Activation method for electromagnetic shielding fabrics before chemical plating based on PAMAM (polyamidoamine)/ palladium ligand

A technology of electromagnetic shielding and activation method, which is applied in the fields of magnetic field/electric field shielding, liquid chemical plating, electrical components, etc., to achieve the effects of reducing usage, increasing catalytic activity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

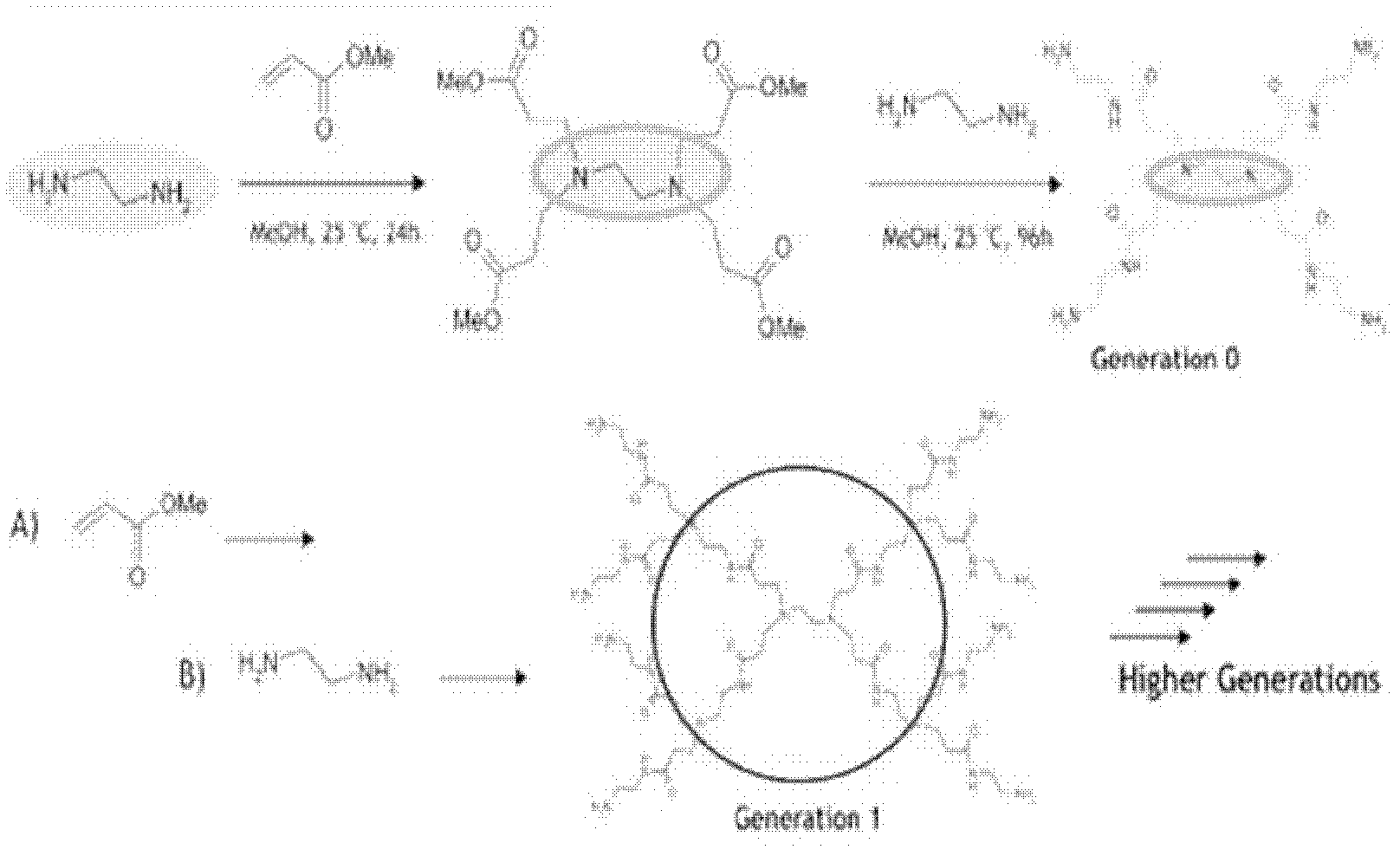

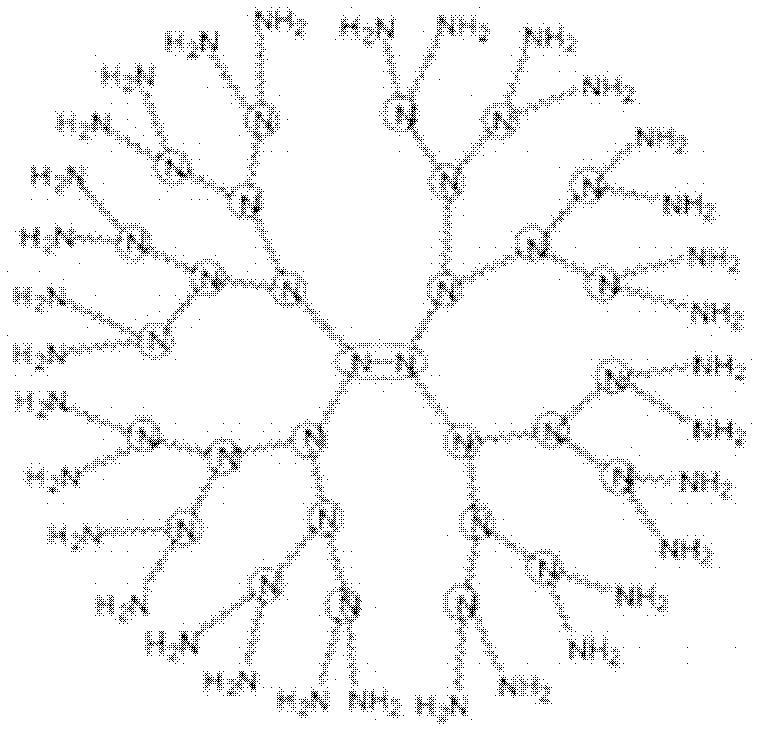

[0041] (1) Synthesis of dendrimer PAMAM

[0042] Add 9.0g (0.15mol) of ethylenediamine and 32g (1.0mol) of methanol into a three-necked flask with a magnetic stirrer, a reflux condenser and a thermometer, and dropwise add 103.2g (1.2mol) of Methyl acrylate was reacted for 24 hours; then, under reduced pressure distillation at 22°C and 133 Pa pressure, the solvent methanol and excess methyl acrylate were removed to obtain 0.5 generation (0.5G) PAMAM.

[0043] Add 60.6g (0.15mol) of 0.5 generation PAMAM and 192g (1.0mol) of methanol into a three-necked flask with a magnetic stirrer, a reflux condenser and a thermometer, and add 216g (1.2mol) of ethyl alcohol dropwise under stirring at 25°C. Diamine, reacted for 24 hours; distilled under reduced pressure at 72°C and 133Pa pressure to remove solvent methanol and excess ethylenediamine to obtain 1.0 generation (1.0G) PAMAM.

[0044] 77.4g (0.15mol) of 1.0 generation PAMAM and 231g (1.0mol) of methanol were added to a three-necked ...

Embodiment 2

[0056] (1) Synthesis of PAMAM

[0057] Synthetic process is with embodiment 1 (1)

[0058] (2) Preparation of activator solution:

