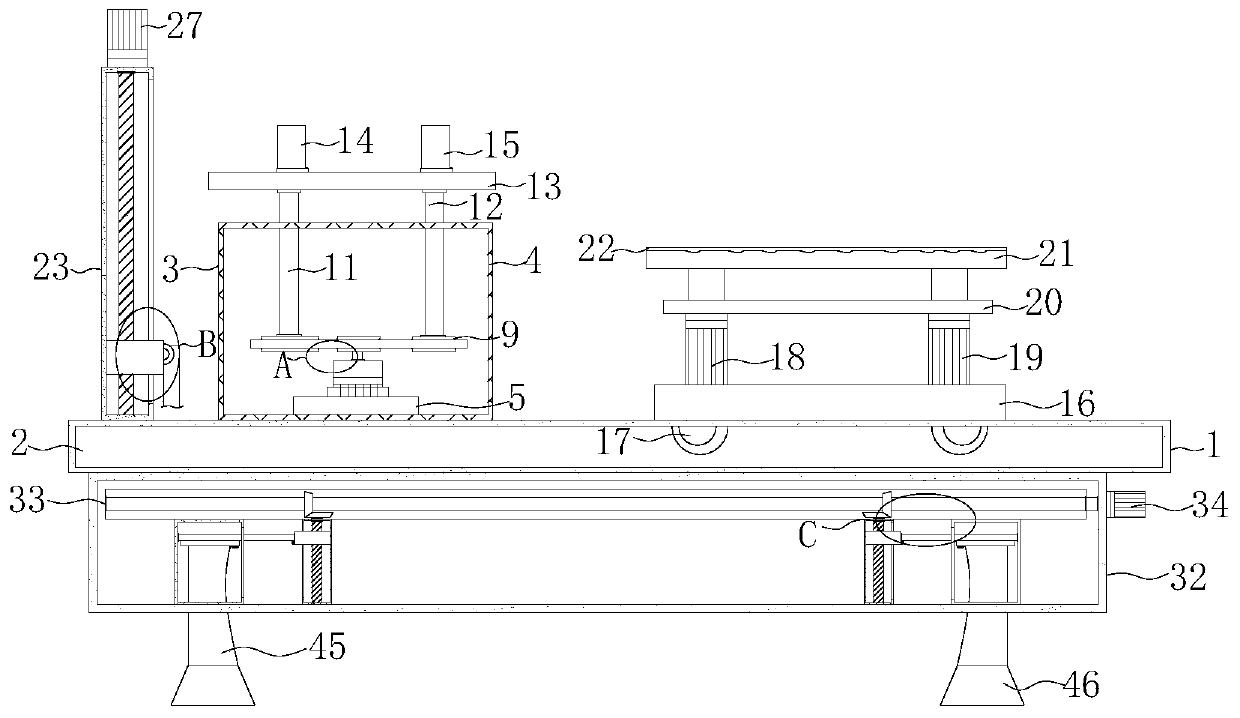

Mounting equipment for machining engine valve

PendingCN114248096AImprove work efficiencyEasy to placeMetal working apparatusStructural engineeringEngine valve

According to the technical scheme, the installation equipment for machining the engine valve is characterized in that the installation equipment comprises a bottom plate, two supporting columns are fixedly installed on the top face of the bottom plate, and a pushing groove is formed in the bottom plate; the machining plate is fixedly mounted at one end of the supporting column, and a mounting groove is formed in the top surface of the machining plate; the pushing assembly is arranged in the pushing groove and used for pushing an air valve; the fixing assembly is arranged on the top face of the machining plate and used for fixing an engine, by arranging an electric push rod, a worker puts a valve into a stabilizing groove, the worker can place the valve into the stabilizing groove according to the number of valve holes of the engine to conduct installation, the electric push rod is started, and the engine is fixed through the electric push rod. The electric push rod telescopic shaft moves to drive the moving plate to move upwards, the moving plate drives the valve in the stabilizing groove to be close to the engine valve hole in the mounting groove to be mounted, and the working efficiency is improved.

