A cover outlet device for a cover unscrambling machine

A cap unscrambling machine and cap opening technology, which is applied in the direction of conveyor control devices, capping containers tightly, packaging, etc., can solve problems such as troublesome disassembly, inability to observe caps, and complicated assembly of the cap outlet device, and achieve disassembly Convenience, return to normal work, smooth shipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

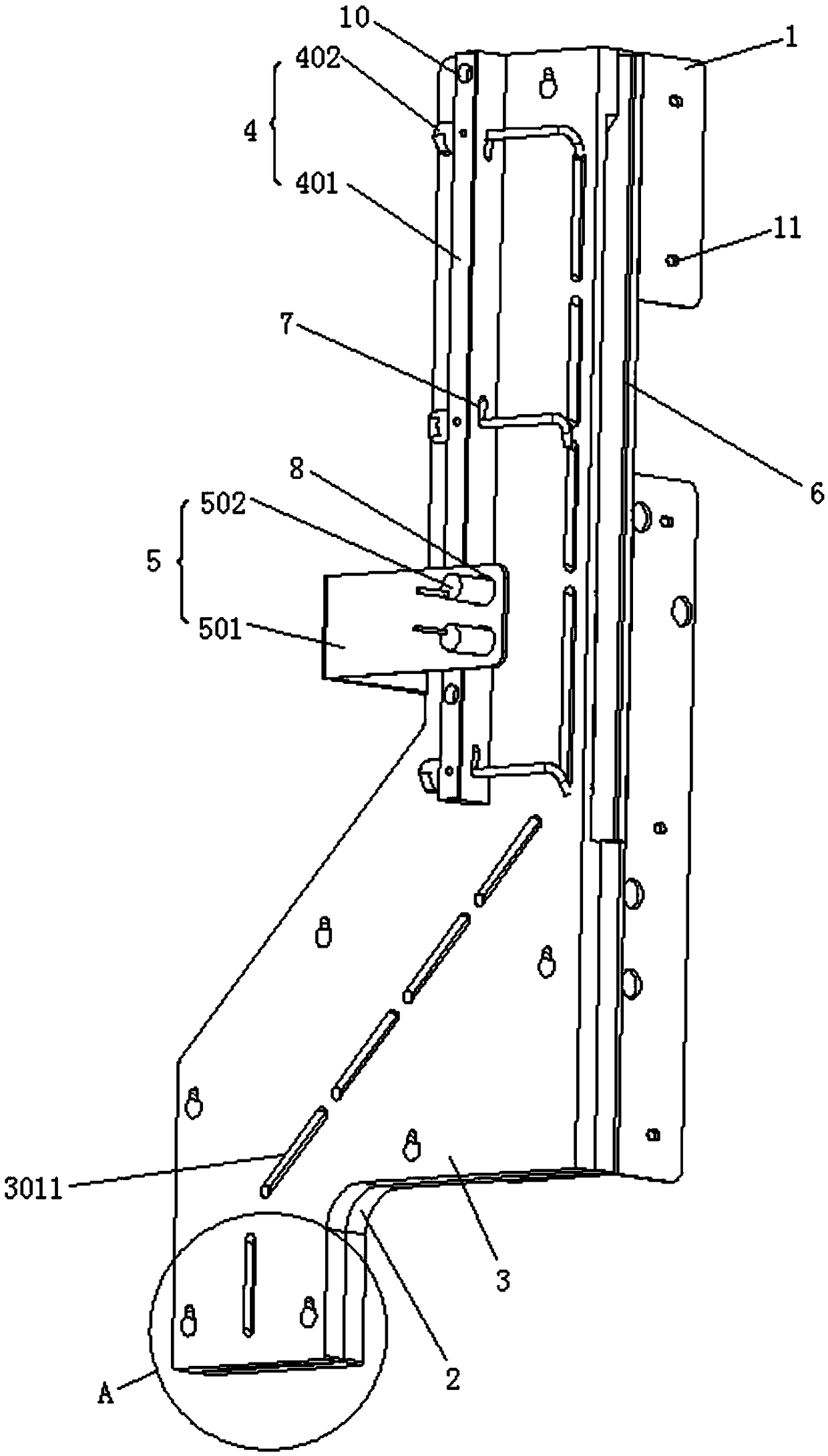

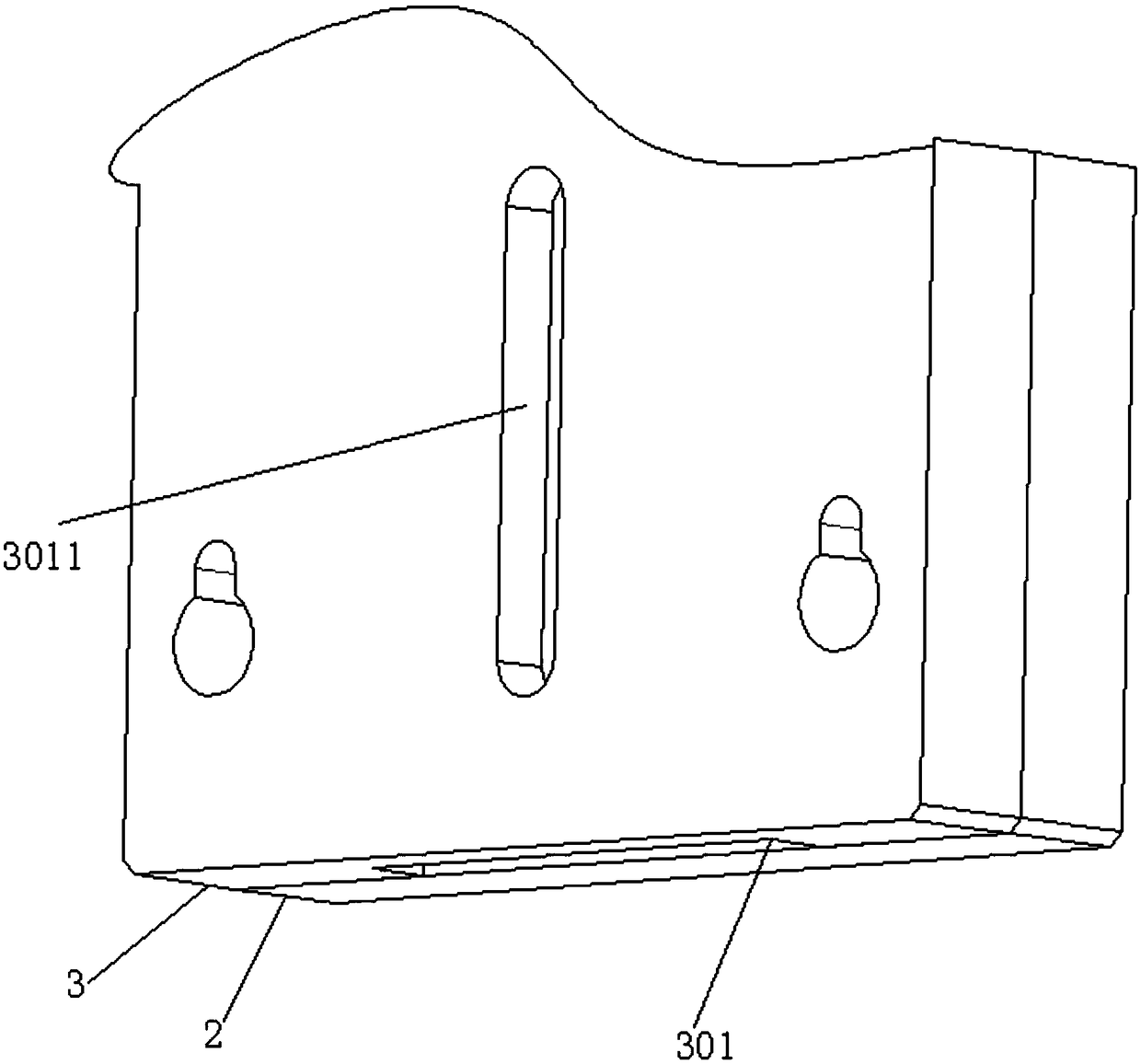

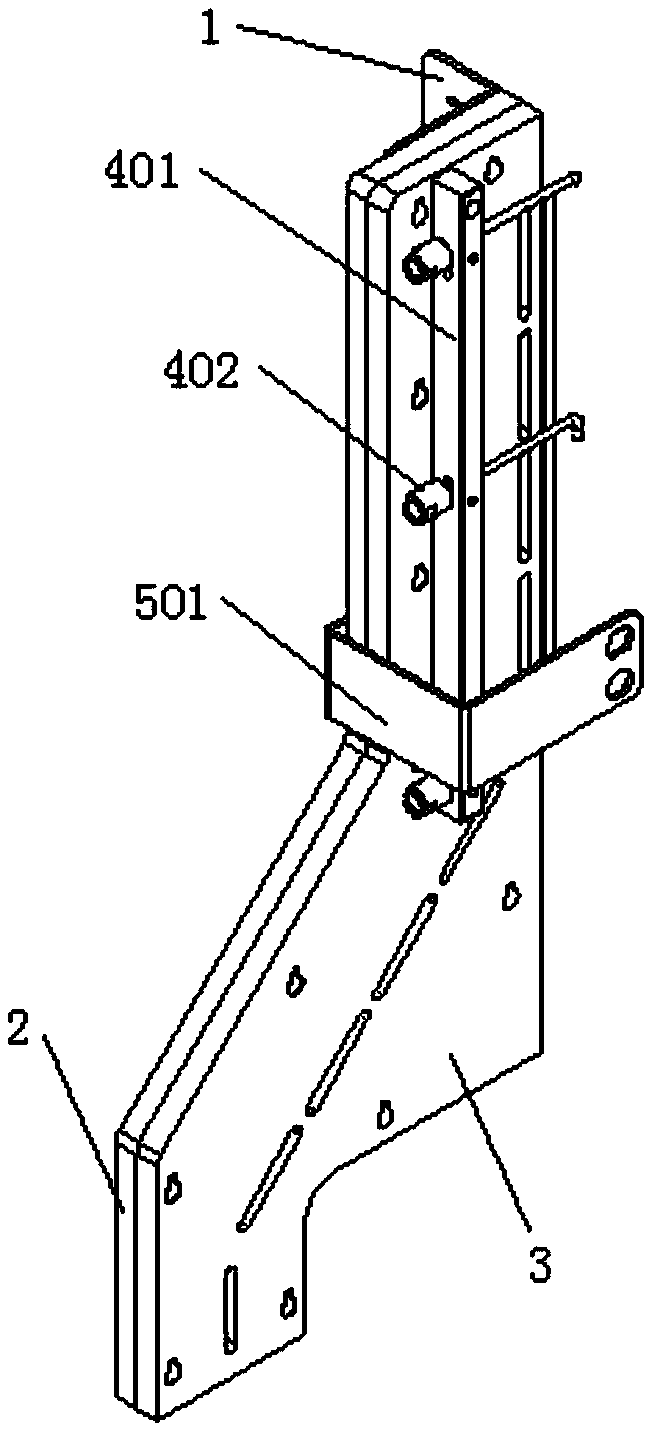

[0024] Such as Figures 1 to 5 , a cover outlet device of a cover unscrambling machine, comprising a rear cover plate 2 and a front pinch plate 3 . The rear cover 2 is provided with a plurality of screw holes 12 (not marked), and the rear cover 2 is fixedly connected with the front gusset 3 by screws. The inner side of the front buckle 3 is provided with a concave guide groove 301 which can accommodate the bottle cap; the concave guide groove 301 is provided with a slot hole 3011 . The concave guide groove 301 is a space for bottle caps to be transported smoothly and orderly; the bottle caps in the concave guide groove 301 can be sorted by penetrating through the slot hole 3011 . The invention does not need several positioning plates, relatively few points to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com