[0059] The preparation concentration is 2.1×10 -2 1G PAMAM solution of mol / L and 2g / L palladium chloride solution (as Pd 2+ concentration meter). Mix palladium chloride and dendrimer solution at a molar ratio of 3:1 to prepare an activator solution, Pd 2+ The concentration is 0.1g / L.

[0060] (3) Fabric activation treatment

[0061] With (3) in embodiment 1.

[0062] (4) Restore

[0063] The process is the same as (4) in Example 1.

[0064] (5) Electroless plating

[0065] The process is the same as (5) in Example 1 to obtain an electroless copper-plated electromagnetic shielding material. The average square resistance value of the surface of the measured material is 65mΩ / sq, and the shielding effectiveness is 50dB.

Embodiment 3

[0067] (1) Synthesis of PAMAM

[0068] Synthetic process is with embodiment 1 (1)

[0069] (2) Preparation of activator solution:

[0070] The preparation concentration is 7.2×10 -3 2G PAMAM solution of mol / L and 1g / L palladium chloride solution (as Pd 2+ concentration meter). Mix palladium chloride and dendrimer solution at a molar ratio of 6:1 to prepare an activator solution, Pd 2+ The concentration is 0.2g / L.

[0071] (3) Fabric activation treatment

[0072] With (3) in embodiment 1.

[0073] (4) Restore

[0074] Immerse the padded fabric in 3g / L borohydride solution for 30min, wash it with deionized water, and dry it.

[0075] (5) Electroless plating

[0076] The process is the same as (5) in Example 1 to obtain an electroless copper-plated electromagnetic shielding material. The average surface resistance of the measured material is 12mΩ / sq, and the shielding effectiveness is 85dB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com