Owner:JIANGSU XINYUE AUTOMOTIVE COMPONENTS

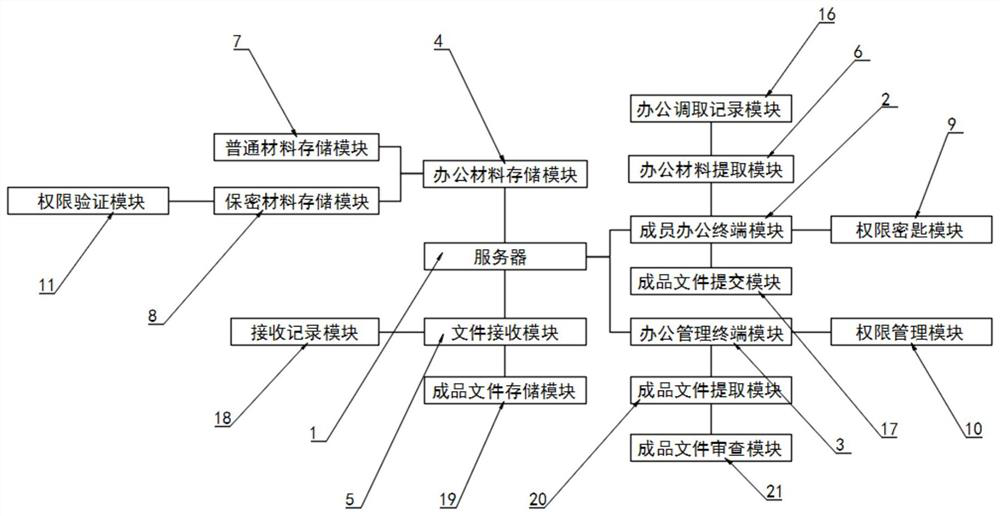

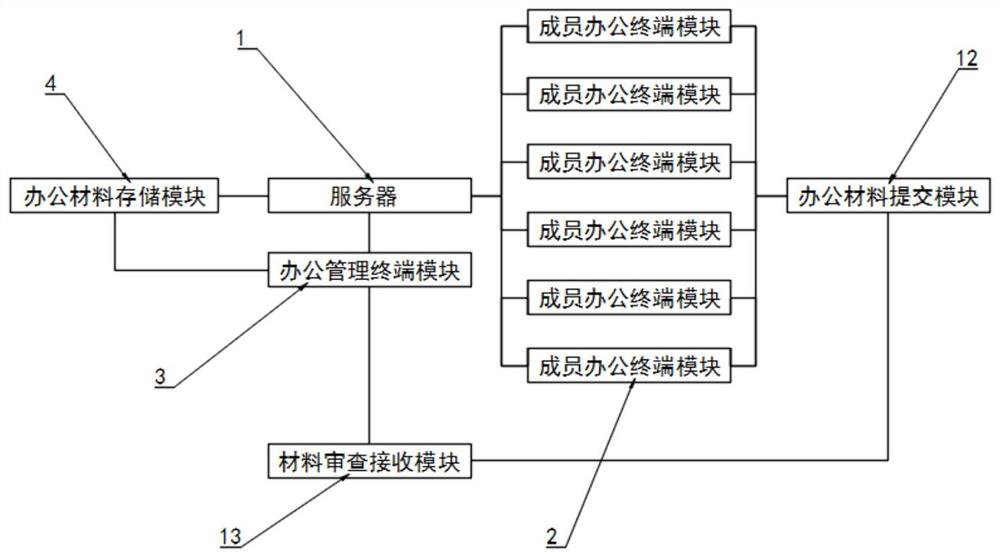

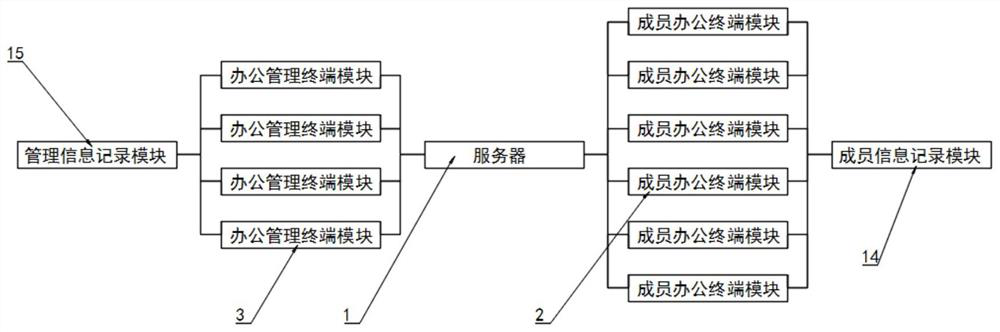

Intelligent office automation system

InactiveCN114282887AEasy to organize and distributePromote redistributionDigital data protectionDigital data authenticationInformation processingOffice management

The invention relates to the technical field of intelligent office, and discloses an intelligent office automation system which comprises a server used for information processing and calculation. The server connecting end is connected with a member office terminal module for login operation of an office programmer, an office management terminal module for login operation of an administrator, an office material storage module for storing office file materials and a file receiving module for receiving finished files submitted by the programmer after completing work. The office material extraction module is used for extracting materials in the office material storage module, the authority key module is matched for distinguishing extraction of common materials and confidential materials, arrangement and distribution of the office materials are facilitated, and the office material submitting module can submit the uncompleted office materials back. And the materials are recovered after being examined by the material examination receiving module, so that the office materials are redistributed conveniently, and the overall office progress is prevented from being influenced by personal factors.

