Snow removing device for steel structure roof

A steel structure and structural frame technology, applied in snow traps and other directions, can solve the problems of low snow removal efficiency by heating method, corrosion of steel structure warehouses, local icing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

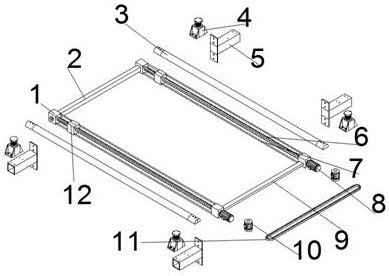

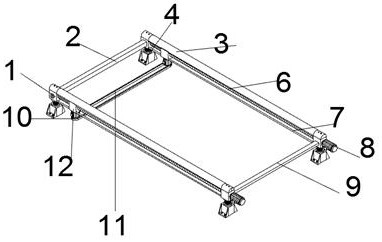

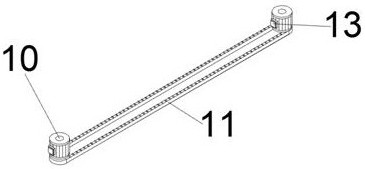

[0020] like Figure 1-6 As shown, a snow removal device for a steel structure roof includes a structural frame 1, a rear reinforcing rib 2, a snowboard 3, a shock-absorbing bracket 4, a positioning and mounting bracket 5, a feeding threaded rod 6, a movement guide rod 7, a drive Motor 8, front reinforcing rib 9, power motor 10, snow removal chain 11, motion slider 12, rear reinforcing rib 2 and front reinforcing rib 9 are installed based on the positioning welding of the front end of the frame body of the structural frame 1, and the snow deflector 3 is installed on the structural frame 1 On the upper ends of the left and right sides, based on the left and right sides of the structural frame 1, a feed threaded rod 6 and a motion guide rod 7 are sequentially installed. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Obtuse angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com