Owner:王子轩

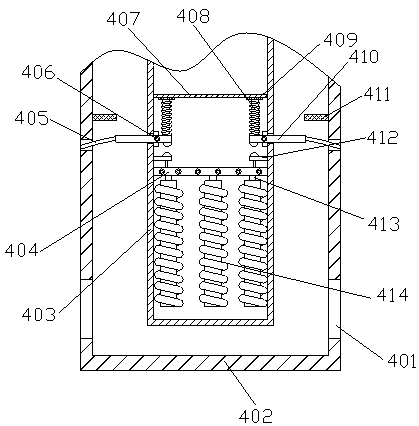

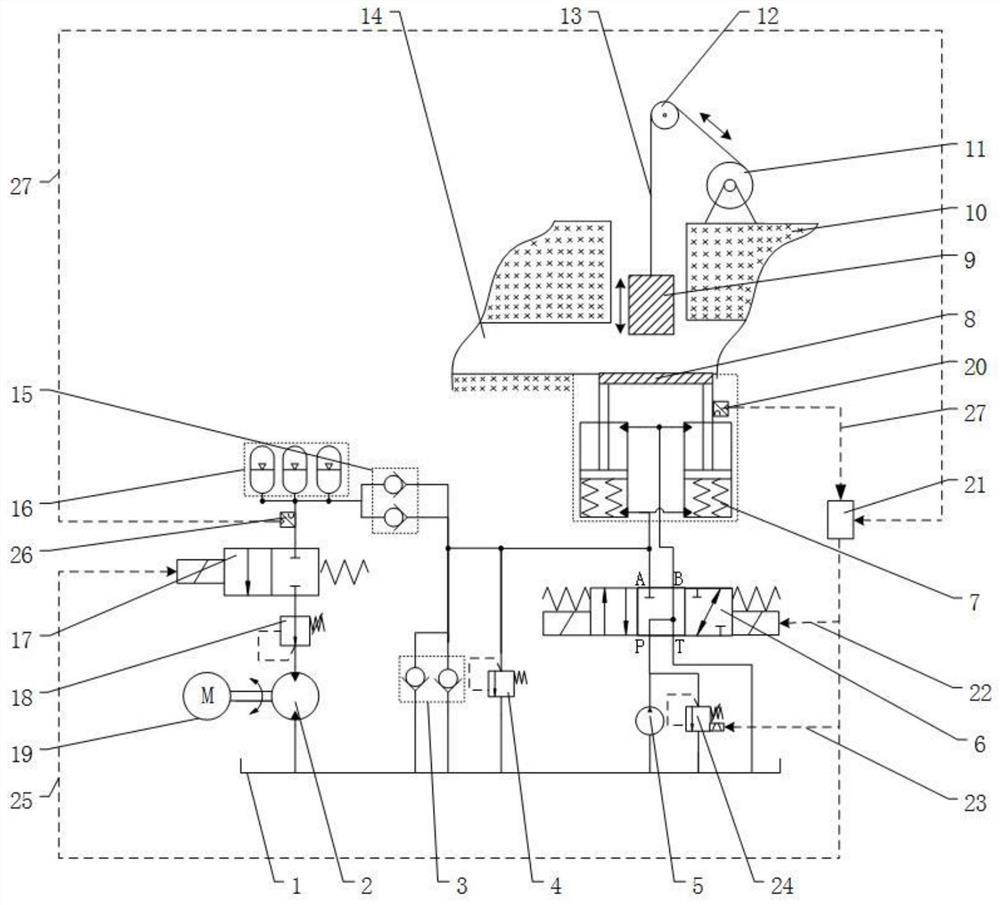

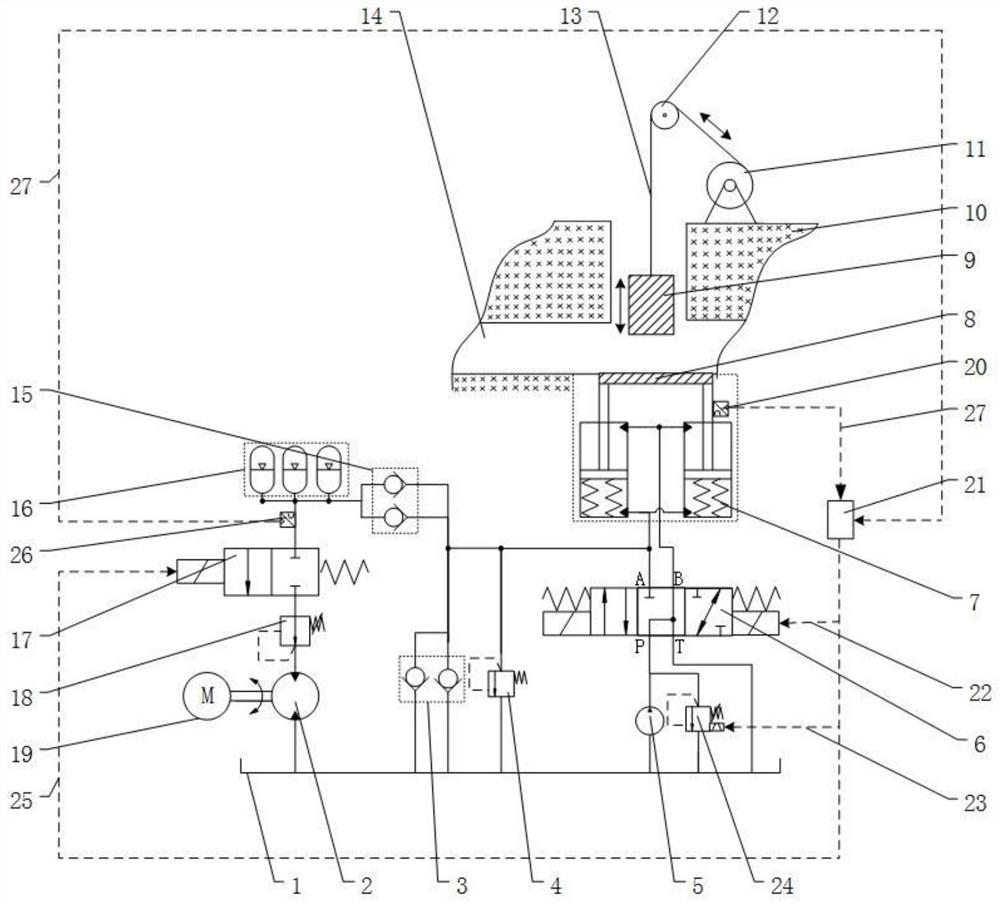

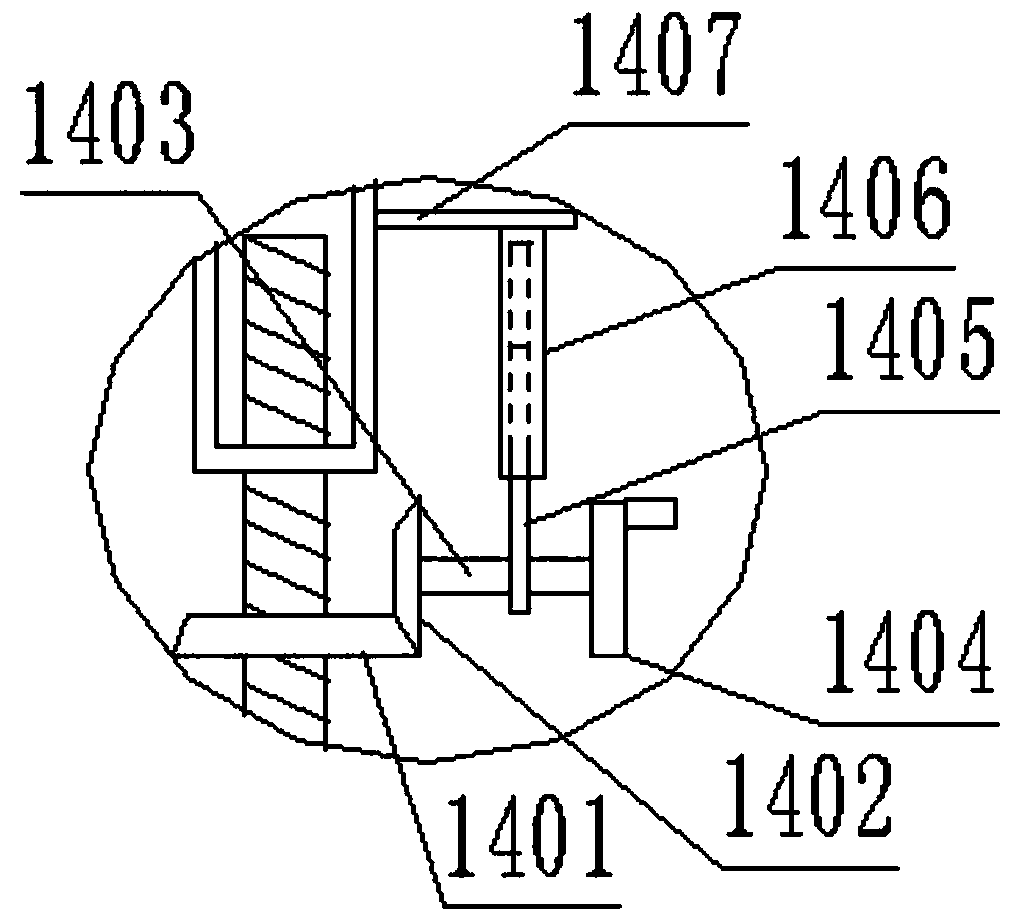

Vertical shaft elevator skip bucket over-release hydraulic buffer energy storage device and system

ActiveCN113371571APrevent destabilizing failureAvoid affecting work progressSpringsVibration dampersStress sensorsAccumulator (energy)

The invention belongs to the field of elevator skip bucket over-release protection, and particularly relates to a vertical shaft elevator skip bucket over-release hydraulic buffer energy storage device which comprises a vertical shaft. An elevator skip bucket is hung on the inner side of the vertical shaft, a hydraulic buffer mechanism is arranged on the inner side of the vertical shaft, and the elevator skip bucket is located above the hydraulic buffer mechanism. The hydraulic buffer mechanism communicates with an energy accumulator set, a pressure relief part and an oil supplementing part through oil conveying pipes, the energy accumulator set communicates with an energy storage part through an oil conveying pipe, the energy storage part, the pressure relief part and the oil supplementing part communicate with an oil tank through oil conveying pipes, the hydraulic buffer mechanism is connected with a displacement sensor, and the energy accumulator set is connected with a pressure sensor. The displacement sensor, the pressure sensor, the energy storage part and the oil supplementing part are electrically connected with a controller. By means of the vertical shaft elevator skip bucket over-release hydraulic buffer energy storage device, over-released elevator skip bucket can be stably and safely braked, the over-released elevator skip bucket can be prevented from generating overlarge impact vibration, and the service life of the elevator skip bucket is prolonged.

Owner:FOSHAN UNIVERSITY

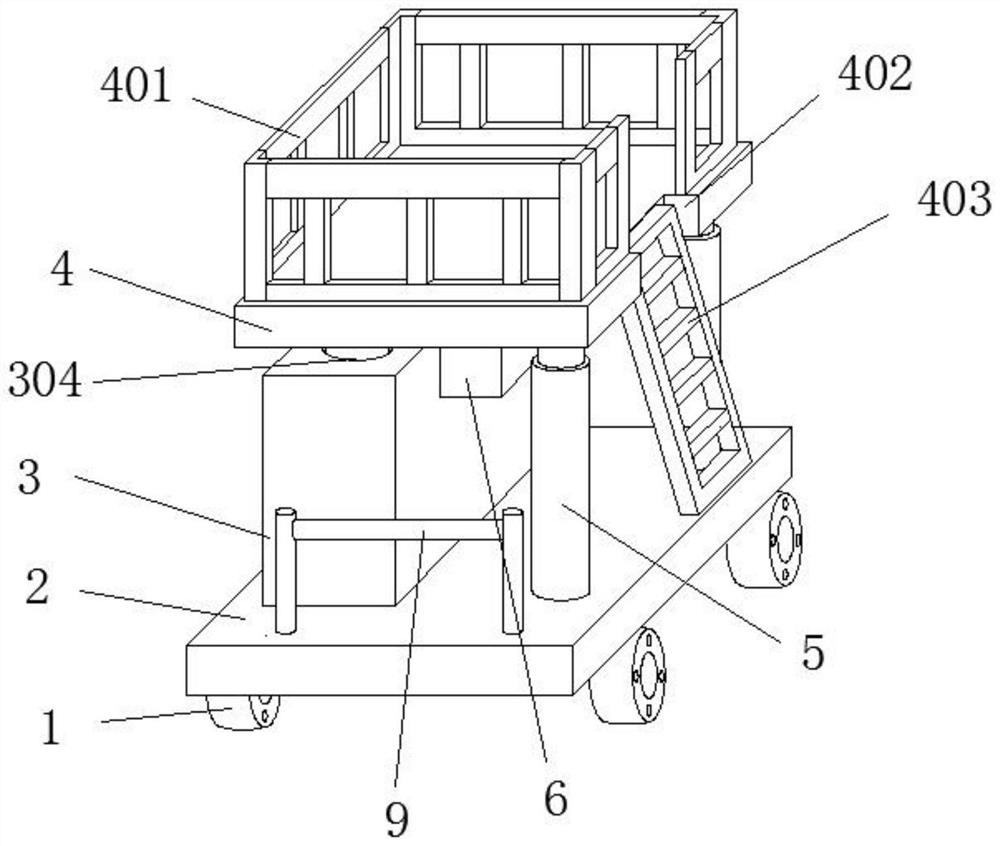

Energy-saving building construction hoist

PendingCN113356549AAvoid affecting work progressEasy to fixScaffold accessoriesGear wheelArchitectural engineering

The invention discloses an energy-saving building construction hoist. The energy-saving building construction hoist comprises a bearing base, a travelling mechanism is installed at the bottom of the bearing base, a lifting mechanism is fixedly installed on one side of a handrail, an infrared distance measuring sensor is fixedly installed above a sliding rail and located on the inner wall of an installation box, cylindrical racks are fixedly installed at the left end and the right end of the top of a first sliding plate, the top ends of the cylindrical racks penetrate through the top end of the installation box to be connected to a first vibration reduction mechanism, the output end of a motor is fixedly connected to one end of a first rotating shaft, a driving gear meshes with a first driven gear, a second driven gear meshes with the cylindrical racks, the top end of the first vibration reduction mechanism is fixedly connected to one end of the bottom of a workbench, and a guardrail is fixedly installed at the top of the workbench. The energy-saving building construction hoist is simple in structure, energy consumption is reduced, resources are saved, the lifting height can be accurately monitored, the working efficiency is improved, and the working comfort is higher and safer due to arrangement of the travelling mechanism and the vibration reduction mechanism.

Owner:云南庞通建筑工程有限公司

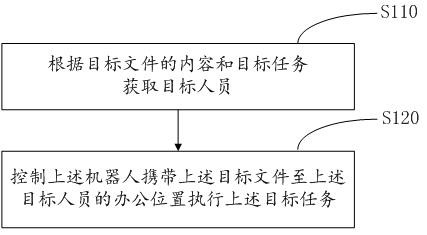

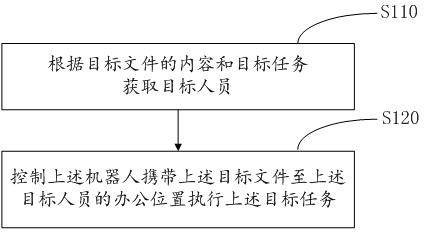

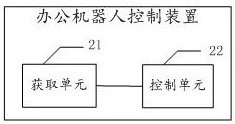

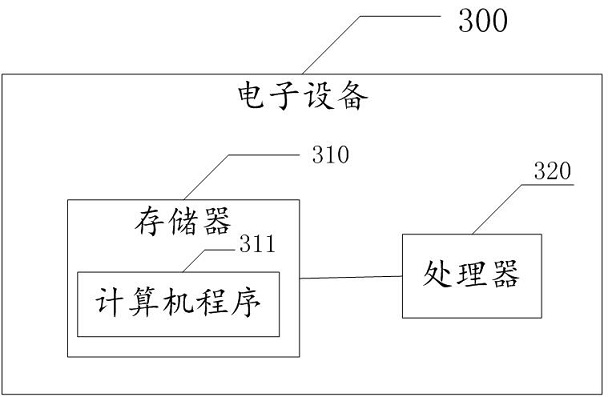

Office robot control method and related equipment

ActiveCN113997294AReduce workloadAvoid affecting work progressProgramme-controlled manipulatorRobot controlWorkload

The invention discloses an office robot control method and related equipment. The method comprises the steps of obtaining a target person according to content of a target file and a target task, and controlling a robot to carry the target file to an office position of the target person to execute the target task. According to the office robot control method, the content of the target file and the target task are obtained, and the robot can carry the target file to move to the office position of the related personnel to handle the business on the basis of the corresponding relation between the preset task and the target personnel. The task initiator does not need to know which personnel need to be found for completing the target task, and only needs to determine the task type and deliver the target file to the robot for handling. According to the office robot control method, the workload of the task initiator is reduced, meanwhile, the situation that the work progress is affected due to the fact that the task initiator is not familiar with the work process is avoided, and the work efficiency is improved.

Owner:北京云迹科技股份有限公司

Cap outlet device of cap arrangement machine

The invention discloses a cap outlet device of a cap arrangement machine. A rear cover plate is detachably and fixedly connected with a front buckling plate. A concave guide groove which can contain bottle caps is formed in the inner side of the front buckling plate. Groove holes are formed in the concave guide groove. The concave guide groove serves as a space allowing the bottle caps to be conveyed smoothly and orderly. When being stuck, the bottle caps in the concave guide groove can be arranged in a manner that a tool penetrates into the groove holes; normal work is resumed; it is not needed to arrange multiple locating plates; the number of points needing to be fixed on the whole is relatively small; and a main body is mounted firmly, and the cap outlet device is provided with a small number of components. The cap outlet device has the beneficial effect of being simple in structure; the device is convenient to mount and detach; maintenance cost is lowered; and the problem that existing buckling plate structures are complex to mount or detach is solved.

Owner:海口尚维科技有限公司

Forming mechanism for sludge granulating and drying machine

PendingCN111359534AGood mud delivery functionWork lessSludge treatment by de-watering/drying/thickeningGranulation by pressingSludgeMolding machine

The invention discloses a forming mechanism for a sludge granulating and drying machine. The forming mechanism comprises a protective shell, wherein the top end of the protective shell is fixedly connected with a heat dissipation opening; a conveying pipeline is fixedly connected to the interior of the protective shell; the right end of the conveying pipeline is fixedly connected with a first clamping block; the inner side of the first clamping block is fixedly connected with a forming mold; a base is fixedly connected to the bottom end of the protective shell; a sealing gasket is fixedly connected to the interior of the forming mold; a deep hole is formed in the forming mold; a fixed plate is arranged at the top end of the protective shell; a sleeve is arranged at the bottom end of the left side of the fixed plate; and a rotating rod is inserted into the sleeve. When the forming mechanism works, sludge in the forming mechanism can be effectively prevented from blocking the forming mechanism and influencing normal working progress; cleaning is more convenient and faster through a detachable mode; and the interior of the forming mechanism is cleaned after work each time, so normal operation of the forming mechanism is guaranteed.

Owner:江苏润翔环保设备有限公司

An office robot control method and related equipment

ActiveCN113997294BReduce workloadAvoid affecting work progressProgramme-controlled manipulatorSimulationRobot control

The invention discloses an office robot control method and related equipment. The method includes: obtaining a target person according to the content of the target file and the target task, and controlling the robot to carry the target file to the office position of the target person to perform the target task. The office robot control method provided in this embodiment obtains the content of the target file and the target task, and based on the preset corresponding relationship between the task and the target person, the robot can carry the target file and move to the office location of the relevant person to handle the business. The task initiator does not need to know who is needed to complete the target task, but only needs to determine the task type and hand over the target file to the robot. The office robot control method reduces the workload of the task initiator, and at the same time avoids the influence of the work progress due to the task initiator not being familiar with the work process, and improves the work efficiency.

Owner:北京云迹科技股份有限公司

Flexible walking mechanism and peeling device

PendingCN111211521AHigh strengthAvoid damageApparatus for removing/armouring cablesPower equipmentEngineering

The invention belongs to the technical field of power equipment and a flexible walking mechanism and a peeling device. The flexible walking mechanism comprises a follow-up assembly which comprises atleast one set of a first sleeve, a connecting shaft and a second sleeve which are sequentially arranged in a vertical direction, wherein the connecting shaft is a flexible part; a to-be-moved part isarranged on the first sleeve; and a gap suitable for the first sleeve to swing along with the to-be-moved part is formed between the first sleeve and the second sleeve. The invention provides the flexible walking mechanism which can swing along with the bending radian of a main wire. The invention further provides a peeling device.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

An automatic gluing equipment for composite wood boards

ActiveCN108656260BRealize automatic gluingWasteful realizationAdhesive application devicesAdhesive glueStructural engineering

The invention relates to a composite board automatic gluing device. The device comprises a bottom plate, a mounting rack, a stacking device and a gluing device; the mounting rack is installed on the bottom plate, sliding chutes are formed in the mounting rack, the gluing device is installed in the sliding chutes, and the stacking device is installed at the lower end of the gluing device; the stacking device is installed on the bottom plate, and the stacking device comprises a linear guide rail, a limiting mechanism and a supporting mechanism; the gluing device comprises a glue discharging mechanism and a leveling mechanism; and the leveling mechanism comprises sliding blocks, sliding rods, a transverse plate, a telescopic leveling frame, a fixed supporting plate, an adjusting length air cylinder, a connecting ring and a driving branched chain. According to the composite board automatic gluing device, the problems that board codes are not even, gluing are non-uniform, glue is easy to waste, the adjustability is poor and the like in an existing composite board gluing process are solved; and the function of automatically gluing the composite board can be achieved, and the device has the advantages of being neat in stacking, uniform in gluing, not easy to waste glue, and flexible to adjust.

Owner:江苏林德曼新材料科技有限公司

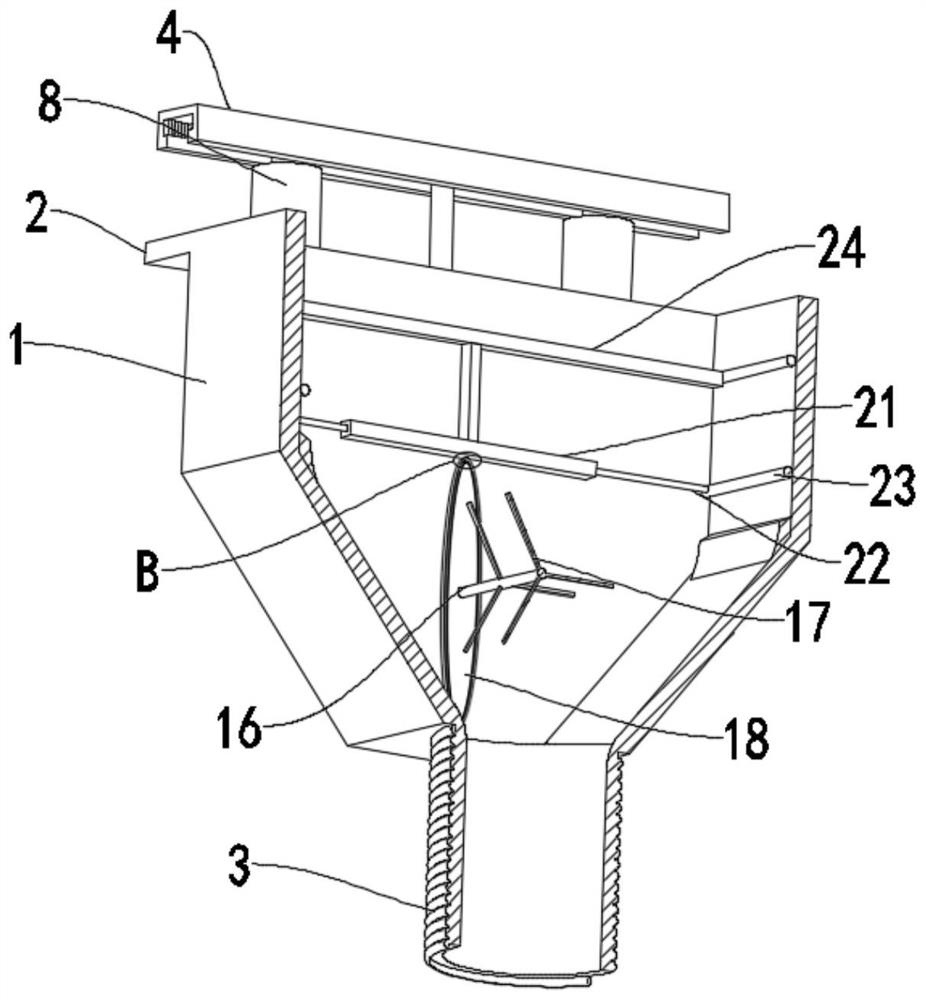

Improved transition hopper of sampling machine

PendingCN114441212AImprove efficiencyAvoid affecting work progressWithdrawing sample devicesCleaning using toolsClassical mechanicsEngineering

The invention discloses an improved sampling machine transition hopper which comprises a shell, a connecting plate is fixedly arranged on the side wall of the shell, and a connecting pipe is fixedly arranged at the bottom of the shell; a rack is fixedly arranged on the inner side wall of the sliding rail, a damping device is arranged on the sliding rail, and the damping device is used for damping the shell; according to the device, when a rotating shaft rotates, an elliptic wheel can rotate, a connecting block can move along with a sliding groove formed in the elliptic wheel through rotation of the elliptic wheel, a lifting plate can move up and down, when the lifting plate moves up and down, a cleaning plate can move up and down, and meanwhile a telescopic rod can abut against a knocking brush towards the inner side wall of a shell; and through reciprocating lifting cooperation of the knocking brush, the lifting plate and the cleaning plate, the inner side wall of the shell is cleaned, the situation that a large number of materials adhere to the interior, equipment is damaged, and the work progress is affected can be effectively avoided, the work efficiency is effectively improved, and the work stability is guaranteed.

Owner:HUANENG YICHUN THERMAL POWER CO LTD

Snow removing device for steel structure roof

The invention discloses a snow removing device for a steel structure roof, which comprises a structural frame, a rear reinforcing rib, snow baffles, a feeding threaded rod, a moving guide rod, a driving motor, a front reinforcing rib, a power motor, a snow removing chain and a moving sliding block, the feeding threaded rod and the moving guide rod are provided with the moving sliding block in a positioning mode, the moving sliding block is connected with the power motor, the power motor is provided with the snow removing chain in a linkage mode, and the driving motor drives the feeding threaded rod to rotate to drive the moving sliding block to move front and back. A driving motor is started, a feeding threaded rod drives a moving sliding block to move slowly, a power motor drives a snow removing chain to move at a high speed, snow removing teeth of the snow removing chain start to locally remove and crush accumulated snow at the top of a roof, the device slowly moves downwards, the accumulated snow bottom slowly forms a suspended state, and the whole accumulated snow instantly falls off in a large area under the influence of gravity.

Owner:蔡先婷

A hydraulic buffer energy storage device and system for skip over-discharging of vertical shaft hoist

ActiveCN113371571BPrevent destabilizing failureAvoid affecting work progressSpringsVibration dampersControl engineeringControl theory

The invention belongs to the field of over-discharge protection of hoist skips, and in particular relates to a hydraulic buffer energy storage device for over-discharging of hoist skips in vertical shafts. The hoist skip is located above the hydraulic buffer mechanism. The hydraulic buffer mechanism is connected with an accumulator group, a pressure relief part and an oil supply part through an oil pipeline. The accumulator group is connected with an energy storage part through an oil pipeline. The energy storage part, the pressure relief part and the The fuel supply part is connected to the fuel tank through the oil delivery pipe, the hydraulic buffer mechanism is connected to the displacement sensor, the accumulator group is connected to the pressure sensor, and the displacement sensor, the pressure sensor, the energy storage part and the fuel supply part are electrically connected to the controller. The invention can smoothly and safely brake the over-discharged hoist skip, and can also avoid excessive impact and vibration caused by the over-discharged hoist skip, thereby improving the service life of the hoist skip.

Owner:FOSHAN UNIVERSITY

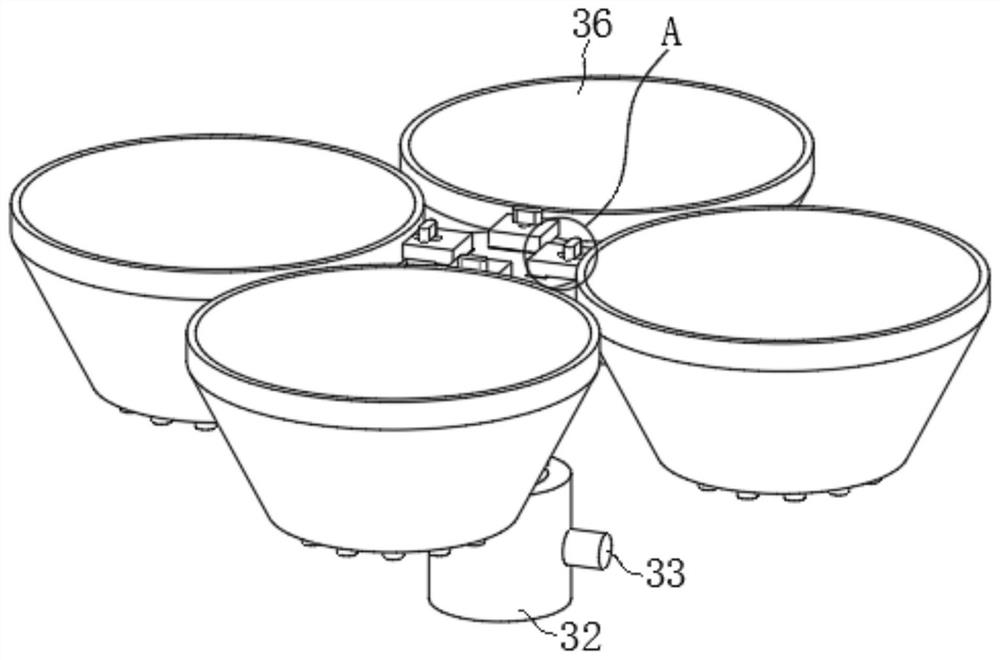

ASA film thermal compounding system for resin tile production

InactiveCN113997448AEasy to operateSpeed up the slippery speedManufacturing engineeringRaw material

The invention provides an ASA film thermal compounding system for resin tile production. The ASA film thermal compounding system for resin tile production comprises a base, a material mixing structure, a wire drawing structure, a cooling structure and a slitting structure, wherein the material mixing structure and the slitting structure are both arranged on the base. According to the ASA film thermal compounding system for resin tile production, the wire drawing structure is arranged, the ASA film thermal compounding system is mainly used for conducting wire drawing treatment on molten raw materials, meanwhile, the function of rapidly replacing a wire drawing hopper is achieved, when the size of wire drawing granules needs to be adjusted, only a positioning rotating piece and the wire drawing hopper need to be rotated, replacement operation of the wire drawing hopper is completed, the wire drawing hopper cannot be influenced by the surrounding environment, the sliding speed of the wire drawing hopper is greatly accelerated, a long time is not cost, the influence on the working progress is avoided, the machining requirements are better met, excessive manual operation is not needed during replacement or disassembly, the system is very flexible and convenient to use, and the traditional design that the wire drawing hopper is internally arranged is changed.

Owner:YINGSHANG BOHAO PLASTIC IND TECH CO LTD

A device for discharging residual iron from a skimmer

InactiveCN108004357BStable supportImprove work efficiencyBlast furnace componentsBlast furnace detailsSlagEngineering

The invention discloses a device for discharging residual iron of a slag skimmer. The device comprises a pneumatic rock drill, a supporting cross rod, a supporting oblique rod, a pulley and a riggingturnbuckle, wherein the pulley and the rigging turnbuckle are connected with the supporting cross rod. A first fixed hanging ring and a fixed sleeve are fixed to the outer wall of the slag skimmer, the first fixed hanging ring is located on the upper side of the fixed sleeve, one end of the supporting cross rod is movably inserted into the fixed sleeve, and a second fixed hanging ring is fixedly connected with the other end of the supporting cross rod; and the supporting cross rod and the outer wall of the slag skimmer are perpendicularly arranged, the two ends of the supporting oblique rod are connected to the first fixed hanging ring and the second fixed hanging ring in a hung mode through hooks correspondingly, and a certain included angle is formed between the supporting cross rod andthe supporting oblique rod. According to the device, the efficiency that a residual iron hole is perforated can be improved.

Owner:杜奕飞

Novel rice thresher and using method thereof

PendingCN112715167AReduce workloadAvoid affecting work progressMowersThreshersRice strawElectric machinery

The invention discloses a novel rice thresher and a using method thereof, and relates to the technical field of rice threshing. The novel rice thresher comprises a box body, a feeding opening, supporting plates and supporting legs, wherein the inner side of the box body is divided into a threshing cavity and a smashing cavity through a partition plate, a first motor is fixedly mounted on the left side of the box body, a first rotating shaft is mounted at the output end of the first motor, and a second gear is rotationally connected to the inner wall of the left side of the threshing cavity through a first fixing column; and threshing rollers are fixedly mounted at one end of a first gear and one end of the second gear, a second motor is fixedly mounted on the back surface of the box body, a second rotating shaft is fixedly mounted at the output end of the second motor, a first screen rotating shaft is fixedly connected to one end of the second rotating shaft, a second fixing column is fixedly mounted on the right side of the lower part of the threshing cavity, and a second screen rotating shaft is rotatably connected to the second fixing column. Rice threshing, impurity removing and smashing are integrated, in addition, a transmission screen rotates to drive rice straw to fall into the smashing cavity to be smashed, and the situation that the rice straw is not sprayed and discharged in time, blocking is caused, and the working process is affected, can be avoided.

Owner:徐日涛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com